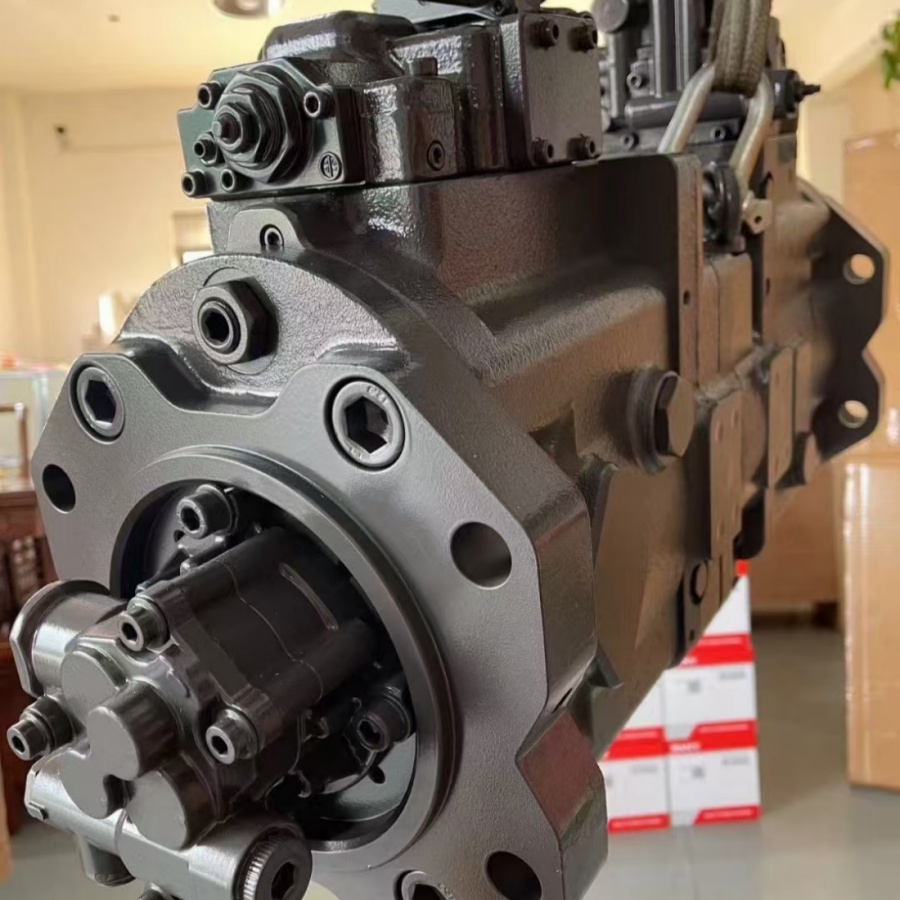

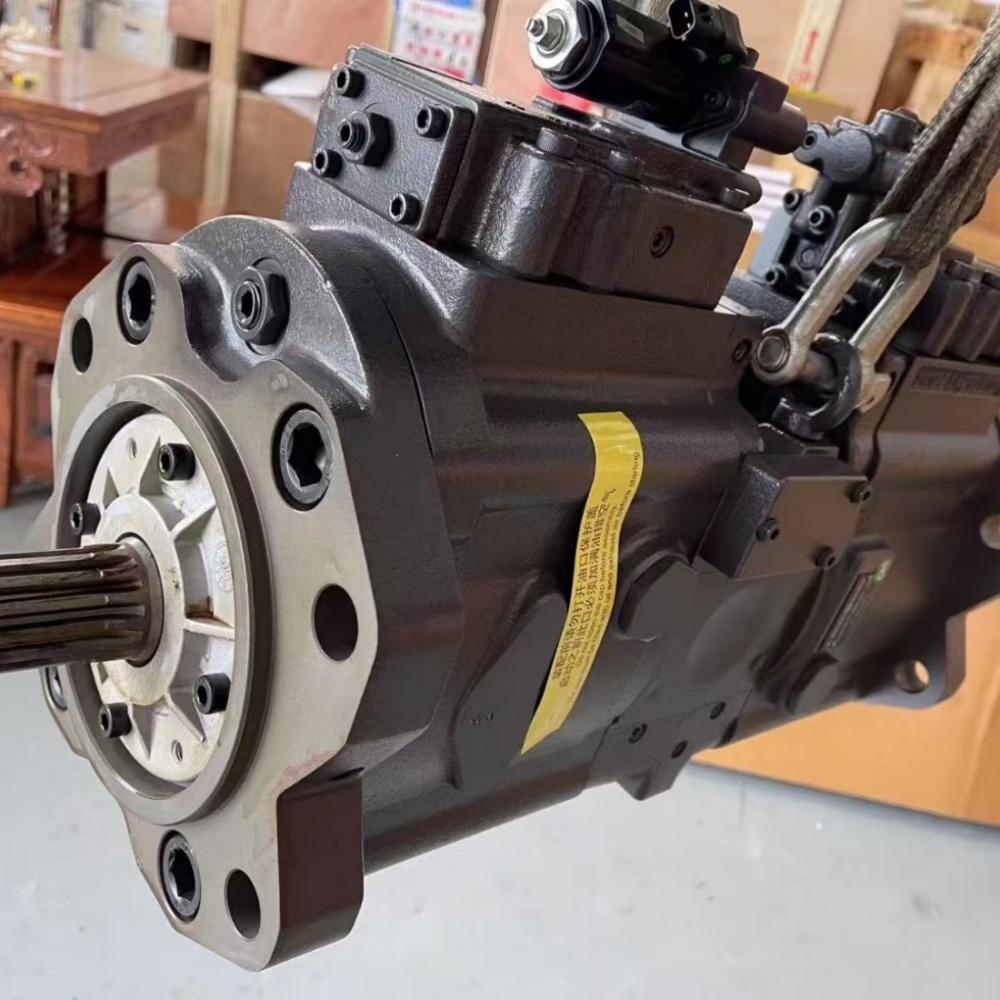

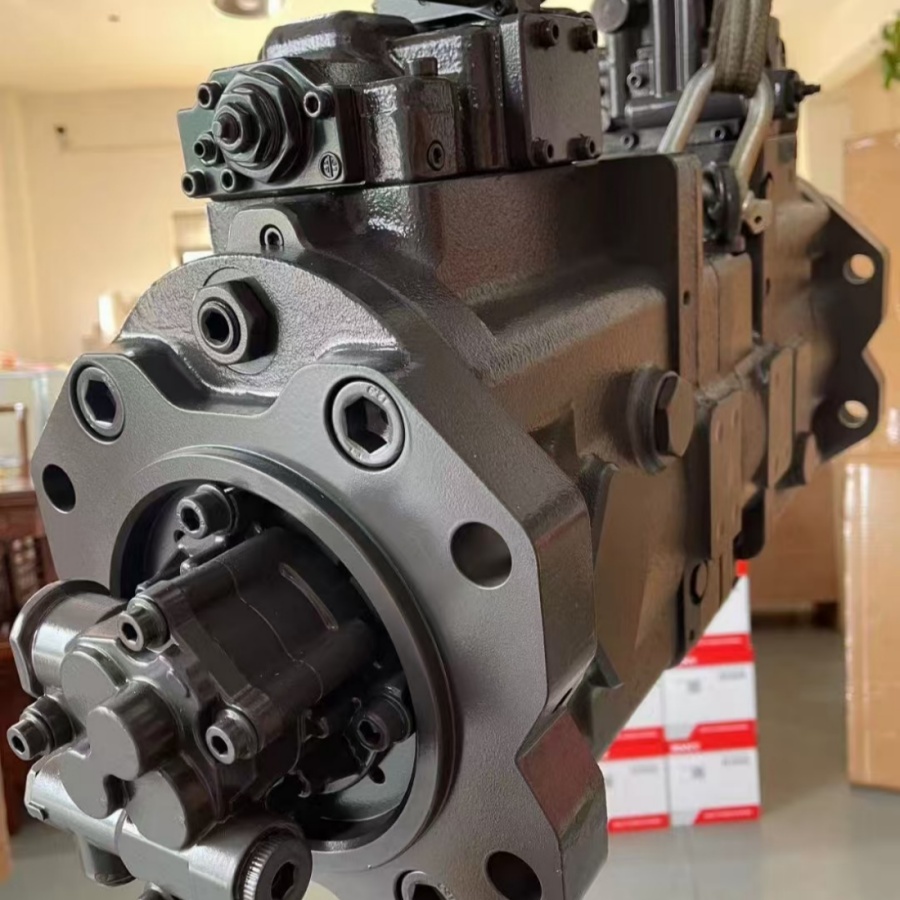

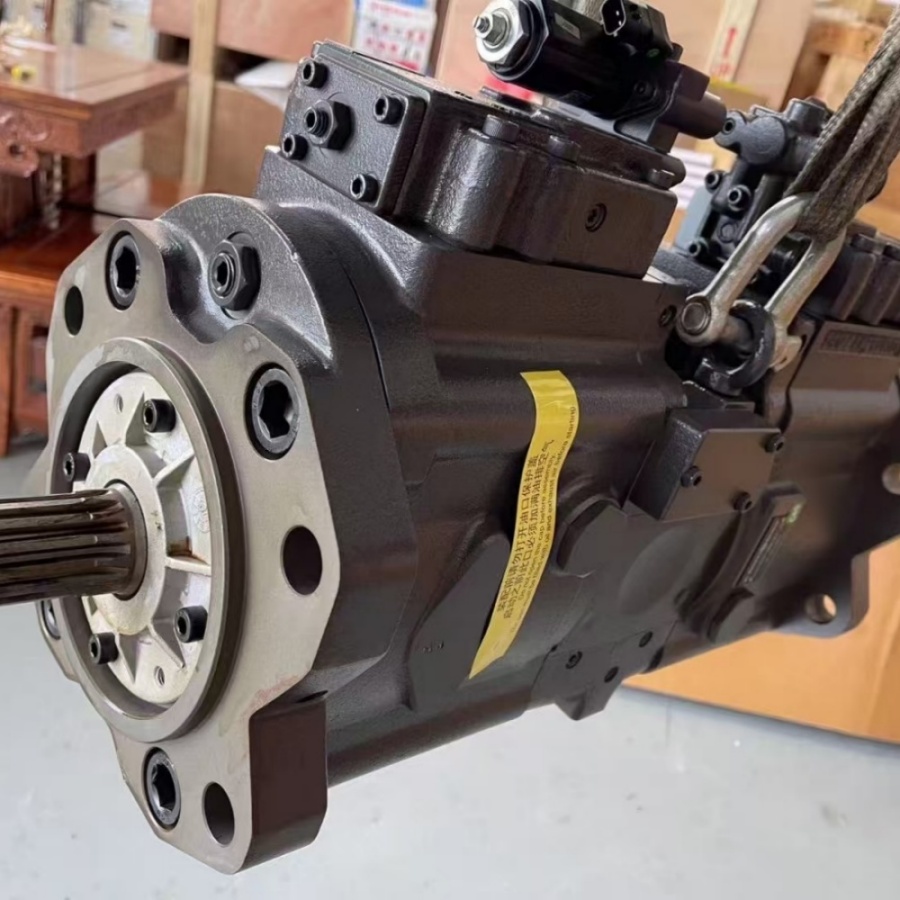

Sany 10424420152 Hydraulic pump Original

1 、 exact compatibility : is designed specifically for the corresponding models of technology , compatible with other components of the hydraulic system. This ensures the ease of installation and stable operation as a whole.

High performance : allows you to quickly and effectively pump hydraulic oil, providing a powerful and smooth effect of hydraulic Actuators. This increases the performance and efficiency of equipment.

2 、 High reliability and durability : is made of durable materials that withstand high pressure and temperature. Accurate production and quality control technologies guarantee a long service life and rare breakdowns.

Product representation

Detailed product information

Common models: such as K3V63DT, K3V112DT, K3V140DT, K5V140DTP, etc.

The principle of operation: the reciprocating movement of the plunger in the cylinder hole changes the volume of the hermetic working chamber, realizing the process of absorption and compression of the oil, converting the mechanical energy of the engine into hydraulic energy and providing the power of various working organs of the excavator.

Features of the product: Usually it has the characteristics of high pressure and high consumption and can satisfy the operational needs of excavators in various working conditions. It is distinguished by good stability and reliability, uses advanced production technologies and materials, reduces internal leakage and increases volumetric efficiency and mechanical efficiency. Equipped with advanced control systems, such as cutting off pressure, regulation of flow and other functions, it can automatically regulate the output flow and pressure in accordance with the operating load of the excavator, ensuring energy savings and optimizing operational characteristics.

Stages of installation

Preparation before installation: turn off the power of the excavator and ensure safety. Check the serviceability of the hydraulic pump and its accessories, make sure that the installation site of the hydraulic pump meets the requirements, as well as prepare installation tools and materials, such as wrench, screwdrivers and sealants.

Remove the old pump: find the place where a hydraulic pump is installed on your excavator, usually next to the engine. Use the wrench and screwdriver to remove fixing bolts and interpretation connections and the final pipe of the original hydraulic pump. Be careful not to damage the surrounding details during the disassembly process, and properly place the removed bolts, nuts and other small details.

Cleaning and inspection: thoroughly clean the mounting surface of the hydraulic pump and the pipe connections connected to it, removing oil, dust and pollution, using clean tissue or detergent. Check if the installation surface is even, if there are scratches or damage. If there are any problems, repair them or polish them to make them smooth. At the same time, check if there are bumps and deformations at the entrance and output of oil, the shaft neck and other details of the new hydraulic pump.

Install a new pump: install a new hydraulic pump to the installation position, combine the mounting holes of the pump with mounting holes on the machine body and wear the fasteners, but do not tighten them. Combine the intake and exhaust pipes of the hydraulic pump and apply the required amount of sealant to the joints of the pipes to provide a strong connection and reliable sealing. In accordance with the requirements of the excavator, adjust the installation angle and the height of the hydraulic pump to ensure its normal operation, and then tighten the fasteners in accordance with the indicated puffing moment.

Installation and verification of accessories: install other accessories of the hydraulic pump, such as sensors, clamps of oil pipes, etc. Check the tightness of all compounds, the correct location of the pipelines, lack of interference and friction. Manually tire the input shaft of the hydraulic pump to check if it rotates freely and if there is no seal or abnormal resistance.

Filling hydraulic oil and debugging: in accordance with the instruction manual for the excavator, fill in the hydraulic system with the necessary amount of hydraulic oil corresponding to specifications. Run the excavator and let the engine work for some time at idle, watch the working condition of the hydraulic pump, check the absence of leaks, extraneous noise or vibration, as well as the compliance of the pressure and temperature of hydraulic oil. Gradually increase the engine speed and load, as well as continue to debug a hydraulic pump to ensure its good operation.

Common errors

The pressure cannot be increased: the causes may be that the oil pump does not supply oil or its flow is insufficient, the bypass valve regulates the pressure too low or fails, the system has a leak, the oil pump wrapps after prolonged operation, which leads to weakening the screws of the pump cover, in the suction pipe there is a leakage of air, the oil is not enough, and also incorrectly The alternating pressure of the pump is adjusted.

Insufficient flow: this can be caused by the internal wear of the hydraulic pump, for example, the wear of the plunger, the distribution plate and other components; It can also be caused by pollution of hydraulic oil, which leads to clogging the filter or jamming of the valve core; It can also be caused by clogging of the oil absorption line, an excessive oil temperature causing a decrease in oil viscosity, etc.

Oil leaks: aging or damage to the oil sector, weakening caused by improper installation of a hydraulic pump, excessive pressure in the oil tank, etc. can lead to a leakage of oil in a hydraulic pump.

Abnormal noise and vibration: damage to the internal parts of the hydraulic pump, for example, damage to the bearing, breakdown of the plunger, etc.; inhalation of air; inappropriate viscosity of oil; A weakened or eccentric connection between the hydraulic pump and the engine, etc. can cause abnormal noise and vibration.

Below are methods for eliminating the common malfunctions of the hydraulic pump of the Sany excavator:

The pressure cannot be increased.

The oil pump does not lubricate or the flow is insufficient:

Reasons: the oil level in the fuel tank is too low, the oil sucking filter is clogged, the oil suction pipeline is broken, it flows or incorrectly installed, the oil pump rotates in the wrong direction or the speed is too low.

Method for eliminating faults: check the oil level in the fuel tank and add a sufficient amount of hydraulic oil; Clean or replace the oil suction filter; Check the oil suction pipeline, eliminate the gap, tighten the connecting parts and provide good sealing; Check the correct direction of the oil pump, check if the engine speed is normal if the speed is too low, check the engine speed control system.

The safety valve is tuned to too low pressure or faulty:

Reason: The safety valve pressure regulation spring is tired, broken or insufficient elasticity, the valve core is stuck or worn out, which leads to a premature opening of the safety valve to discharge the load.

Method for eliminating faults: using professional tools, adjust the pressure of the safety valve to the specified value; Check the safety valve spring if it is damaged, replace it with a new one; Discharge the safety valve, clean the valve core and the valve saddle, check the wear of the valve core and valve saddles, and replace the worn parts if necessary.

The system has a leak:

Causes: The compounds of hydraulic pipelines are weakened, the seals are worn out or damaged, the seals of the piston of the hydraulic cylinder are worn out, and the hydraulic pump itself is leaks.

Method for eliminating faults: check each connection of the hydraulic pipeline, tighten the weakened compounds and replace worn or damaged seals; Check the seals of the piston of the hydraulic cylinder, if they are worn out, replace them with new ones; Check the sealing parts of the hydraulic pump, such as shaft seals, seals of the end cover, etc., and repair or replace damaged seals.

The oil pump vibrates after prolonged work, which leads to a weakening of the screws of the pump cover:

Reason: the oil pump vibrates during operation, which leads to weakening the screws of the pump cover, an increase in the leakage in the pump and a drop in pressure.

Method for eliminating malfunctions: after turning off, check the puff of the pumping screws of the pump cover and, using a dynamometric key, tighten the pump lids in accordance with the indicated puffing moment.

Salting pipe leaks:

Reason: The connecting parts of the suction pipe are not tightly sealed, for example, the laying of the flange is damaged, the pipe connection, etc., which leads to air enters the hydraulic system, is weakened.

Method for eliminating malfunctions: check the connecting parts of the suction pipe, replace the damaged flange gasket, tighten the pipes to ensure good sealing. You can apply soapy water to the connection and check the presence of bubbles to determine the place of leakage.

Insufficient oil absorption:

Reason: the oil temperature is too low, and the viscosity of the oil is too high, which makes it difficult to absorb oil; The oil absorption filter is seriously clogged, which affects the effectiveness of oil absorption.

Method for eliminating malfunctions: if the oil temperature is too low, use the heater for the corresponding oil heating to improve its fluidity; Clean or replace the oil absorption filter to ensure smooth suction.

Incorrect adjustment of the pressure of the variable pump:

Reason: The mechanism of adjusting the pressure of the alternating pump is faulty, for example, the adjusting screw is weakened, the adjusting piston is stuck, etc., which leads to inaccurate pressure adjustment.

Method for eliminating faults: check the mechanism of adjustment of the pressure of the alternating pump, tighten the adjusting screw, clean the adjusting piston and make sure that it can move freely. If necessary, adjust the setting of the alternating pressure of the pump.

Insufficient flow

Interior wear of the hydraulic pump:

The reason: the wear of components such as a plunger, the distribution plate and the cylinder body leads to an increase in the internal leakage and a decrease in the flow.

Method for eliminating faults: disassemble the hydraulic pump and check the wear of the plunger, the distribution plate, the cylinder body and other components. Parts with small wear can be repaired, for example, with polishing the surface of the distribution plate; Parts with severe wear must be replaced with new ones. After repairing or replacing parts, reinstall the hydraulic pump and debug it.

Contaminating hydraulic oil:

Reason: hydraulic oil contains impurities, moisture or other pollutants that clog the filter and affect the flow of oils, or pollutants fall into the hydraulic pump, wear out parts and increase the leak.

Method for eliminating malfunctions: replace hydraulic oil and filter, clean the hydraulic system, including an oil tank, pipelines, hydraulic cylinders and other components, as well as remove pollutants. Spend the quality of hydraulic oil regularly and replace hydraulic oil and filter on time to prevent oil pollution.

The oil absorption line is blocked:

Reason: the oil absorption line is blocked by extraneous objects, such as welding slag, rust, rubber fragments, etc., or oil suction line is deformed or flattened, which leads to a poor oil flow.

Method for eliminating malfunctions: check the suction oil pipeline, clean the pipeline from foreign objects, repair or replace the deformed or flattened pipeline. Make sure that the inner diameter of the suction oil pipeline meets the requirements, and its length is sufficient to prevent sharp bends or dead ends.

The oil temperature is too high:

Reason: poor dissipation of heat of the hydraulic system, for example, clogging of the radiator, fan refusal, etc., or the hydraulic pump operates under a high load for a long time, which leads to an increase in oil temperature, reducing the viscosity of the oil, increasing leaks and reducing the consumption.

Method for eliminating faults: check the working condition of the radiator, clean the radiator and make sure that the channels between the radiator ribs are not clogged; Check the fan and repair or replace a faulty fan. Reasonably distribute the load on the excavator to avoid continuous operation under high load for a long time. If necessary, you can install an auxiliary device for the heat to improve the effect of heat removal.

Oil leak

Aging or damage to oil seals:

Reason: after prolonged use, the seal is aging, hardening, cracking, etc., loses its sealing properties and causes oil leakage.

Method for eliminating a malfunction: disassemble the hydraulic pump and check the condition of the oil seal. If there is any worn or damaged oil seal, replace it with new ones. When installing the omentum, pay attention to the installation direction and the position of the oil seal, make sure that the oil seal adjacent to the shaft and hole, and do not damage the oil seal during the installation.

Incorrect installation of a hydraulic pump leads to its weakening:

Reason: The fasteners of the hydraulic pump are not tightened or the sealing laying between the pump housing and the landing place is damaged during the installation, which leads to a weakening of the pump body and oil leak.

Method for eliminating malfunctions: check the bolts of fastening the hydraulic pump and tighten the bolts with the indicated moment of the tightening using a dynamometric key. Check the sealing gasket and replace it with the new one if it is damaged. Make sure that the hydraulic pump is reliably installed, and the joint surface between the pump body and the mounting base is even and well sealrated.

The pressure in the fuel tank is too high:

Reason: the ventilation hole of the oil tank is clogged, which leads to an increase in the pressure inside the oil tank and a leakage of hydraulic oil through a weak seal.

Method for eliminating malfunctions: check the fuel tank ventilation hole, clean it from blockages and make sure that the ventilation hole is not clogged. The air filter can be installed on the ventilation hole to prevent dust and pollution from the fuel tank.

Unusual noise and vibration

Damage to the internal parts of the hydraulic pump:

Reason: damage to internal details, for example, damage to the bearing, a breakdown of the plunger and wear of the distribution plate, leads to the fact that the hydraulic pump makes an abnormal noise and vibration during operation.

Method for eliminating faults: disassemble the hydraulic pump and check the internal parts for damage. Replace damaged bearings, pistons, distribution plates and other parts. When installing new parts, pay attention to the accuracy of the installation and gaps when installing parts to ensure the normal operation of the hydraulic pump.

Inhaled air:

Reason: leakage in the oil absorption line, low oil in the oil tank, a cut oil filter, etc. can lead to air entering the hydraulic system, which will lead to the occurrence of the noise and vibration of the hydraulic pump.

Method for eliminating malfunctions: check the tightness of the suction oil pipeline and eliminate the leak; Check the oil level in the oil tank and add a sufficient amount of hydraulic oil; Clean or replace the oil absorption filter to ensure smooth suction. At the highest point of the suction oil pipeline, you can install the exhaust valve for regular air release from the system.

The viscosity of the oil is not suitable:

Reason: The viscosity of the used hydraulic oil does not meet the requirements. Too high viscosity will cause the difficulty of absorption of oil and create noise and vibration; Too low viscosity will increase the internal leak, as well as create noise and vibration.

Method for eliminating faults: check the viscosity of hydraulic oil and select the hydraulic oil of the corresponding viscosity in accordance with the operating instructions of the excavator. If the viscosity of hydraulic oil does not meet the requirements, replace it with hydraulic oil that meets the requirements.

The connection between the hydraulic pump and the engine is weakened or not specified:

Reason: The connection between the hydraulic pump and the engine is weakened or worn, or the axis of the hydraulic pump and the engine were not concentric during installation, which will lead to vibration and the noise of the hydraulic pump during operation.

Method for eliminating a malfunction: check the connection of the coupling, tighten the coupling bolts and replace the worn clutch. Use professional tools to check the concentricity of the axes of the hydraulic pump and engine. If there is any deviation, adjust it to make sure that the axis of both are concentric.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive