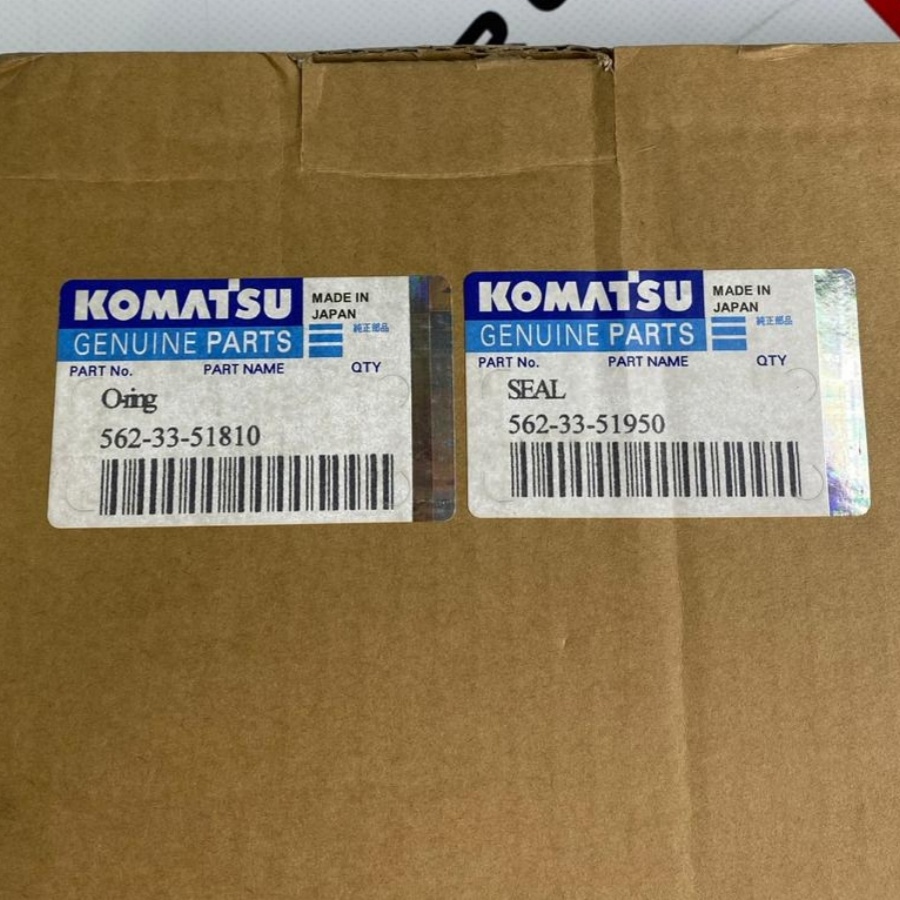

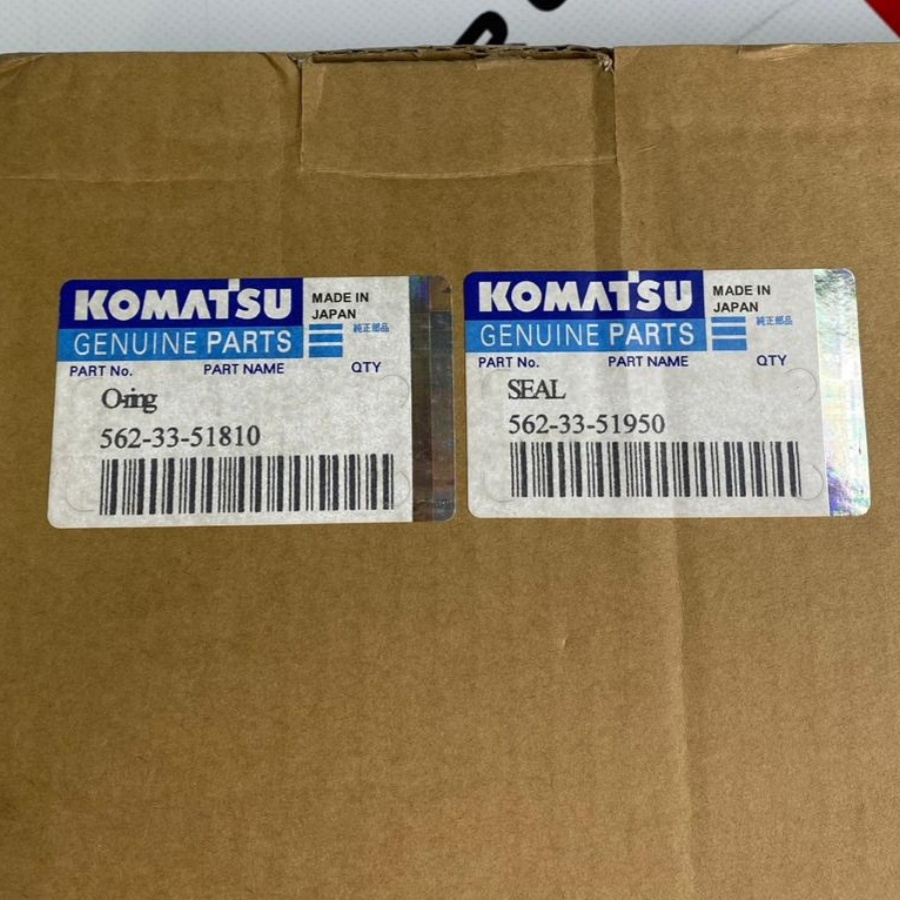

Komatsu 562-33-51810 sealing sealing original

1 、 High tightness : These sealing rings o provide excellent tightness, effectively preventing fluid and gas leaks. This allows you to maintain the integrity of the system and its effective work.

2 、 High strength and durability : are made of strong and resistant material that can withstand strong mechanical loads, temperature fluctuations and chemical effects. This guarantees a long service life and rare breakdowns.

3 、 exact compatibility : specially designed for equipment 小松, are perfectly compatible with other components of the system. This ensures the ease of installation and reliable operation as part of the whole system.

Product representation

Detailed product information

Structural composition: usually consists of a pair of wear -resistant metal rings (floating sealing rings) and a pair of rubber rings. A floating sealing ring consists of an internal metal ring and an external metal ring. The internal metal ring can rotate along with the shaft, while the outer metal ring is fixed. The rubber ring is installed between the back of the floating sealing ring and the saddle of the floating sealing ring to play the role of positioning and ensuring elastic compensation. In addition, it can be equipped with a spring to maintain tension of the sealing ring.

Material characteristics: a floating sealing ring is usually made of special chromomolibden cast iron with a chromium content of 15%, molybdenum 1-3%, hardness HRC65-72, with high wear resistance, high hardness and corrosion resistance. Rubber rings are usually made of oil -resistant and resistant to the aging of rubber materials.

The principle of operation: due to the elasticity of the rubber ring, during the operation of the equipment, even with vibration, movement, swing, etc., the sealing surface of the metal ring can maintain an effective planting, provide dynamic seal, prevent leakage of lubricant oil and prevent external pollutants from entering,, Such as dirt, water, sand, etc., inside equipment.

Technical characteristics and dimensions: various technical characteristics, the dimensions of the external diameter are usually in the range from 50 mm to 1425 mm.

Type: standard type, type L, type XY, etc.

Stages of installation

Preparation: thoroughly clean the installation parts, including the corresponding shafts, cavities, etc., remove oil, dust, pollution, etc. And make sure that there are no particles left. Also prepare suitable lubricants and special mounting tools.

Check the components: carefully check the static and dynamic rings of floating oil seals to make sure that there are no damage, deformations, aging, etc., as well as that the sizes correspond to the shaft of the equipment and the mounting cavity.

Install the motionless ring: apply a thin layer of lubricant to the surface of the motionless ring and installation site, and then, using bolts or other fasteners, securely secure the motionless ring on the stationary part of the equipment to ensure its reliable installation and accurate positioning.

Install the movable ring: apply grease to the surface of the moving ring and shaft and carefully install the movable ring on the shaft. Pay attention to the correct direction of the installation and do not damage and do not bend the mobile ring during installation.

Press in place: use a special mounting tool to evenly and effort to press the floating oil seal into the installation position, making sure that it has completely risen in place and tightly adjacent to the installation surface.

Adjustment: after installation, check whether the gap between the static ring and the dynamic ring corresponds to guarantee the absence of foreign substances or pollution between the sealing surfaces. Turn the shaft to check whether the floating oil seal is moving smoothly and if there is no seal or abnormal resistance.

Common errors

Verification: the rubber ring can grow old, damage and lose elasticity, which makes it unable to ensure a good compaction; or the metal ring can be worn out, crack or deformed, which will lead to a loose fit to the sealing surface; It can also be caused by pollution on the sealing surface during installation, an incorrect clearance during installation or improper installation.

Wear: prolonged work in severe conditions, such as high dustiness, dirt and water, accelerates the wear of metal and rubber rings; vibration and blows during the equipment are large, which forces a floating oil seal to withstand a large load, and also leads to increased wear; In addition, insufficient lubrication or low quality of lubricating oil also increases friction and cause wear.

Strengthening: the entry of extraneous substances on a sealing surface or aging, hardening or deformation of the rubber ring can lead to the stuck of a floating oil seal during operation, which will violate its normal floating and sealing functions.

After -sales service

Warranty service: As a rule, floating oil seals for the Komatsu career dump trucks have a certain warranty period. During the warranty period, if the malfunction occurs due to problems with product quality, you can use free repair or replacement services.

Technical support: Komatsu or its authorized dealers will provide users with technical support, including installation manual, operating instructions, elimination of malfunctions and other services. If users have problems during use, they can contact technical personnel by phone, e-mail, through the online customer support service, etc. To obtain professional solutions.

Supplies of accessories: a comprehensive system of supplies of accessories was created that guarantees the timely supply of original accessories if it is necessary to replace the floating oil seal or its parts, which guarantees the quality and compatibility of accessories.

Regular repeated visits: we can hold regular repeated visits to users to understand the use of the product and its working condition, as well as collect user reviews in order to constant improve the quality of the product and maintenance.

Swimming seals have a wide range of important applications on Komatsu career dump trucks, mainly in key areas where it is necessary to prevent lubricant leakage and external pollution falling, namely:

The axis system: the axis of the Komatsu career dump trucks is a key component that carries the weight of the vehicle and transfers power. Swimming oil seals are usually used in the joints of the wheel hub with the bridge pennant, the chief gearbox and other details. These details withstand heavy loads and twisting moments during the movement of the vehicle, and are also exposed to uneven roads and vibrations. Swimming oil seals effectively prevent leakage of lubricating oil from these parts, providing good lubrication of gears, bearings and other components inside the axis and reducing wear. At the same time, he can also prevent external pollutants, such as dirt, sand, water, etc., inside the axis, preventing damage to the components with these pollution and prolonging the service life of the axis.

Wheel gearbox: A wheel gearbox of a career dump truck should work in difficult conditions, and its internal gears and bearings require reliable sealing protection. The floating oil seal is installed in the key position of the wheel gearbox. It can adapt to a relative movement and vibration created by a wheel gearbox during operation, maintain good tightness, prevent leakage of lubricating oil and the penetration of external pollution, as well as ensure the normal operation and effectiveness of the transmission of a wheel gearbox.

The steering system: floating oil seals are also used in the steering system of the Komatsu career controls, for example, in the connection between a swivel fist and a pins. The steering system will often rotate and swing when the car turns. Elastic sealing characteristics of floating oil seals can adapt to this dynamic working environment, prevent the leakage of lubricating oil, provide lubrication of various components of the steering system and prevent the effect of the flexibility and reliability of the steering system and ensuring the safety and stability of the steering of the steering .

The connection of the drive shaft: the drive shaft is an important component that transfers the engine power to the axis. The floating oil seal plays a key role in the connection between the drive shaft and the transmission, the axis and other components. These compounds are subject to leakage of lubricating oil due to high-speed rotation and changing the angle of rotation of the drive shaft. Swimming oil seals can effectively seal these parts, ensure the normal operation of the drive shaft, reduce energy loss when transmitting power and prevent external pollution and deterioration of the drive shaft.

Suspension system: The Komatsu career suspension system is subjected to greater impacts and vibration during movement. Some key components are inside, such as shock absorbers and connecting parts of the suspension levers, can also use floating oil seals. Swimming oil seals can prevent leakage of lubricating oil in these details, maintain a suspension system in good working condition and at the same time prevent dust, dirt and water from the outside, protect the components of the suspension system and increase the comfort and stability of the vehicle.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive