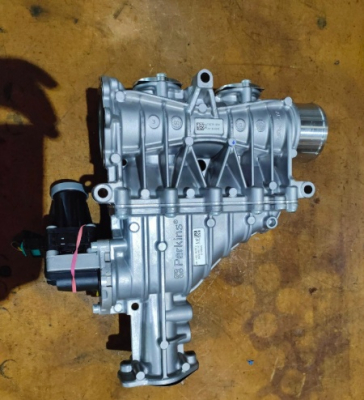

D638-002-02+B Fuel filter original spare parts

1. Highly effective filtering: the use of advanced filter paper allows you to effectively capture the smallest impurities with high filtration accuracy, providing fuel purity and stable engine operation.

2. Durable: the case is made of high -strength material, which is resistant to pressure and corrosion. It can work steadily for a long time in difficult working conditions and has a long service life.

3. Exact adaptation: specially designed for Shanghai Diesel engines, with an exact interface and size, a simple installation and high adaptability.

Product representation

1. General performance

Manufacturer: Shangchai, a leading player in the engine manufacturing market in China, known for its long history and rich experience in the development and production of motor attitudes.

Purpose: The D638 - 002 - 02 + B fuel filter is specially designed to clean the fuel in Shangchai engines, guaranteeing its uninterrupted operation and the long service life.

2. Design and materials

The filter element: the main filter element is made of high -quality fiberglass or special synthetic fabric. These materials have excellent filtration properties that can hold the smallest fuel pollutants, up to a dimensions of less than 10 microns.

The filter case: made of durable plastic or metal, which protects the filter element from mechanical damage and provides its tightness. The case has the corresponding holes for connecting the fuel pipes and the pressure sensor.

Shangchai fuel filter service method

1. Definition of the service cycle

According to the leadership: strictly follow the recommendations of the Shanghai Diesel Engine Guide to determine the maintenance cycle. As a rule, under normal working conditions and the frequency of use, the fuel filter replacement period is every 500-1000 hours of operation. However, if the operating conditions are harsh, for example, the low quality of the fuel, the dustiness of the workplace, etc., the maintenance cycle should be reduced accordingly, and maintenance may be required every 300-500 hours.

Watch the engine operation: pay attention to the working condition of the engine. If there are difficulties with the launch, the power, an unstable idle passage, increases fuel consumption, etc., the fuel filter can be clogged, which leads to poor fuel supply. At this time, even if this is not a prescribed service time, the fuel filter must be checked or replaced.

2. Stages of replacement

1. Preparation

Preparation of the tool: Prepare suitable wrenches, such as ring, rock or end, to remove the bolts and nuts of the filter or connecting pipes; Prepare special filter removal tools. If a filter of a screw -out type, this tool can more conveniently remove the filter; also prepare the oil collection container to collect fuel arising when the filter is replaced to prevent the environmental pollution by leakage of fuel; Also prepare a clean fabric or towel to wipe the filter and the surrounding parts.

Select the filter: Select the original fuel filter corresponding to the Shanghai Diesel engine model, or a branded filter that meets quality standards. Make sure that the filter characteristics, filtering accuracy and other parameters meet the engine requirements to provide a good filtration effect and engine performance.

Precautions: operators must wear protective gloves, glasses and other protective equipment to prevent fuel spraying to the skin and eyes. Before starting work, make sure that the engine is stopped and cooled to normal temperature to avoid burns and other accidents.

(II) Removing the old filter

Reset fuel pressure: before removing the filter, reset the pressure in the fuel system. The pressure can be discarded slowly, weakening the air output bolt on the fuel filter (if any) or using a special tool for connecting to the safety valve of the fuel system, until the fuel ceases to flow out or the pressure does not fall to zero.

Remove the filter: For screwed fuel filters, use the filter tool to turn the filter counterclockwise and unscrew it from the mounting bracket. Unscrewing the filter, be careful to prevent fuel to flow. For other types of filters, for example, to replace the filter element, you must first unscrew the fasteners or nuts of the filter case, then carefully remove the housing and remove the old filter element.

(III) install a new filter

Clean the installation location: wipe the surface of the filter seating with a clean cloth to remove oil, pollution, sealants, etc. Make sure that the surface of the seat is clean and even to provide a good basis for installing a new filter.

Install a new filter: If it is a spin-on filter, apply a thin layer of clean fuel to the sealing rubber ring of the new filter to enhance the sealing effect. Next, screw the filter clockwise to the mounting base, tighten it by hand, and then use the filter removal tool to tighten it to the specified torque to ensure that the filter is securely installed and sealed. For replaceable filter elements, install the new element in the filter housing, paying attention to the correct installation direction of the element, then replace the housing and tighten the mounting bolts or nuts, also according to the specified tightening torque.

(IV) Refueling and Exhaust

Refueling: After installing a new filter, fill the fuel system with fuel that meets the requirements. Fuel can be filled through the fuel tank filling. Pay attention to the quality and grade of fuel, which must meet the requirements of the engine.

Air Release: After refueling, the air must be released from the fuel system. Air from the fuel system can be released by activating the manual fuel pump (if available) and pressing the manual fuel pump repeatedly until the fuel fills the filter and tubes and no bubbles come out. You can also start the engine and let it run for a while to use the fuel pump pressure to remove the air, but pay attention to the operating condition of the engine to avoid difficulty starting the engine or abnormal operation due to incomplete air removal.

3. Daily maintenance

Appearance Check: Regularly check the exterior of the fuel filter to ensure that there is no damage, deformation, corrosion, etc., to the filter housing, and that there are no loose or leaking connecting pipes. If damage to the outer sheath is detected, the filter should be replaced in a timely manner; if the pipeline is loose, the connection needs to be tightened; If a leak is found, the leak site should be found and the relevant parts repaired or replaced.

Drainage operation: Some fuel filters have a drainage function. Especially when using fuels with a high water content, drainage operations must be carried out regularly. As a general rule, at regular intervals (such as every week or every 50 hours of operation), unscrew the drain bolt at the bottom of the filter to drain any water that has accumulated at the bottom of the filter until there is no water left in the leaking fuel. Once the drain is complete, tighten the drain bolt to prevent fuel leakage.

Fuel quality problem: Using high-quality fuel is key to protecting the fuel filter. Avoid using fuel of unknown origin or poor quality, as it may contain impurities, moisture, colloid, etc., which will accelerate clogging and damage to the filter. Try to choose regular gas stations for refueling and pay attention to the storage and transportation of fuel in order to prevent its contamination.

Exhibition cabinets

Acquaintance with the plant

The factory has a team of highly qualified and experienced engineers who continuously introduce technological innovation and improve products. At present, the company owns a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment, such as excavators, loaders, cranes, bulldozers and other machines. The products are characterized by high performance, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working environments around the world.

Awards and qualifiersFiction

Frequently Asked Questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive