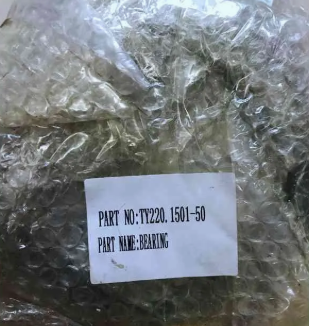

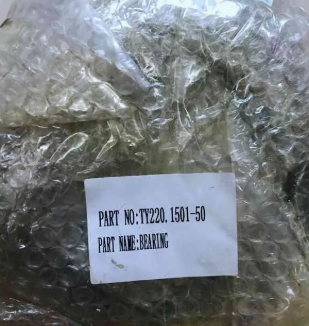

Zoomlion Ty220.1501-50 Bulldozer bearing

1. Excellent bearing capacity: a special design of the structure is able to withstand huge radial and axial loads, ensuring stable work of the bulldozer.

2. Durability: made of high -quality materials, subjected to surface hardening, wear -resistant, resistant to fatigue and has a long service life.

3. Accurate adaptation: adjusted to various types of bulldozers, has an exact size, easy to install and has high adaptability.

Product representation

1. General information about the product

Manufacturer: Zoomlion, one of the leading world manufacturers of construction and industrial equipment, known for its high -quality products and advanced technologies.

Bearing model: TY220.1501 - 50, designed specifically for GRARERS ZD220.

2. Technical characteristics and design

Type of bearing: [Clarify the type of bearing, for example, roller, ball, etc.]. It has a design that allows him to effectively fulfill his function in the working conditions of a grader.

Material: The main material of the bearing is high -quality steel, which provides strength and resistance to wear. Steel is subjected to special heat treatment, which increases its mechanical properties.

Buldozer bearing installation method

1. Preparation before installation

1. Preparation of tools and materials

Installation tools: Prepare various types of wounds, such as unfortunate, mate and end, for disassembling and installing parts associated with bearings, such as end covers, nuts on the shafts, etc. Prepare a copper rod and carefully tap it with the bearing in the bearing in the bearing in the bearing in the bearing installation time to ensure its smooth landing and avoid damage caused direct tapping. A press is also required. For some bearings with high requirements for planting with an tightening, press is required to ensure the accuracy and quality of the installation.

Measuring tools: Prepare measuring tools, such as a micrometer for measuring the external diameter and an hour -long type indicator for measuring the inner diameter to measure the size of the shaft neck and the internal diameter of the bearing to make sure that the accuracy of their correspondence meets the requirements. For example, having measured the size of the neck and comparing it with the internal diameter of the bearing, you can determine whether the tension is located within reasonable limits.

Lubricants: Prepare a suitable lubricant and select it in accordance with the working environment of the bulldozer and type of bearing. For example, in high temperature and high load conditions, you should choose a lubricant resistant to high temperatures and high loads. At the same time, prepare a cleaning tool for cleaning the installation site and the surface of the bearing from oil and pollution.

(II) Checking bearings and related details

Bearing check: Carefully check whether the bearing model corresponds to the bulldozer installation site correspond to its technical characteristics. Check the appearance of the bearing to make sure that there are no rolling defects, such as wear, cracks, potholes, etc., as well as in the absence of deformation or scratches on the inner and outer rings. Turn the bearing manually to feel whether it rotates smoothly and if there is no seal. If there are any deviations, it cannot be used.

Checking the shaft and landing opening: check whether the surface of the neck of the installed bearing, whether there are scratches, rust, deformation, etc., measure the size of the neck to determine whether they are within the tolerance. For the hole for the seading seat, check its inner diameter, roundness and cylindricalness to make sure that the accuracy of the hole for the seat meets the requirements. At the same time, check the roughness of the surface of the landing hole and, if necessary, perform the appropriate repair or grinding.

3. Preparation of the site and safety measures

Choosing a place: choose a flat, dry, well -ventilated and lit place, for example, a workshop in maintenance. Make sure that there are no obstacles around the venue that facilitate the work, and stay away from the sources of fire and flammable materials to prevent accidents.

Precautions: operators must use personal protective equipment, such as protective helmets, protective gloves and protective shoes. A protective helmet can protect the head from random blows, protective gloves can protect the hands from scratches and burns, and protective shoes can prevent blows on the legs with heavy objects. When using equipment such as press, strictly observe the operating rules in order to prevent mechanical injuries.

2. Stages of installation

1. Cleaning installation location

Use the cleaning product and clean fabric to thoroughly clean the surface of the neck and the planting opening of the bearing from oil, pollution, rust, etc. To remove oil spots, use the brush with a detergent, and then wipe dry fabric dry. After cleaning, apply a thin layer of lubricating oil to the surface of the neck and landing opening to facilitate the installation of the bearing.

Clean the surface of the bearing and remove anti -corrosion oil and pollution. Be careful not to damage the rolling elements and the surface of the bearing roller paths.

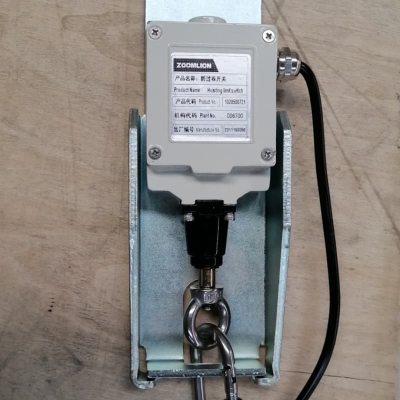

(II) installation of heating (applicable to bearings with an interference)

If the bearing and shaft are planted with an interference, the bearing must be heated during installation. Place the bearing in a special heating device, for example, a bearing heater. The heating temperature is usually controlled in the range of 80 - 120 ° C. Heating time is determined depending on the size and material of the bearing, usually 15 - 30 minutes. In the process of heating, pay attention to temperature control in order to avoid excessive heating, causing annealing the bearing and affecting its operational characteristics.

After the heating is completed, quickly put the bearing onto the shaft neck using a special tool and install it in place. During the insert process, make sure that the axial lines of the bearing and shaft neck coincide to avoid deviation. If at the place of installation of the bearing there is a fixing tube, then the inner ring of the bearing should be located close to the fixing buck.

(III) Installation with a press planting (applicable to some bearings with a fit with an interference and transitional landing)

For some bearings with a lower tightening or transitional planting for installation, you can use a press planting. Place the shaft horizontally on the bracket and place a suitable gasket, for example, a copper gasket or a special tool for installing a bearing, on the inner ring of the bearing.

Slowly pressing the press, press the bearing into the neck. In the process of pressing, the pressure of the press should be uniform in order to avoid the distortion of the bearing. At the same time, follow the position of installation of the bearing to make sure that it is installed correctly. Stop the pressing when the inner ring of the bearing complines with the installation beech or a label of the installation on the shaft.

(IV) install in the place of the bearing

Set the shaft knot with a bearing installed in the bearing nest. When installing, pay attention to the landing of the outer ring of the bearing and the landing hole so that their axial lines match. To facilitate the installation on the outer ring of the bearing, you can apply the corresponding amount of grease.

If the bearing housing has end covers, install the end covers after installing the shaft assembly. When tightening the end lid bolts, tighten them gradually along the diagonal to ensure uniform pressing of the end cover to the outer bearing ring and avoid uneven pressure on the bearing.

(V) Lubricant processing

After installing the bearing, fill it with the appropriate amount of lubrication. The volume of filling is usually 1/3 - 1/2 of the internal space of the bearing. Too much or too little lubricant can affect the normal operation of the bearing. When filling out, make sure that the lubricant is evenly distributed through the rolling bodies and the surfaces of the roller -rolling paths.

For bearings with oil lubricant, connect the lubricant to ensure uninterrupted supply of lubricating oil into the bearing. Check the lubricant for leaks. If there are leaks, timely eliminate them.

3. Check after installation

1. External inspection

Check the correctness of the mounting position of the bearing, the density of the adjacent of the inner ring of the bearing to the shaft neck, as well as the outer ring to the landing hole, as well as the absence of a backlash or displacement.

Check if the end cover is reliably installed and whether the end cover bolts are tightened to make sure that there are no missing or weakened parts.

Check the presence of lubrication or oil supply to provide normal lubricant.

(II) Rotation check

Turn the shaft manually to check whether the bearing rotates smoothly, whether there is no seal or excessive friction. Under normal conditions, the shaft should rotate easily, without extraneous noise and vibrations.

Run the bulldozer and let the shaft work for a while at low speed, then gradually increase the speed. During work, listen to the unusual noise of the bearing, such as sharp friction, knock or vibration. If any deviations from the norm are detected, immediately stop the car to check and eliminate malfunctions.

3. Temperature check

After the bulldozer works for some time, measure the temperature of the bearings using an infrared thermometer. Under normal conditions, the bearing temperature should be in the specified range, as a rule, without exceeding 80 ℃. If the temperature is too high, it can be caused by improper installation of the bearing, poor grease or excessive load. The reason must be found and eliminated on time.

Regularly check the changes in the temperature of the bearing to make sure that it is stable. If the temperature continues to grow, the bearing problem may have arisen, and further inspection and maintenance are required.

Primensed list for zoomlion:

But. |

Parts Number |

Description |

1 |

004904030A0201060 |

Pad - Track Frame |

2 |

004904030A0001190 |

Bushing Track Frame |

3 |

004904030A2000000 |

Oil Seal 80x105x13 Track Frame |

4 |

1080000206 |

Oil Cup / Nipple Grease |

5 |

004904030A0001290 |

Sleeve Track Frame |

6 |

004904030A0001300 |

Sleeve Track Frame |

7 |

004904030A0001260 |

Sleeve Track Frame Cover |

8 |

004904030A0001050 |

Oring- Recoll Spring |

9 |

004903030A5800000 |

Lubricator - Recoll Spring |

10 |

004904032A0001090 |

Track Shoe |

11 |

004904032A0001010 |

Track Link |

12 |

004904032A0001020 |

Track Link |

13 |

004904032A0001070 |

Bushing Track |

14 |

004904032A0001080 |

Dust Seal Track |

15 |

004904032A0001060 |

Pin |

16 |

004904032A0001050 |

Master Bushing -Track |

17 |

004904032A0200000 |

Dust Seal Track |

18 |

004904032A0001040 |

Master Pin - Track |

19 |

004904030A1410000 |

Carrier Roller |

20 |

1050200746 |

Rolling Bearing |

21 |

004904030A1401070 |

Oring Carrier Roller |

22 |

004904030A0601060 |

Oring |

23 |

004904030A1401040 |

Oring |

24 |

004904030A0601040 |

Oring |

25 |

004904030A0601040 |

Oring |

26 |

1081001464 |

Oring |

27 |

004904030A0601060 |

Oring |

28 |

004904030A3210000 |

Single Flange Track Roller |

29 |

004904030A3010000 |

Double Flange Track Roller |

30 |

004904030A0630010 |

Bushing Track Roller |

31 |

004904030A0601060 |

Oring |

32 |

004904030A0601060 |

Oring |

33 |

004904030A0601040 |

Oring |

No. |

Parts Code |

Description |

||||||||

1 |

004904030A0001050 |

Oring |

||||||||

2 |

004904030A0001060 |

Oil Seal |

||||||||

3 |

1081001901 |

Oil Seal |

||||||||

4 |

004904030A0001210 |

Oring |

||||||||

5 |

004904030A0001230 |

Sealing Ring |

||||||||

6 |

004904030A3200000 |

Single Flange Track |

||||||||

7 |

004904030A1410000 |

Carrier Roller |

||||||||

But. |

Parts Number |

Description |

1 |

004904030A0201060 |

Pad - Track Frame |

2 |

004904030A0001190 |

Bushing Track Frame |

3 |

004904030A2000000 |

Oil Seal 80x105x13 Track Frame |

4 |

1080000206 |

Oil Cup / Nipple Grease |

5 |

004904030A0001290 |

Sleeve Track Frame |

6 |

004904030A0001300 |

Sleeve Track Frame |

7 |

004904030A0001260 |

Sleeve Track Frame Cover |

8 |

004904030A0001050 |

Oring- Recoll Spring |

9 |

004903030A5800000 |

Lubricator - Recoll Spring |

10 |

004904032A0001090 |

Track Shoe |

11 |

004904032A0001010 |

Track Link |

12 |

004904032A0001020 |

Track Link |

13 |

004904032A0001070 |

Bushing Track |

14 |

004904032A0001080 |

Dust Seal Track |

15 |

004904032A0001060 |

Pin |

16 |

004904032A0001050 |

Master Bushing -Track |

17 |

004904032A0200000 |

Dust Seal Track |

18 |

004904032A0001040 |

Master Pin - Track |

19 |

004904030A1410000 |

Carrier Roller |

20 |

1050200746 |

Rolling Bearing |

21 |

004904030A1401070 |

Oring Carrier Roller |

22 |

004904030A0601060 |

Oring |

23 |

004904030A1401040 |

Oring |

24 |

004904030A0601040 |

Oring |

25 |

004904030A0601040 |

Oring |

26 |

1081001464 |

Oring |

27 |

004904030A0601060 |

Oring |

28 |

004904030A3210000 |

Single Flange Track Roller |

29 |

004904030A3010000 |

Double Flange Track Roller |

30 |

004904030A0630010 |

Bushing Track Roller |

31 |

004904030A0601060 |

Oring |

32 |

004904030A0601060 |

Oring |

33 |

004904030A0601040 |

Oring |

But |

Parts No |

Description |

Transmission Torque Converter Housing |

||

1 |

07002-43634 |

Oh, Ring |

2 |

07000-62070 |

Oh, Ring |

3 |

07000-63046 |

Oh, Ring |

4 |

07000-63046 |

Oh, Ring |

5 |

07000-63045 |

Oh, Ring |

Transmission and Case |

||

6 |

TY220.1501-60 |

Gasket |

7 |

TY220.15-14161 |

Gasket |

8 |

07000-02018 |

Oh, Ring |

9 |

07000-03032 |

Oh, Ring |

Transmission Gear and Shaft (1/3) |

||

10 |

TY220.1501-76 |

Planetary Carrier |

11 |

TY220.1501-3 |

Friction Disk |

12 |

TY220.1501-5 |

Brake Plate |

13 |

TY220.1501-2 |

Sealing Ring |

14 |

TY220.1501-94 |

Sealing Ring |

15 |

TY220.1501-7 |

Bearing |

16 |

HG4-692-67 |

Oil Seal |

17 |

09233-0512 |

Trust Washer |

18 |

0700-05125 |

O, ring |

19 |

07018-11805 |

Sealing Ring |

Transmission Gear and Shaft (2/3) |

||

20 |

TY220.1501-13 |

Sealing Ring |

21 |

TY220.1501-2 |

Sealing Ring |

22 |

07000-63022 |

O, ring |

23 |

TY220.1501-3 |

Friction Disk |

24 |

TY220.1501-5 |

Brake Plate |

Transmission Gear and Shaft (3/3) |

||

25 |

TY220.1501-54 |

Sealing Ring |

26 |

TY220.1501-62 |

O, ring |

27 |

TY220.1501-25 |

Sealing Ring |

28 |

TY220.1501-21 |

Friction Disk |

29 |

TY220.1501-20 |

Friction Disk |

30 |

TY220.1501-63 |

Wave Spring |

31 |

TY220.1501-27 |

Sealing Ring |

Transmission Control Valve (1/2) |

||

32 |

07000-03022 |

O, ring |

33 |

07000-03025 |

O, ring |

34 |

07000-03022 |

O, ring |

35 |

07000-03032 |

O, ring |

Transmission Control Valve (2/2) |

||

36 |

07000-03040 |

O, ring |

Transmission Control Valve Housing |

||

37 |

TY220.1502-6 |

Gasket |

38 |

TY220.1502-10 |

Gasket |

39 |

TY220.1502-42 |

Gasket |

40 |

TY220.21-4 |

Gasket |

41 |

07002-05234 |

O, ring |

42 |

07000-03028 |

O, ring |

TORQUE |

||

43 |

07000-02065 |

O, ring |

44 |

07201-51527 |

NUT |

45 |

TY220.49-15 |

PIPE |

Transmission and Pump |

||

46 |

T220.49.41 |

PUMP ASSY |

47 |

GB1235-76 |

O, ring |

48 |

GB1235-76 |

O, ring |

49 |

GB1235-76 |

O, ring |

50 |

GB1235-76 |

O, ring |

51 |

GB1235-76 |

O, ring |

52 |

T220.49.17.7 |

ELEMENT |

Transmission and Piping |

||

53 |

T220.49.19.17 |

ELEMENT |

54 |

07000-03032 |

O, ring |

55 |

07000-03022 |

O, ring |

56 |

07000-03028 |

O, ring |

Steering and Relief Valve |

||

57 |

07000-13042 |

O, ring |

58 |

07000-03042 |

O, ring |

Transmission and Filter |

||

59 |

07000-02065 |

O, ring |

60 |

GB1235-76 |

O, ring |

Steering and Filter |

||

61 |

T220.49.19.7 |

ELEMENT |

62 |

07000-02115 |

O, ring |

Exhibition cabinets

Acquaintance with the plant

The factory has a team of highly qualified and experienced engineers who continuously introduce technological innovation and improve products. At present, the company owns a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment, such as excavators, loaders, cranes, bulldozers and other machines. The products are characterized by high performance, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working environments around the world.

Awards and qualifiersFiction

Frequently Asked Questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipment

3. What logistics ways can we work for shipping?

1) For most countries in Europe, South America and Africa, etc., we can go by container or Roro through ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or railway.

3) For light spare parts in urgent requirement, we can send it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you ensure that you have delivered the goods to customers?

A: We will provide you with full shipping information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive