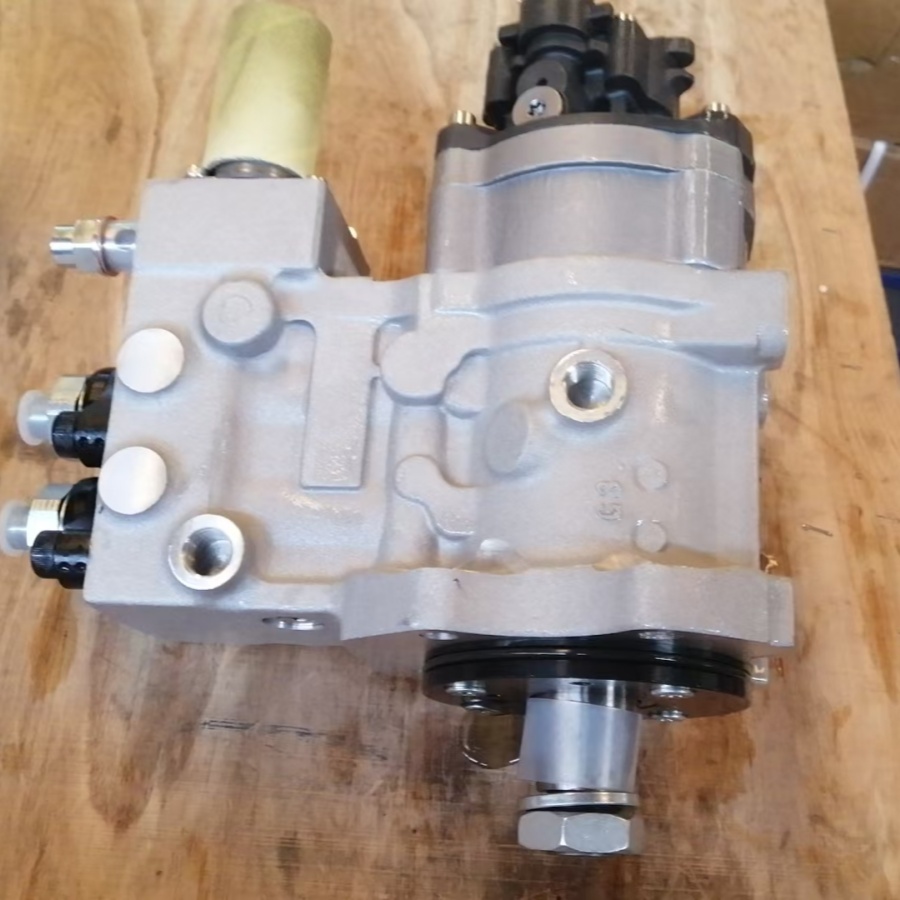

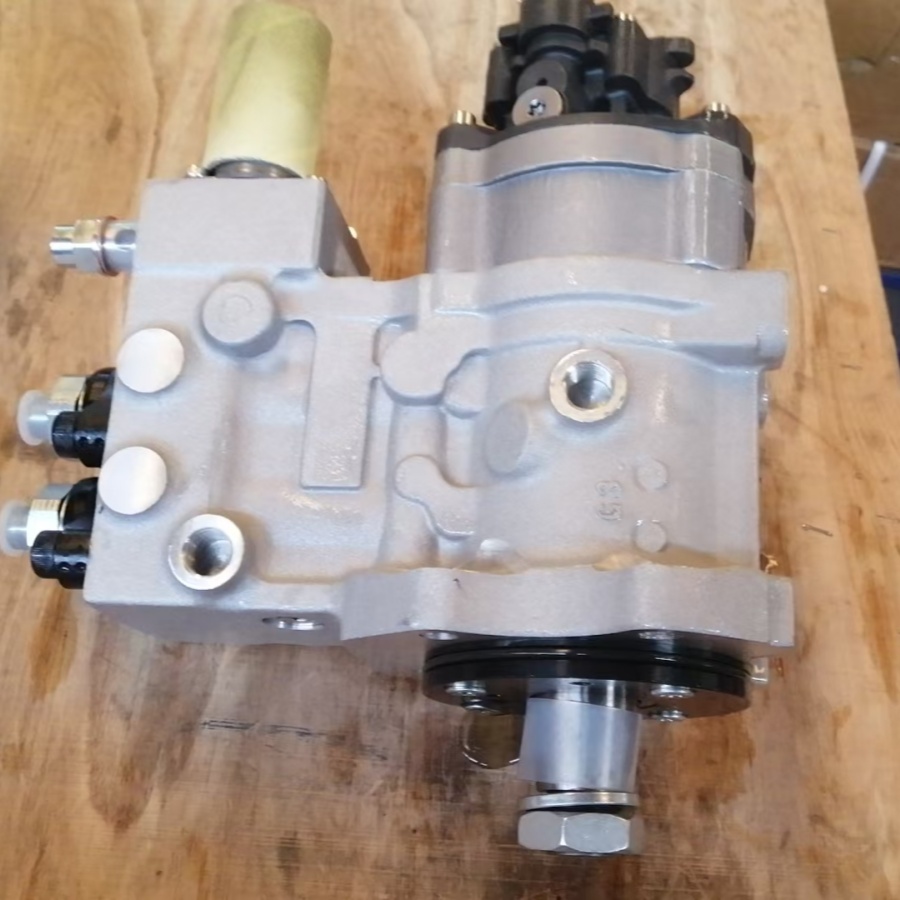

Shacman 612640030001 TNVD

1 、 exact compatibility : specially designed for the Shaanxi X3000 models, is ideally combined with other components of the machine fuel system. This ensures the ease of installation and uninterrupted operation as part of the whole system.

2 、 Fuel injection accuracy : allows you to accurately control the volume and time of fuel injection into the engine combustion chamber. This allows you to achieve optimal combustion of fuel, increases the power and economy of the engine, and also reduces emissions of harmful substances into the atmosphere.

3 、 High reliability and durability : is made of strong and resistant materials that withstand high pressure and temperatures that occur during the operation of the fuel system. This provides a long service life and rare breakdowns.

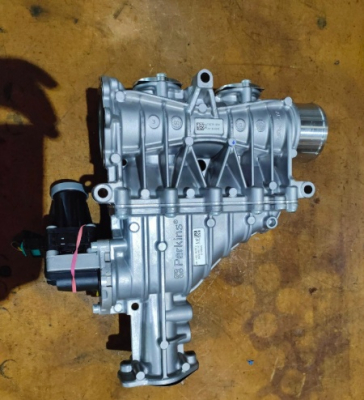

Product representation

Detailed product information

The principle of operation: this is a two -cylinder in a high -pressure plunger pump with oil grease, which provides a tolers of the Common Rail injection, necessary for various engine operating conditions. The fuel is sucked from the fuel tank with a fuel pump built into the high pressure pump. The fuel supply by a high -pressure pump is controlled by controlling the fuel dispenser installed on the pump, thereby adjusting the pressure in the system and reaching zero fuel supply. The supply of fuel can be continuously controlled between the maximum volume of fuel and the zero volume of fuel, so that the pressure in the system can be continuously and smoothly controlled.

Parameters of performance: it can comply with the requirements of high power and torque of the Weichai WP12 engine, can produce higher fuel pressure and provide accurate fuel injection. The injection pressure can usually reach 1600 bar and higher, providing a good effect of spraying fuel and more complete combustion, which helps to improve the performance of the engine and fuel savings.

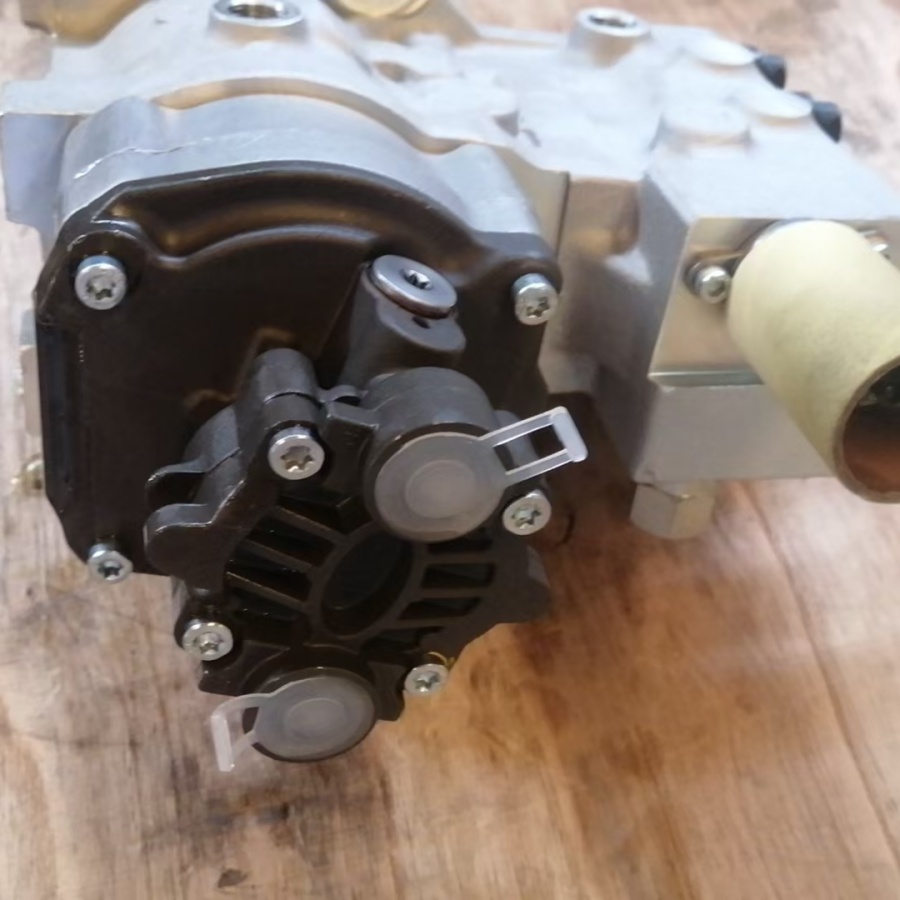

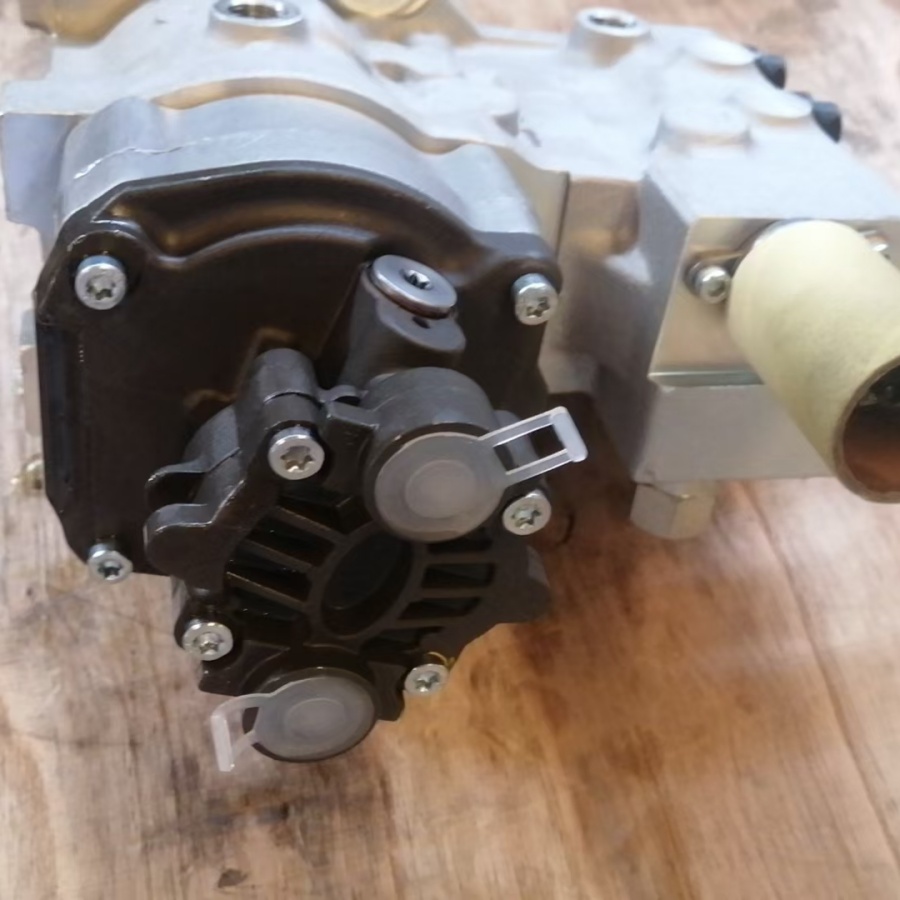

Design features: it uses the improved design of the plunger pump, and key components, such as the internal plunger and the exhaust valve, have high accuracy and high wear resistance. The degree of integration is high, and the components such as the oil pumping pump and the oil dosing unit are integrated into the high -pressure pump case, which reduces the amount of external connecting pipelines, reduces the risk of leaks and increases the reliability of the system.

Stages of installation

Preparation: Make sure that the installation site is clean, and prepare the necessary tools, such as a dynamometric key, etc. At the same time, check if the high -pressure oil pump and concomitant oil pumps are not deformed.

Install the camshaft of the oil pump and the gear of the transmission: during the installation, make sure that the distribution shaft of the oil pump and the gear of the transmission are well combined. The conical surface must be degreased to ensure good contact and transmission efficiency. The tightening moment should be controlled in the range of 250-300 N · m. Use the appropriate tightening tools in accordance with the specified moment.

Install the flange and gear of high -pressure fuel pump: when installing the flange and gear of high -pressure fuel pressure on the fuel pump of the high pressure of Common Rail, make sure that the synchronization lines of two parts are combined before installing them in the hearing chamber. When the piston of the first cylinder is at the upper dead point, the synchronization line of the high -pressure fuel pump should be combined with a line of the M30x1.5 viewing opening scale on the gear chamber to ensure the exact synchronization of the injection.

Connect oil pipes and other components: connect high -pressure oil pipes, low -pressure oil pipes and other related pipelines in the correct order and method to guarantee the reliability of the joints and the lack of leaks. At the same time, connect the electrical circuits of components such as the oil accounting unit to provide reliable electrical connections.

Checking and eliminating problems: after installation, carefully check the correct installation of a high -pressure oil pump to make sure that all parts are installed in its place, and the connections are hermetic. Then start the engine, conduct preliminary debugging and inspection, follow the operating condition of the high -pressure fuel pump, check if the fuel pressure is normal, whether fuel is injected, etc.

Common errors

The engine does not start: perhaps a low-pressure oil contour is closed, because of which fuel cannot get into the high-pressure oil pump. For example, in the oil circuit there is air, the input filter of the oil pump and the filter element, or the oil pipeline or its connecting parts have serious leaks are clogged.

Insufficient engine power: high pressure fuel pump may not supply fuel enough. The reasons may be a malfunction of the fuel dispenser, the wear of the plunger, the loose fit of the exhaust fuel valve, etc., which leads to insufficient fuel injection and cannot satisfy the engine's needs in power.

Unstable engine speed: if unevenness is observed, that is, the engine speed changes periodically, then increases, then decreases, and it is unstable, then this may be associated with uneven supply of fuel to the cylinders or non -normal operation of the regulator, for example, with an excessive difference in injection pressure. between the cylinders, reduced sensitivity of the regulator, wear transmission and connecting parts of the high -pressure oil pump regulator, improper adjustment of the idle speed, etc.

The abnormal noise of the high -pressure oil pump: it can be caused by wear, weakening or damage to internal components, such as the wear of the plunger and the plunger’s sleeve, the wear of the distribution shaft, damage to the bearing, etc., which leads to an abnormal noise of friction or clash during operation .

After -sales service

Three Guarantees Service: with normal use and maintenance, if there is really a problem with the quality of products, within three warranties, the client can use high -quality, fast and effective after -sales maintenance provided by the authorized service center for maintenance or dealer of spare parts at the location of the client Having presented an invoice or list of sales printed by the system Weichai spare parts.

Technical support: Weichai has a global telephone service center that provides a 24 -hour instant response service, as well as a professional technical team that can provide users with technical advice and recommendations by phone, Internet, etc., to help users solve problems arising during installations, use, maintenance, etc.

Service service network: There are many service centers of sales and authorized service stations in China. The service network covers a wide range. Users can choose the nearest service station for service. We can react in a timely manner to customer needs and provide service or delivery services.

Supply of spare parts: Weichai has a comprehensive system for delivering spare parts, which provides timely supply of original parts for high -pressure oil pumps, guarantees the quality and compatibility of parts, and also provides protection for repair and maintenance.

The common problems of after -sales service of the high -pressure oil pressure of Weichai WP12 include many aspects. Below is a detailed introduction for you:

Problems with the supply of accessories

Untimely delivery: due to fluctuations in market demand, adjusting the production plan or logistics and transportation of the supply of components for the high-pressure oil pressure of the Weichai WP12 oil pump, it can be untimely. For example, during periods of peak sales or with a sudden increase in demand for maintenance, some key supplies, such as plungers, graduation valves for oil, oil accounting nodes, etc., may not be in the warehouse, which makes it impossible to carry out timely work on technical maintenance And increases the downtime of equipment.

The quality of accessories varies: although Weichai seeks to supply genuine original accessories, fake and poor -quality accessories can fall into the market through some unofficial channels or in some individual regions. If users use these poor -quality accessories, they will not only not solve the problem of high -pressure oil pump, but can also lead to further damage to the equipment, increase the cost of maintenance and difficulty after sales maintenance.

Technical level of service problems

Insufficient qualifications of maintenance personnel: high -pressure oil pump WEICHII WP12 is a relatively complex component requiring a high level of technical skills of maintenance personnel. Technical maintenance personnel of some post -sales maintenance points may not have systematic training and do not own the principles of work, methods for diagnosing malfunctions and high -pressure oil pump service techniques. For example, when eliminating a malfunction in the electronic control unit of high -pressure fuel pump, it may be impossible to determine exactly whether the problem is due to the fuel dosing unit or with a malfunction associated with it, which will lead to an increase in the repair time or its improper implementation.

Incomplete diagnostic equipment: some after -sales service stations may not have modern diagnostic equipment and not be able to conduct comprehensive and accurate checks of high -pressure fuel pumps. For example, the absence of professional fuel system testers does not allow you to accurately measure the output pressure, consumption and other parameters of high -pressure fuel pump, which affects the accuracy of evaluating malfunctions and the quality of maintenance.

Service response problem problem

Untimely response: if the user fails of the high pressure of the high pressure of the Weichai WP12 and he informs about this to the after -sales service, the service reaction may be untimely. Especially in remote areas or areas with insufficient coverage of the network of after -sales service, service personnel may not be able to arrive at the promised time, which will lead to long -term downtime of the user's equipment and affect the course of production.

Mallence: in the process of after -sales service, a misunderstanding between the user and the after -sales service personnel may occur. The user may not be able to accurately describe the phenomenon of high -pressure oil pump failure, and after the after -sales service personnel can not inform the user about maintenance and decisions, which leads to misunderstanding and dissatisfaction with both sides.

Problems of implementing the policy of "three guarantees"

The dispute on the definition: in the Three Guarantees service, disagreements may arise about whether the refusal of a high -pressure oil pump is a problem of quality problem. For example, the user may believe that the malfunction is caused by defects in the quality of the product itself, while the after -sales service department may believe that it is caused by improper use or improper service by the user. It is difficult for both parties to reach an agreement, which affects the uninterrupted implementation of the “three guarantees” services.

Complex procedures: Some users said that when submitting an application for the Three Guarantees Service, the required procedures were quite complicated, for example, the provision of various confirming documents, filling out complex forms, etc. This not only increases the time and energy of the user, but also It may lead to the fact that some users will abandon the “three guarantees” services and will bear the cost of maintenance on their own.

Technology and training updating issues

Knowledge is not updated over time: thanks to the constant development of technology, the Weichai WP12 high -pressure oil pump is also constantly modernized and improved. However, some after -sales service employees may not understand and not master these new technologies and functions in a timely manner. When working with the refusals of new high -pressure oil pumps, they may have “blind spots” in knowledge that can affect the results of the service.

Insufficient training: Weichai training for after -sales services may be insufficient. The content of training is not comprehensive and deep enough, and teaching methods are not flexible and diverse enough. For example, training can be focused on explaining theoretical knowledge, but to a lesser extent on practical operation, as a result of which the personnel of after -sales services will not have practical experience in real maintenance work.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive