Caterpillar tension roller E320

1. Excellent material: high -strength wear -resistant steel was chosen, which, after special heat treatment, has both hardness and viscosity, wear -resistant, impact and has a long service life.

2. Stable work: The design of the wheel has a reasonable design and rotates smoothly, which allows you to effectively direct the operation, reduce deviations and gatherings from the rails, and also ensure the safety of operation.

3. High adaptability: sets up for various types of excavators, has the exact dimensions, is easy to install and high compatibility with the entire machine.

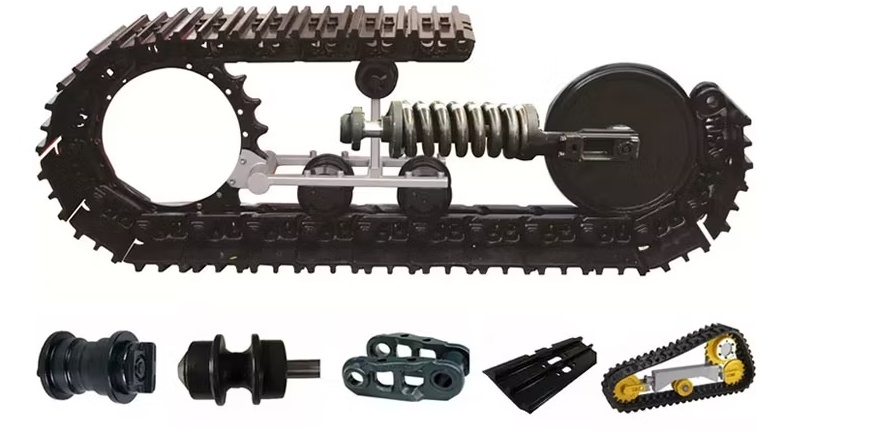

Product representation

Detailed product information

Structural composition: usually consists of a wheel housing, bearings, shaft, seals, etc. The wheel housing is the main part of the guide wheel. It is usually welded from cast steel of high hardening or high -quality structural steel, and the tread is subjected to induction hardening to increase wear resistance and strength. Bearings and shafts are installed inside the wheel housing to support the rotation of the wheel housing. Bearings are usually used by bimetallic bearings or cast bearings made of copper alloy, which are suitable for low speed and high load conditions. Seals are used to prevent lubricating oil leakage and dust and pollution.

The principle of operation: is installed at the front or back end of the caterpillar of the excavator and directs the caterpillar for movement in a given direction, interacting with the caterpillar. At the same time, it interacts with the tension device to maintain the trace of the caterpillar so that the caterpillar does not weaken and does not deviate during the walking process, ensuring the stability and reliability of the excavator walk.

Technical characteristics and models: various models of excavators are equipped with guide wheels of various specifics. General specifications include the diameter of the wheel, wheel width, the number of teeth, etc. For example, the guiding wheel of an excavator weighing 6–9 tons can have a diameter of 200 mm.

Stages of installation

Preparation: Install an excavator on a flat, solid surface, turn off the engine and disconnect the power source. Prepare the necessary tools such as wrenches, heads, jacks, etc., as well as new guides and corresponding seals, lubricants, etc.

Dismantling of the caterpillar: if the caterpillar is stretched, first remove the caterpillar masillaum, release the lubricant and loosen the caterpillar. Then use the jack to support the caterpillar cart on one side of the excavator so that it is at a certain distance from the ground for ease of use. Using a wrench or other tool, weaken the connecting bolts of the caterpillar tape, remove the caterpillar tape from the excavator and install it in a suitable place.

Remove the old guide wheel: weaken the fasteners of the guide wheel and remove the old guide wheel from the installation site. Be careful to save the removed bolts, gaskets and other details.

Cleaning and inspection: use clean fabric or brush to clean the installation area of the guide wheel from dirt, rust, etc., and also check whether the installation surface is even and is not damaged. At the same time, check if there are no appearance defects on the new guiding wheel, whether the bearing is easy to rotate, etc.

Install the new guide wheel: apply the required amount of lubricant to the bearing and shaft of the new guide wheel, correctly install the guide wheel to the installation position, tighten the fasteners and tighten them in accordance with the indicated puffing moment.

Install the caterpillar cart: put on the caterpillar cart on the guide wheel and the drive wheel and adjust the position of the caterpillar trolley so that it is correctly caught with the guide wheel and other moving parts. Then tighten the caterpillar bolts to ensure its reliable connection.

Adjust the tension: enter the oil into the caterpillar through the caterpillar tension device so that the caterpillar reaches the necessary tension. In the general case, the tension of the caterpillar tape should be such that when the excavator is parking between the middle of the caterpillar tape and the supporting wheel, a certain gap remains.

Checking and testing: Launch the excavator and let him drive some distance. Check whether the guide wheels can rotate flexibly, and also whether caterpillar tapes are not rejected or abnormally worn.

Common malfunctions

Damage to the bearing: prolonged use, poor lubrication, overload and other causes can lead to wear and damage to the bearing, which can manifest itself in the form of an abnormal noise or sealing when rotating the guide wheel, as well as a strong heating of the bearing.

Wheel wear: Due to prolonged friction on the rail, the wheel protrud wear out, which leads to a decrease in the diameter of the wheel and the formation of irregularities on the surface, which affects the guide effect of the rail and can cause problems such as the deviation of the track and the railway from the rails.

The failure of the seals: aging and damage to the seals will lead to a leakage of lubricating oil, which will lead to loss of lubrication with bearings and other components. At the same time, dust and pollution can easily get inside, which will aggravate the wear of the components.

Wal wear: problems with the landing of the shaft and bearing or wheel housing, as well as excessive external effort can lead to wear and deformation of the shaft, which will affect the normal operation of the guide wheel.

After -sales service

Warranty period: As a rule, the warranty period for the guide wheels of excavators is 1 year. During the warranty period, if the refusal occurred due to problems with the quality of the product, the supplier or the manufacturer will provide free repair or replacement services.

Supply of accessories: we can supply original guide wheels and related accessories in a timely manner, guaranteeing the quality and compatibility of accessories to meet the needs of users in maintenance.

Technical support: manufacturers or dealers will provide users with professional technical support and answer users' questions about installing, using, maintenance, etc. On the phone, via the Internet, etc.

Repair services: We have a professional repair team and a network of after -sales service that can provide repair services “from the door to the door”, or users can send the device to the specified repair workshop for repair.

The most common malfunctions of the guide wheels of excavators are:

Distribution problems

Wheel tread wear: due to prolonged friction on the rail, the wheel protrud wear out unevenly, which leads to an uneven surface and a decrease in the diameter of the wheel. This will worsen coordination between the caterpillar and the guide wheel and can easily cause problems such as the deviation and bouncing of the caterpillar, which will affect the stability of the excavator, and can also accelerate the wear of the caterpillar.

PAZ wear: the groove in the middle of the guide wheel used for the clip is worn out, which is why the groove becomes larger, which can lead to easily slipping the path from the groove during operation and immediately from the rails.

Dear wear: due to the long load and the relative movement of the tsapf of the guide wheel and the bearing or sleeve wears out, which leads to an increase in the clearance in the landing, as a result of which the guide wheel begins to swing and get stuck during rotation, which affects its normal operation.

The failure of the bearing and shaft

Damage to the bearing: insufficient lubrication, prolonged overload, impurities and other reasons lead to the wear of balls, rolling paths and other components of the bearing, fatigue exfoliation, cracks and other damage, which leads to non -normal noise, vibration during the rotation of the guide wheel.

Wear and deformation of the shaft: with prolonged use, the shaft can wear out and deform due to uneven load, overload, etc. The wear of the shaft will reduce the accuracy of the installation, and the deformation of the shaft will lead to the displacement of the installation position of the guide wheel, which will affect the normal direction of the caterpillar, and It can also cause abnormal wear of other components.

Burning of the sleeve: the lubrication state between the shaft of the guide wheel and the sleeve deteriorates, and the boundary lubricant gradually goes into a state of partial dry friction, which leads to an increase in the temperature of the sleeve and its burnout.

Hermetization problems

Acting and damage to seals: after prolonged use, the seals are aging, hard, crack, etc., lose their sealing properties and cause a leak of lubricating oil. At the same time, extraneous impurities, such as dust and dirt, can easily penetrate the guide wheel, which will lead to acceleration of wear of parts and reducing the service life of the guide wheel.

Incorrect installation installation: if it is installed incorrectly when installing the sealing of the guide wheel, twisted or damaged, this can also lead to the exit of the seal, leakage of the oil and the penetration of pollution.

Installation and positioning errors

Weakened fasteners: the guide wheels fasteners can weaken due to vibration, shock, etc. during the excavator operation. The weakened bolts will change the position of the installation of the guide wheel, which will lead to uneven effort on the path, deviation, immediately from the rails and other problems.

Displacement of the position of the guide wheel: during installation or operation, the guide wheel can be shifted, for example, not in the same plane or on one straight wheel with a drive wheel, a support wheel, etc. This will lead to an abnormal force on the path during operation, It will accelerate the wear of the path and the guide wheel, and also increase the risk of traveling the track from the rails.

Tent

The tent cylinder malfunction: the tension cylinder is an important component for adjusting the tracked tension. If the oil seals of the tension cylinder is damaged or the piston is worn out, this will lead to a leak in the cylinder and will not be able to maintain normal caterpillar tension, making the caterpillar too free and prone to the rails.

The tent spring malfunction: the tensioner of some guide wheels uses the spring tension method. After prolonged use, the spring can weaken in elasticity or break, which will lead to insufficient stretching of the caterpillar.

Basic information:

Product features:

Part Name |

Track Ilder |

Packaging Details |

Standard Pallet |

Model |

CAT325 330 335 |

Warranty Time |

12 months |

Finish |

Smooth |

Delivery Time |

Within 15 Days After Contract Established |

Color |

Yellow |

Payment Term |

T/t |

Material |

35MNB |

Moq |

1 PCS |

Technique |

Forging / Casting |

Loading Prort |

Be negotiated |

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive