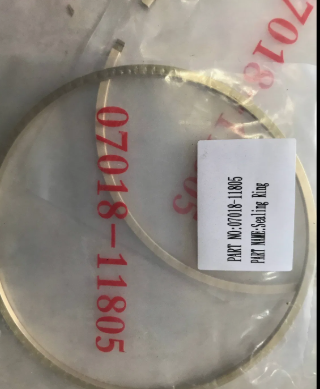

Zoomlion 07018-11805 Assit

1. District resistance and resistance to damage: made of high -quality copper material, has a strong texture and a specially processed surface, which has excellent wear resistance, can reduce wear and extend the life.

2. Excellent sealing: high -precision treatment, accurate size, dense fit to the components, can effectively seal and prevent fluid or gas leakage.

3. High adaptability: designed for various types of bulldozers, is easy to install and can adapt perfectly to various related components.

Product representation

1. General information about the product

Manufacturer: Zoomlion, a world company, widely known in the field of production and industrial equipment. She uses advanced technologies and strict quality standards for the production of her products.

The name and number of the part: the sealing ring O 07018 - 11805, which is the factory spare part for Grauders Zoomlion and is intended for the ZD220 models.

2. Technical characteristics and design

Dimensions: has strictly defined dimensions, including the inner diameter, external diameter and thickness. These sizes were precisely designed for the nodes and parts of the ZD220 grader, providing perfect landing and tightness.

Design: has a simple and compact structure in the form of a ring, which allows it to effectively perform the function of compaction. Its shape and dimensions provide uniform pressure distribution during compression, which improves its tightness.

Buldozer Copper Ring Method

1. Daily cleaning

1. Cleaning frequency

After each working day, the copper ring of the bulldozer should first be cleaned. This allows you to quickly remove dust, dirt, butter and other pollution, adhering to the surface of the copper ring during the day of operation, preventing the prolonged accumulation of these contaminants and the occurrence of wear or corrosion of the copper ring.

2. Cleaning tools and materials

Soft brush: use a soft brush, for example, from a boar bristles to gently brush off dust and dirt from the surface of the copper ring. The bristles of the soft brush have a soft texture and do not scratch the surface of the copper ring, which allows you to effectively protect the accuracy and quality of the surface of the copper ring.

Cleaning: Use a specialized cleaner for metals, for example, designed for copper. This cleaner effectively removes oil and light oxide layers, without causing corrosion of copper rings. Avoid the use of cleaning products containing strong acids or alkalis so as not to damage the copper ring.

Pure fabric: Prepare a clean cotton fabric or dust without dust to wipe the detergent and pollution, making sure that the surface of the copper ring is clean and dry.

(III) Cleaning stages

First, use the brush with soft bristles to gently brush off dust and dirt from the surface of the copper ring. Spread evenly with a brush around the circumference from the inner circle to the outer circle of the copper ring to make sure that each part can be cleaned.

Spray the required amount of detergent to the surface of the copper ring, but be careful and do not use too much product so that the detergent does not get to other parts and does not cause damage.

Gently wipe the copper ring with a clean cloth to remove oil and detergent. Some persistent spots can be wiped several times or gently rubbed with a soft brush, but be careful not to damage the copper ring.

After cleaning, wipe the copper ring dry with a clean cloth so that there is no moisture on the surface and prevent rust on the copper ring.

2. Lubrication maintenance

1. Lubrication frequency

Lubricate the copper ring regularly depending on the frequency of use and operating conditions of the bulldozer. As a rule, lubrication must be done every 50-100 hours of operation. In difficult working conditions, such as high temperature, high humidity, dust, etc., the lubricant cycle should be reduced accordingly.

(Ii) selection of lubricants

Choose lubricants suitable for copper rings, for example, lubricant based on copper or special lubricants resistant to high temperatures and wear. Lubrication based on copper has good adhesion and corrosion resistance, and can also form a protective film on the surface of the copper ring, reducing friction and wear. Special additives are added to special lubricants in accordance with the working characteristics and requirements of copper rings to better satisfy their lubricants.

(III) Lubrication method

Before lubrication, clean the surface of the copper ring so that the lubricant can fully stick to the copper ring.

Use a special lubricant tool, for example, a lubricant syringe or a brush to evenly apply grease to the surface of the copper ring. For copper rings installed on the shafts, make sure that the lubricant is evenly distributed along the internal and external rings of copper rings, as well as on the surfaces that are in contact with other components.

When applying lubrication, be careful and do not apply too much lubrication so that it does not result in and does not pollute other details. At the same time, make sure that the lubricant is applied evenly to avoid a local lubrication lack.

3. Regular inspection

1. The frequency of checks

Carry out a comprehensive check of the copper ring through regular working hours or run intervals. It is usually recommended to check every 200-300 hours of work or once every two months. During the inspection, carefully inspect the copper ring for wear, deformation, corrosion, etc., in order to detect potential problems in time.

(II) The content of the audit

Checking wear: use measuring tools such as caliper or micrometers to measure the thickness, inner diameter and external diameter of the copper ring, compare them with the initial dimensions and determine the degree of wear of the copper ring. If the wear of the copper ring exceeds the specified tolerance range, this may affect its normal work and requires timely replacement.

Checking for deformation: Check if the copper ring is deformed by visual inspection or using special detection tools. If the copper ring becomes elliptical or twisted, the accuracy of conjugation with other parts will decrease, which will affect the performance of the equipment. It should be replaced or replaced in time.

Corrosion check: check if there are corrosion or rust stains on the surface of the copper ring. If corrosion is detected on the surface of the copper ring, the cause of corrosion should be analyzed, for example, whether it is caused by chemicals, moisture, etc. In the working environment. Minor corrosion can be eliminated by cleaning and applying a protective agent; In the case of severe corrosion, a copper ring should be replaced in time.

Checking of landing: Check the landing of a copper ring in relation to other details, for example, the tightness of the landing in relation to the shaft, the bearing nest, etc. If it is found that the planting is not loose, this can lead to the movement or vibration of the copper ring during operation, which will affect the stability of the equipment, so the corresponding parts must be adjusted in a timely manner or replaced.

4. Elimination of problems

1. Elimination of wear and breakdowns

If the copper ring is slightly worn, it can be repaired with grinding. Use special grinding tools and grinding paste for grinding the worn surface of the copper ring to restore it to a given size and surface accuracy. During the grinding process, pay attention to the control of force and direction of grinding to avoid damage to the copper ring due to excessive grinding. If the copper ring is strongly worn out and its service life exceeds the repair life, it should be replaced in a timely manner with a new one. When replacing copper rings, choose products of the same model and with the same characteristics as original copper rings to guarantee their performance and installation accuracy.

(Ii) processing defects of deformation

To eliminate minor deformations, you can use correction methods. Use a special correction tool, for example, a press or a corrective device, to slowly return its original shape to the copper ring. During the calibration process, pay attention to the control of the strength and speed of calibration to avoid damage to the copper ring due to excessive calibration. If the copper ring is very deformed and is not subject to repair by correction, it should be replaced in a timely manner with a new one.

(III) elimination of malfunctions associated with corrosion

If corrosion appears on the surface of the copper ring, then it is necessary to first remove corrosion products. You can use sandpaper or metal brush to carefully polish the corroded area and remove corrosion products. Then clean and dry the corroded parts and apply a protective agent, for example, anti -corrosion paint or anti -corrosion coating to prevent further corrosion of the copper ring. If corrosion influenced the performance and strength of the structure of the copper ring, replace the copper ring with a new one in a timely manner.

Basic Info.

Model no.

07018-11805

Load Capacy

61-70t

Emission Standard

Euro 2

Drive Wheel

4 × 4

Engine Capacy

> 8l

Seats

≤5

Horsepower

451-500HP

Tire Certification

ISO, SGS

Tire Design

Tubeless

Dumping Type

Front Lifting Style

Condition

New

Zoomlion Bull Dozer

SD220

Part Name

Zoomlion Bull Dozer Sealing Ring

Part Number

07018-11805

Size

Standard

MOQ

1 Piece

Warranty

3 Months

Stock

in Stock

Feature

Original Used

Payment

Tt;Western Union;

Sample

Support

Transport Package

Zoomlion

Specification

zoomlion

Trademark

zoomlion

Origin

Zoomlion

Production Capacity

5000

NO. |

PARTS NUMBER |

DESCRIPTION |

1 |

004904030A0201060 |

PAD - TRACK FRAME |

2 |

004904030A0001190 |

BUSHING TRACK FRAME |

3 |

004904030A2000000 |

OIL SEAL 80X105X13 TRACK FRAME |

4 |

1080000206 |

OIL CUP / NIPPLE GREASE |

5 |

004904030A0001290 |

SLEEVE TRACK FRAME |

6 |

004904030A0001300 |

SLEEVE TRACK FRAME |

7 |

004904030A0001260 |

SLEEVE TRACK FRAME COVER |

8 |

004904030A0001050 |

ORING- RECOLL SPRING |

9 |

004903030A5800000 |

LUBRICATOR - RECOLL SPRING |

10 |

004904032A0001090 |

TRACK SHOE |

11 |

004904032A0001010 |

TRACK LINK |

12 |

004904032A0001020 |

TRACK LINK |

13 |

004904032A0001070 |

BUSHING TRACK |

14 |

004904032A0001080 |

DUST SEAL TRACK |

15 |

004904032A0001060 |

PIN |

16 |

004904032A0001050 |

MASTER BUSHING -TRACK |

17 |

004904032A0200000 |

DUST SEAL TRACK |

18 |

004904032A0001040 |

MASTER PIN - TRACK |

19 |

004904030A1410000 |

CARRIER ROLLER |

20 |

1050200746 |

ROLLING BEARING |

21 |

004904030A1401070 |

ORING CARRIER ROLLER |

22 |

004904030A0601060 |

ORING |

23 |

004904030A1401040 |

ORING |

24 |

004904030A0601040 |

ORING |

25 |

004904030A0601040 |

ORING |

26 |

1081001464 |

ORING |

27 |

004904030A0601060 |

ORING |

28 |

004904030A3210000 |

SINGLE FLANGE TRACK ROLLER |

29 |

004904030A3010000 |

DOUBLE FLANGE TRACK ROLLER |

30 |

004904030A0630010 |

BUSHING TRACK ROLLER |

31 |

004904030A0601060 |

ORING |

32 |

004904030A0601060 |

ORING |

33 |

004904030A0601040 |

ORING |

No. |

Parts Code |

Description |

||||||||

1 |

004904030A0001050 |

Oring |

||||||||

2 |

004904030A0001060 |

Oil Seal |

||||||||

3 |

1081001901 |

Oil Seal |

||||||||

4 |

004904030A0001210 |

Oring |

||||||||

5 |

004904030A0001230 |

Sealing ring |

||||||||

6 |

004904030A3200000 |

Single Flange Track |

||||||||

7 |

004904030A1410000 |

Carrier roller |

||||||||

NO. |

PARTS NUMBER |

DESCRIPTION |

1 |

004904030A0201060 |

PAD - TRACK FRAME |

2 |

004904030A0001190 |

BUSHING TRACK FRAME |

3 |

004904030A2000000 |

OIL SEAL 80X105X13 TRACK FRAME |

4 |

1080000206 |

OIL CUP / NIPPLE GREASE |

5 |

004904030A0001290 |

SLEEVE TRACK FRAME |

6 |

004904030A0001300 |

SLEEVE TRACK FRAME |

7 |

004904030A0001260 |

SLEEVE TRACK FRAME COVER |

8 |

004904030A0001050 |

ORING- RECOLL SPRING |

9 |

004903030A5800000 |

LUBRICATOR - RECOLL SPRING |

10 |

004904032A0001090 |

TRACK SHOE |

11 |

004904032A0001010 |

TRACK LINK |

12 |

004904032A0001020 |

TRACK LINK |

13 |

004904032A0001070 |

BUSHING TRACK |

14 |

004904032A0001080 |

DUST SEAL TRACK |

15 |

004904032A0001060 |

PIN |

16 |

004904032A0001050 |

MASTER BUSHING -TRACK |

17 |

004904032A0200000 |

DUST SEAL TRACK |

18 |

004904032A0001040 |

MASTER PIN - TRACK |

19 |

004904030A1410000 |

CARRIER ROLLER |

20 |

1050200746 |

ROLLING BEARING |

21 |

004904030A1401070 |

ORING CARRIER ROLLER |

22 |

004904030A0601060 |

ORING |

23 |

004904030A1401040 |

ORING |

24 |

004904030A0601040 |

ORING |

25 |

004904030A0601040 |

ORING |

26 |

1081001464 |

ORING |

27 |

004904030A0601060 |

ORING |

28 |

004904030A3210000 |

SINGLE FLANGE TRACK ROLLER |

29 |

004904030A3010000 |

DOUBLE FLANGE TRACK ROLLER |

30 |

004904030A0630010 |

BUSHING TRACK ROLLER |

31 |

004904030A0601060 |

ORING |

32 |

004904030A0601060 |

ORING |

33 |

004904030A0601040 |

ORING |

NO |

PARTS NO |

DESCRIPTION |

Transmission Torque Converter Housing |

||

1 |

07002-43634 |

O, ring |

2 |

07000-62070 |

O, ring |

3 |

07000-63046 |

O, ring |

4 |

07000-63046 |

O, ring |

5 |

07000-63045 |

O, ring |

Transmission and case |

||

6 |

TY220.1501-60 |

Gasket |

7 |

TY220.15-14161 |

Gasket |

8 |

07000-02018 |

O, ring |

9 |

07000-03032 |

O, ring |

Transmission Gear and Shaft (1/3) |

||

10 |

TY220.1501-76 |

Planetary carrier |

11 |

TY220.1501-3 |

Friction Disk |

12 |

TY220.1501-5 |

Brake Plate |

13 |

TY220.1501-2 |

Sealing Ring |

14 |

TY220.1501-94 |

Sealing Ring |

15 |

TY220.1501-7 |

Bearing |

16 |

HG4-692-67 |

Oil Seal |

17 |

09233-0512 |

Trust Washer |

18 |

0700-05125 |

O, ring |

19 |

07018-11805 |

Sealing Ring |

Transmission Gear and Shaft (2/3) |

||

20 |

TY220.1501-13 |

Sealing Ring |

21 |

TY220.1501-2 |

Sealing Ring |

22 |

07000-63022 |

O, ring |

23 |

TY220.1501-3 |

Friction Disk |

24 |

TY220.1501-5 |

Brake Plate |

Transmission Gear and Shaft (3/3) |

||

25 |

TY220.1501-54 |

Sealing Ring |

26 |

TY220.1501-62 |

O, ring |

27 |

TY220.1501-25 |

Sealing Ring |

28 |

TY220.1501-21 |

Friction Disk |

29 |

TY220.1501-20 |

Friction Disk |

30 |

TY220.1501-63 |

Wave Spring |

31 |

TY220.1501-27 |

Sealing Ring |

Transmission Control Valve (1/2) |

||

32 |

07000-03022 |

O, ring |

33 |

07000-03025 |

O, ring |

34 |

07000-03022 |

O, ring |

35 |

07000-03032 |

O, ring |

Transmission Control Valve (2/2) |

||

36 |

07000-03040 |

O, ring |

Transmission Control Valve Housing |

||

37 |

TY220.1502-6 |

Gasket |

38 |

TY220.1502-10 |

Gasket |

39 |

TY220.1502-42 |

Gasket |

40 |

TY220.21-4 |

Gasket |

41 |

07002-05234 |

O, ring |

42 |

07000-03028 |

O, ring |

TORQUE |

||

43 |

07000-02065 |

O, ring |

44 |

07201-51527 |

NUT |

45 |

TY220.49-15 |

PIPE |

Transmission and Pump |

||

46 |

T220.49.41 |

PUMP ASSY |

47 |

GB1235-76 |

O, ring |

48 |

GB1235-76 |

O, ring |

49 |

GB1235-76 |

O, ring |

50 |

GB1235-76 |

O, ring |

51 |

GB1235-76 |

O, ring |

52 |

T220.49.17.7 |

ELEMENT |

Transmission and Piping |

||

53 |

T220.49.19.17 |

ELEMENT |

54 |

07000-03032 |

O, ring |

55 |

07000-03022 |

O, ring |

56 |

07000-03028 |

O, ring |

Steering and Relief Valve |

||

57 |

07000-13042 |

O, ring |

58 |

07000-03042 |

O, ring |

Transmission and Filter |

||

59 |

07000-02065 |

O, ring |

60 |

GB1235-76 |

O, ring |

Steering and Filter |

||

61 |

T220.49.19.7 |

ELEMENT |

62 |

07000-02115 |

O, ring |

Выставочные шкафы

Знакомство с заводом

На заводе работает команда высококвалифицированных и опытных инженеров, которые непрерывно внедряют технологические инновации и совершенствуют продукцию. В настоящее время предприятие владеет рядом независимых прав интеллектуальной собственности и запатентованных технологий. Выпускаемая строительная техника включает широкий ассортимент оборудования, такого как экскаваторы, погрузчики, краны, бульдозеры и другие машины. Продукция отличается высокой производительностью, надежностью, энергоэффективностью и экологичностью, а также способностью адаптироваться к сложным условиям эксплуатации в различных климатических и рабочих средах по всему миру.

Награды и квалификация

часто задаваемые вопросы

1. В какие страны мы экспортируем?

Азия: Вьетнам, Индия, Индонезия, Пакистан, Казахстан, Узбекистан и т.д.

Европа: Россия, Беларусь, Украина, Литва, Саудовская Аравия и др.

Южная Америка: Бразилия, Чили, Парагвай, Аргентина и др.

Африка: ЮАР, Эфиопия, Ливия и др.

2.Какие условия оплаты мы можем принять?

Обычно мы можем работать на T/T, 30% TT перед производством и 70% TT перед отгрузкой

3.Какие способы логистики мы можем работать для доставки?

1) Для большинства стран Европы, Южной Америки и Африки и т.д. мы можем пойти по контейнеру или Roro через океанский фрахт.

2) Для соседних стран Китая, таких как Россия, Вьетнам, Казахстан, Узбекистан и т.д. мы можем доставить по автомобильной или железной дороге.

3) Для легких запасных частей в срочном требовании, мы можем отправить его с помощью международной курьерской службы, таких как DHL, TNT, EMS или других воздушных перевозок.

4. Как вы можете гарантировать, что вы доставили товары клиентам?

A: Мы предоставим вам полную информацию о доставке для вас подтвердил.

5.Каковы наши преимущества по сравнению с другими производителями/фабриками?

1) Надежное качество: Тщательно выбираем постоянных производителей для поддержки запасных частей, таких как двигатели, мосты, трансмиссии, и многие части, разработанные и произведенные нами, всегда адаптируя лучшие материалы.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive