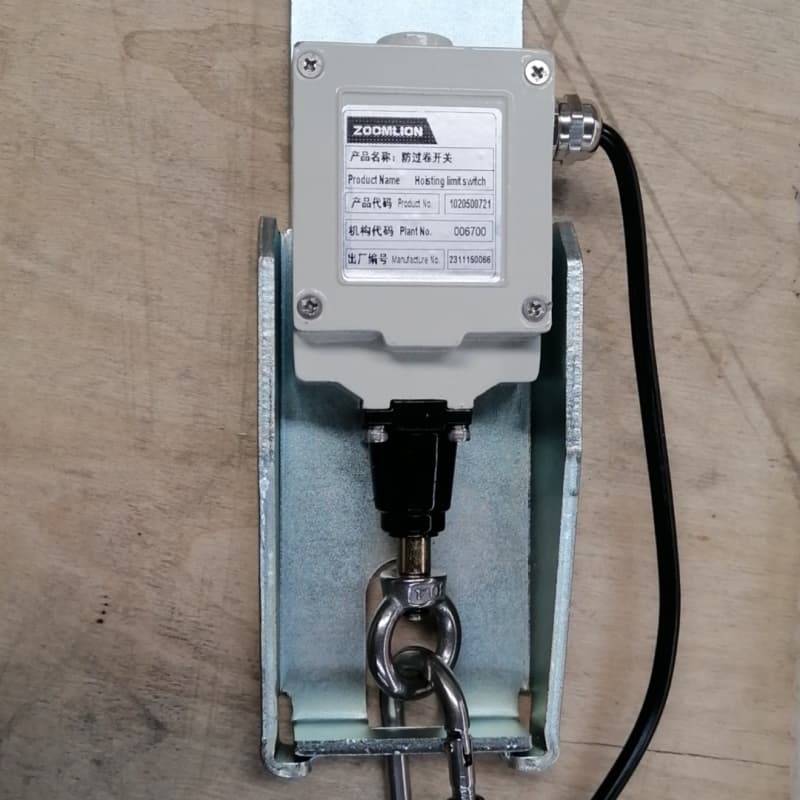

1020500721 Anti-rollover hazard warning switch GJ-3

1. Extremely fast alert for safety: millisecond response, early roll warning, effectively reducing the risk of accidents and ensuring the safety of personnel and equipment.

2. Wide temperature range and stable performance: It can adapt to high temperature environments from -50℃ to high temperatures, and can work stably regardless of extreme cold or heat.

3. Convenient installation and maintenance: modular design, easy installation, no need for major structural changes; convenient fault diagnosis and easy maintenance.

4. Very cost-effective choice: the performance is comparable with European and American products, the price is affordable, the durability and replacement need is minimal, which reduces the overall cost.

Product representation

1. General idea of a warning switch about the risk of skew 1020500721 GJ-3

Switch 1020500721 GJ-3 is a key component of the safety system of heavy special equipment, designed to timely detect the threat of skewing of the machine and transmit the warning signal to the operator. It refers to sensory devices with a mechanical or electronic principle of action, adapted for operation in difficult conditions: vibrations, dust, moisture and temperature fluctuations typical of construction sites, quarries, agricultural lands and mining objects.

Unlike standard warning devices, GJ-3 is characterized by high sensitivity and accuracy of determining the angle of tilt of the technique-this allows it to respond to minimal deviations from a safe position. The main objective of the product: protecting the operator, technology and environment from accidents caused by distortion (for example, when the excavator was working on unequal soil, lifting heavy cargo or maneuvering on steep slopes). Due to the reliability and ease of integration, 1020500721 GJ-3 is actively used in the technique of brands Shantui, XCMG, Liugong and other manufacturers of heavy equipment, confirming the effectiveness of ensuring operations.

2. Technical characteristics of the warning switch about the risk of skew 1020500721 GJ-3

2.1 Work parameters and sensitivity

Sensor type: Two-axis angular sensor (along the X-axis — horizontal and Y-axis — vertical) with a mechanical trigger. Allows you to control the tilt of equipment in two planes — critically important for machines with a high center of mass (excavators, loaders).

The tilt angle measurement range is ±30° on both axes – sufficient for most types of heavy equipment in standard and difficult conditions. The maximum permissible angle for safe operation is 15°; if it is exceeded, a warning signal is activated.

Measurement accuracy: ±0.5° in the range of 0–20° of tilt. High accuracy eliminates false signals and ensures timely response to a real threat.

Response speed: ≤100 ms. Rapid activation of the warning gives the operator time to take corrective action (lower the bucket, change the direction of travel).

2.2 Electrical parameters

Supply voltage: 12V or 24V DC - compatible with most heavy equipment electrical systems (12V for light duty, 24V for larger equipment such as 20-30 ton class excavators).

Current consumption: ≤50mA in standby mode, ≤150mA in active signal mode. Low power consumption does not overload the battery.

Output signal type: Push-pull (to control panel):

Light signal: Red LED indicator (luminous flux ≥50 lm) - visible even in bright sunlight.

Sound signal: Beeper with a frequency of 1000-2000 Hz and a volume of ≥85 dB - clearly audible in the workplace, including conditions of engine noise.

IP protection level: IP67 - completely protected from dust and short-term immersion in water (depth up to 1 meter, duration 30 minutes), ensuring reliable operation in wet and dusty conditions.

2.3 Temperature and performance characteristics

Operating temperature range: -40 °C to +85 °C — adapted to extreme climatic conditions (cold winters of Siberia, hot summer days of Central Asia) without loss of functionality.

Vibration resistance: Complies with IEC 60068-2-6 - withstands vibrations with a frequency of 10–2000 Hz and acceleration up to 50 m/s², typical for the operation of heavy equipment engines.

Service life: ≥10,000 operating hours under standard conditions. Durable components minimize replacement frequency and operating costs.

Exhibition cabinets

Getting to know the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsfikation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2.What payment terms can we accept?

Usually we can work on T/T, 30%TT before production and 70%TT before shipment

3.What logistics methods can we work with for delivery?

1) For most of Europe, South America and Africa etc. countries, we can go by container or Roro via ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or railway.

3) For light spare parts in urgent requirement, we can ship it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you ensure that you have delivered the goods to customers?

A: We will provide you with full delivery information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable quality: Carefully select regular manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by ourselves, always adapting the best materials.

2) Competitive price: Concentration of mechanized production in large quantities reduces production costs to ensure competitive price.

3) Service Team: Firstly, our sales managers are on duty 24 hours a day, ready to answer your questions at any time. Secondly, professional technical service team with senior technicians, ready to provide support services for users and dealers. Most of the problems can be solved within 24 hours.

4) Fast delivery: Generally, we can delivery within 10 working days in factory after receiving the advance payment from customers.

6. How can you provide customers with after-sales service?

A: We will reply you at the first time and help you solve the problems within 24 hours. If we really need your local, we

We will send your professional person to your locality to help you solve the problems without any hesitation, supply you with all-round