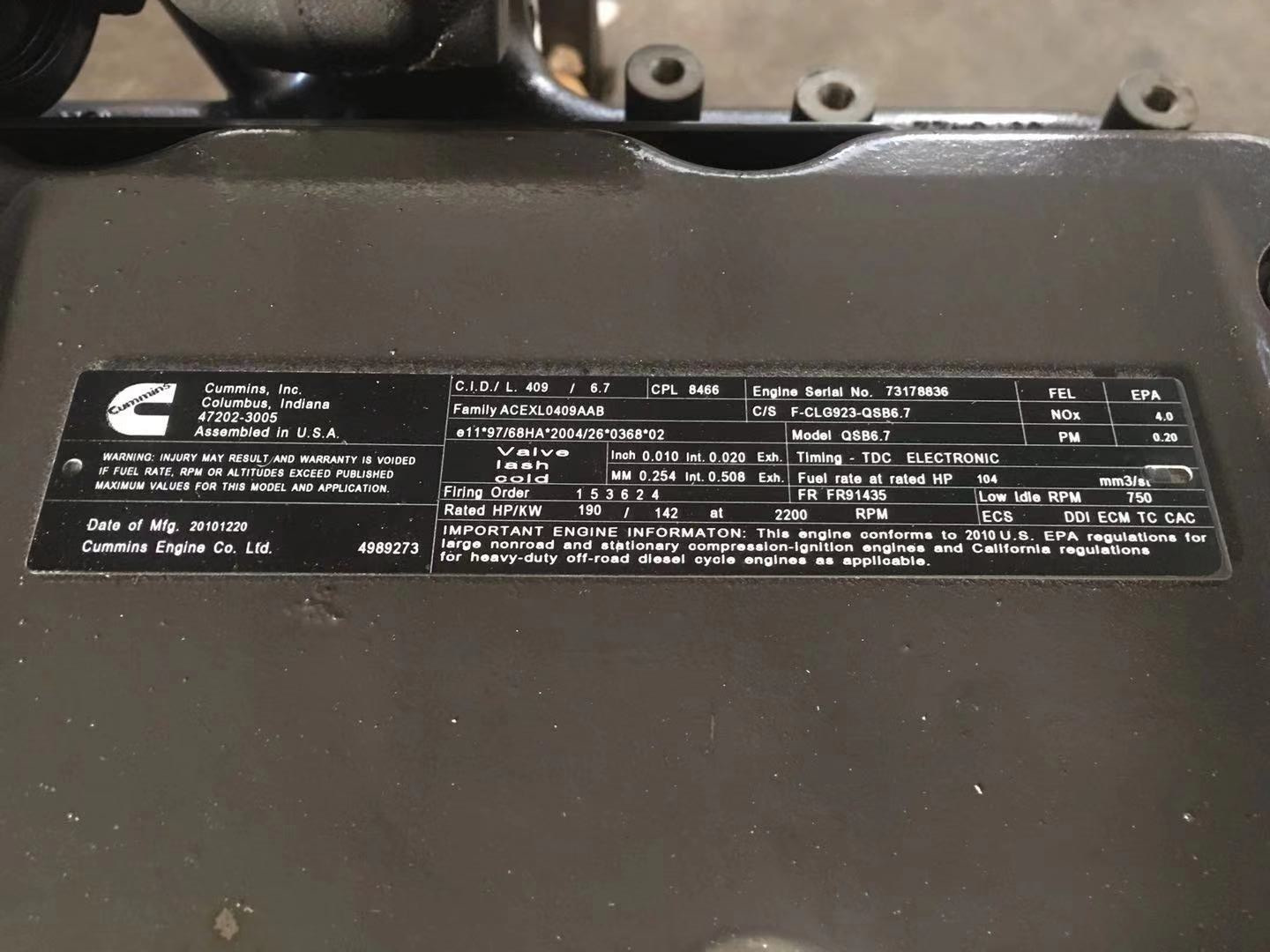

Cummins 4989273 Engine assembly diesel engine Original QSB5.9

1. Exact compatibility

It is specially designed for compatibility with equipment. It is suitable for transmission and ventilation systems. It will launch easy installation and stable operation as part of the machine.

2. High power and the torque of the moment is the powerful and stable rotation of the shaft. It is possible to effectively carry out heavy work. The high torque provides a powerful start and smooth acceleration under load.

3. Savings of fueling the advanced fuel injection technologies. The effectiveness of combustion is superimposed.

Significantly reduces fuel consumption and costs.

Product representation

Detailed product information

Models and product parameters: There are platform products such as B3.9, B5.9, B6.7, L9 and 15L. For example, the working volume of B3.9 is 3.9 liters, and there are also series as M14 and M15Plus. If you take as an example the M15Plus, then the ultra -low fuel consumption is ensured by 5 basic innovations in the field of fuel saving technologies such as low friction cylinder; Innovative structures are integrated in it, such as the design of the upper distribution shaft and fewer parts; It can be launched at a temperature of -15 ℃ without a device for cold launch and can be launched at a temperature of -35 ℃ using a device; It can intellectually switch the working modes and has the functions of self -diagnosis, alarm and remote monitoring.

Areas of application: widely used in light, medium and heavy trucks, medium and high -class intercity buses, large and medium buses, construction equipment, main main and auxiliary engines, generator installations and other areas.

The advantages of the product: a new modernized fuel system provides more complete combustion and significantly reduces fuel consumption; Having inherited the world experience of application, it has a superbly with cleaning, an intellectual reminder of cleaning and a continuous intellectual function of regeneration; Equipped with Cummins emissions, has a modular design, compact structure, high adaptability, flexible installation and savings of space; Digital capabilities, OTA technology can guarantee that the equipment is in the best state at any time and anywhere, as well as full remote calibration and updating in five minutes; Intellectual identification of the working condition, accurate analysis of the work and remote control of the use of equipment.

Stages of installation

Preparation for installation

Confirm the installation environment: select a well -ventilated place without flammable or explosive objects. The floor should be even, and the bearing capacity must comply with the requirements of the equipment.

Prepare tools for installation: Prepare the necessary tools, such as screwdrivers, wrenches and levels.

Equipment verification: Check the serviceability of the Dongfeng Cummins equipment and its accessories, as well as their compliance with installation requirements.

Installation process

Installation of the foundation: install the equipment in a predetermined place, align it horizontally using the level, and then secure it on the foundation with bolts to ensure its reliability.

Connecting cables: select the corresponding characteristics of the cables in accordance with the power of the device and power requirements, connect the cables to the output terminals of the device and make sure that the connections are strong and not weakened, as well as wrap the connections with insulating materials.

Connect the exhaust duct: select the appropriate exhaust duct, make sure that it is not clogged, connect it to the equipment of the equipment and make sure that the connection is airtight and has no leaks.

Connect the fuel system: select a suitable fuel system in accordance with the equipment model and the type of fuel and connect it to the fuel recording of the equipment, making sure that the connection is reliable and sealed.

Start debugging

Check the connection: Check the correct connection of the device.

Follow the instructions in accordance with the instructions: Start debugging according to the requirements of the equipment operating manual.

Follow the working condition: carefully monitor the working condition of the equipment to make sure that there are no deviations from the norm.

Common errors

The difficulty of starting

Problems with the fuel system: a fuel pump malfunction, clogging of the fuel filter, etc.

The problem with the battery: the low ambient temperature leads to a decrease in the battery capacity or the battery itself is discharged.

Other: the viscosity of the engine oil increases due to low temperature, and the friction of the parts increases; The viscosity of diesel fuel increases at low temperatures, and the efficiency of fuel supply decreases, etc.

Insufficient power

The air filter is clogged, which leads to insufficient air supply.

Turbocompressor malfunction: affects the effect of boost.

Poor fuel supply: if there is a leak or clog in the fuel system.

Abnormal noise

The internal details are worn out or weakened: for example, belts, bearings, etc.

Lubrication system problem: poor oil quality or insufficient amount of oil.

White smoke comes out of the exhaust pipe

Diesel fuel contains water: in added diesel fuel there are many water molecules.

Damage to the cylinder gasket, etc.: the cylinder head bolts are weakened or the cylinder laying is damaged, which leads to cooling water in the cylinder; The cylinder block or cylinder head has sand shells or cracks.

The water temperature in the engine is too high

The radiator is clogged: heat removal deteriorates.

Malfunction of the water pump: it is not possible to provide proper circulation of the coolant.

There is no water tank: not enough coolant.

After -sales service

Service points: There are many service points throughout the country, which allows customers to receive operational support in all regions.

Professional team: Our maintenance specialists have high professionalism and experience, they can quickly and accurately diagnose and solve problems and are available 24 hours a day.

Service mode: Providing a variety of service modes for various products and needs, including equipment installation, commissioning and maintenance, etc., conducting comprehensive inspections in strict accordance with the manufacturer's requirements, optimization of performance in accordance with customer needs, implementation of regular technical service and timely elimination of malfunctions.

Improvement: Conducting events such as service skills, we can improve the level of qualifications and awareness of maintenance personnel, as well as form a more professional, intellectual and effective service team.

Customer service: focusing on customer service, deep understanding of their needs and providing a full range of services, including pre -sale consultations, support during sales and after -sales service, for an effective solution to customer problems.

In addition to the above, Dongfeng Cummins also include the following categories:

Refusal of the electric system

The sensor malfunction: for example, the coolant temperature sensor, the pressure sensor in the intake manifold, the accelerator pedal position sensor, etc. This can cause problems such as difficulties with the engine launch, reduced power, increased fuel consumption and abnormal emissions. For example, if the coolant temperature sensor fails, the engine control unit will not be able to accurately receive information about the engine temperature, which will affect at the time of injection and ignition.

The generator malfunction: if the generator does not produce electricity or the generated voltage is unstable, the battery will not be charged normally, the electric system will work with insufficient power, the headlights will fade, the sound of the hut will become quieter, and the engine will be difficult. The reason may be a short circuit or a break in the inner coil of the generator, a rectifier malfunction, a weakened or cut belt.

Line malfunction: aging, damage, poor contact of wires, etc. can lead to a short circuit circuit, a chain break and cause various malfunctions. For example, a launching malfunction can lead to the fact that the starter will not work properly and the engine will not start.

Refusal of the system of subsequent processing

The malfunction of the urea pump: for example, an unsuccessful preliminary filling of the urea pump, too high or too low urea injection pressure, the valve of the urea pump, etc., will lead to problems such as the non -use of urea, excessive emissions and restriction of the torque of the car. The most common reasons include the low quality of urea solution, clogging of the urea pump, leakage in the pipeline, engine malfunction or electromagnetic valve, etc.

NOX NOX: the internal malfunction of the NOX sensor, the expiration time of the message, etc. will not allow the engine control unit to accurately receive information about the emissions of nitrogen oxides, which will affect the normal operation of the system of subsequent processing and lead to excess emissions. This can be caused by damage to the sensor itself, a poor connection of the wire burning, abnormal power, etc.

The abnormal efficiency of SCR transformation: can be caused by leakage of exhaust gases, urea pollution, injection malfunction, malfunction of the SCR catalyst, etc. This will lead to the fact that the emissions of the vehicle will not comply with the standards, will affect its environmental characteristics, and in serious cases may lead to the impossibility of normal driving.

Refusal of the cooling system

Cooling fluid leaks: leakage in pipes, radiator, water pump, cylinder laying and other components of the cooling system will lead to a drop in coolant level, poor heat removal from the engine and an increase in water temperature. Cooling fluid leaks can be caused by aging or damage to the components, failure of seals or external effects on the engine.

The cooling fan malfunction: if the cooling fan does not rotate or the speed of its rotation is abnormal, this will affect the efficiency of heat dispersion by the radiator and will lead to an too high level of engine coolant temperature. This can be caused by a fan malfunction, a fan relay malfunction, a temperature malfunction or a circuit malfunction.

Lubrication of the lubrication system

Too low oil pressure: the causes can be an insufficient amount of oil, a malfunction of the oil pump, clogging of the oil filter, a malfunction of the oil pressure sensor, the internal wear of the engine, leading to the oil leak, etc. If the oil pressure is too low, the engine components are not well lubricated that will increase wear. In severe cases, this can lead to engine failures, such as jamming the cylinders and burden of bearings.

Motor oil is consumed too quickly: it can be caused by wear of piston rings, the aging of oil -removable valve caps, damage to the cylinder gasket, etc., as a result of which the engine oil enters the combustion chamber and participates in combustion, which leads to its fire. Also, oil leaks outside the engine can also take place, for example, leaks through the gasket of an oil pallet, a crankshaft oil seal, etc.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive