Komatsu GM35VL running engine

1. Powerful power: it has an improved structure, has a large torque, can give out powerful driving force, can easily cope with a complex relief and has excellent skills to rise and overcome obstacles.

2. Durable and reliable: made of high -quality materials and processed using special technology, it is wear -resistant and shock -resistant. It can work stably in difficult working conditions and has a long service life.

3. Accurate control: sensitive reaction, the possibility of accurate management of walking speed and steering, flexible operation and compliance with the requirements of various working scenarios.

Product representation

Detailed product information

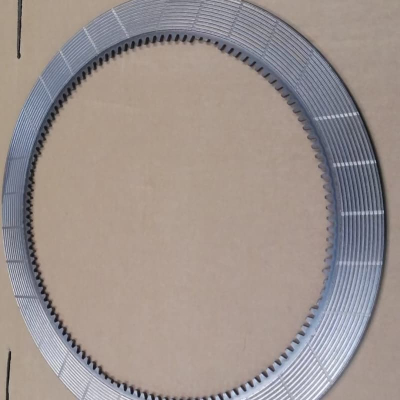

Structural composition: usually consists of a high -speed hydraulic engine, brake, planetary gearbox, valve group, etc.

The principle of operation: the hydraulic engine is rotated by the pressure of hydraulic oil, then the speed decreases, and the torque increases through the planetary gearbox, and, finally, the power is transmitted to the caterpillars or wheels to carry out the movement of the excavator.

Common types

Cycloidal engine: like the cycloidal engine of the Hengli HDL series, the operating volume range is usually 200–470 cubic meters. cm/b, the maximum output torque is 999 N · m, the maximum pressure difference is 207 bar, and the maximum speed is 100 rpm.

Piston engine: for example, the Kawasaki KMX15 hydraulic engine, which has a plunger -type design and operating pressure up to 35 MPa.

Operational characteristics

Iky/XZ chassis: it uses the design of a conical roller bearing with high load, which can withstand the axial strength and radial power when operating and turning the excavator. It has a compact design, beautiful appearance and excellent performance.

The engine with a spiral axis K6VM: is characterized by a high power density, a rapid response, impact resistance, long service life and can comply with the requirements of high speed, high torque and a wide range of speed control.

Stages of installation

Preparation: Make sure that the chassis model corresponds to the excavator, prepare screwdrivers, wrenches, jacks and other mounting tools, and also check the integrity of other parts of the excavator running mechanism.

Stop and fix it: Park the excavator on a flat hard surface, turn off the engine, turn on the manual brake and make sure that the equipment is stable.

Remove the accompanying details: use the jack to raise the chassis of the excavator, and remove the accompanying parts, such as caterpillars or running device to provide the best access to the chassis engine.

Remove the old engine: carefully remove the oil tubes, wires, bolts and other connectors on the engine engine, remove the old drive engine from the installation site and take care of maintaining the removed parts to avoid loss or damage.

Install a new engine: align the new engine engine at the installation location, install the fasteners and tighten them, but do not tighten too much. Connect the oil tube and wires, making sure that the connection is reliable and there are no leaks in the oil tube.

Adjusting and checking: manually crap the engine engine to check whether it is easy to rotate, if there are no seals or unusual sounds. Run the excavator and conduct a chassis test to check the normal functioning, speed and power of the walking engine.

Install a caterpillar trolley or chassis: making sure that the chassis is installed correctly, install a caterpillar trolley or running device back to its original position and adjust the tension of the caterpillar trolley to the appropriate condition.

Common malfunctions

The engine does not start: if the pressure does not increase, perhaps the built -in safety valve is faulty; If the pressure rises, a negative brake may not be released. The reasons include: blocking the throttle, which turns off the pressure canal, installing the valve core in the reverse order, jamming the friction plate or insulating plate, jamming of the brake piston, burning the sliding part, jamming of the core of the valve, etc.

The engine is launched by poorly: the set pressure is normal, but the brake release time is delayed, which can be associated with a malfunction of the valve core; The negative brake is released, but starts slowly, which can be associated with excessive viscosity of the working oil; The negative brake is released, but it is launched weakly, which can be associated with clogging the throttle in the release of the release of the release, getting the mud in the bypass valve or the burning of the sliding part.

The revolutions do not reach the given value: perhaps the flow of oil is insufficient, or a sliding sleeve, a pump lining or a distribution plate are worn or damaged.

Ineffective brake operation: a negative brake can be faulty, the friction plate can be worn out or the spring can be damaged; The ineffectiveness of the reverse brake can be caused by a valve core malfue, jaming the valve core and the main body, jaming a one -sided valve or getting dirt, or blocking the throttle.

Oil leaks: bolts or pins can be weakened, the sealing ring can be squeezed and cracked, the gearbox can proceed, or the chief of the pilot valve can be jammed.

An abnormal sound: when the brake is slowly activated and at the same time the circuits other than the engine are activated, strong vibrations and sounds may occur. This can be caused by a malfunction of the valve core or air in a circuit or valve core.

Vibration when moving under the slope: vibration is intense with slow movement. This can be caused by the poor movement of the valve core, jaming the valve and body core and a poor saddle of the throttle or with interference of a negative brake, such as softening or damage to the spring at the end of the valve core.

After -sales service

Warranty service: usually products have a certain warranty period. During the warranty period, if the product fails due to quality problems, the manufacturer or dealer will be responsible for free repair or replacement.

Maintenance: We provide a professional maintenance and technical support team, and we can also carry out maintenance on the spot or factory repairs. Technical maintenance staff can quickly diagnose the cause of the malfunction and eliminate it.

Supply of accessories: to ensure a sufficient supply of original accessories, guarantee the quality and compatibility of accessories, as well as reduce maintenance time.

Technical consultations: the provision of technical consulting services to users, answers to questions arising from users in the process of use and maintenance, as well as providing recommendations for operation and maintenance.

Regular repeated visits: regular repeated visits to users to understand the use of the product and user needs, collect reviews and constant improvement of products and services.

Maintenance of the excavator engine engine is very important to extend its service life and ensure the normal operation of the excavator. Here are some specific service methods:

Daily inspection

Inspection of appearance: Before and after daily operation, check the appearance of the running engine for the presence of oil leaks, weakened bolts or damaged oil tubes. If oil leaks are detected, it is necessary to find and eliminate the place of leakage in a timely manner in order to avoid loss and pollution of hydraulic oil. Weakened bolts must be tightened in a timely manner so that they do not fall off due to vibration and do not affect the normal operation of the running engine.

Temperature check: During the excavator operation, pay attention to the change in the temperature of the running engine. If the temperature of the running engine is too high, it can be caused by wear of internal parts, poor lubrication or excessive load. If an abnormal temperature is detected, the car should be immediately stopped for verification, find out the cause and take appropriate measures.

Sound Check: Listen if there are any unusual sounds during the running engine, such as sharp friction, shots or vibration. Unusual sounds are often an early sign of malfunction of the running engine, which can be caused by worn gears, damaged bearings or problems with other internal details. Timely detection and elimination of these problems can prevent further distribution of malfunctions.

Regular maintenance

Replacing hydraulic oil and filter element: regularly replace hydraulic oil and filtering element of the running engine in accordance with the time interval specified in the operating manual. During operation, hydraulic oil gradually deteriorates and contains impurities and moisture, which affects the performance and service life of the running engine. When replacing hydraulic oil, be sure to thoroughly drain the old oil and clean the oil tank and pipes to prevent impurities from the old oil into a new one. At the same time, replacing the filter element can effectively filter impurities in hydraulic oil and maintain the purity of the hydraulic system.

Lubrication of parts: regularly lubricate each point of lubrication of the running engine, use the appropriate lubricants and provide sufficient grease. Bearings, gears and other parts of the running engine need good lubrication to reduce friction and wear. Regular lubrication can extend the service life of these parts and reduce the likelihood of failure.

Check and adjust the tension of the caterpillar: too strong or too weak tension of the caterpillar will affect the efficiency of work and the life of the running engine. Regularly check the trace of the caterpillar and adjust it in accordance with the actual conditions. If the caterpillar tension is too strong, this will increase the load on the running engine and lead to increased wear of the components; If the caterpillar tension is too weak, this can easily lead to its decline or deviation, which will affect the stability of the excavator movement.

Operation notes

Avoid overload when working: When working at the excavator, avoid prolonged overload of the running engine. Work in the conditions of overload will lead to the fact that the chassis will be subjected to excessive pressure and load, which will accelerate wear and damage to parts. Reasonably control the intensity of the excavator and choose the corresponding speed of movement and the operating mode in accordance with the working environment and the requirements of the problem.

Smoothness: When walking, try to maintain smoothness, avoid sharp accelerations, braking and steep turns. Sudden movements can expose the chassis of a stronger impact and vibration, which can easily lead to weakening the fastening or damage to the parts. Smooth work reduces the wear of the running engine and extends its service life.

Correct parking: if the excavator is parked for a long time, it should be park on a flat and hard surface, and caterpillar should be placed lining to prevent their compression and deformation for a long time. At the same time, turn off the engine and all electrical equipment to prevent the electrolyte leak from the battery.

Elimination of malfunctions and repair

Eliminate the malfunctions immediately: if the running engine is detected, stop using the excavator immediately and eliminate the malfunction. Do not continue to use the engine in a faulty state to avoid more serious damage. Check and eliminate the malfunction in accordance with its manifestation and possible causes. If you cannot solve the problem yourself, you should contact a professional technical personnel in a timely manner for repairs.

Regular maintenance records: Create a file of records on the maintenance of the running engine, fixing the time, maintenance and replaced parts of each maintenance. Thanks to the records of maintenance, we can understand the history of the use and maintenance of the running engine, find potential problems in time and take appropriate measures to prevent and eliminate them.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive