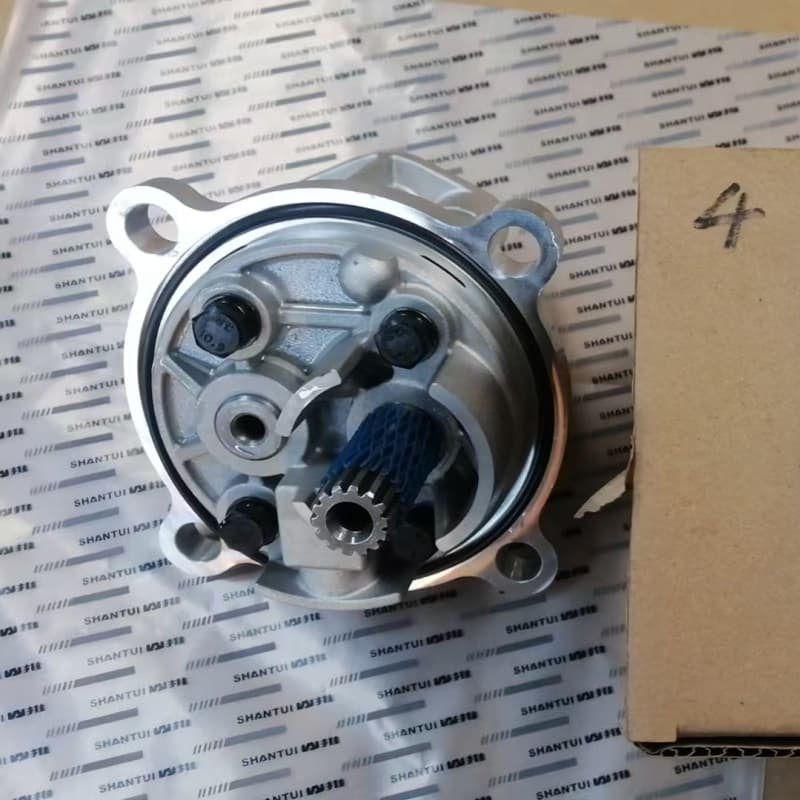

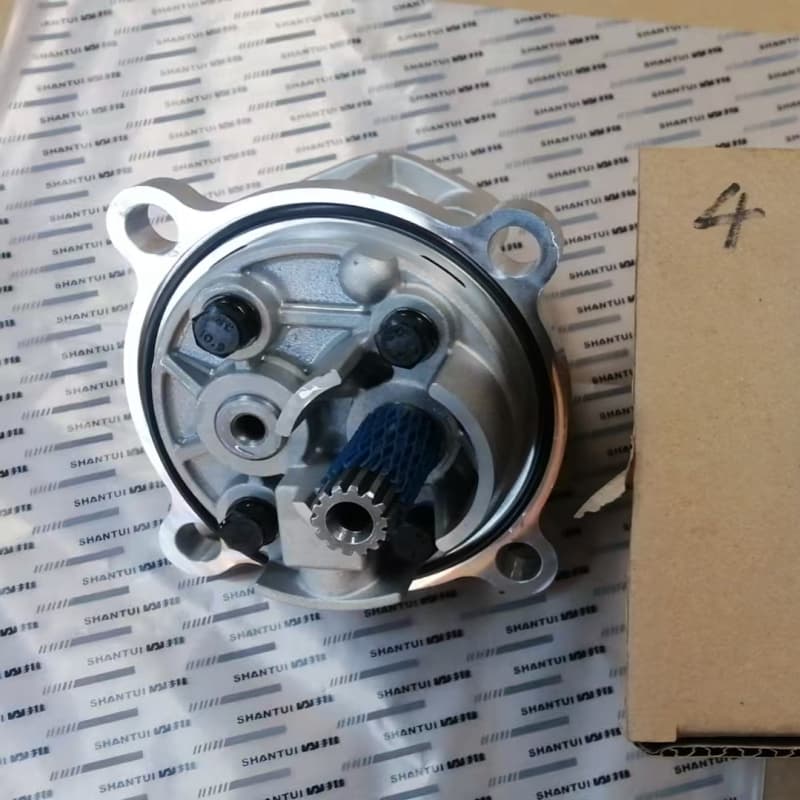

Shantui 175-13-23500 converter Oil Return pump

1. Effective oil return: a unique design of the working wheel, high pumping efficiency, allows you to quickly return excess oil from the system to tank, ensuring stable operation of the hydraulic system.

2. Durable and wear -resistant: made from high -strength wear -resistant materials and processed using special technology, it can steadily work for a long time in high pressure and high loads, which reduces the likelihood of failures.

3. Exact adaptation: it is made individually for various types of bulldozers, has accurate installation dimensions, perfect adaptation to the hydraulic system of the entire machine and a simple installation.

Product representation

Basic information

Application: used for Shantui SD22 for oil recirculation in a hydrotransformer in an oil tank to ensure normal operation of the hydrotransformer.

Adaptability: specially designed for the Shantui SD22 hydrotransformer, adapted to the hydraulic system of the entire machine, the installation dimensions and interfaces are the same as in the original car, and can be directly replaced.

Work parameters

Speed: Suitable for the SHANTUI SD22 engine speed and can work stably at various speeds.

The volume of pumping: the need for the return of the hydrotransformer oil can be satisfied, the specific value depends on the model.

The advantage of the product

Effective oil return: the impeller is optimized for effective oil return even at low speeds, preventing the heating of the hydrotransformer and a decrease in efficiency due to accumulation of oil.

Stability and reliability: high manufacturing accuracy and dense assembly, smooth work, low level of vibration and noise, few failures in prolonged work with high intensity.

High strength: the main components are made of wear -resistant and corrosion -resistant materials, such as the hull of the pump from aluminum alloy and the working wheel of special alloy steel, which are resistant to erosion of oil impurities and have a long service life.

Energy conservation and decrease in consumption: the optimized structure and principle of operation allow us to satisfy the need for oil return while reducing energy consumption and fuel consumption.

Production process

Processing technology: the use of precision production technology to ensure the exact size of the pump, the working wheel and other components to ensure stable operation.

Quality testing: strict quality control and checking key performance indicators to ensure product quality.

After -sales warranty

We provide a guarantee, technical advice and quick delivery of spare parts, free repair or replacement when problems arise during the warranty period.

Detailed documentation for the installation of a return oil pump of a bulldozer

1. Preparation before installation

1. Preparing the tool

Prepare wrenches of different specifications, such as unfortunate, lacture and end keys, to remove and install bolts and nuts.

Prepare the screwdrivers (cross and flat) for possible unscrewing and installing screws.

Prepare the pliers, for example, prisoners to capture small parts and pliers with a mobile connection to capture larger parts.

Prepare a sealant for sealing oil pipelines and other parts to prevent oil leakage.

Prepare cleaners, for example, special oil cleaners, to clean the installation sites and oil pipes.

Prepare a dynamometric key for accurate control of the moment of tightening the bolts to ensure the reliability of the installation and compliance with the standards.

(II) Verification of accessories and equipment

Carefully check the oil return model to make sure that it corresponds to the bulldozer model. For example, the Shantui SD16 bulldozer requires an appropriate model of the oil return pump.

Check if there are any damage to the appearance on the return pump, for example, cracks or sand shells on the pump housing, whether the working wheel is deformed, etc.

Check the completeness of appropriate accessories, including gaskets, sealing rings, connecting bolts, oil tubes, etc.

Check if you are worn out, not deformed, whether the gasket and the sealing ring are damaged, etc. If so, replace them on time.

3. Safety and preparation of a place

In order to avoid injuries during operation, use personal protective equipment, such as protective helmets, protective gloves, protective shoes, etc.

Choose an even, firm and open place for parking a bulldozer and make sure that there are no obstacles around for ease of work.

Install warning signs throughout the object to prevent the penetration of unauthorized persons and ensure the safe performance of installation work.

(IV) Diagon for equipment and preparation for the dismantling of the old pump

Turn off the bulldozer engine, turn on the hand brake and make sure that the equipment is stopped.

Disconnect the negative terminal terminal to prevent random inclusion in the power during installation.

Mark the position of the oil pipe, the position of the fasteners, etc. The old return oil pump to facilitate the subsequent installation of a new pump.

2. Remove the old oil return pump.

1. Drainage of hydraulic oil

Set the suitable container for collecting oil to the old return pump of oil to prevent a leakage of hydraulic oil to the ground.

Find the oil tube connected to the old reciprocal oil pump, slowly unscrew the nut of the oil tube connection and drain hydraulic oil from the oil tube into the oil collection container. During the drain process, be careful to avoid spraying hydraulic oil. If there is pressure in the oil tube, first carefully loosen the nut, let the pressure slowly drop, and then completely unscrew it.

(Ii) removal of oil pipes

Using a wrench, unscrew all the nuts of the oil pipe mounted, connected to the old reciprocal oil pump, and carefully remove the oil pipe. For some compounds that are difficult to disassemble, you can spray the baking powder before disassembly, but be careful so that the baking powder does not fall into other exact details.

After removing the oil pipe, immediately close the place of connection of the oil pipe and the junction of the return oil pump to prevent dust and pollution.

(III) Remove the fasteners.

Use a suitable wrench to unscrew the bolts that attach the old oil return. These bolts are usually distributed along the mounting bracket of the oil return.

Gradually loosen the bolts diagonally to avoid damage or deformation of the return oil pump due to uneven effort. First, spray the tool for weakening on rusted or too long bolts and wait a while before unscrewing them.

(IV) Remove the old oil return pump.

After removing all the fasteners and oil tubes, carefully remove the old oil return pump from the mounting bracket and place it in a safe place.

Check the mounting bracket of the old return oil pump, clean the surface of the bracket from oil, pollution and the residues of the sealant, and also make sure that the mounting bracket is even, clean, without damage and deformations.

3. Install a new oil return pump.

(I) Install the oil return pump to the bracket.

Install a new return oil pump on the mounting bracket, combining the mounting holes.

Install the connecting bolts, but do not tighten them completely to ensure the possibility of subsequent adjustment of the position of the return oil pump.

(II) connection of the oil pipe

Connect the oil pipe to the new reciprocal oil pump in accordance with the previously applied marking.

Apply the required amount of sealant on the connection of oil pipes to enhance the sealing effect and prevent oil leakage.

Use the wrench to tighten the nut of the oil pipe to make sure that the oil pipe is securely connected. Be careful not to pull it so as not to damage the oil pipe or connection.

(III) adjustment and fixation of the return oil pump

Use the alcohol level to check the horizontal of the return oil pump and maintain its horizontal, adjusting the tightening of the connecting bolts.

Check the gap between the oil return pump and the surrounding components to make sure that the oil return pump does not interfere with the work of other components.

Using a dynamometric key, tighten the connecting bolts one at a time in accordance with the specified moment of the tightening. Pull them gradually diagonally to provide an uniform tightening force of each bolt and reliable fastening of the return oil pump.

4. Checking and testing after installation

1. External inspection

Check the correctness and reliability of all the compounds of the oil tubes, as well as the absence of weakening, twisting or incorrect connection.

Check the correctness of the mounting position of the return oil pump and the reliability of its attachment to the mounting bracket.

Check if the sealant is evenly applied, whether there are no passes or excessive overflows.

2. Stress testing

Connect the negative terminal terminal, start the bulldozer engine and let it work at idle.

Use professional equipment for checking the pressure, connect to the output pipeline of the return oil pump and check the output pressure of the return oil pump.

Observe whether the pressure value is within the technical parameters specified for the equipment. If not, check if there are malfunctions in the reverse oil pump, the safety valve, the oil pipe and other components, and perform the appropriate adjustments or repair.

(III) testing for tightness

When the engine is running, carefully check if there is no oil leakage at the junction of the return oil pump with an oil tube, on the surface of the pump body, etc.

If the oil leak is detected, stop the car immediately and find out the cause of the leak. The reasons can be damaged seal, improper installation, weakened bolts, etc. Report or reinstall depending on specific problems.

(IV) Verification of the sound of the operation

Listen to the sound of a return oil pump. Under normal conditions, he must make an even and smooth sound.

If you hear an unusual noise, such as a sharp friction, blow or vibration, this can be caused by damage to the bearing, weakened by the working wheel or the hit of foreign objects into the machine. You need to immediately stop the car to check and eliminate the malfunction.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive