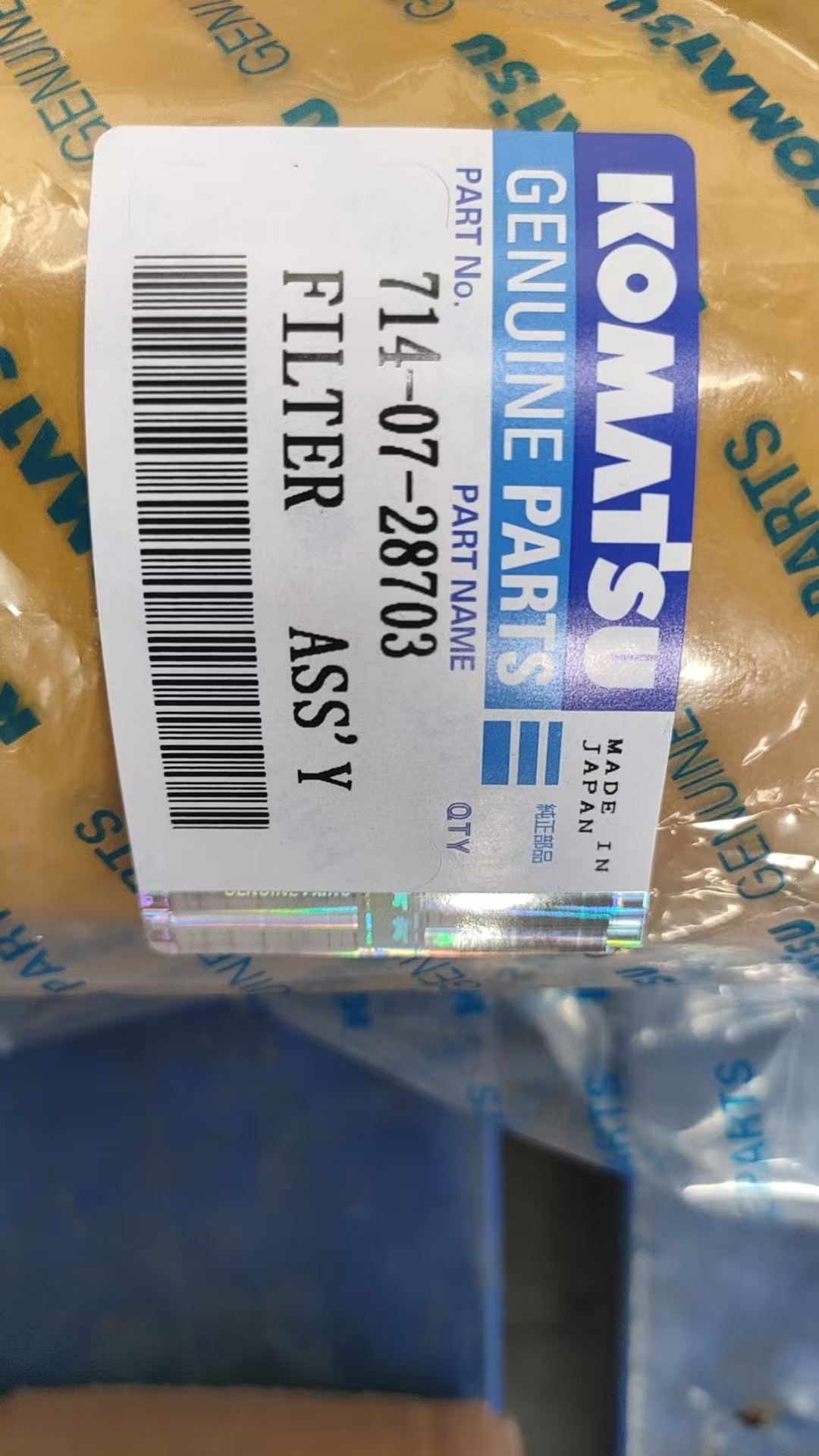

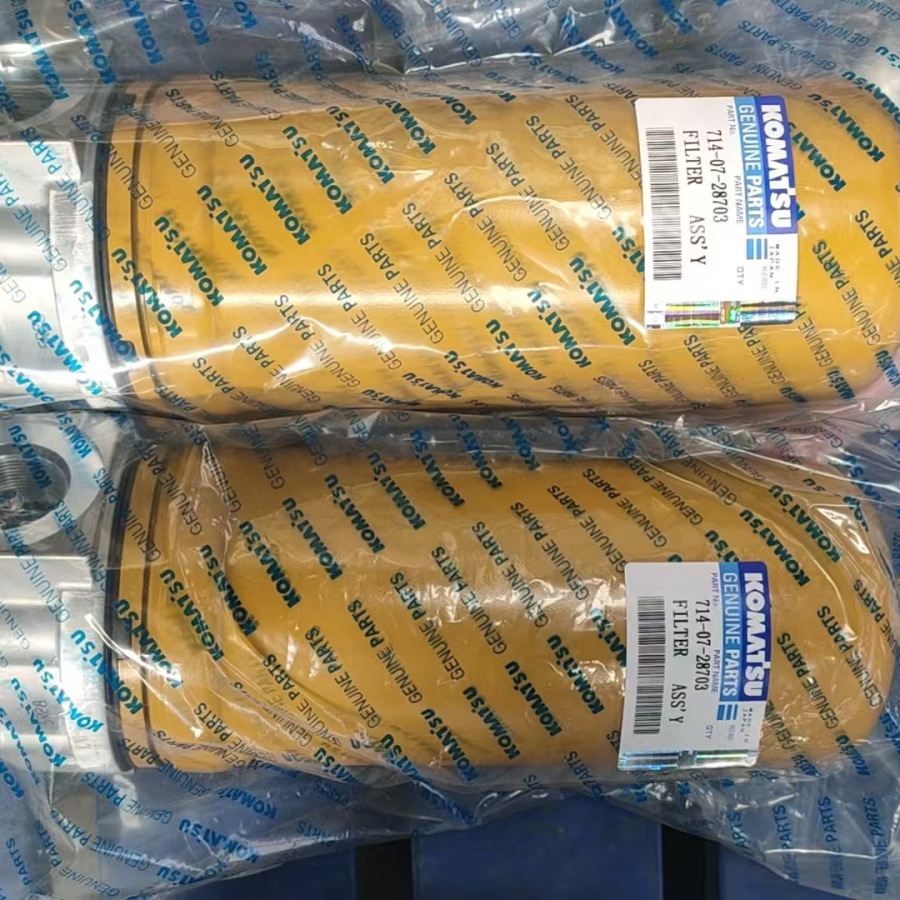

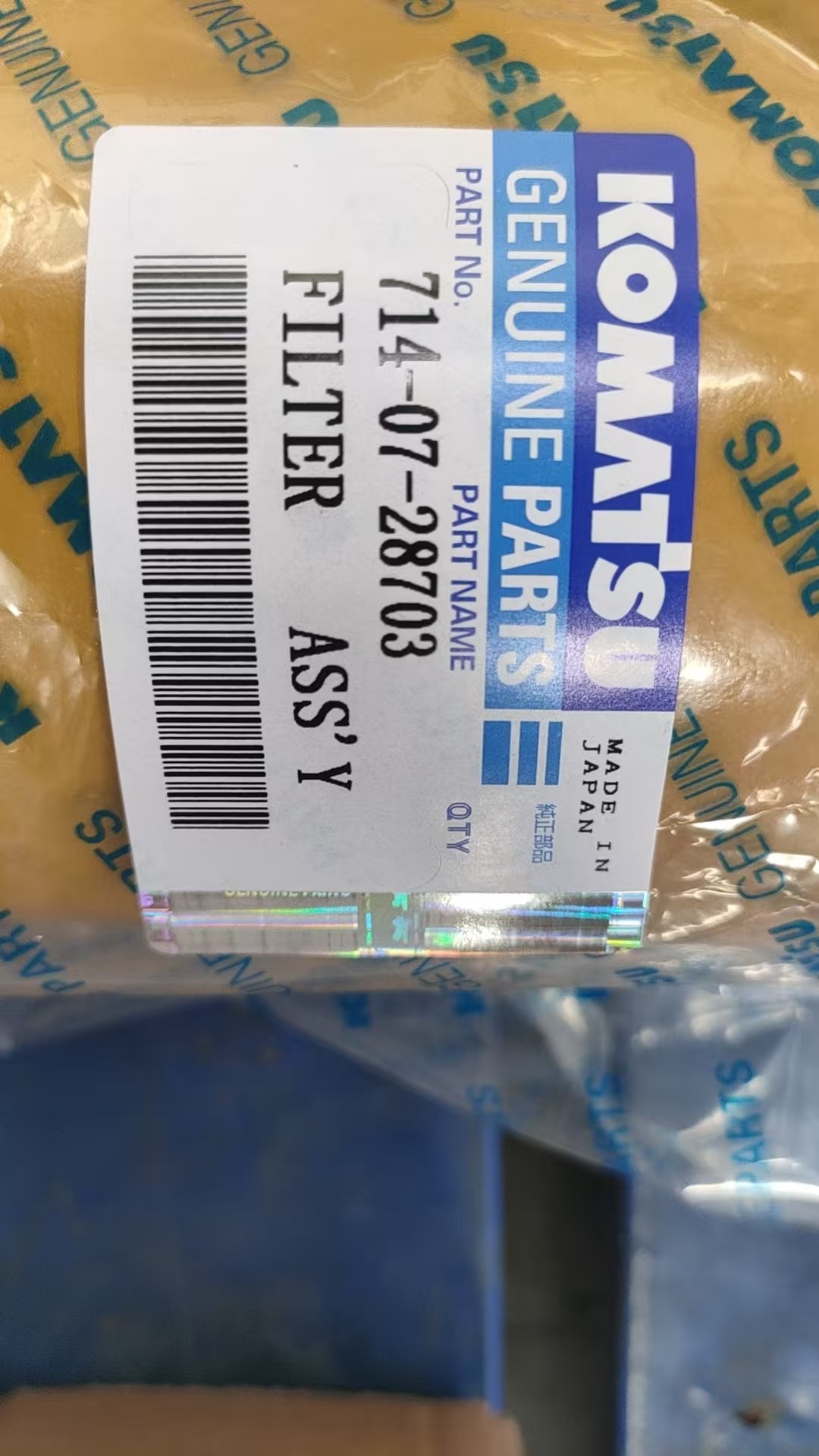

Komatsu 714-07-28703 Filter Unit

1. High filtration efficiency - retains up to 99% of contaminants, protecting the Komatsu hydraulic system from wear.

2.Strength and Durability - Made of durable materials, it guarantees stable operation under harsh conditions with a 1-year warranty.

3. Perfect compatibility - article 714-07-28703 fully complies with the original Komatsu requirements and is easy to install without any adaptations.

Product Introduction

1. Design feature of filter element 714-07-28703

Filter element 714-07-28703 features a multilayer design optimized for maximum filtration efficiency and durability. Key components include filter media, housings (outer and inner), sealing elements, and fasteners—each made from high-quality materials that meet Komatsu manufacturer standards.

Filter material: Synthetic polyester fiber with high density (2.5 g/cm³) and porosity of 10 microns is used. This material has two key advantages: firstly, it retains up to 99.5% of small particles (including metal bran 5-10 microns in size, which are the main cause of wear of hydraulic pumps), and secondly, it has high permeability to fluid (throughput up to 15 l/min), which does not create excess pressure in the system. The surface of the material is treated with a hydrophobic composition - this prevents the accumulation of moisture (which causes corrosion of metal components) and increases the service life of the filter by 25-30% compared to cellulose analogues.

Housings: The outer housing is made of impact-resistant plastic polyamide 66 (PA66) with the addition of glass fiber (30% content) - the material is resistant to temperature changes (-40 ° C to +120 ° C) and chemicals (gasoline, diesel fuel, Komatsu HD 46 hydraulic oils). The internal supporting frame is made of thin-sheet steel 08KP, galvanized - it prevents deformation of the filter material at high pressure in the system (up to 30 MPa). The dimensions of the housing exactly repeat the original filter: height 180 mm, diameter 95 mm, internal mounting diameter 30 mm - thanks to this, the element can be easily mounted in standard Komatsu filters without additional adaptations.

Sealing elements: The kit includes two seals made of elastic nitrile rubber (NBR) - upper (diameter 95 mm) and lower (diameter 30 mm). The seals have a “D” shape with a ribbed surface, which ensures a tight connection with the filter housing and prevents “slipping” of unfiltered liquid into the system. NBR material is resistant to wear and aging - the service life of the seals is up to 2 years if used correctly.

Fasteners: 12X18H10T stainless steel metal fasteners are provided to secure the filter media to the internal frame. The fasteners are made in the form of M4×8 threaded bolts with washers - they provide reliable fixation and can be easily disassembled when it is necessary to replace the material (although filter 714-07-28703 is intended for one-time use, this is convenient for recycling components).

2. Specifications and compliance

Filter element 714-07-28703 fully complies with Komatsu technical requirements and undergoes strict quality control at all stages of production, from material manufacture to final packaging. Key specifications include:

Part number: 714-07-28703 (matches the original Komatsu number, guaranteeing compatibility with the equipment).

Komatsu equipment models: Designed for use in hydraulic systems and fuel circuits of the following models: PC200-8, PC220-8, D65EX-17, WA380-7, GD655-5 (as well as all modifications of these models produced since 2015).

Filtration type: Hydraulic/fuel (universal for use in both systems, depending on the equipment configuration).

Particle size retained: 10 µm (99.5% efficiency according to ISO 4572).

Flow rate: 15 l/min (at 10 MPa pressure).

Maximum working pressure: 30 MPa.

Operating temperature range: -40 °C to +120 °C.

Element weight: 380 g.

Service life (recommended): 200 working hours (or 3 months - depending on the intensity of use and the degree of pollution of the working environment).

Warranty period: 1 year from date of purchase (subject to use in accordance with Komatsu recommendations).

In addition, the product is certified in accordance with international standards:

ISO 16889:2018 (standard for hydraulic system filters - confirms filtration efficiency and safety in use).

ISO 9001:2015 (quality management system – guarantees consistent quality at all stages of production).

SAE J1839 (heavy equipment component standard - certifies compatibility with Komatsu electronics and mechanics).

3. Advantages compared to analogues

The 714-07-28703 filter element has a number of key advantages that make it the preferred choice for Komatsu equipment owners, compared to non-original filters or similar products from other brands:

High filtration efficiency and system protection: Thanks to a synthetic material with a density of 10 microns, the element retains almost all small contaminants, including metal debris, sand particles, and corrosion products. This prevents wear on hydraulic pumps, motors, and valves—according to service prices.

Exhibition cabinets

Getting to know the plant

The plant employs a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. The company currently owns a number of independent intellectual property rights and patented technologies. The construction equipment produced includes a wide range of equipment such as excavators, loaders, cranes, bulldozers and other machines. Products are characterized by high performance, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to challenging operating conditions in a variety of climates and operating environments around the world.

Awards and qualificationsfication

frequently asked questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2.What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipment

3.What logistics methods can we use for delivery?

1) For most of Europe, South America and Africa etc. countries, we can go by container or Roro via ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or rail.

3) For light spare parts in urgent requirement, we can ship it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you ensure that you deliver the goods to customers?

A: We will provide you with full delivery information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable quality: Carefully select reliable manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by ourselves, always adopting the best materials.

2) Competitive price: Concentration of mechanized production in large quantities reduces production costs to ensure competitive price.

3) Service Team: Firstly, our sales managers are available 24/7, ready to answer your questions at any time. Secondly, our professional technical support team, with senior technicians, is ready to provide support to users and dealers. Most issues can be resolved within 24 hours.

4) Fast delivery: Generally, we can delivery within 10 working days in factory after receiving the advance payment from customers.

6. How can you provide after-sales service to customers?

A: We will reply you at the first time and help you solve the problems within 24 hours. If we really need your local, we

We will send your professional person to your locality to help you solve the problems without any hesitation, supply you with all-round