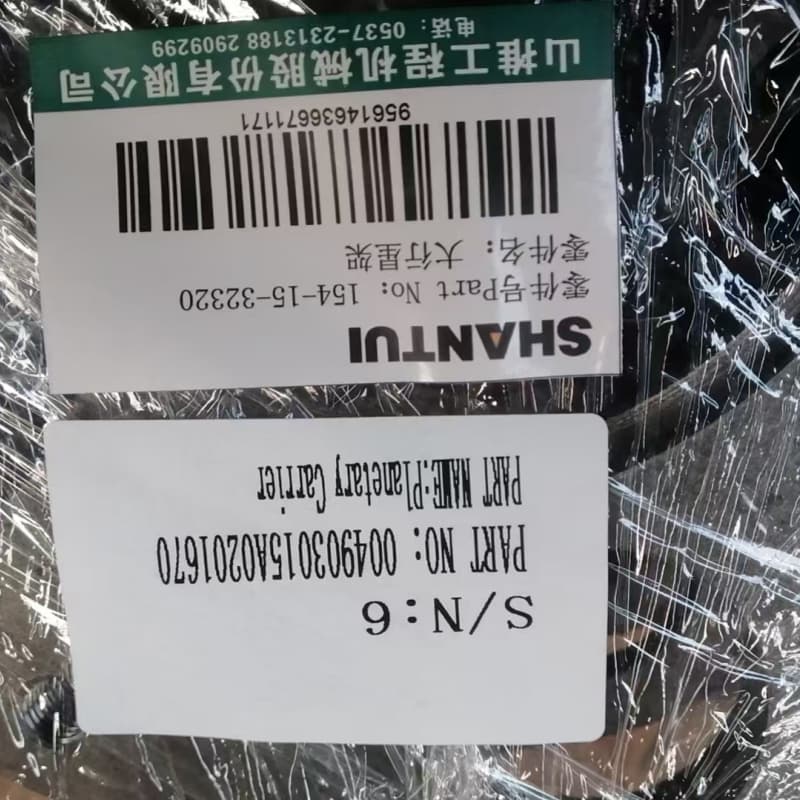

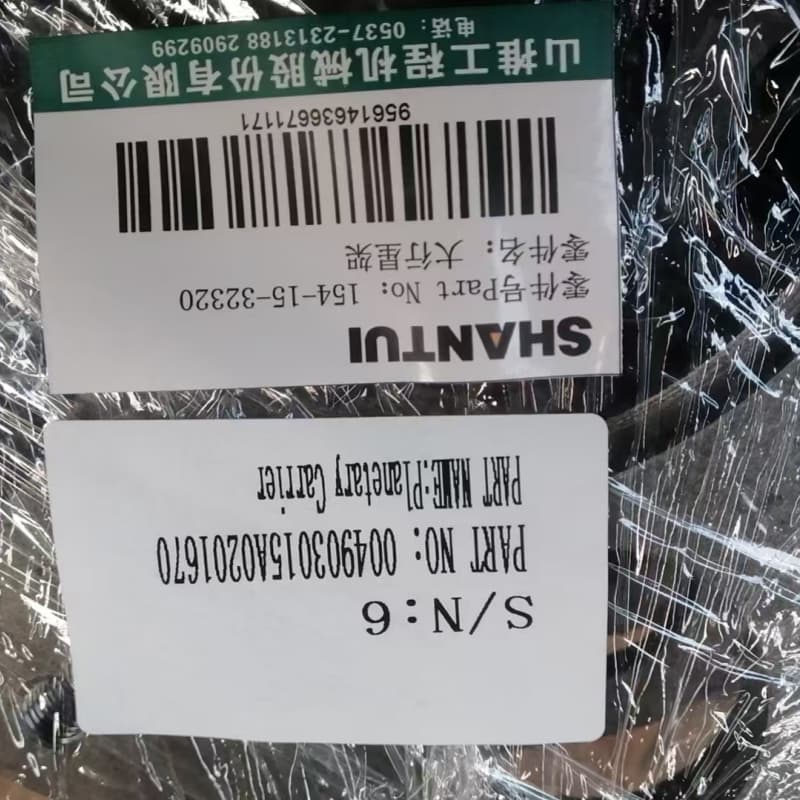

154-15-32320 Bulldozer gearbox large planetary trolley

1. Strong material: made of high -strength alloy steel, which has passed special heat treatment, has high hardness, strength, wear resistance, impact resistance and long service life.

2. Optimization of the structure: a unique design design, effective load distribution, smooth work, high transmission efficiency and reduced frequency of failures.

3. Accurate adaptation: made specifically for the Shantui SD22 bulldozer, has the exact dimensions, a simple installation and perfect adaptation to the gearbox.

Product representation

Basic information

Model: model of the planetary support for the transmission Shantui SD22 usually has a specific code, for example, 154 - 15 - 32320, etc. (depending on the production party and the manufacturer submodel).

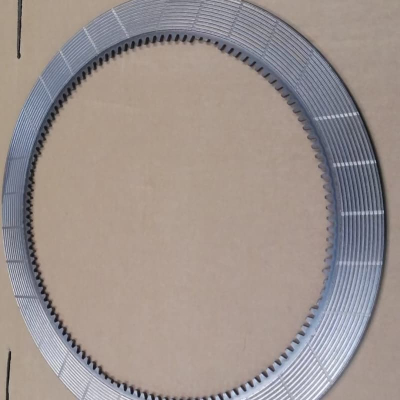

Application: as a key component of the Shantui SD22 transmission, planetary transmission is mainly used to transmit power to achieve various gear ratio by interacting with planetary wheels, solar wheels, gear rings and other components to complete the transfers and speed changes.

Structural design

The main material of the case: a high -strength alloy steel is used, which has good strength and viscosity, capable of withstanding a high torque and greater load, adapting to the needs of the bulldozer in difficult working conditions.

Structural layout: the planetary holder is evenly distributed with several mounting holes for the installation of planetary wheels, which guarantees that planetary wheels can maintain a stable position and trajectory during operation; At the same time, the connecting parts of the planetary holder and other components of the gearbox are reasonably designed, which contributes to the exact installation and stable gear.

Work parameters

Torque: withstands a large torque, usually reaching more than 215 N ・ m, which provides stable power transmission and lack of deformation and damage when working with a large load.

Speed range: Suitable for the speed of the Shantui SD22 engine, the normal operating speed range is [a certain speed range], which allows you to maintain an effective and stable power transmission in the speed range.

Production process

Processing technology: after accurate forging, machining, heat treatment and other processes. Forging makes the internal organization of the material dense and increases strength; mechanical processing provides the accuracy of the size of each part and meets the requirements of the assembly; The heat treatment increases the wear resistance and fatigue strength of the material.

Quality check: In the production process, strict quality control is carried out, including checking the accuracy of sizes, checking hardness, flaw detector, etc., to guarantee that each planetary support corresponds to high quality standards.

Adaptability and after -sales maintenance

Adaptability: it has good adaptability with other parts of the Shantui SD22 transmission, such as the solar wheel, gear crown, the clutch disc, and can directly replace the original parts to guarantee that the overall transmission performance will not be affected.

After -sales maintenance: provides perfect after -sales service, including a certain warranty period, during the warranty period, if the product has problems with quality, it can use free repair or replacement of services; At the same time, the manufacturer or distributor provides technical advice and maintenance manual, which is convenient for users to solve the problems that arose during use.

The most common faults of the planetary transmission of the SHANTUI SD22 bulldozer gearbox are:

Distribution problems

Hister wear: gears on the launch of planetary gear are engaged with other gears for a long time. At high loads and high speeds, the surface of the teeth will wear out. This leads to an increase in the clearance in the engagement of gears, which leads to blows and noise during transmission, affecting the smoothness of power transmission. In severe cases, the teeth can occur, which makes the gearbox unable to work normally.

Test wear: the compounds between the tsapfa drove the planetary transmission and the bearing or other components are susceptible to wear due to prolonged relative movement and load. When the neck is wear, the planting gap increases, which leads to the vibration of the driving planetary transmission during operation, which affects the normal engagement of planetary gears and can lead to damage to other components.

The problem of deformation

Thermal deformation: During the operation of the bulldozer, the gearbox will produce a lot of heat. If the heat voltage is bad, the drive of the planetary transmission can be deformed due to uneven heating. Thermal deformation changes the relative position of the components on the water supply of planetary transmission, reduces the accuracy of the engagement between planetary gears and other gears, causes unbalanced loads, accelerates the wear of the gears and drove planetary transmission, and can also cause a leakage of transmission oil.

Deformation due to stress: when the bulldozer works in severe conditions, the gearbox will be subjected to a large shock load, and the drive of the planetary transmission can be deformed due to excessive external power. The deformed drive of the planetary transmission will change the trajectory of planetary gears, causing abnormal vibration and noise. In severe cases, the planetary gears will get stuck along with the crown gear, solar gear and other components, which will lead to the refusal of the gearbox.

Cracks and fractures

Strength cracks: with prolonged sizoing loads inside the driving of planetary transmission, fatigue stresses occur. When the fatigue voltage reaches a certain level, cracks appear in the drive of the planetary transmission. Strength cracks usually first appear in the zones of the stress concentration of planetary transmission, such as the base of the gear and the transition tick of the neck. If you do not detect and eliminate cracks in time, they will gradually expand and will ultimately lead to a breakdown of a planetary transmission.

A reloading gap: when a bulldozer encounters a sharp strong resistance or the operator makes an error in the work, the drive of the planetary transmission of the gearbox can be subjected to a load exceeding its carrying capacity, which will lead to an overload of the gap. The gap due to overload usually occurs suddenly, as a result of which the gearbox instantly loses the ability to transmit power, which seriously affects the normal operation of the bulldozer and can even lead to damage to equipment and human victims.

Problems with lubrication and sealing

Poor lubricant: if in the gearbox there is not enough lubricating oil, its quality worsens or the oil circuit is clogged, the lubricants of the deriva of the planetary transmission cannot be well lubricated. This will increase the friction between the Drill Planetary transmission and other components, will lead to the release of a large amount of heat, accelerate wear of components, and can even cause ablation, which will lead to the exit of the conduct of planetary passing.

Seal malfunction: sealing on the launch of planetary transmission, such as seals and sealing rings, are aging, deformed or damaged after prolonged use, which leads to a leakage of transmission oil. A leakage of transmission oil not only leads to its overspending, but also to a deterioration in the conditions of lubrication and cooling of components such as the drive of planetary transmission, which increases the probability of failure.

The installation guide to the planetary wagon of the transmission of the bulldozer Shantui SD22

1. Preparation before installation

1. Preparing the tool

End wrench keys, wounds, dynamometric keys, and uniform worships of the corresponding specifications.

The lifting equipment (for example, a crane or a fork loader) should be designed for a weight that meets the requirements of a planetary transmission.

To measure the mounting clearance and alignment, the dial indicator and the base of the dial are used.

To measure the corresponding sizes, internal and external micrometers are used.

Copper rod, rubber hammer, for easy tapping in detail during installation.

The detergent and brush for cleaning parts.

Pure rag, rust inhibitor.

2. Preparation of a place

Choose a spacious, even, clean and well -ventilated workplace.

Take out the garbage and obstacles at the place of the event to ensure safe work.

Prepare a suitable workbench or stand for installing a gearbox and related components.

3. Preparation of personnel

The installer should be familiar with the design and principle of operation of the gearbox of the bulldozer Shantui SD22.

Installers need to undergo professional training and master the correct installation methods and operating skills.

Installers must use the necessary personal protective equipment, such as protective helmets, gloves, etc.

(IV) Checking the components

Check the new drive of the planetary transmission for damage, cracks, holes and other defects. Measure the main dimensions of the driving planetary transmission, such as the diameter of the opening of the planetary wheel shaft, the center distance, etc., to make sure that they meet the design requirements.

Check the wear of planetary transmission, solar gear, crown gear and other related details. If there is excessive wear, replace them on time.

Check all the seals, such as sealing rings, seals, etc., to make sure that they are not worn out and not damaged.

2. Dismantling of the gearbox (preparation for the installation of a planetary transmission)

1. Drain the oil.

Find a plug for draining the oil from the gearbox and put a suitable container under it.

Slowly unscrew the bolt of oil drain to drain the lubricating oil from the gearbox.

(Ii) disassembly of external connecting parts

Remove oil tubes, wires, joysticks and other components connected to the gearbox, and place them for the subsequent installation.

Remove the connecting bolts between the gearbox and the engine, frame, etc.

(III) lifting gearbox

Use lifting equipment to raise the gearbox and install it on a workbench.

(IV) Dismantling gearbox

Consistently remove the gearbox, the end cover and other parts from the outside inside.

Carefully remove the inner gears, shafts, couplings and other components and put them in order.

3. The stages of installation drove a planetary transmission

1. Cleaning parts

Use the cleaning product and brush to carefully clean the drive of the planetary transmission, the planetary gear shaft, bearings and other parts, removing oil, pollution and iron sawdust.

Wipe the details dry with a clean rag and apply the required amount of the Rusta.

(II) Installation of planetary programs and bearings

Apply the required amount of lubricating oil to the internal hole of the planetary transmission and the planetary transmission shaft.

Install the bearing in the inner hole of the planetary transmission, making sure that it is securely fixed.

Use special tools to install planetary transmission and bearing unit in the opening of the shaft of the planetary transmission, paying attention to the direction and sequence of the installation.

(III) Install the drive of the planetary gear in the gearbox.

Small the drive of the planetary gear to the appropriate position of the gearbox, making sure that the central hole drove the planetary transmission is combined with the center of the shaft of the solar gear, the gear crown and other components.

Use the dial indicator to check the alignment of the drive of the planetary gear. The error should be controlled within the specified range.

Install the fasteners of the planetary gear and tighten them with the indicated puffing.

(IV) Installation of other related components

Set the sun gear, crown gear, clutch and other components in the order, reverse disassembly.

During the installation, pay attention to the gaps and the direction of installation of each component to ensure the correct installation.

(V) Set the seals

Install new seals on the gearbox, the end cover and other parts to provide good sealing and prevent leakage of lubricating oil.

(VI) assembly of the gearbox

Install the gearbox, the end cover and other components in place and tighten the connecting bolts.

(VII) Connection of external components

Connect oil tubes, wires, joysticks and other components connected to the gearbox, and make sure of the reliability of the connections.

4. Check after installation

1. External inspection

Check the appearance of the gearbox for damage, deformation, etc.

Check that all connecting bolts are tightened, and the seals are installed correctly.

(II) Size check

Using the measuring tool, check the installation position and the corresponding dimensions of the planetary transmission again to make sure that they meet the design requirements.

(III) Verification of lubrication

Add to the gearbox the required amount of lubricants that meets the requirements, and check if the oil level is in the specified range.

(IV) Functional testing

Run the bulldozer and conduct the test of idle to check the smoothness of the gear and the absence of extraneous noise or vibration.

Draw a test under load to check the working characteristics of the gearbox in various working conditions and make sure of its normal operation.

5. Notes

Throughout the installation process, strictly follow the operating rules to ensure safety.

During the installation, pay attention to the protection of the surface of each component in order to avoid scratches and damage.

Important bolts and nuts must be tightened in accordance with the indicated puffing moment in order to avoid breakdowns caused by insufficient or excessive puffing moment.

After completing the installation, clean the working area and remove the tools and the remaining parts.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive