Product introduction

1. Design feature of the baking powder assembler 222-84-B0000

The 222-84-B0000 cultivator assembler features a robust and compact design that combines high load capacity with smooth operation. Key components include the working teeth, frame, hydraulic cylinders, and fasteners—each made from high-quality materials and subject to strict quality control.

Working teeth: Made of 40CrNiMoA alloy steel (according to Chinese standard GB/T 3077), which is characterized by high hardness (HRc 58-62 after carburizing and tempering) and wear resistance. The length of each tooth is 320 mm, the width of the base is 80 mm, and the tip has a sharp profile with a radius of curvature of 5 mm - this ensures high penetrating ability into hard soil (pressure per point up to 150 MPa). Each tooth is equipped with a removable protective tip made of H13 steel (hardness HRc 55-57), which can be replaced individually when worn - reducing maintenance costs by 30-40% compared to disposable teeth.

Frame (frame): The main frame is made of Q690D plate steel (tensile strength up to 730 MPa), which is resistant to deformation under intense loads. The frame design has a closed section with stiffening ribs (rib pitch - 150 mm), which increases its rigidity by 25% and prevents bending when loosening rocks. The frame dimensions are adapted to the Shantui technique: length - 1200 mm, width - 350 mm, height - 480 mm. At the same time, the frame weight is 280 kg, which does not overload the hydraulic system of the equipment and maintains maneuverability.

Hydraulic cylinders: The kit includes two double-acting hydraulic cylinders with a piston diameter of 120 mm and a stroke of 250 mm. The cylinders are made of 27SiMn steel (tensile strength up to 680 MPa), and the internal surface is smoothly machined (roughness Ra ≤ 0.8 μm) - this reduces friction and extends the life of the seals. The sealing elements are made of material 聚氨酯 (PU) with the addition of fluoroplastic - they are resistant to high temperatures (+100 °C) and Shantui HM 46 hydraulic oils. The cylinders are controlled by an electronic distributor, which allows you to adjust the speed of the teeth and their inclination angle (from 0° to 30°) - this adapts the loosening agent to different types of soil.

Fasteners: The assembler is secured to Shantui equipment using M24×100 hexagon-head bolts made of grade 10.9 steel (ISO 898-1), which have high compressive strength (up to 1000 MPa). Each bolt is equipped with a 65Mn steel washer and elbow nut (prevents self-loosening due to vibration). Also included are CuSn10Pb10 bronze guide plates, which reduce friction between the frame and the equipment body and ensure smooth installation.

2. Technical characteristics and compliance with standards

The 222-84-B0000 loosening aggregate assembler fully complies with Shantui specifications and international standards for heavy construction equipment. Key specifications include:

Part number: 222-84-B0000 (matches the original Shantui part number, ensuring compatibility with equipment).

Shantui adaptable models: Bulldozers SD22, SD32, SD42; excavators SE210, SE240, SE300 (all modifications produced since 2018).

Drive type: Hydraulic (requires an operating pressure of 25–30 MPa and an oil flow rate of 40–50 l/min).

Number of working teeth: 3 (optionally 2 or 4 teeth can be installed for specific tasks).

Maximum loosening force: 80 kN (for hard soil with a density of 2.2 g/cm³).

Operating temperature range: -30 °C to +80 °C (resistant to extreme climatic conditions).

Total weight of the assembler: 450 kg.

Warranty period: 1.5 years or 2000 working hours (when used in accordance with Shantui recommendations).

The product is certified in accordance with key international standards:

ISO 9001:2015 (quality management system – guarantees stability of parameters at all stages of production).

ISO 12100:2010 (safety of machinery - design to prevent injury to the operator during operation).

GB/T 3766-2015 (Chinese standard for hydraulic systems - cylinders meet the requirements for tightness and durability).

EN 13000:2010 (European standard for bulldozers and rippers - confirms performance in difficult conditions).

3. Advantages compared to analogues

The 222-84-B0000 baking powder assembler has a number of key advantages that make it a preferred choice for Shantui appliance owners compared to other brands of baking powder or non-genuine products:

Highly efficient loosening: Thanks to sharp 40CrNiMoA steel teeth and an adjustable tilt angle (0°–30°), the assembler quickly breaks up hard soil, frozen ground (down to -30°C), and soft rock (e.g., sandstone, siltstone). In highway construction tests, it processed 150 m² of land in 1 hour—20% faster than a similar XCMG brand loosener.

Strength and Durability: The use of Q690D steel for the frame and 27SiMn cylinders ensures resistance to deformation and wear. When used in a quarry (where vibrations and loads are high), the service life of the working teeth reaches 800 working hours - while the teeth of non-original openers wear out after 300–400 hours. Removable tip guards further extend tooth life, reducing replacement costs.

Ease of installation and adaptability: The assembler has standard mounting points that replicate the original Shantui baking powder - installation can be performed by two specialists in 1.5–2 hours without the use of special equipment. Hydraulic cylinders with adjustable speed allow you to adapt the work to different types of soil: for example, for soft soil, low speed is used (overload protection), and for hard soil, high speed is used (increasing loosening force). The kit also includes an installation diagram and an instruction manual in Russian - this is convenient for operators in the CIS countries.

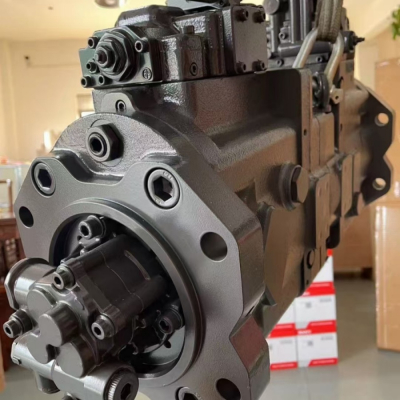

![Shantui 222-84-B0000 Soil ripper assembly Shantui 222-84-B0000 Soil ripper assembly]()

![Shantui 222-84-B0000 Soil ripper assembly Shantui 222-84-B0000 Soil ripper assembly]()

![Shantui 222-84-B0000 Soil ripper assembly Shantui 222-84-B0000 Soil ripper assembly]()

![Shantui 222-84-B0000 Soil ripper assembly Shantui 222-84-B0000 Soil ripper assembly]()

![Shantui 222-84-B0000 Soil ripper assembly Shantui 222-84-B0000 Soil ripper assembly]()

![Shantui 222-84-B0000 Soil ripper assembly Shantui 222-84-B0000 Soil ripper assembly]()

Exhibition cabinets

![Exhibition cabinets Exhibition cabinets]()

Getting to know the plant

The plant employs a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. The company currently owns a number of independent intellectual property rights and patented technologies. The construction equipment produced includes a wide range of equipment such as excavators, loaders, cranes, bulldozers and other machines. Products are characterized by high performance, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to challenging operating conditions in a variety of climates and operating environments around the world.

![Getting to know the plant Getting to know the plant]()

Awards and qualificationsfication

![Awards and qualifications Awards and qualifications]()

frequently asked questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2.What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipment

3.What logistics methods can we use for delivery?

1) For most of Europe, South America and Africa etc. countries, we can go by container or Roro via ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or rail.

3) For light spare parts in urgent requirement, we can ship it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you guarantee that you have delivered the goods to customers?

A: We will provide you with full delivery information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable quality: Carefully select reliable manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by ourselves, always adopting the best materials.

2) Competitive price: Concentration of mechanized production in large quantities reduces production costs to ensure competitive price.

3) Service Team: Firstly, our sales managers are available 24/7, ready to answer your questions at any time. Secondly, our professional technical support team, with senior technicians, is ready to provide support to users and dealers. Most issues can be resolved within 24 hours.

4) Fast delivery: Generally, we can delivery within 10 working days in factory after receiving the advance payment from customers.

6. How can you provide after-sales service to customers?

A: We will reply you at the first time and help you solve the problems within 24 hours. If we really need your local, we

We will send your professional person to your locality to help you solve the problems without any hesitation, supply you with all-round