175-30-25184 SD32 supporting wheel bracket

1. Durable and durable: made of high -strength steel and welded using special technology, it has a stable design, can withstand huge pressure and blows, and it is not easy to deform it.

2. Wear resistance and corrosion resistance: the surface is treated with anti -corrosion and wear resistant treatment, so it can be used for a long time in severe operating conditions and reduced the maintenance frequency.

3. High adaptability: designed for various types of bulldozers, has accurate installation dimensions, is easy to install and is ideal for the whole machine.

Product representation

1. General information about the product

Manufacturer: Shantui, who is one of the leaders in the industry in the production of construction and road equipment. The company has rich experience and advanced technologies, which ensures the high quality of its products.

The name and number of the part: support 175 - 30 - 25184, which is a factory spare part for Shantui SD32 and is used as part of chain caterpillars.

2. Technical characteristics and design

Material: The main material for this support is a special steel selected due to its high strength and resistance to mechanical loads. This steel passes the heat treatment, which increases its strength characteristics and wear resistance.

Dimensions: has strictly defined dimensions that were designed taking into account the design of the Shantui SD32 and its chain caterpillars. These dimensions provide an ideal landing and a reliable connection with other details.

The method of installing the bracket of the bulldozer wheel

1. Preparation before installation

1. Preparation of tools and materials

Tools: Prepare various types of keys, such as ring, wrenches with open yawning and end keys to remove and install bolts and nuts belonging to the roller bracket. For connectors of different sizes, the keys of different specifications should be used. Prepare the copper rod that you will carefully tap during the installation to help the components to fall into place and avoid damage caused by direct blows. You also need to prepare a jack for lifting a hubbling bulldozer to facilitate the installation of a rink bracket; Prepare scrap to adjust the position of the caterpillar and the bracket rink.

Measuring tools: Prepare roulette, levels and other measuring tools. The roulette is used to measure the installation site and size of the roller bracket to ensure the accuracy of the installation; The level is used to check the horizontal roller bracket to ensure its flat installation.

Materials: Prepare the roller bracket and related accessories, corresponding to the bulldozer models, such as bolts, nuts, gaskets, sealing rings, etc. Make sure that the hardware meets the requirements of quality and does not have problems such as deformation, damage and slipping of the thread. At the same time, prepare the required amount of grease and apply it to the mating parts of the shaft of the support roller and bracket to reduce friction and ensure smooth rotation of the support roller.

2. Equipment and preparation of a place

Equipment checks: Complete the bulldozer check to make sure that the engine is stopped and is in a safe shutdown state. Check the trace of the caterpillar and, if necessary, adjust it to facilitate the subsequent installation of the bracket of the support wheel.

Choosing a place: Select a flat, solid place, for example, a concrete floor in a repair shop or a rammed area in the open air. Make sure that there are no obstacles around the venue that facilitate the work, and stay away from the sources of fire and flammable materials to prevent accidents. When installing outdoors, pay attention to weather conditions and avoid installing installation work on rainy or windy days.

(III) Preparation of protective equipment

Operators should wear personal protective equipment, such as protective helmets, protective gloves and protective shoes. A protective helmet can protect the head from random blows, protective gloves can protect the hands from scratches and burns, and protective shoes can prevent blows on the legs with heavy objects.

Install warning signs such as warning tapes and signal lamps at the installation site to prevent the penetration of unauthorized persons into the installation zone and the occurrence of accidents.

2. Stages of installation

1. Remove the old roller bracket (if any)

Using a wrench, unscrew the bolts and nuts that attach the old roller bracket to the bulldozer chassis or a caterpillar frame. When tightening the bolts and nuts, be sure to weaken them gradually in diagonal to avoid deformation or damage to the bracket due to uneven effort.

If the old roller bracket is welded or otherwise fixed on the chassis or frame of the caterpillar, it must be removed using gas cutting or other suitable tools, but care must be observed to protect the surrounding components and avoid unnecessary damage.

After removing the old roller bracket, clean the surface of the mounting part from oil, rust, pollution, etc., so that the installation surface is even and clean, providing a good basis for installing a new roller bracket.

(II) Install the new bracket of the support wheel.

Raise the new roller bracket to the installation site and with the help of a jack, lift the bulldozer caterpillar so that the roller bracket can be smoothly installed in place. When lifting the caterpillar, pay attention to the position of the jack and the stability of the support to prevent the slide of the caterpillar or overturning the jack.

Combine the roller bracket with a mounting hole, insert the connecting bolts and manually tighten the nuts to make sure that the roller bracket is initially fixed. When installing the bolts, pay attention to the direction and length of the bolts so that they can freely pass through the mounting holes and do not damage the thread.

Using a wrench, gradually tighten the nuts diagonally so that the roller bracket tightly adjacent to the chassis or frame of the caterpillar. In the process of tightening, constantly check the horizontality of the roller bracket using a level. If there are any deviations, make adjustments in time. Finally, using a dynamometric key, tighten the connecting bolts one at a time in accordance with the specified torque value to ensure a reliable installation of the bracket of the support wheel.

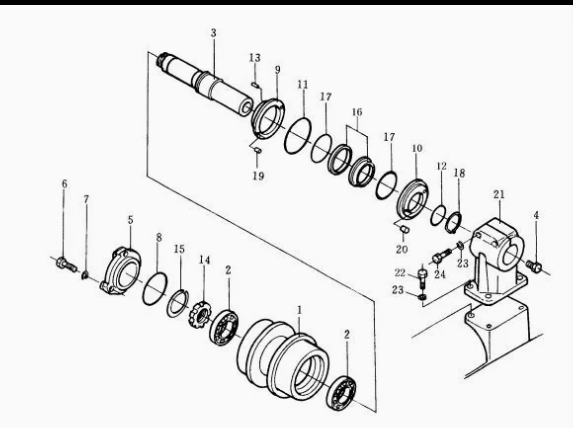

(III) installation of support wheels and related parts

Apply the required amount of lubrication to the mounting hole of the roller bracket, insert the roller shaft into the mounting hole, and then set the video. When installing a support roller, pay attention to its direction and position so that it can rotate freely and interact well with the caterpillar.

Install the end cover, sealing ring, stop ring and other components of the support roller to ensure good tightness of the support roller and prevent the entrance to the support roller of pollution, such as dust, dirt and moisture, and violation of its normal operation. When installing these components, pay attention to the sequence and installation method to ensure a reliable installation of each component.

After installation, turn the supporting wheel by hand to check the smoothness of its rotation, the lack of sealing or excessive friction. If it is found that the support wheel rotates abnormally, find out the cause in a timely manner and adjust or repair.

(IV) adjustment and fixation

After installing the skating rink and rink, adjust the caterpillar tension in accordance with the technical requirements of the bulldozer. The tension of the caterpillar can be changed by adjusting the bolts or nuts of the caterpillar tensioner. During the adjustment, pay attention to the sagging and tension of the caterpillar to make sure that it is stretched correctly and not too tight.

Check the installation of the roller and the roller bracket again to make sure that all connecting bolts are tightened, the video rotates smoothly, and the trace of the caterpillar is proper. Finally, clean the bracket of the support wheel and related parts to remove oil spots, pollution, etc., remaining during the installation process.

3. Checking and debugging after installation

1. External inspection

Check the correct position of the installation of the bracket of the support wheel, the reliability of the connection to the chassis or the tracking of the caterpillar, the tightening of the connecting bolts, the lack of weakening and the loose fit.

Check if the support roller is reliably set, whether the support roller is easy to rotate, whether the contact between the support roller and the caterpillar rotates, whether there is eccentric wear.

Check if the roller bracket is damaged and a video or whether they are deformed. If there are any problems, repair or replace them on time.

(II) Operating check

Run the bulldozer and slowly eat on it a certain distance along the flat site, observing the working conditions of the rink bracket and the rink itself. During driving, carefully listen to any extraneous noise, such as friction, blows, etc. If you hear any unusual noise, immediately stop the car, find out the cause and eliminate it.

Check the changes in the temperature of the support roller during operation and regularly measure the temperature of the support roller using the infrared thermometer. Under normal conditions, the temperature of the support wheel increases after a certain period of operation, but it should not exceed the specified temperature range. If the temperature of the support roller is too high, it can be caused by improper installation, poor grease or excessive load. The reason must be found and eliminated on time.

(III) Adjustment and maintenance

After checking the operability, make the necessary adjustments and maintenance of the roller bracket and roller according to the actual situation. For example, if the track roller is found to be unevenly worn, the position of the track roller bracket can be adjusted accordingly to ensure uniform contact between the track roller and the track; If it is found that the support roller is not sufficiently lubricated, lubricant should be added in a timely manner.

Regularly inspect and maintain the roller bracket and roller, including checking the tightening of the connecting bolts, the wear and lubrication of the roller, etc.

Exhibition cabinets

Acquaintance with the plant

The factory has a team of highly qualified and experienced engineers who continuously introduce technological innovation and improve products. At present, the company owns a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment, such as excavators, loaders, cranes, bulldozers and other machines. The products are characterized by high performance, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working environments around the world.

Awards and qualifiersFiction

Frequently Asked Questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipment

3. What logistics ways can we work for shipping?

1) For most countries in Europe, South America and Africa, etc., we can go by container or Roro through ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or railway.

3) For light spare parts in urgent requirement, we can send it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you ensure that you have delivered the goods to customers?

A: We will provide you with full shipping information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable Quality: Carefully select regular manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by us, always adapting the best materials.

2) Competitive price: The concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) Service Team: Firstly, our sales managers are available 24 hours a day, ready to answer your questions at any time. Secondly, a professional technical service team with senior technicians, ready to provide support services to users and dealers. Most problems can be resolved within 24 hours.

4) Fast Delivery: Generally, we can deliver within 10 working days at the factory after receiving the advance payment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive