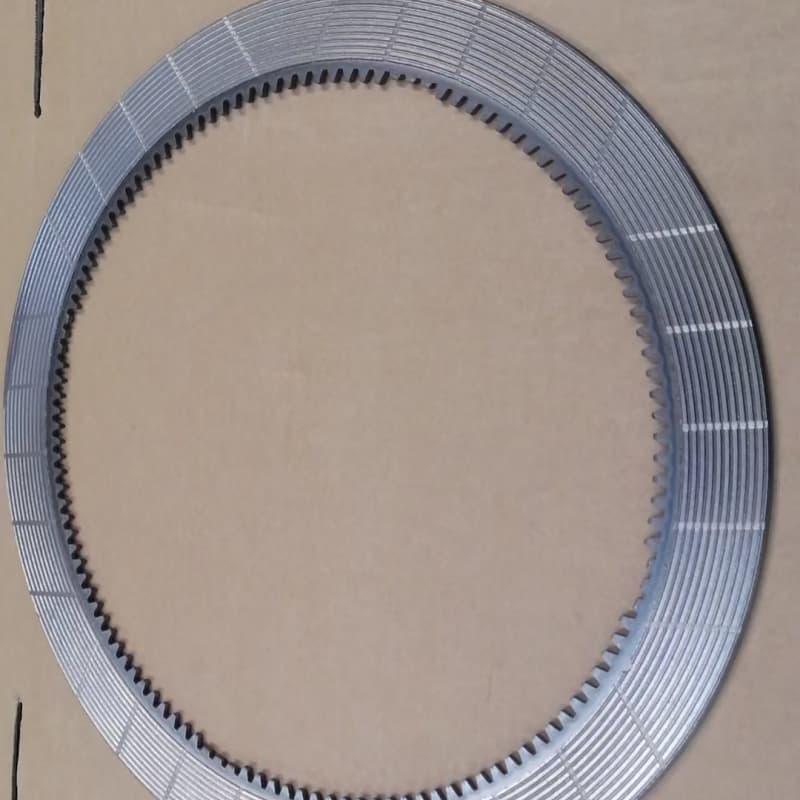

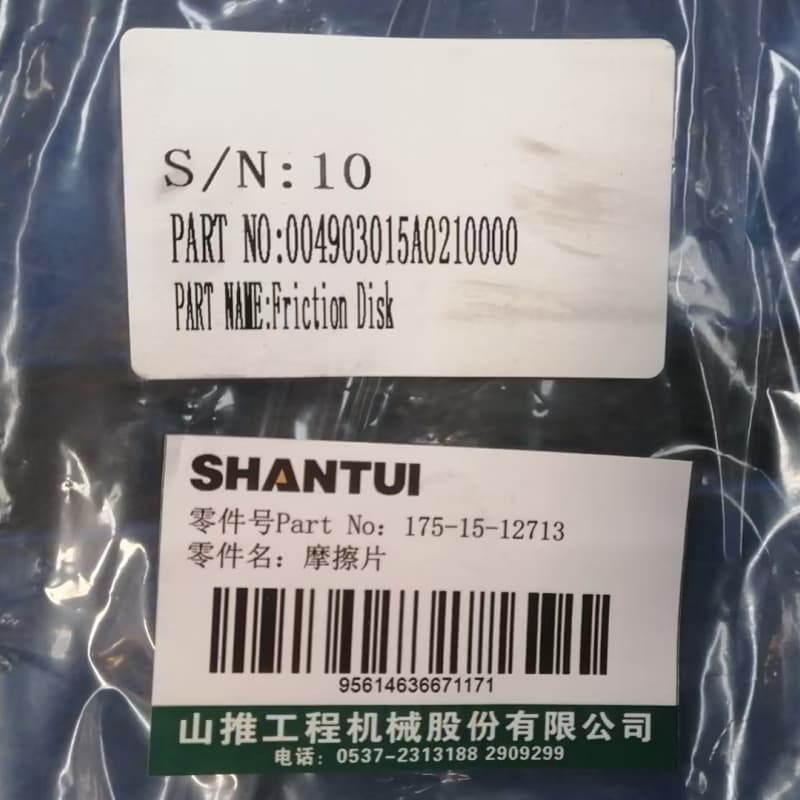

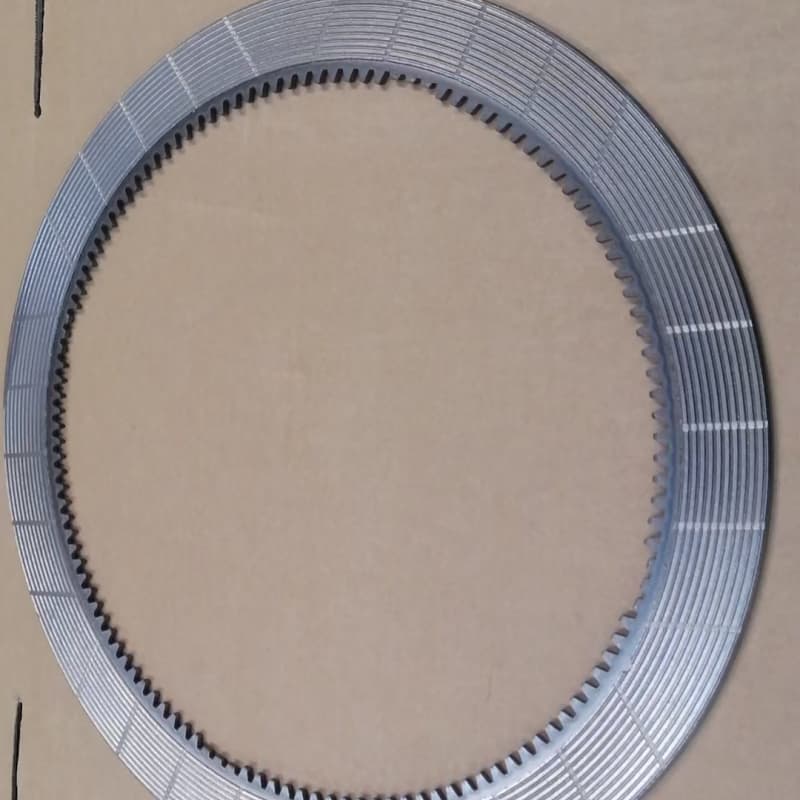

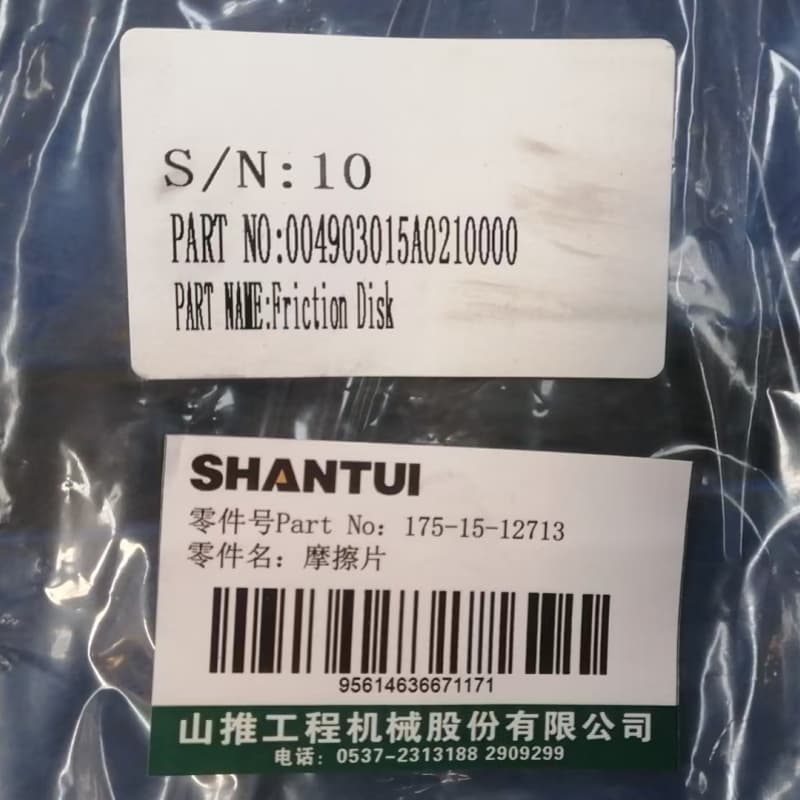

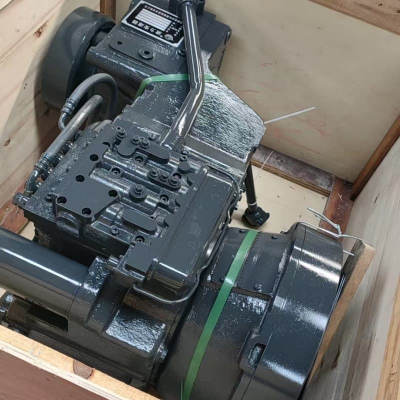

175-15-12713 Friction plate of the gearbox of the bulldozer

1. Excellent friction: high -performance friction material with a stable friction coefficient is used, which can provide severe friction and efficient power transmission.

2. Durability: after special processing, high surface hardness, high wear resistance and resistance to ablation are achieved, it can withstand frequent clutch operations and has a long service life.

3. Accurate adaptation: designed for various types of bulldozers, have an exact size, are convenient to install, have high adaptability, provide a tight landing after installation.

Premedproduct of the product

Basic information

Model: Model of the friction disk for gearboxes Shantui SD22 usually has a specific code (depending on the production batch and the manufacturer).

Purpose: as an element of the transmission mechanism, it interacts with steel disks to achieve transmission and disconnecting power, as well as completing the gearboxes of the box.

The structure of the product

A layer of friction material: to ensure a high and stable friction coefficient, specially designed friction materials are used, for example, based on copper and paper.

Steel substrate: made of high -strength steel, provides support for friction material and the total strength of the friction disk.

Technical parameters

Friction coefficient: usually 0.3 - 0.5 for the effective transmission of torque.

Thickness: usually 2 - 4 mm, may slightly differ from the party to the party.

Range of operating temperatures: - 40 ℃ - 250 ℃.

Production process

Material compound: friction material is tightly glued to the steel substrate by hot pressing and other processes to ensure the strength of the connection.

Surface processing: the surface of the friction disk is polished and polished to ensure a tight fit to the steel disk and uniform contact area.

Detailed steps for installing a friction plate of a bulldozer

1. Preparation before installation

1. Preparing the tool

Gadial keys: Prepare various specifications of the unitary, ore and end keys to remove and install various bolts and nuts. For example, to remove the bolts of a clutch pressure disc, a end key in size is 17-19 mm in size.

Sprinkle: is equipped with a cross -shaped screwdriver and flat screwdriver, used to unscrew and twist some small screws, for example, screws fixing the dust gap or sensor.

Strokes for stop -rings: there are forceps for internal and external locking rings, which are used to remove and install stop rings. Stop rings are often used to fix the position of friction plates on the slotted shafts.

Dynamometric key: this is a key tool used to accurately monitor the moment of tightening the bolts to provide a reliable installation that meets the standards. The moment of tightening of the clutch or brake bolts in different models of bulldozers is different, and they must be operated strictly in accordance with the requirements of the equipment operating manual.

Special tools: Depending on the model and design of the bulldozer, some special tools may be required, for example, special tools for removing and installing the clutch pressure, which can provide uniform load on the pressing disk during removal and installation to avoid damage.

(II) Verification of accessories and equipment

Checking the friction plate: Carefully check whether the model and technical specifications of the new friction plate to the bulldozer fully correspond. For example, for the Shantui SD16 bulldozer, it is necessary to use friction discs of certain models and sizes that cannot be mixed. Check the appearance of the friction plate to make sure that there are no defects, such as cracks, detachment, swelling, etc. on the surface of the friction material, as well as that the steel base is not deformed and did not rust.

Checking the relevant accessories: check the completeness of the corresponding bolts, nuts, springs, stop rings and other accessories, as well as their quality. Bolts and nuts should not be disrupted or deformed, the springs should not be broken or worn out, and the locking rings should have good elasticity.

Preparation of lifting equipment: select the right lifting equipment, for example, a hydraulic jack or lift. The hydraulic jack should have a sufficient carrying capacity for the safe lifting of the appropriate parts of the bulldozer and ensuring the convenience of operation. Before using lifting equipment, check its performance to ensure safety and reliability.

3. Planning of the site and security measures

Choosing a place: choose a flat, dry, well -ventilated and lit place, for example, a workshop for maintenance or a specialized work site. Make sure there are no obstacles around, leave enough space for work and stay away from the sources of fire and flammable materials.

Safety measures: Operators must wear personal protective equipment, such as protective helmets, protective gloves and protective shoes. A protective helmet can protect the head from random blows, protective gloves can protect the hands from scratches and burns, and protective shoes can prevent blows on the legs with heavy objects.

(IV) Preparation for the removal of the old friction plate

Turn off the equipment and turn off the power: Parke the bulldozer in a safe place, turn on the manual brake and make sure that the vehicle is motionless. Turn off the engine and disconnect the negative terminal terminal to prevent random launch or electric shock during operation.

Cleaning the working area: use brushes, vacuum cleaners and other tools for garbage, dust and oil harvesting in the work area, maintain cleanliness and order at the workplace, do not allow pollution to the installation zone and influence the installation and operation of the friction plate.

Marking and recording: mark and write down the installation site, direction of the old friction plate and the method of connecting related components. For example, make appropriate marks on the clutch clutch and flywheel, and also write down the relative position of the slotted openings of the friction discs and the slotted shaft to ensure an accurate certificate to install new friction discs.

2. Remove the old friction plate.

1. Separation of related components

Clutch friction disk: first find the working clutch mechanism, for example, cable clutch, using a wrench, weaken the adjusting trox nut to separate the cable from the clutch; For hydraulic clutch, first drain the hydraulic clutch oil, then remove the oil pipe connection to separate the hydraulic system from the clutch.

Friction brake pad: For drum brakes, use the end key to unscrew the mounting bolts of the brake drum and remove the brake drum from the wheel hub; For disc brakes, first unscrew the mounting bolts of the brake caliper and remove the brake caliper from the brake disk.

(ii) removal of a pressure plate or brake caliper

Clutch pressure: using the end key, gradually unscrew the fasteners of the pressure disk in the diagonal order. Since the spring plate spring has a great compression force, observe safety measures during disassembly to prevent sudden jumping out of the clamping plate and injuries to anyone. Having unscrewed the last few bolts, do it slowly and hold the clamping plate with your hand to remove it smoothly.

Brake caliper: Upling the brake caliper mounting bolts, carefully remove the caliper from the mounting bracket. If a clutch forms between the brake caliper and the brake disk, you can slightly tap the brake with a rubber hammer on the brake caliper to loosen it, but be careful not to damage the brake caliper and brake disk.

(III) removal of the old friction plate

Clutch friction disk: remove the old friction disk from the slotted shaft and pay attention to the wear of the slotted opening and the slotted shaft. If there is a locking ring between the old friction plate and the slot shaft, remove it with pliers, and then remove the friction plate.

Brake pads: for drum brakes, remove the old pads from the grooves on the brake hub; For disk brakes, remove the old pads directly from the caliper clamps. When removing the old friction lining, be careful not to damage the brake hub or brake disk.

3. Install a new friction plate.

1. Cleaning installation location

Slit shaft cleaning: use a cleaning agent and clean fabric to carefully clean the surface of the slot shaft from oil, pollution and rust. To remove oil spots, use a brush with a detergent, and then wipe dry with a clean cloth. After cleaning, apply the required amount of lubricant on the slotted shaft to reduce wear during installation and use of the friction plate.

Cleaning the brake hub or brake disk: for the brake hub, use sandpaper to carefully polish the rust and rough areas on the surface, making the surface smooth and even. Then peel it with a cleaning agent to remove garbage and oil spots formed as a result of grinding with sandpaper. To polish the brake disk, also use sandpaper and a detergent for cleaning to make sure that there is no oil or pollution on the surface of the brake disk and avoid deterioration of braking efficiency.

Cleaning the pressure disk or brake caliper: clean the mounting surface of the pressure disk or brake caliper to remove oil, pollution and residual friction materials from the surface. Check if the spring plate spring has good elasticity. If the spring is broken or tired, it should be replaced in time. For brake calipers, check if the piston moves freely. If he is stuck, it must be repaired or replaced.

(II) Frice plate installation

The clutch friction disk: install a new friction disk on the slotted shaft, making sure that the slotted openings properly coincide with the slot shaft, and the gap is uniform. Pay attention to the installation direction. Typically, on the friction plate there is a marking indicating the direction of the installation, for example, arrows or letter designations. Install it correctly in accordance with the marking to avoid the reverse installation, which can lead to abnormal clutch operation.

Friction brake pad: for drum brakes, carefully install a new friction lining in the brake hub groove, making sure that the friction lining fit tightly to the brake hub, without a backlash. For disk brakes, install new friction pads in the caliper lips so that the gap between the blocks and the disk is uniform.

(III) installation of a pressure plate or brake caliper

Clutch pressing disk: set the pressing disk back to its original position and gradually tighten the fasteners with a dynamometric key in a diagonal order. In the process of tightening, observe the value of the torque specified in the equipment operating manual to guarantee uniform compression of the clamping plate of the friction plate. For example, the moment of tightening the bolt of the clutch of the clutch of a certain bulldozer model is 100-120 N · m. The tightening moment must be strictly monitored in order to avoid the clutch failure due to excessive or insufficient torque.

Brake caliper: Install the brake caliper on the brake disk and tighten the fasteners. Similarly, tighten to the specified value of the tightening point to ensure a reliable installation of the brake caliper. After installation, check whether the gap between the brake caliper and the brake disc is uniform, adjust it if necessary.

(IV) Installation of other components

Installation of the clutch drive mechanism: setting the clutch drive mechanism is carried out in the order, reverse disassembly. For example, to clutch the cable type, connect the cable to clutch and adjust the length of the cable so that the free move and the working course of the clutch pedal meets the requirements. For hydraulic clutch, connect the oil pipe connection, add the required amount of hydraulic oil and remove air from the system.

Installation of a brake drum or brake disk: if the brake drum or brake disk has previously been removed, install it in place and tighten the fasteners. After installation, check whether the brake drum or brake disk rotates freely and there are no seizures.

4. Checking and debugging after installation

1. External inspection

Checking the position of the installation of the friction plate: check whether the friction plate is installed in the correct position, whether it adjacent to the slotted shaft, the brake hub or brake disk, and whether there is no backlash or displacement.

Checking the installation of a pressing disk or brake caliper: check if the pressure disk or brake caliper is reliably installed, whether the fasteners are tightened, whether there are missing or weakened parts. Check the uniformity of compression of the pressure spring and the correct position of the piston of the brake caliper.

Check the connection of other components: check the correctness and reliability of the connection of other components, such as the clutch drive and brake lines, as well as the absence of weakening, deformation or leaks.

(Ii) clearance adjustment

Adjustment adjustment: check the free stroke of the clutch pedal, which is usually 30-50 mm and can be achieved by adjusting the length of the cable or the adjusting bolt of the hydraulic system. After adjustment, press the clutch pedal and check whether the clutch turns on and turns off, if there is no seal or slipping.

Adjusting the brake clearance: For drum brakes, use the adjusting key to adjust the gap between the brake block and the brake drum, usually it is 0.2-0.5 mm. When adjusting, adjust the gap, rotating the brake drum until it rotates smoothly, without obvious resistance. For disk brakes, check the gap between the brake block and the brake disc, which is usually 0.1 - 0.3 mm. If necessary, adjust the gap by adjusting the position of the brake caliper piston.

(III) performance testing

Launch test: Connect a negative battery terminal, start the bulldozer engine and check if the engine is running and if there are any unusual noise or vibrations.

Test driving: Drive on a bulldozer at low speed a certain distance to check the smoothness of the clutch and the absence of slipping or shaking. During movement, pay attention to the smoothness of the acceleration of the car and switching gear.

Brake test: conduct the brake test when moving at low speed to check the braking efficiency, sensitivity and reliability of braking, as well as the presence of deviations or resistance to movement. The braking distance must comply with the requirements of the equipment operating manual. For example, the braking distance of a particular bulldozer model at the specified speed should not exceed 3 m.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive