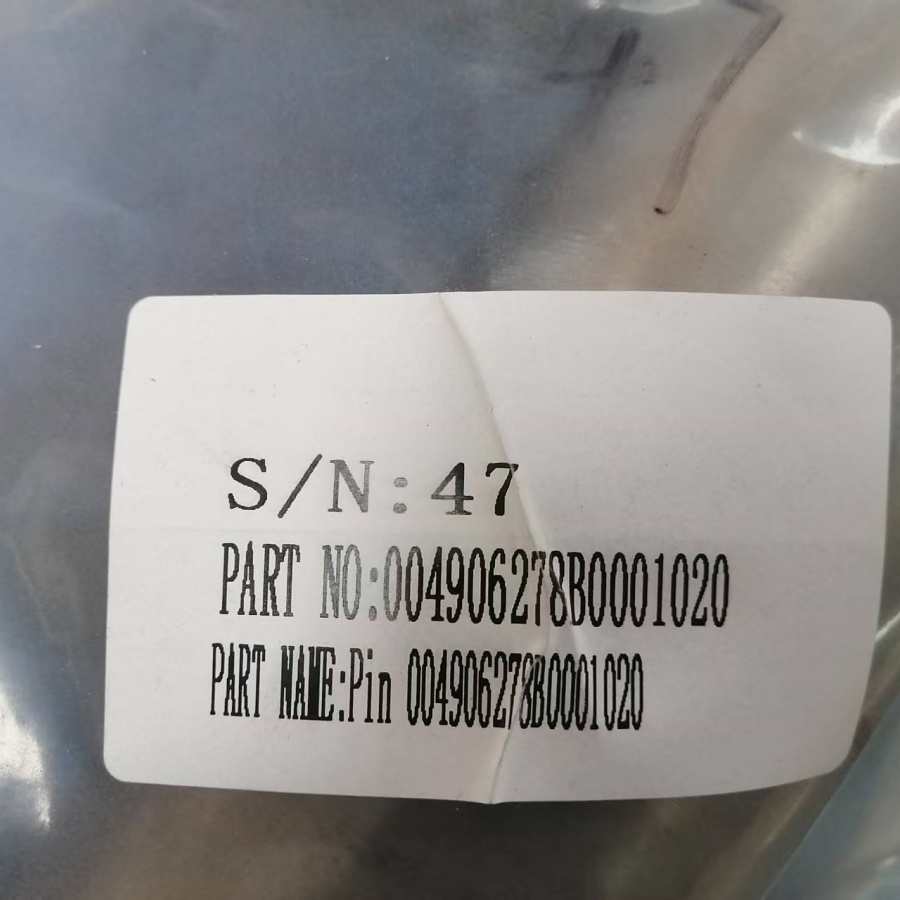

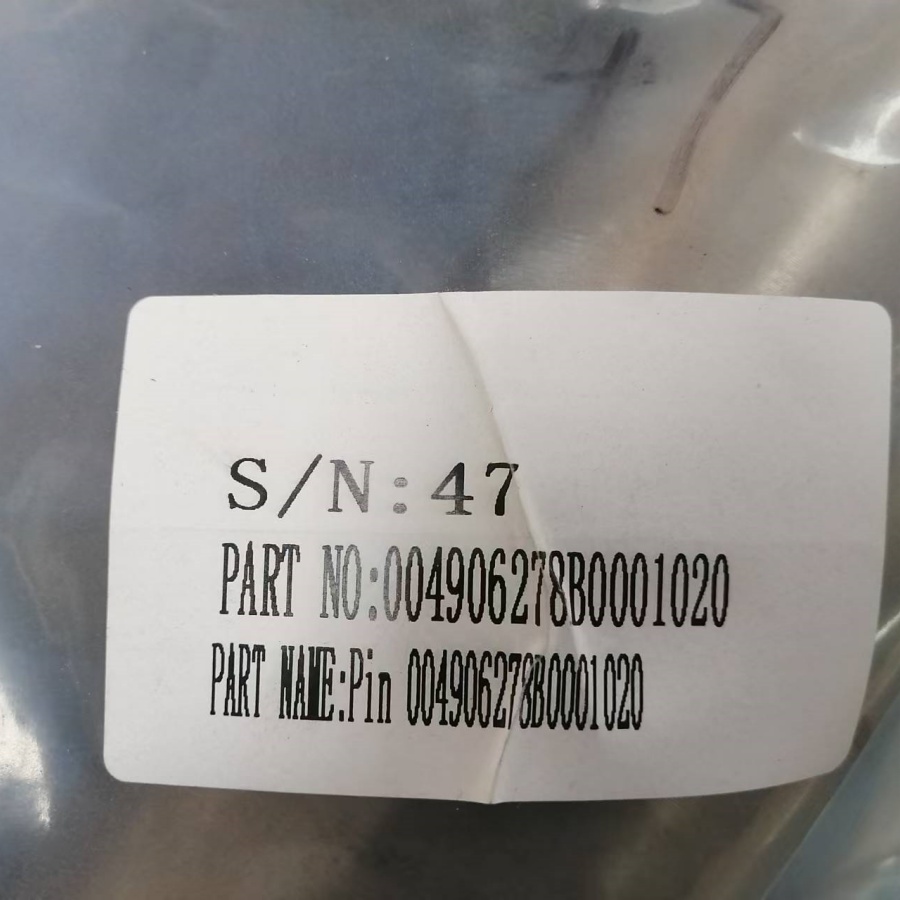

Zoomlion 004906278b0001020 pin

1. Strong and durable: made of high -strength alloy, passed special heat treatment, wear -resistant and impact, has a long service life and requires less replacement.

2. Stable design: optimized design, tight fit of the teeth of the bucket to the nests of the teeth, accurate positioning of the teeth of the bucket, uniform transmission of effort and protection against weakening.

3. Ease of installation: practical design, simple assembly and disassembly, short downtime and ease of maintenance.

Product representation

Detailed product information

type

The pin of the tooth of the bucket with a side clamp: the tooth of the bucket is attached to the tooth nest with side clamps, holding springs and other components. A bucket pin and a holding spring can be separated, and installation and dismantling are relatively convenient. It is often used in situations where the teeth of the bucket are often replaced.

The pin of the bucket tooth of medium thickness: the locking ring is located in the middle of the pin and usually cannot be removed. This design makes a bucket tooth more stable after installation. Suitable for equipment working in relatively difficult operating conditions, and can withstand a large shock.

form

Transverse pin: the installation direction is horizontal, which allows the teeth of the bucket to maintain better stability when exposed to lateral force. It is more common in some models.

Vertical pin: The installation direction is vertical. It has unique advantages in the vertical location and transmission of the effort of the teeth of the bucket. In some models, vertical pins will be used.

Material: usually made of high -strength alloy steel or high -quality carbon steel and other materials. After forging, heat treatment and other processes, it acquires high strength, hardness and wear resistance, and can also withstand huge blows and friction during the operation of the bulldozer.

Stages of installation

Preparation: Put a bulldozer on a flat, hard surface, turn on the parking brake and turn off the engine so that the machine does not move during the installation process. Prepare the necessary tools, such as wrenches, hammers, screwdrivers, lubricants, etc., as well as suitable pins of the bucket and corresponding locking rings, side clamps and other details.

Remove the old pin of the bucket tooth: weaken and remove the bolts or nuts that attach the bucket tooth and remove the old bucket teeth from the grinding of the stard. Then, depending on the type of finger tooth tooth, remove the side clamps, stop rings and other fasteners and carefully tap the bucket tooth with a hammer or another tool to remove it from the tooth nest.

Cleaning and inspection: Use clean tissue or brush to clean the seat of the tooth and teeth of the bucket from oil, dirt and garbage, and check if the installation parts of the tooth and teeth of the bucket are not deformed and the installation parts of the tooth -tooth are worn out. If there are any problems, they must be replaced or replaced in time. At the same time, check whether the sizes and shape of the new finger of the bucket tooth correspond to the original, as well as there are no defects on the surface.

Install a new pile of the tooth of the bucket: apply the required amount of lubric oil to the surface of the new pin of the bucket tooth, combine it with the hole under the pin in the saddle of the tooth and carefully tap it with a hammer or other tool so that it slowly enters the hole under the pin until it gets up until it gets up in place. For a pin of the bucket tooth with a side clip after installing the pin, set the side clamp and the lock ring to the appropriate position to make sure that the stop ring is covered; For a pin of the bucket tooth with an average clamp, make sure that the locking ring is in the correct position and is reliably installed.

Install the teeth of the bucket: combine the teeth of the bucket with the installation position on the holder of the teeth, combine the holes for pins on the teeth of the bucket with pins on the holder of the teeth, then install the teeth of the teeth and tighten the fasteners or nuts.

Inspection and elimination of malfunctions: after installation, check whether the teeth of the bucket are reliably installed, wheels, stop rings and other components are installed correctly, and whether there is no backlash or excessive clearance. Launch a bulldozer, hold the tests at idle and under load, check the working condition of the bucket tooth and timely adjust or repair them if any malfunctions are detected.

Common errors

Destruction of the tooth of the bucket tooth: this can be caused by a long exposure to excessive shock force, for example, when digging solid or perzed soil, when the load on the finger of the bucket tooth exceeds the limit of its bearing capacity; It can also be caused by defects in the tooth of the bucket tooth or the wrong process of heat treatment, leading to insufficient strength.

The weakened pin of the tooth of the bucket: the pin of the tooth of the bucket, the locking spring and other components were not installed in place during the installation, or the locking spring was out of order due to fatigue, or the side clamp was damaged during use, as a result of which the bucket pin was not to the tooth Reliably recorded and became weakened.

Bucket tooth pin wear: During the operation of the bulldozer, there is constant friction between the bucket tooth pin and the tooth socket and bucket teeth. After long-term use, the pin surface of the bucket tooth wears out, which affects the installation accuracy and stability of the bucket teeth, and makes the bucket teeth prone to shaking.

After-sales Service

Quality Assurance: Generally, manufacturers provide a certain quality guarantee period, usually ranging from 3 months to 1 year, depending on the product and the manufacturer's regulations. During the warranty period, if the bucket tooth pin is broken or badly worn due to quality problems, the manufacturer should replace or repair it for the user free of charge.

Technical Support: Manufacturers should provide professional technical consulting services to answer users' questions about the installation, use, and maintenance of bucket tooth pins. Support can be provided to users via phone, email, online customer service, etc.

Accessory Supply: Ensure a long-term and stable supply of bucket tines and related accessories so that users can purchase the right products in a timely manner when replacement is needed, reducing equipment downtime.

Handling customer feedback: Establishing a comprehensive customer feedback mechanism, collecting users' opinions and suggestions on products in a timely manner, eliminating and optimizing existing problems, and continuously improving product quality and service levels.

The following are common faults and maintenance methods for dozer bucket tooth pins:

Broken bucket tooth pin

Cause of malfunction: the bucket tooth pin is subjected to excessive impact for a long time during operation, such as when digging hard materials; the bucket tooth pin is made of low-quality material or improperly heat-treated, resulting in insufficient strength; The bucket teeth and tooth seats are badly worn, which leads to uneven force on the bucket tooth pin.

Maintenance method: replace the bucket tooth pin with one that meets the quality standards and is suitable for the model; repair or replace worn bucket teeth and tooth sockets to ensure installation accuracy and appropriate clearance; Optimize the operation method to avoid excessive impact.

Loose bucket tooth pin

Cause of malfunction: the components were not installed in place during installation, and the retaining rings, side clips and other fasteners were not tightened; the retaining rings have failed due to fatigue, and the side clips have been damaged during use; The bucket tooth pins and pin holes were worn and the clearance increased.

Maintenance method: Reinstall the bucket tooth pin and make sure the retaining ring, side clamps, etc., are securely installed; replace failed or damaged retaining rings and side clamps; If the bucket tooth pin and pin hole are badly worn, they need to be replaced at the same time, and choose accessories of the right size and high precision.

Bucket tooth pin wear

Causes of failure: During the operation of the bulldozer, there is constant friction between the pin of the bucket tooth and the tooth socket and the teeth of the bucket; the working environment is harsh, dust, dirt and other impurities get on the friction surface, which increases wear; insufficient lubrication, lubricating oil is not added regularly or poor quality lubricating oil is used.

Maintenance method: Minor wear can be eliminated by grinding, deburring and sharp edges, and applying lubricating oil; if the wear is severe, replace the bucket tooth pin; Enhance the cleaning of the equipment, remove impurities from the bucket teeth and tooth sockets after operation; Add the required amount of lubricating oil regularly.

Rust on bucket tooth pin

Cause of malfunction: the working environment is wet or in contact with caustic substances; The equipment was idle for a long time without protection, and the surface anti-corrosion layer was damaged.

Maintenance method: If there is slight rust, remove it with sandpaper or a metal brush and apply anti-corrosion oil; if rust seriously affects performance and installation, it needs to be replaced; Protect the equipment, place it in a dry and ventilated place, and apply anti-corrosion paint and lubricant if necessary.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive