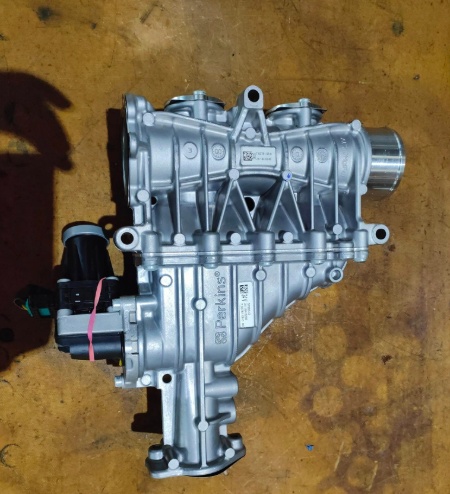

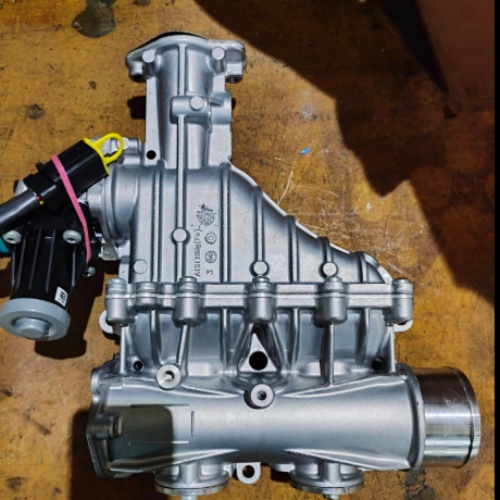

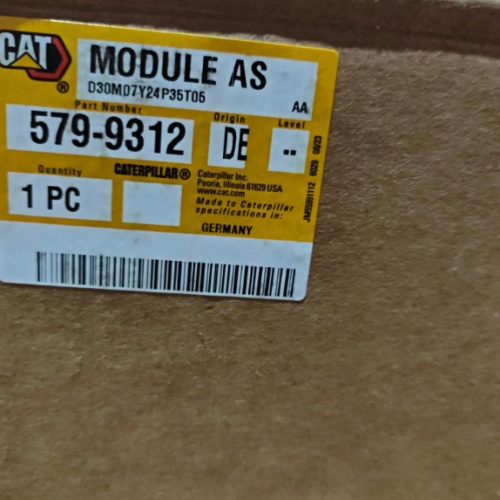

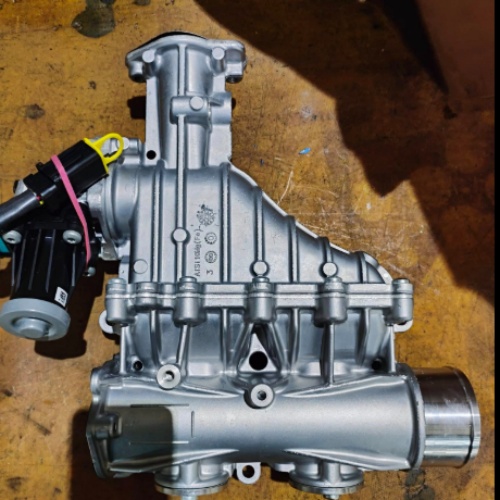

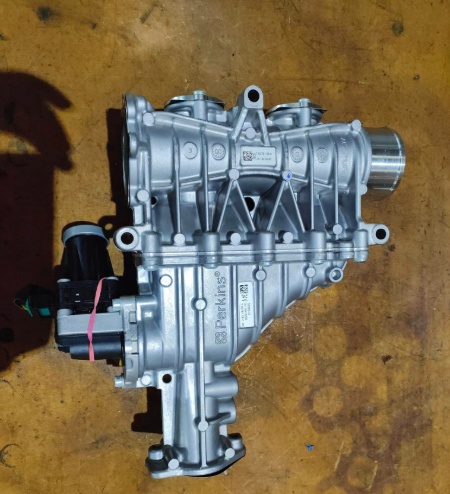

Caterpillar 579-9312 EGR valve assembly

1 、 accurate compatibility : specially designed for the relevant Caterpillar models , compatible with other components of the release system and. This ensures the ease of installation and uninterrupted operation as part of the whole system.

2 、 Effective emissions management : effectively controls the overheval of the exhaust gases into the system , reducing the combustion temperature and the number of Harmful Nox emissions. This allows you to comply with strict ecology standards.

3 、 High reliability and durability : made of strong and stable materials for corrosion , can withstand high temperatures and pressure in the release system. Production and quality control technologies guarantee a long service life and rare breakdowns.

Product representation

Detailed product information

Piston rings

Take as an example the piston ring 1W-8922: it is suitable for the Caterpillar 3406 engine. It can be functionally sealing the cylinder, preventing the gas leakage, increasing the degree of engine compression to improve its power characteristics; It can effectively control the oil supply, prevent the ingress of an oil-gas mixture into the combustion chamber and maintain the purity of combustion; It also fulfills the task of transmitting heat from the piston to the cylinder wall, helping to maintain the normal operating temperature of the engine. The material, as a rule, is a modern material with high wear resistance and long service life.

Cornflower bearing

Take as an example the connecting rod 9Y-9497: it is used in the Caterpillar 3406B engine. It is made of high -strength material, has excellent wear resistance and resistance to high temperatures. After precision processing, dimensions and tolerances comply with national standards, and the accuracy of the mating is high. A reasonable design can provide a more uniform formation of an oil film, effectively reduce friction losses and extend the life of the engine.

Assembly of the core

As an example, we take the core node 2555477: this is the Carter C15 engine. It mainly is responsible for the process of air compression, which allows you to achieve effective air compression and ensure engine performance when operating under a high load. Materials and designs withstand high temperatures, thorough tests have passed, are stable and durable. The optimized design also allows you to reduce noise levels during operation and increase the comfort of the working environment.

Other accessories

Filters: including air filters, oil filters, etc., which can effectively filter impurities in the air and pollutants in oil, protect the internal components of the engine and extend its service life. There are many types of air filters, for example, dry and panel, and some of them are equipped with service indicators.

The head of the cylinder block and its components: such as the head of the cylinder block, rocker, valve, valve tube, etc., are important components of the valve mechanism of the engine, which provide the normal process of intake and production of the engine that affect the effectiveness of combustion and the output power of the engine.

Fuel system accessories: high -pressure fuel pump can injure fuel pressure and direct it to high pressure fuel ramp in order to provide the necessary pressure for fuel injection; The injector sprays fuel into the cylinder exactly in accordance with the instructions of the electronic control unit, providing effective combustion.

After -sales service

Warranty service

Standard guarantee: Carter accessories usually have a certain warranty period. With normal use, if accessories have problems with quality during the warranty period, they can use free repair or replacement services.

Extended warranty service: Caterpillar provides expanded warranty service, and customers can additionally protect the security of their assets after registering a warranty on the engine.

Supply of accessories

Global network: Caterpillar has created a full network of spare parts supply around the world and has a large number of warehouse centers, which allows it to quickly respond to customer needs and supply original details in a timely manner.

Quality guarantee: all accessories have passed strict quality control and meet high standards of Caterpillar, which guarantees compatibility and compliance with the engine, as well as the productivity and reliability of the equipment.

Technical support

Professional team: We have a professional team of technical engineers who can provide customers with comprehensive technical support, including recommendations for choosing accessories, installing, debugging, diagnostics of faults, etc.

Learning services: providing customers for training and maintenance training, helping customer personnel in the development of the right methods of use and maintenance, as well as improving the efficiency of work and the service life of equipment.

Repair services

The service network: around the world there are many authorized repair stations equipped with professional repair personnel and modern repair equipment that can provide repair services on the spot, repair “from door to door” or repairing with delivery.

Quick response: we provide round -the -clock emergency maintenance services in order to guarantee the operational repair of customer equipment in case of failures, reducing downtime and impact on production.

Here are a few ways to determine the authenticity of Carter engine parts:

Identification of details of appearance:

Package:

The packaging of the original parts of the Carter engine is usually made high -quality, has a clear print and contains a full brand logo, product model, technical characteristics and other information. The packaging material is high -quality, durable and moisture resistant.

The packaging of fake accessories is often rough, with blurry seal, fuzzy colors and may even contain spelling errors or missing information.

The technology for processing the surface of accessories:

The surface of the original accessories is carefully processed, without obvious flaws, burrs and sand shells. For example, the piston has a smooth surface and a homogeneous texture; The cylinder body is characterized by exquisite casting technology and neat faces.

Fake accessories can have problems such as an uneven surface, obvious traces of processing, as well as uneven edges and angles.

Logo and marking:

On original accessories, there are usually clear and standardized Carter brand logos, details and other markings, and these markings are not susceptible to wear or erasure.

Logos on fake accessories can be fuzzy, fonts can be uneven, and marking can easily be erased.

Material identification:

weight:

Original accessories are usually made of high -quality materials, and their weight meets the standards. For example, the weight of such important components such as a crankshaft is relatively stable and will not significantly deviate.

Since fake accessories can be made of low -quality materials, their weight may differ from genuine ones. Too light or too difficult can be a sign of quality problems.

Hardness and wear resistance:

The material of original accessories has moderate hardness and good wear resistance. This can be done using some simple testing methods, such as measurement using a solidometer or observation of wear with normal use.

The hardness of the material of fake accessories may not meet the requirements, and they can wear out too quickly or deform.

Identification of performance and user experience:

Suitability for installation:

Original accessories are well compatible with the engine, and the installation process goes smoothly, without any problems, such as the mismatch of sizes and difficulties in installation.

Fake accessories can have deviations in size, which can lead to loose or incorrect installation.

Cherry characteristics:

Original accessories are able to ensure the normal operation of the engine during its operation, such as a stable output capacity, normal fuel consumption and low noise.

Fake accessories can affect the engine operation, which will lead to problems such as reducing power, increased fuel consumption and increased noise.

Identification of the source channel:

Authorized dealers:

It is recommended to purchase details from officially authorized Caterpillar dealers, which have established procurement channels and can guarantee the quality of parts.

You can check the list of authorized dealers on the official Caterpillar website to avoid buying spare parts from unknown suppliers.

Beware of low prices:

If the price of the accessory is much lower than the average market, most likely this is a fake. The price of the original parts of the Carter engine is relatively stable due to their quality and value of the brand.

Do not buy cheap accessories so as not to miss the overall picture and not damage the engine.

Professional testing and identification:

Professional testing of the agency:

If you have doubts about the authenticity of the details, you can send them for testing to the officially authorized Caterpillar test center or to a professional laboratory of mechanical tests.

These institutions have professional equipment and technical personnel that can conduct comprehensive tests of materials, operational characteristics and other aspects of accessories, as well as accurately determine the authenticity of accessories.

Compared to original details:

If the conditions allow, you can get a genuine original accessory for comparison. A detailed comparison in appearance, size, material, etc. will facilitate the detection of differences in fake accessories.

Thanks to the comprehensive use of the above methods, the authenticity of Carter engine parts can be determined more accurately, which guarantees the quality of the parts used in the engine.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive