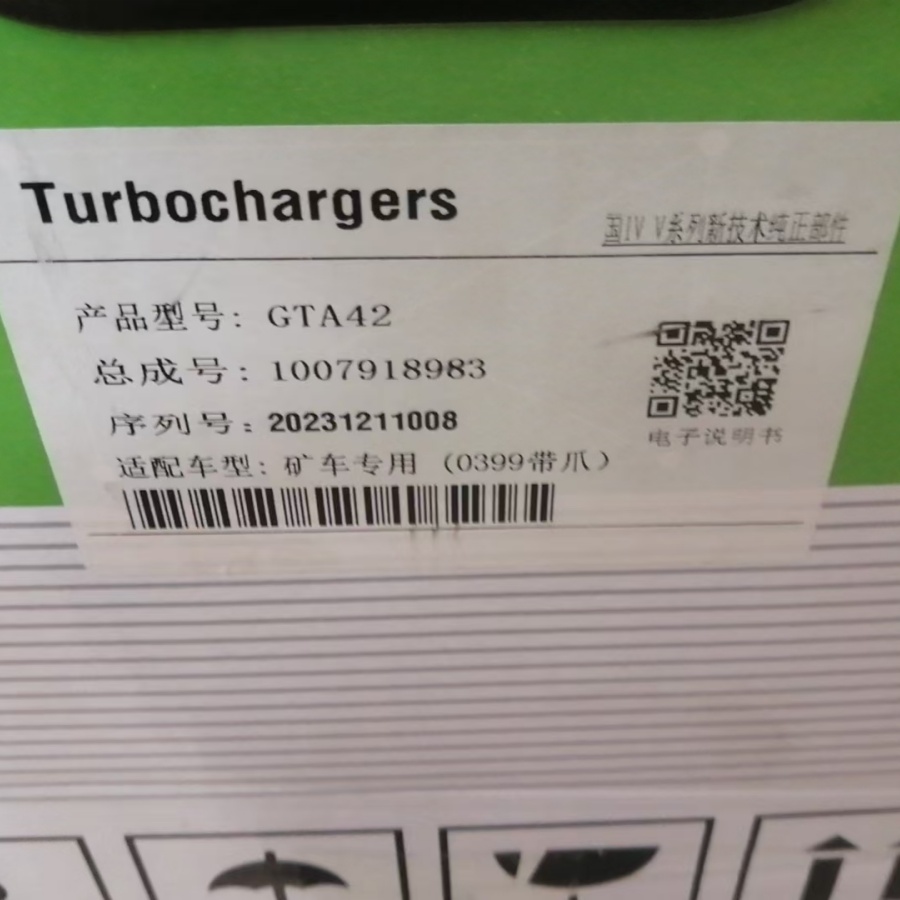

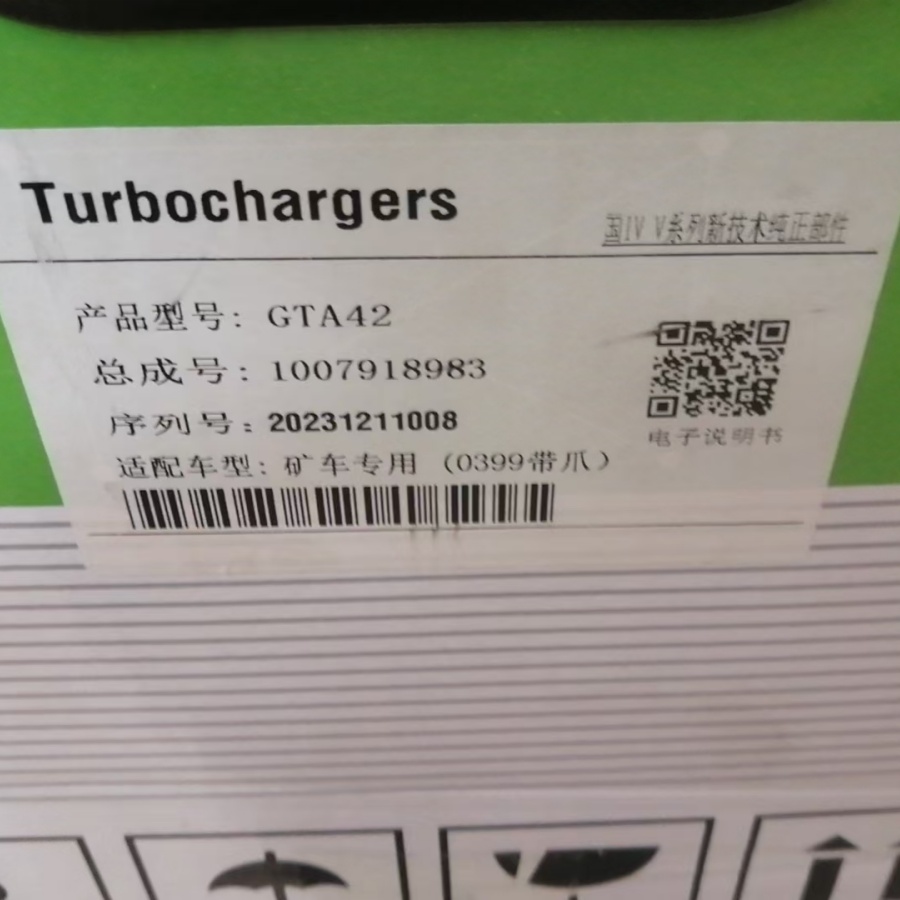

Weichai 1007918983 turbocharger

1 、 increased power : effectively increases the volume of flowing air into the engine, allowing you to burn more fuel and significantly increases the power and torque of the engine. This makes it powerful to carry out hard work, both when transporting goods and on construction sites.

2 、 accurate compatibility : is designed specifically for the corresponding models of Weichai engines, perfectly compatible with other components of the engine and system. This ensures the ease of installation and uninterrupted operation as part of the whole system.

3 、 Fuel saving : helps the engine more efficiently burn fuel, which increases the efficiency of the machine. This allows you to reduce fuel consumption and the cost of its acquisition.

Product representation

I. Operational parameters

Bost coefficient: Due to the wide range of boost coefficients, reaching 2.5-4.5 for common models, high boost coefficients allow the engine to maintain high combustion efficiency, despite the significant increase in the volume of the suction, which significantly increases the engine power by 30-50 % by 30-50 % Comparison with natural absorption engines.

Working speed: working speed is extremely high, usually in the range of 80,000 - 200,000 rpm. Such high speed allows you to quickly compress the air to meet the need for air intake under various working conditions, providing the engine with good performance when starting, accelerating and working with high load.

Efficiency: excellent performance indicators in which the Turbine efficiency is 70 - 85 %, and the compressor efficiency is 75 - 88 %. High efficiency means that more compressed air can be supplied to the engine with the same energy consumption, which improves fuel efficiency and reduces exhaust gas emissions.

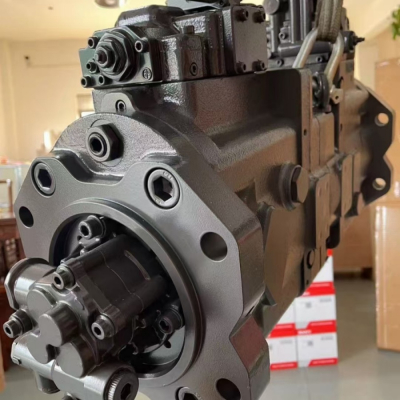

Secondly, the structure of the product

Turbine: mainly consists of turbine impeller and turbine corps. The turbine impeller is made of a frying high -strength rafting based on the nickel method by accurate casting, and the shape of its blades is optimized using aerodynamic design, which allows you to effectively convert the energy of exhaust gases emitted from the engine to mechanical energy and bring the turbine into rotation. The turbine case is made of heat -resistant cast iron or aluminum alloy with good thermal stability and tightness to ensure smooth rotation of the turbine impeller due to exhaust gases.

Compressor side: includes components such as the compressor work wheel, compressor housing and diffuser. The compressor impeller is usually made of aluminum alloy, light and strong enough to work stably at high rotation speeds. Its blades are designed to quickly compress the air and supply it to the inlet collector of the engine. The compressor case serves to collect and direction compressed air, and the diffuser increases the pressure and air density, allowing it to enter the engine more evenly and increasing the effectiveness of combustion.

Intermediate case: connects the end of the turbine and the end of the compressor, has an internal system of bearings and a lubrication and cooling device. The bearings system use floating bearings or ball bearings that withstand huge axial and radial efforts that occur during the rotation of the turbocharger at high speed, and ensure uninterrupted operation of the turbine and compressor. The grease and cooling device provides lubrication and cooling of bearings due to oil circulation, preventing bearings damage due to high temperature and friction, and also helps to reduce the total temperature of the turbocharger, increasing its reliability and service life.

III. Technical advantages

Turning -cross -section turbocharger technology (VGT): in some high -class models, a turbocharged technology with a variable section is used, which allows you to regulate the contraining pressure, depending on the working conditions of the engine by changing the angle of inclination of the turbine blades. Когда двигатель работает на низких оборотах, угол наклона лопаток турбины уменьшается, чтобы увеличить скорость потока выхлопных газов, повысить скорость реакции турбины, эффективно решить проблему гистерезиса турбины, так что двигатель может выдавать сильный крутящий момент и на низких оборотах; At high speeds, the angle of inclination of the turbine blades increases to improve the boost coefficient, fully revealing the potential of the engine power.

The use of ceramic bearings: some advanced Weichai turbochargers use ceramic bearings that have a lower friction coefficient, higher heat resistance and better wear resistance compared to traditional metal bearings. This allows not only to increase the efficiency of the turbocharger and reduce energy losses, but also to extend its service life and reduce service costs.

Advanced sealing technology: specially designed sealing rings and gaskets are used to effectively prevent oil leakage and exhaust gases to the end of the compressor. The sealing material has good heat resistance and oil resistance, which allows you to maintain stable tightness for a long time in severe operating conditions, ensuring the normal operation of the turbocharger, as well as preventing the pollution and damage of other engine parts.

Applicable models

Commercial transport: It is widely used in various types of weichai commercial transport, such as engines for heavy trucks of the WP10, WP12, WP13 series, these engines are widely used in long -range transportation, engineering construction and other areas, power and reliability requirements are extremely high. The turbocharger can significantly improve the characteristics of the engine power to satisfy the needs of commercial cars in heavy, climbing and other working conditions.

Construction equipment: used for loaders, excavators, bulldozers and other engines of construction equipment. For example, the engines of the WP7 and WP9 series usually used in loaders, together with turbochargers, can increase the efficiency of construction equipment so that it can work stably in various difficult construction conditions.

5. Method of installation

Preparation before installation: In order to avoid burns, make sure that the engine has cooled down. Prepare the necessary installation tools, such as wrenches, screwdrivers, dynamometric keys, etc. Check if the turbocharger model corresponds to the engine, whether all the components are intact and not damaged, especially the seal. At the same time, clean the mounting part of the engine to remove oil, pollution, etc. to prevent them from getting into the engine.

Remove the old supercharger (if any): with the help of a wrench, unscrew the bolts and nuts that attach the old turbocharger to the exhaust collector and the intake manifold, and carefully remove the old supercharger. Be careful to save the gasket, heat -protective screen and other parts of the old supercharger. If they are damaged, replace them with new ones. During the removal process, be careful not to damage the surrounding components, such as exhaust pipe, intake pipe, etc.

Install a new turbocharger: combine the turbine end of the new turbocharger with the exhaust collector, install the gasket and fix it with bolts and nuts, but do not tighten it. Next, connect the end of the compressor to the inlet collector of the engine, also install the gasket and pre -fix it. Then, using a dynamometric key, tighten the connecting bolts and nuts of the graduation and inlet collectors diagonally in accordance with the indicated puffing point to ensure a reliable connection and good sealing. Connect the intake oil pipeline and the return pipeline of the turbocharger, pay attention to the direction of the installation and tightness of the oil pipeline to prevent oil leakage. After installation, check whether the turbocharger is installed correctly and whether all connecting parts are tightened.

Debugging and checking: start the engine and let it work for a while at idle, and then check if there is an abnormal vibration, noise or leakage of oil in a turbocharger. Check if the pressure is normal. This can be done using the manometer of the boost of the engine or the corresponding diagnostic equipment. If any problem is detected, the engine should immediately be stopped for verification and restart for verification after eliminating the malfunction.

6. Precautions when using

Launch and preliminary heating: after starting the engine, do not launch it at high speed and do not load it immediately. Let the engine idle for 3-5 minutes so that the oil completely lubricates the turbocharger bearings and other components, and let the turbocharger achieve a certain operating temperature to avoid damage to the components due to poor lubrication or uneven temperature.

Stop and cooling: before stopping the engine, he should let him work at idle for 3-5 minutes, so that the turbocharger gradually cooled and prevent the hair stings in a turbocharger due to a sharp stop, which can affect its service life. If the engine must be stopped immediately after working with a high load, you can let it work for some time at idle, and then drown out or use the cooling system of a turbocharger with a delay function.

Motor oil and filter: Use high -quality motor oil that meets the requirements of Weichai, and regularly change the engine oil and oil filter. Poor -quality engine oil or filter can lead to wear of the turbocharger bearings, clogging the lubricant system and affect the normal operation of the turbocharger. It is usually recommended to replace motor oil and filter every 5000 - 10,000 kilometers. A specific replacement cycle can be adjusted in accordance with the use of the vehicle and the recommendations of the manufacturer.

Air filter maintenance: regularly check and replace the air filter to provide unhindered air access. A dirty air filter will increase the absorption resistance, which will lead to a decrease in the boost effect of a turbocharger and can even lead to a turbocharger of such impurities as dust, which will lead to damage to the impeller and bearings. As a rule, the air filter should be checked every 10,000-15,000 km and, if necessary, replace it.

Avoid sharp accelerations and slowdown: during movement, try to avoid frequent sharp accelerations and slowdown, as this will lead to stronger pressure drops in a turbocharger, which can easily lead to damage to the components. The smooth operation of the engine helps to extend the life of the turbocharger.

Regular inspection: regularly check the appearance of the turbocharger for leakage of oil, air, weakening fasteners, etc. At the same time, you can judge the working condition of the turbocharger, determining indicators such as the pressure of the engine and exhaust gases emissions. If you detect any malfunctions, timely repair or replace them.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive