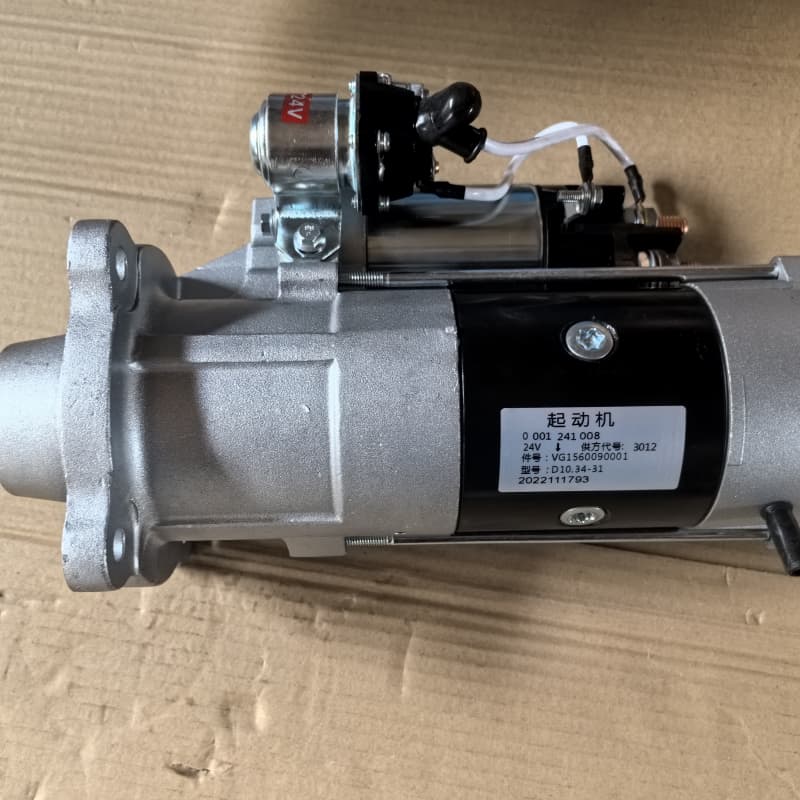

Sinotruk vg1560090001 engine starter

1 、 high power and effective launch : has high power, is able to provide a powerful and smooth launch of the Sinotruk engine even in extreme conditions, such as low temperatures. This allows the engine to quickly enter the operation and increases the efficiency of the machine.

2 、 exact compatibility : is designed specifically for the corresponding models of Sinotruk engines, is ideally compatible with other components of the system. This ensures the ease of installation and uninterrupted operation as part of the whole system.

3 、 High reliability and durability : is made of strong and resistant materials that withstand high temperatures, pressure and mechanical loads that occur during the operation of the system. This guarantees a long service life and rare breakdowns.

Product representation

1. The structure of the product

DC engine: as the main source of the starter power supply, it has a structure with a sequential excitation of direct current. This design allows the electric motor at the time of the start to generate a powerful electromagnetic torque, effectively driving the engine flywheel. Inside it are key components, such as an anchor, collector, pole, brushes, bearings and housing. The anchor consists of an iron core and winding. When the current passes through it, it generates a magnetic field that interacts with magnetic poles to achieve rotation. The switch ensures the correct switching of the direction of the anchor and maintains continuous rotation of the engine. The brushes are in close contact with the switch, providing a stable input of the anchor current. The bearings maintain the anchor rotation, reduce friction resistance and increase the engine efficiency. The case is made of high -strength material, which can not only protect the internal components, but also contribute to heat scattering.

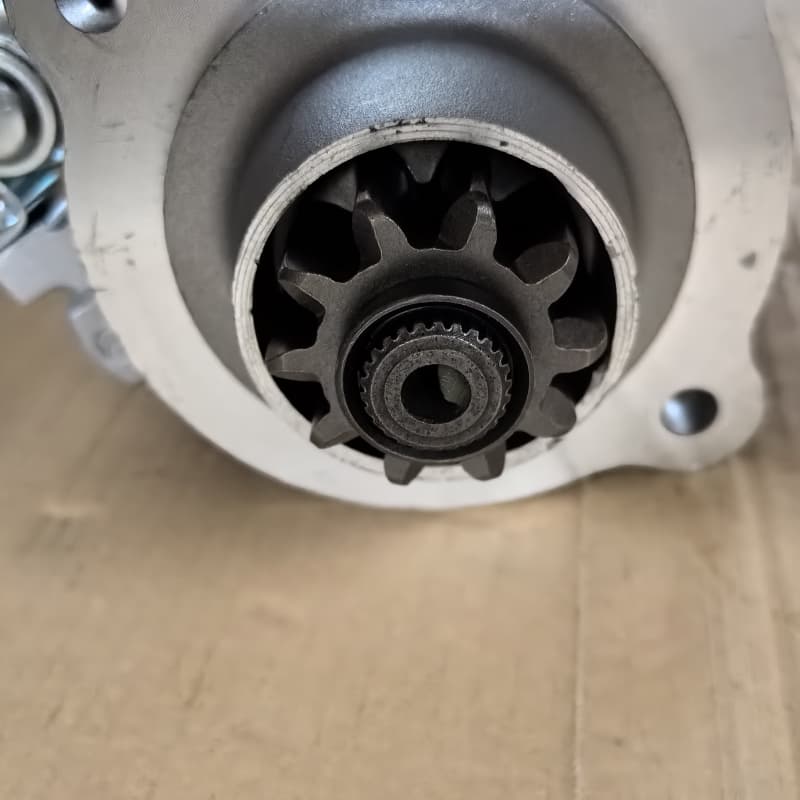

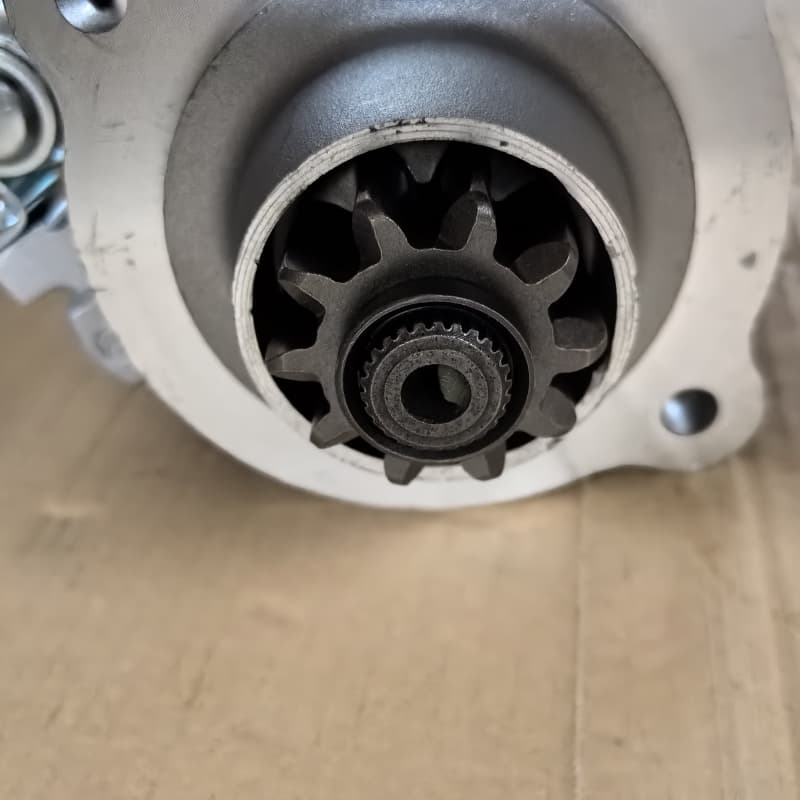

Transmission mechanism: mainly consists of a lead gear, one -sided coupling, gearbox forces, etc. When the starter is operating, the sliding gear is entered with the gear crown of the engine of the gearbox by means of the gearbox, transfers the engine torque to the engine crankshaft and launches the engine and launches the engine and launches the engine . The unilateral coupling provides the automatic separation of the lead gear from the gear crown of the flywheel after the engine starts, preventing the starter rotation in the opposite direction due to the engine operation at high speeds and its damage.

Management device: an electromagnetic switch is usually used as the main component to control the starter circuit turning on and off. When the driver turns the ignition key or presses the start button, the electromagnetic switch receives an electrical signal, and the internal electromagnetic coil generates the magnetic field, forcing the mobile iron core to move, thereby closing the circuit between the starter and the battery and starting the starter into the work. At the same time, the electromagnetic circuit breaker can also connect and turn off the additional resistance of the ignition coil during the start process, ensuring a smooth start of the engine.

2. Operational characteristics

High output power: thanks to a well -thought -out design, it can quickly provide a powerful starting torque for the engine. In conditions of low temperatures, for example, at minus 30 degrees Celsius, it can still provide a smooth start of the engine and quickly respond to the needs of the car for launch. Even with frequent launches and stops in high load conditions, it can work stably, ensuring the reliable operation of the engine.

High reliability and durability: in the production of Howo starters, China National Heavy Duty Truck Group strictly selects materials and uses high -quality metal and insulating materials to increase wear resistance and corrosion resistance of the starter. The production process is optimized and strictly corresponds to the quality control system, which guarantees the exceptional durability and stability of each starter. Even in harsh and variable working conditions, such as high temperature, dust and other conditions, he can maintain reliable work, extend the total service life of the vehicle and reduce maintenance costs.

Low level of noise and vibration: thanks to the introduction of advanced noise reduction technologies and measures to reduce vibration, noise and vibration created by the starter during the launch are effectively reduced. For example, optimize the design of the electric motor to reduce friction and collision between the components; Use shock absorbing materials for the starter winding to absorb vibration energy. This not only provides more comfortable conditions for drivers and passengers, but also reduces interference and environmental impact, and also helps to extend the life of other components of the vehicle.

The function of intellectual control and the diagnosis of malfunctions: some of the Howo starters are equipped with intelligent electronic control systems, which can provide accurate control and detection of faults in real time. The sensor monitors the working condition of the starter in real time, for example, current, voltage, speed and other parameters. If a deviation from the norm is detected, you can give an alarm in time, and information about the malfunction can be transferred back to the control system of a vehicle, which allows the maintenance personnel to quickly localize and eliminate the problem. This helps to increase work efficiency, ensure driving safety and provide users with more convenient service support.

3. Applicable models

The starters of Howo are suitable for various models of Howo heavy vehicles, including Howo T7H, Howo T5G, Howo A7 and others. These models are widely used in intercity transportation, construction, mining industry and other areas. At the same time, it is also suitable for related models, such as Haohan, as well as some vehicles equipped with WeICHAI STEYR WD615 and WP612 engines to satisfy the needs of various users.

4. The installation method

Preparation: Make sure that the vehicle is in a safe state, remove the key and disconnect the negative wire of the battery to avoid electric shock or short circuit during installation. Prepare the necessary tools, such as wrenches, screwdrivers, pliers, etc., as well as the new starter of Howo and appropriate installations, such as gaskets, bolts, etc.

Remove the old starter: find the starter mounting place, usually from the side or below of the engine. Using a wrench, unscrew the nuts connecting the wires of the power and starter control, and mark the wires for subsequent installation. Then, using a suitable wrench, unscrew the bolts connecting the starter with the engine, and carefully remove the old starter from the engine, trying not to hit the parts.

Install a new starter: install a new starter on the engine, combine it with mounting holes and fix it with bolts, but do not tighten it. Then connect the wires of the food and control of the starter in accordance with the previously marked positions, making sure that the connections are reliable and the nuts are tightened. Finally, using a wrench, tighten the bolts connecting the starter to the engine, in accordance with the indicated puffing moment, to ensure the reliable installation of the starter.

Checking and eliminating problems: after installation, check the reliability of the starter mount, the correct connection of the line, the lack of weakening of the connections or a short circuit. Connect the negative wire of the battery, start the car and watch the starter. The starter must provide a quick and smooth start of the engine without extraneous noise and vibrations. If it turns out that the starter is faulty, immediately stop the car for checking and restart it after eliminating problems.

5. Precautions when using

Proper operation of the start -up switch: When starting the car, do not rotate the starting switch continuously for a long time. The time of each launch should not exceed 5 seconds. If the launch failed, wait for more than 15 seconds before re -launch to avoid overheating and damage to the starter.

Avoid the frequent start of the engine: the frequent start of the engine for a short period of time will lead to the continuous operation of the starter, which will lead to its overheating and reducing its service life. Therefore, if possible, you should avoid unnecessary frequent engine starts, for example, when waiting for a traffic light, do not start and do not stop the car too often.

Maintain the battery completely charged: the work of the starter depends on the power generated by the battery, so regularly check the battery charge and the electrolyte level to maintain the battery in good working condition. With a low battery charge, the starter speed is reduced, which affects the efficiency of engine start.

Pay attention to the operating conditions of the vehicle: severe environmental conditions, such as high or low temperature, humidity, dust, etc., can affect the work of the starter. In high temperatures, pay attention to the heat transfer of the starter and avoid its long -term continuous use; In low temperatures, pre -pre -warm the engine before launching the vehicle to reduce the load on the starter; In wet or dusty conditions, make sure that moisture or dust does not get into the starter, which can lead to rust or wear of parts.

Regular inspection and maintenance: regularly inspect and serve the starter, including check if there is damage to it, whether the connection of the wires, the degree of wear of the brushes is weakened, etc. If any problems are detected, they should be eliminated in a timely manner or replaced. to ensure the normal work of the starter. At the same time, regularly clean the starter to remove dust and oil from the surface and maintain good heat scattering efficiency.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive