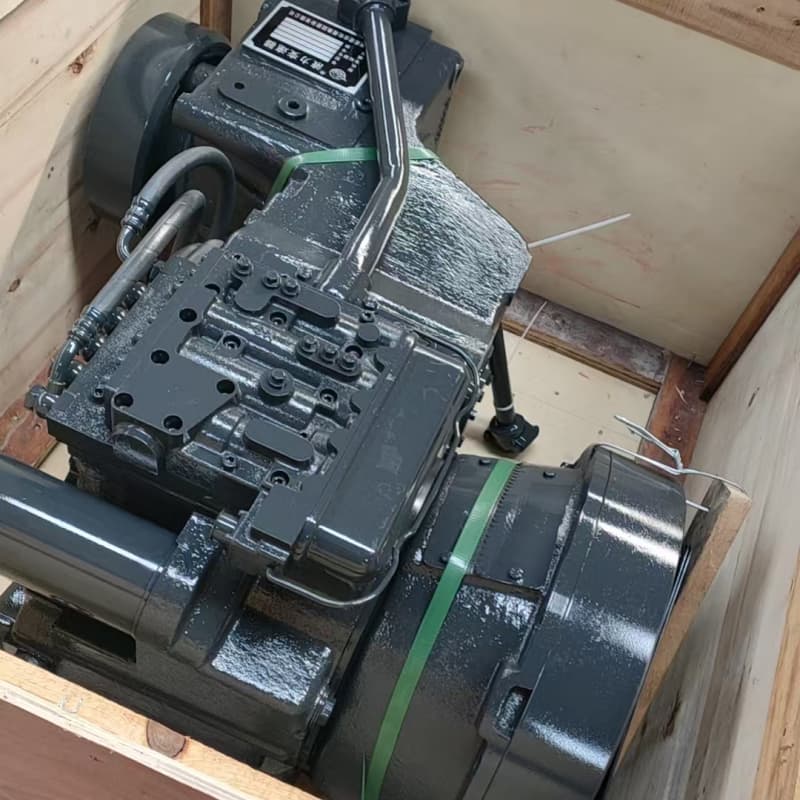

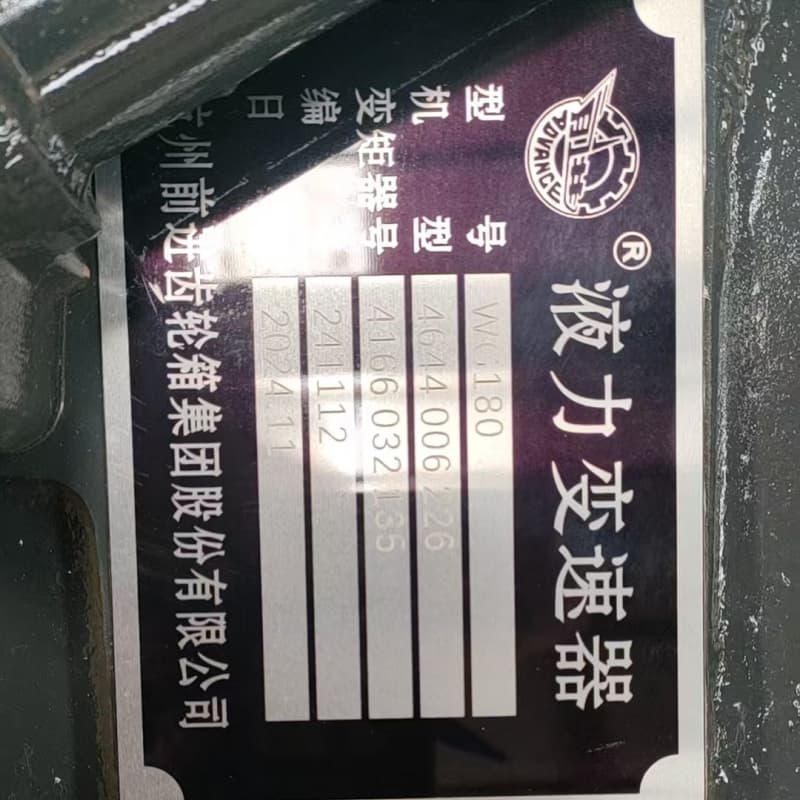

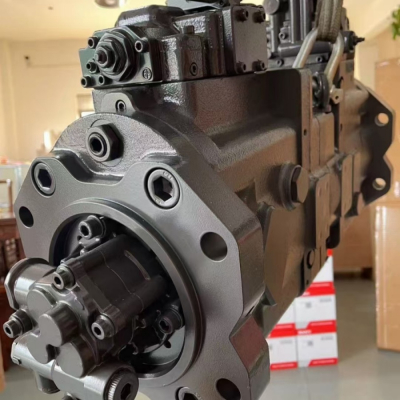

ZF WG180 REDUTOR AUTO GRADER SG18

1. Effective operation and increased efficiency: optimized design, effective electricity transmission and accelerated construction progress meet the needs of Russian customers in effective projects.

2. The strength and resistance to environmental impacts, a decrease in maintenance costs: thanks to the use of high -quality materials and exquisite skill, the product can adapt to difficult working conditions, as well as reduce the cost of maintenance and the frequency of its implementation.

3. Frost -resistant and stable, not causing worries in winter: developed for low temperatures in Russia, it can work stably at low temperatures, ensuring uninterrupted operation in winter.

4. Simplicity of installation, saving working time: a reasonable design, a simplified installation process, fast installation, reduction of equipment downtime.

Product representation

1. Detailed product information

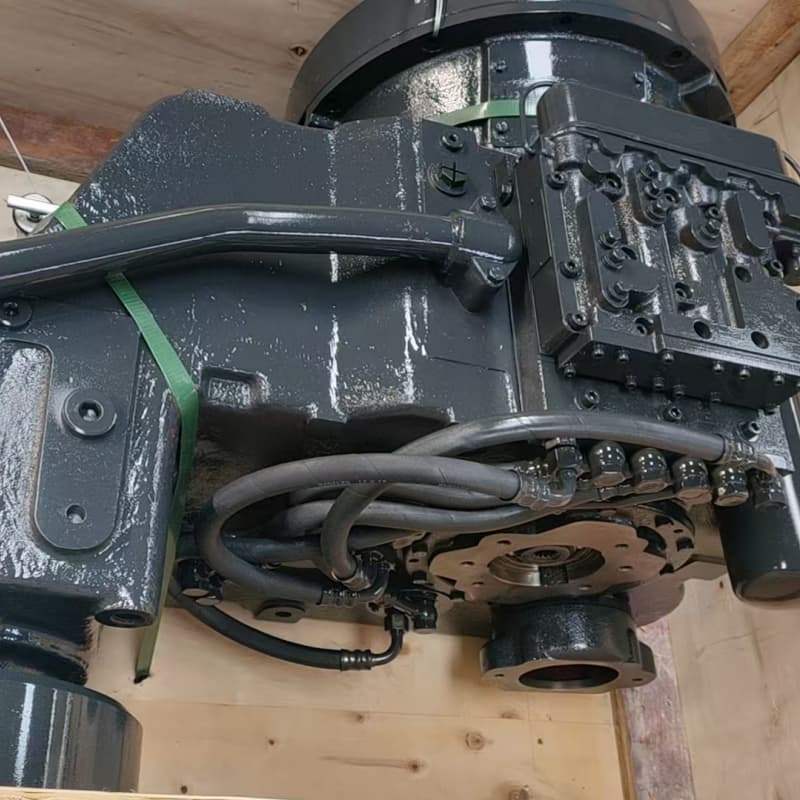

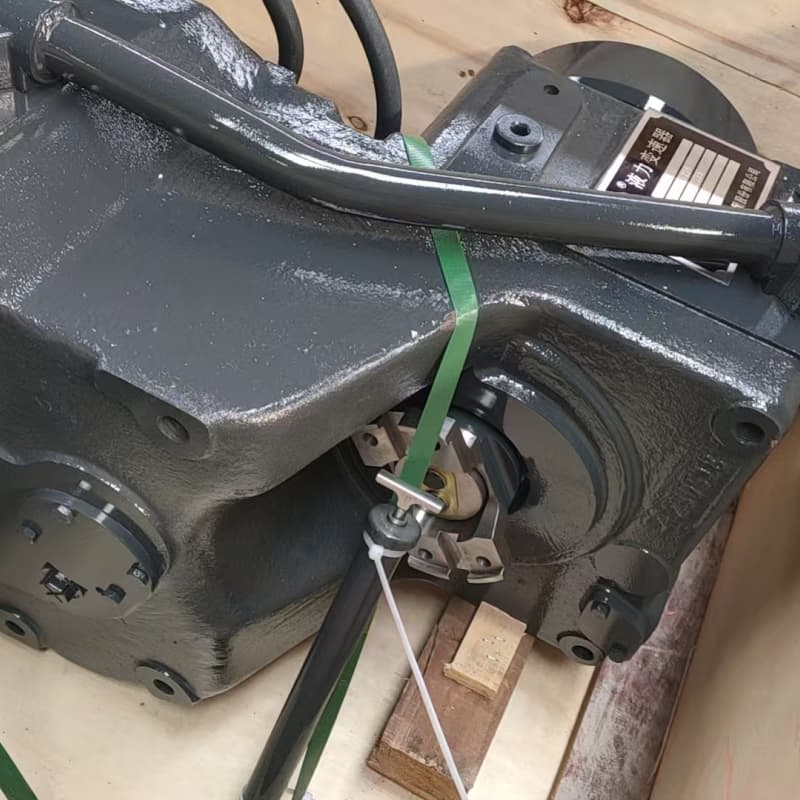

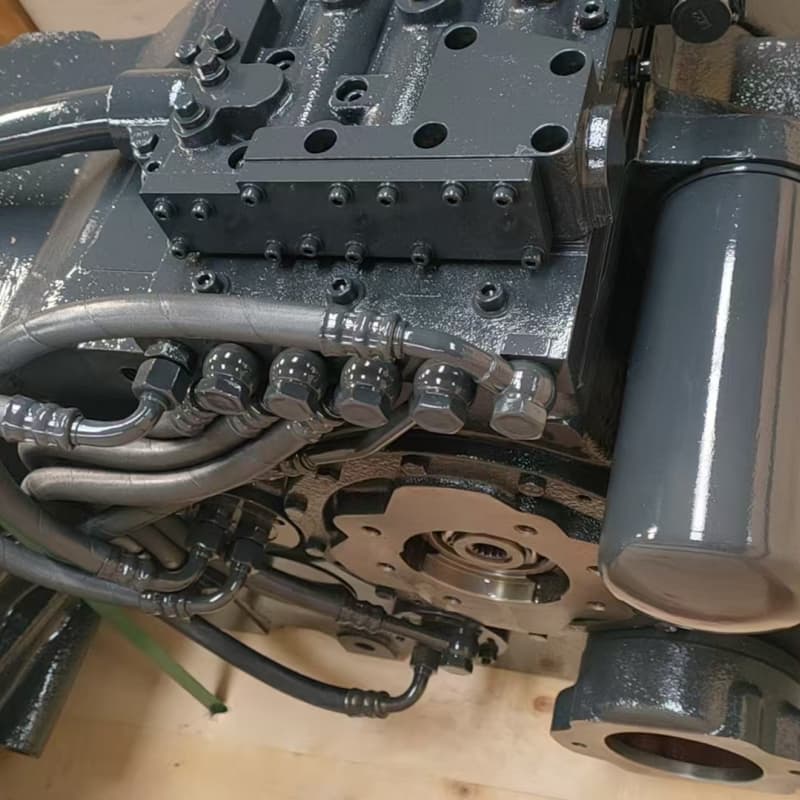

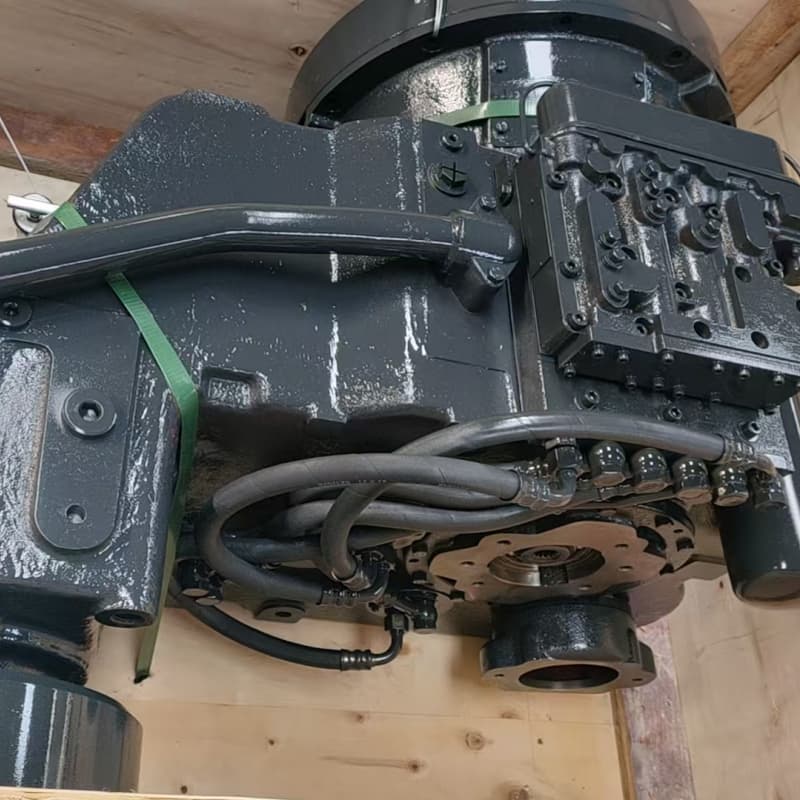

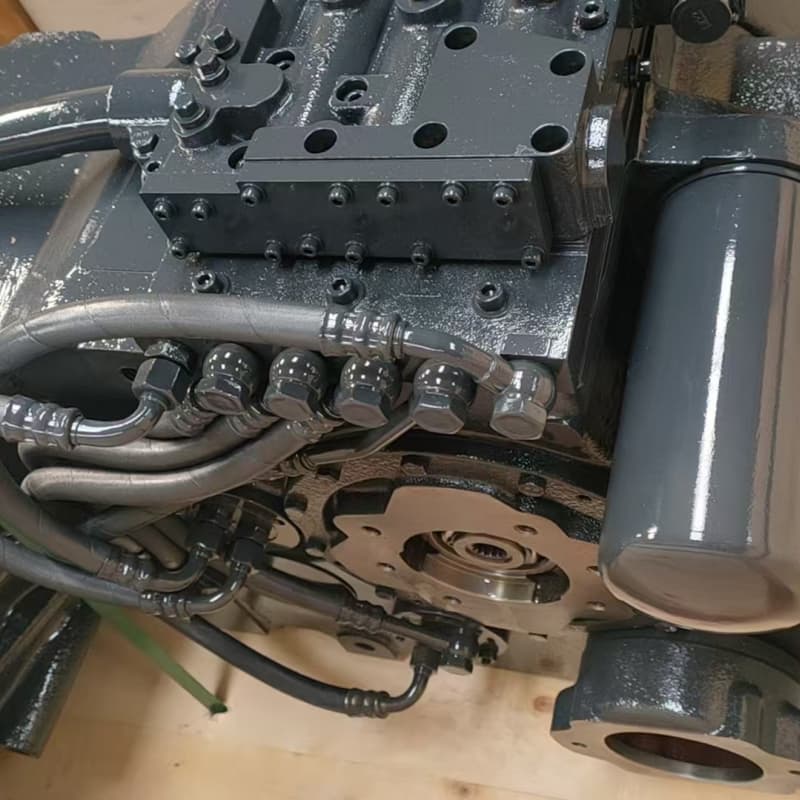

Design: Graider gearbox has a compact and reasonable design. The box usually casts from high -strength alloy steel. It has good rigidity and impact resistance and can withstand high grader loads in difficult working conditions. The internal gear gear has passed accurate machining and heat treatment, has high accuracy of the teeth profile and the corresponding surface hardness, which ensures smoothness and reliability of the transmission. At the same time, the use of multi -disc clutch and brake provides quick, smooth and accurate gear shift.

The range of transmission transfer numbers is equipped with several different transmission transfer numbers to satisfy Grauder's needs in various working scenarios. For example, when leveling the soil, you can choose the appropriate transmission ratio to maintain a stable working speed of the grader; When towing heavy cargoes or lifting to the slopes, you can switch to a low gear ratio of the transmission in order to provide a greater torque. The range of transmission transfer numbers usually covers various working conditions: from low speed and high torque to high speed and low torque, in order to satisfy the needs for power under various operating conditions.

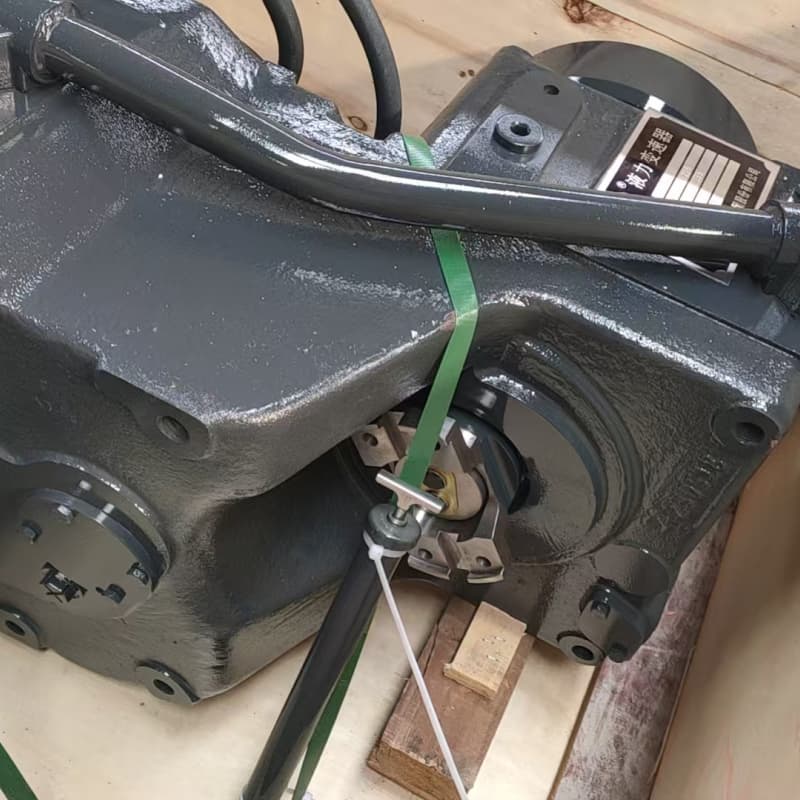

Transfiguration method: common transfers of transfers of gears include manual gear shift and gear shift under load. Manual gear shift directly controls the gearbox through the joystick. The operation is simple and straight, suitable for drivers with a high level of control skills. Power Shift uses a hydraulic control system that controls the clutch and brakes through electromagnetic valves to achieve automatic switching. The operation is more convenient and fast, which can effectively reduce the driver’s labor intensity and increase the efficiency of work.

Lubrication and cooling system: a forced lubrication and cooling system is used to guarantee that all the parts inside the gearbox are completely lubricated and cooled during operation. Lubric oil circulates through the oil pump, removing the heat released by gears, bearings and other components during operation, and forming an oil film on each surface of the friction, which reduces wear. The cooling system usually uses air or water cooling, which is selected depending on various working conditions and requirements to guarantee the operation of the gearbox in the corresponding temperature range.

The efficiency of the seal: the gearbox has good characteristics of the seal and uses high -quality seals, such as oil seals, sealing rings, etc., which effectively prevent leakage of lubricating oil and entering the gearbox of external pollution, such as dust and moisture, ensuring the normal operation and service life of the gearbox.

2. The installation method

Preparation before installation: before installing the grader gearbox, the installation site must be cleaned and inspected to make sure that the installation surface is even and free from garbage. At the same time, prepare the necessary installation tools and accessories, such as bolts, gaskets, etc.

Rise and positioning: Use the appropriate lifting equipment to smoothly raise the gearbox to the installation site and accurately place it in accordance with the relative location of the gearbox and engine, drive shaft and other components. Make sure that the input shaft of the gearbox is concentrated, the output shaft of the engine and that the connection between the output shaft and the drive shaft is accurate.

Fastening and connection: Use the indicated bolts and washers for reliable fixation of the gearbox at the installation site and tighten the bolts in accordance with the indicated requirements for the torque to guarantee that the gearbox does not weaken during operation. At the same time, connect the lubricant of the gear lubricant, the cooling pipeline, the control pipeline, etc., to verify the reliability of the connection and a good sealed connection.

Adjustment and check: After installation, the gearbox must be completely adjusted and checked. Check the flexibility and accuracy of the gear shift mechanism, the correspondence of the lubricating oil level to the specified range, the serviceability of the cooling system, etc. If necessary, perform the appropriate adjustments and repairs to ensure the correct and reliable installation of the gearbox.

3. Repair and maintenance

Daily service: regularly check the level of lubricant oil in the gearbox to make sure that it is in the specified range. Check the quality of lubricating oil. If it is found that the lubricant has deteriorated, emulsized or impurities, it should be replaced in time. At the same time, check if there are leaks in the sealing part of the gearbox. If there are leaks, they should be eliminated on time.

Regularly replace the lubricating oil: regularly replace the lubricant in accordance with the instructions for the operation of the gearbox and operating conditions. As a rule, under normal operating conditions, lubricants should be replaced every 500-1000 working hours or every six months. In difficult working conditions, such as high temperature, high dustiness, high humidity, etc., the replacement cycle should be reduced accordingly.

Filter replacement: regularly replace the oil transmission oil filter to ensure the purity of lubricant oil. The filter replacement cycle is usually the same as the lubricating oil replacement cycle. When replacing the filter, pay attention to the direction of the installation and the tightness of the filter to make sure that the filter is installed.

Checking and maintenance of the components: regularly check the working condition of the gearbox, clutch, brake and other gearbox components. If any parts are worn out, weakened or damaged, they should be repaired or replaced in time. Check if the transmission cooling system correctly works, for example, whether the radiator is clogged, whether the fan works, etc. If there are any problems, they should be eliminated on time.

Elimination of malfunctions: in case of malfunctions in the operation of the gearbox, the car should be stopped in a timely manner, to analyze the cause of the malfunction and take appropriate measures to eliminate it. In case of elimination of malfunctions, it is necessary to strictly comply with the requirements of the maintenance management manual in order to avoid expanding the malfunction or damage to other components due to improper operation.

4. Common malfunctions

Difficult gear shift: this can be caused by the malfunctions of the gear shift mechanism, incomplete clutch turning off, dirty or tall lubricants or a malfunction of the electromagnetic gearbox. The decisions include checking and adjusting the gear shift mechanism, adjusting the clutch clearance, replacing lubricating oil, checking and repairing the electromagnetic gearbox, etc.

An unusual noise: an unusual noise in the gearbox can be caused by wear of gears, damage to the bearings, insufficient amounts or deterioration of the quality of lubricating oil, weakening the fastening of internal components, etc. The solutions include checking the wear of gears and bearings and replacing them if necessary; check the level of oil and the quality of lubricating oil, as well as a timely piece or replacement of lubricating oil; Checking the tightness of the internal components and tightening the weakened bolts.

Oil leak: oil leaks can be caused by aging, damage, improper installation of seals or cracks in the box. The decisions include checking the state of seals and their timely replacement in case of damage or aging; check the correctness of the installation of seals to ensure good sealing; If there are cracks in the box, repair or replace the box depending on the seriousness of the cracks.

Too high oil temperature: too high oil temperature can be caused by a cooling system malfunction, insufficient amount or deterioration in the quality of lubricating oil, prolonged work under high load, etc. The solutions include checking the working condition of the cooling system (for example, whether the radiator is closed, whether the fan, as well as its timely elimination of malfunctions, work normally; check the level of oil and the quality of lubricating oil, as well as replenishment or replacement of lubricating oil; avoiding long -term work with high load and reasonable distribution of working time and intensity of work.

5. After -sales warranty

Warranty policy: Grauder gearbox provides a certain warranty period. During the warranty period, if the gearbox fails due to problems with product quality, it will be repaired or replaced for free. A specific warranty and warranty volume will be determined in accordance with the product model and operating instructions.

Technical support: providing a professional technical support group for users to provide users with technical recommendations and training for installation, commissioning, technical maintenance of gearboxes, etc. If users have any technical problems during use, they can contact the technical support service at any time in order to get timely assistance and solutions.

Delivery of details: a comprehensive system of deliveries of parts has been created that allows users to receive the necessary details of the gearbox in a timely manner. The quality and operational characteristics of accessories correspond to the original, which guarantees the quality and reliability of the repair and maintenance of the gearbox. At the same time, we offer reasonable prices for accessories to reduce user costs for their use.

After -sales service time: we undertake to quickly respond and attract professional personnel to process the request for after -sales service after receiving the user's request for after -sales service. In the case of emergency malfunctions, we will arrive at the place for repairs in the shortest possible time to reduce the downtime of the user and increase the efficiency of work.

User reviews: we attach great importance to user reviews and have developed a user review processing mechanism. The issues and suggestions of users will be timely analyzed and processed, and the processing results will be promptly transmitted to users to constant product quality and the level of after -sales service.

There are many types of malfunctions that may occur in the gearbox of the grader during use. Below are some common types of malfunctions and their causes:

The complexity of the gear shift:

The malfunction of the transfers mechanism: for example, the gearbox fork is worn out, deformed or stuck, which leads to the impossibility of normal gear shifts.

Clutch problem: the clutch is not completely disconnected, so it is impossible to completely turn off the power, which is why the gears are difficult to turn on when switching gears, which leads to a knock of gears that make it difficult to switch.

The problem with lubricating oil: the lubricant oil is too dirty or has too high viscosity, which affects the lubricant and movement between the switching parts and increases the resistance to switching.

The malfunction of the electromagnetic gearbox valve (for transmissions with transfers of gears under load): if the electromagnetic valve fails, it cannot accurately control the flow and pressure of hydraulic oil, which, in turn, affects the clutch and brake, which leads to difficulty gearing.

Abnormal sound:

Histers wear: after prolonged use, the surface of the gears wears out, covered with potholes, peeling, etc., which leads to the appearance of unusual hooking sounds during operation.

Bearing damage: carrier wear, cracks on balls or damage to the separator can lead to poor operation of the bearing and noise.

Insufficient amount or worsening of the quality of lubricating oil: insufficient amount of lubricating oil or deterioration of its quality will lead to the fact that it cannot effectively lubricate and soften friction between the components, which will lead to abnormal noise.

Weakened internal components: if components such as shutter shafts and bolts are weakened, vibrations can lead to knocks during operation.

Oil leak:

Acting or damage to seals: after prolonged use, oil seals, sealing rings and other seals of the gearbox are aging, hard or break, which leads to a leakage of lubricating oil.

An uneven sealing surface: the sealing surfaces of the case, shaft neck and other parts have defects obtained during the manufacture or installation, or deformed due to a long load, which leads to a deterioration in the seal and leakage of the oil.

A clogged ventilation hole: a clogged ventilation hole leads to an increase in the internal pressure in the transmission, which leads to seeping lubricant over a weak seal.

The oil temperature is too high:

Cooling malfunction: clogging of the radiator, fan failure, or clogging of cooling lines worsen the excretion of heat and lead to an increase in oil temperature.

Insufficient or spoiled lubricants: insufficient amount of lubricating oil will increase friction between the components and release more heat; While spoiled lubricants will reduce heat scattering and lubricants, which will also lead to an increase in oil temperature.

Long -term work with high load: when a grader works in high load conditions for a long time, loss of power inside the gearbox increases, which leads to the formation of excess heat and an increase in oil temperature.

Poor gear engagement: improper gear clutch, poor contact of the surfaces of the teeth, etc. Increase friction and wear between gears, generate additional heat and increase oil temperature.

Jumping equipment:

Distribution of the gearbox fork: strong wear of the gearbox fork will lead to inaccurate positioning of the gears, and the gears will easily automatically leave the engagement during operation, which will lead to jumping of the gears.

The malfunction of the self -locking device: a self -locking device of the gearbox (for example, a self -locking spring, steel ball, etc.) fails and cannot reliably fix the position of the gear, which leads to easily jumping on the gear from the transmission during operation.

Val deformation: the shaft of the gearbox is deformed under the influence of prolonged power, which violates the normal engagement of gears and leads to the transfer of gears.

A break in the supply of electricity:

Clutch malfunction: severe wear of the clutch friction disk, erosion during fire or refusal of a hydraulic adhesion system will lead to the fact that the clutch will not be able to normally transmit power, which will lead to an interruption of power transmission.

The internal breakdown of the gear or shaft: in the case of a strong overload or blow, the gear or shaft may break, which will make normal power transmission impossible.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive