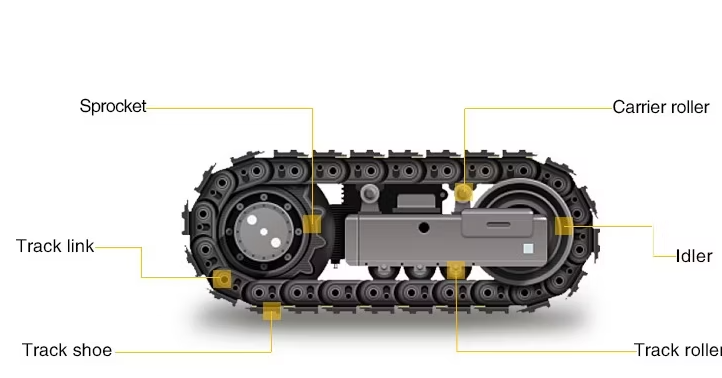

Zoomlion ZD160 Buldozer chassis details

1. Strong and stable: made of high -strength steel and wear -resistant materials, processed using special technology, it is shock -resistant and wear -resistant, can adapt to severe working conditions and has a long service life.

2. Stability and reliability: a reasonable structural design and optimized layout allow you to effectively dissipate pressure and vibration during operation, ensuring stable operation and safe operation of the bulldozer.

3. High adaptability: designed for various types of bulldozers, have accurate sizes, easy to install, have good versatility and reduced maintenance costs.

Product representation

Detailed product information

Support wheels: their main function is to maintain the weight of the bulldozer and ensure the movement of caterpillars along the wheels. The material of the wheel housing is usually 50MN, 40MN2, etc. The process includes forging, machining and heat treatment. The hardness of the wheel surface after hardening reaches HRC45-52. The accuracy of the shaft processing is high, so CNC machines are often required. The bimetallic sleeve is made of a steel plate as a base and seduced by a special alloy. It has a high bearing capacity and fatigue strength. It is combined with a floating oil sealing group from a special alloy and has high sealing characteristics.

Supported asterisk: is used to support the caterpillar to hold it in a certain tension and position, reduce sagging and swinging the caterpillar, as well as ensure its normal work. Usually it is made of high -strength wear -resistant materials, and the surface is hardened to increase wear resistance and corrosion resistance.

Leading wheel: enters into a hook with a caterpillar, providing the traction force of the bulldozer. The teeth of gears are susceptible to wear and require high standards in materials and production processes. They must have sufficient strength, hardness and wear resistance to convey large torque and withstand large shock loads.

The guide wheel: directs the direction of movement of the caterpillar and maintains its tension. Usually installed on the front or back end of the caterpillar. It can regulate the tension of the caterpillar to ensure the normal interaction of the caterpillar and other parts of the chassis. The adjustable design is often used.

Caterpillar: consists of shoes of a caterpillar, fingers of caterpillar, fingertips, etc. It is in direct contact with the ground, providing traction and clutch. Shoes of caterpillars are produced by various shapes and sizes for various working conditions. Fingers and bushings of caterpillars connect shoes of caterpillars, allowing the caterpillar to bend and lengthen when moving.

Stages of installation

Preparation before installation: check the installation site and make sure that the surface is even and durable. Prepare wrenches, jacks and other tools and equipment necessary for installation.

Assembly of the chassis components

Remove the wheels: Raise the bulldozer using a jack and remove the tires, observing safety regulations.

Install the drive block: install the drive block, including the leading bridge, the transmission and frame, on the chassis and tighten all points of the connection.

Install the suspension system: select a suitable suspension system in accordance with the model and technical characteristics, install it on the chassis and adjust it.

Install the stars of the caterpillars and caterpillars: connect the stars of the caterpillars to the leading axis and check the stability of the stars. Pull the caterpillar from one end of the chassis to the other, paying attention to the tension of the caterpillar.

Install the wheel: set the wheel in the starting position and evenly tighten the screws.

Adjusting and checking: tighten all the screws and check the tension of the caterpillar chain. Run the engine and move the bulldozer a few steps to check the flexibility and stability of the chassis, as well as pay attention to the presence of extraneous noise or vibrations.

Common malfunctions

Distribution problems

The wear of the caterpillar: the relative movement of the finger and sleeve of the finger causes wear, which increases the step of the caterpillar, and also leads to the displacement of the side of the caterpillar, which enhances the wear of other details. The contact between the shoes of the caterpillar and the soil will lead to a decrease in the height of the soil -bearing, and the contact between the surface of the track rolling track and other wheels will lead to a decrease in the height of the caterpillar link, which in severe cases will lead to loss of traction.

The wear of the drive wheel: wear will occur at the base of the teeth of the gears, the front and back of the left and right sides and the upper part. If the caterpillar is too free and bend, this will lead to the wear of the side of the teeth of the gears. If the caterpillar and teeth of the gears are filled with sticky materials, this will lead to the wear of the upper part.

Stretch wheel wear: the width of the protrusion of the tensioning wheel housing, the diameter of the surface of the rolling track and the diameter of the wheel body will decrease due to contact with the links of the caterpillar.

The wear of the leading star: the width of the flange, the outer diameter of the surface of the rolling track and the outer diameter of the flange of the leading star will be reduced due to contact with the surface of the rolling track of the chain segment.

Distribution of support rollers: the diameter of the outer flange, the diameter of the rolling path, the diameter and width of the bilateral inner flange, as well as the width of the outer flange will decrease.

The problem of tension: improper tension of the caterpillar chain. Excessive tension will lead to premature wear of the chain, pins, bushings and guide wheels. Insufficient tension will lead to easy disconnection of the caterpillar from the support wheels and guide wheels, which will lead to an unstable course and abnormal wear.

The problem of alignment: if the guide wheel is in the wrong position, this will lead to the instability of the chain and abnormal wear.

Weakened bolts: weakened bolts and nuts on the support wheels, drive wheels, etc. can lead to the instability of the chassis and damage to the components.

After -sales service

Maintenance: We provide a professional maintenance team that can perform maintenance on the spot or factory repair, quickly diagnose and eliminate the malfunctions of the chassis, as well as reduce equipment downtime.

Supply of accessories: ensuring a sufficient stock of original or high -quality chassis details so that customers can receive the necessary details in a timely manner, as well as providing a guarantee of the quality of accessories.

Regular repeated visits: regular repeated visits are held to customers who repaired or replaced the chassis details to understand their use, quickly solve the problems that customers encountered, and provide recommendations for operation and maintenance.

Technical support: providing technical consulting services to customers and answers to questions about the installation, use, maintenance of the chassis, etc. by phone, e -mail, through consultations on the spot, etc.

Training services: providing training for operators and service personnel of customers, including the principles of the construction of the chassis, operational characteristics, daily maintenance and elimination of common faults, to improve customer skills in the use and maintenance of equipment.

The chassis of the bulldozer plays a key role in the work of the bulldozer, and its service life directly affects the performance and cost of equipment service. Here are several ways to extend the service life of the parts of the chassis of your bulldozer:

Reasonable operation

Avoid overload: operate the bulldozer strictly in accordance with its nominal workload and avoid prolonged overload. For example, when digging a solid breed or frozen soil, the digging volume should be reduced accordingly in order to prevent excessive pressure and blows to the chassis.

Smooth driving: during driving and operation, try to maintain smooth driving, avoid sharp accelerations, braking and steep turns. Sudden movements can create an additional load on the components of the chassis, accelerating wear. For example, when turning, you should reduce the speed in advance and slowly turn the steering wheel so that the load on the track is distributed evenly.

Correctly choose working conditions: choose the right working conditions and methods of work in accordance with various working environments and tasks. For example, when working on soft soil, you should reduce the speed of movement and increase the area of the caterpillar contact in order to reduce the pressure on the soil and wear of the chassis parts.

Regular maintenance

Clean the chassis: after each operation, clean the chassis of the mud, sand, oil and other contaminants in a timely manner to prevent these substances from entering the gaps and rotating parts of the chassis and wear of wear. For cleaning, you can use a water -pressure water pistol or a special cleaning agent, but be careful so that the water does not get into the electrical system and lubricants.

Check and adjust the tension of the caterpillars: regularly check the tension of the caterpillars and adjust it in accordance with the actual conditions. If the caterpillar is too stretched, this will increase the wear of the chassis details, and if it is too free, it can easily lead to slipping or deviation of the caterpillar. In the general case, the sagging of the caterpillar should be maintained in the specified range, which can be achieved by adjusting the stretch cylinder.

Lubricate all the details: regularly lubricate all points of lubrication of the chassis parts in accordance with the instructions for the operation of the equipment. Use the appropriate lubricants to provide sufficient lubrication and reduce friction and wear between the components. For example, the lubrication of bearings and Tsapf of the support rollers, stars, drive wheels, etc. can effectively extend their service life.

Check the bolts and nuts: regularly check the bolts and nuts on the details of the chassis to make sure that they are not weakened, and tighten the weakened bolts and nuts in time to prevent the vibration and wear of the details due to weakening. Bolts and nuts in some key details, such as connecting bolts of drive wheels and shoes of caterpillars, should be regularly checked and replaced.

Timely repair and replacement of worn parts

Spend the degree of wear regularly: regularly carry out a comprehensive examination of the chassis and measure the degree of wear of each component, for example, the thickness of the caterpillar shoes, the shape of the tooth of the drive wheel, the diameter of the support wheel, etc. If it is detected, that the component is detected, it should be repaired in a timely manner Or replace.

Repair of worn parts: for some slightly worn parts, you can use such repair methods as surfacing, spraying, applying brush coating, etc. To restore their size and operational characteristics. However, repaired parts must undergo strict quality control in order to guarantee their compliance with the requirements of operation.

Replace worn parts: parts that are very worn out or not subject to repair should be replaced in a timely manner with new ones. Choose original accessories of reliable quality or interchangeable accessories that meet the standards to guarantee that the replaced parts are well combined with other parts of the equipment.

Storage and ensuring safety

Select a suitable place for storage: if the bulldozer must be parked for a long time, it should be stored in dry, ventilated and even place to protect the chassis from moisture, corrosion and mechanical damage.

Take protective measures: during the storage of the chassis, you should properly protect, for example, apply anti -corrosion oil, cover with dustproof tissue, etc., to prevent rusting and pollution of their dust. At the same time, the caterpillar should be slightly pulled so that it does not sag and does not reduce the service life.

Regular inspection and maintenance: during storage, the bulldozer should be regularly inspected and maintained. Run the engine and give the chassis to work for a while to prevent rusting parts and staging due to a long static state.

Thanks to the above measures, it is possible to significantly extend the service life of the bulldozer chassis, reduce the cost of maintenance of equipment and increase the efficiency of work.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive