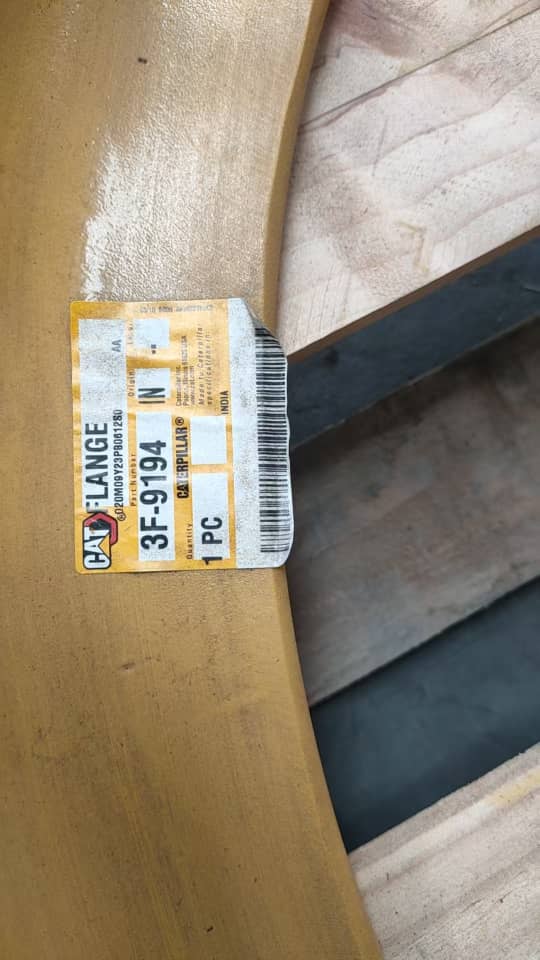

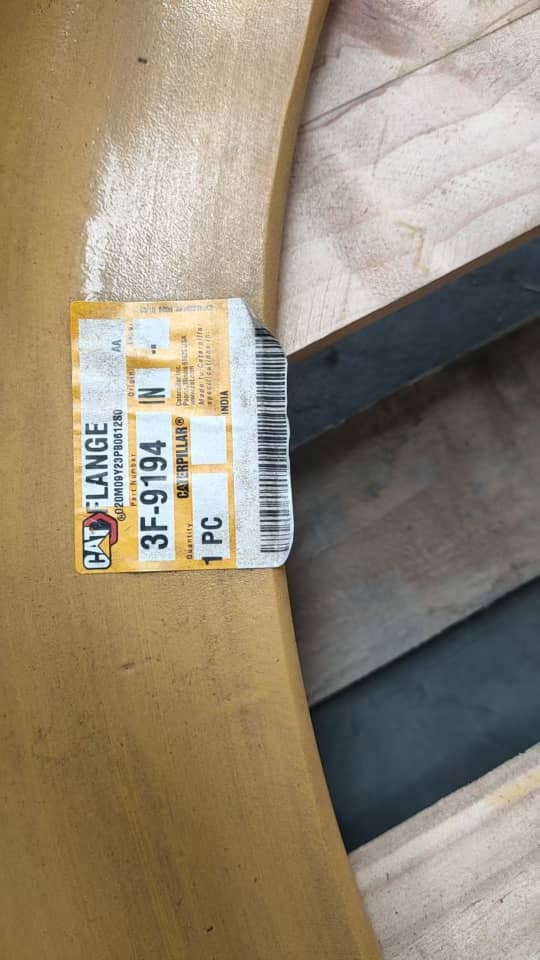

Caterpillar 3F9194 Final Drive Flange

1. High strength: Made of high-quality materials, wear-resistant and stress-resistant, durable.

2.Easy installation: Same with the original Caterpillar standard, easy to combine with other components.

3. Reliability in extreme conditions: Resistant to corrosion and temperature fluctuations, it operates reliably in difficult environments.

Product representation

The Caterpillar 3F9194 leading wheel flange is the most important component of the transmission of heavy construction and mining equipment. This component provides a reliable connection in the system of the drive wheel, plays a key role in transmitting power from engine to wheels and maintaining stable operation of the machine in extreme operating conditions. Thanks to strict Caterpillar production standards and innovative technologies, the 3F9194 flange has become a reliable standard for professionals around the world.

Production features and materials

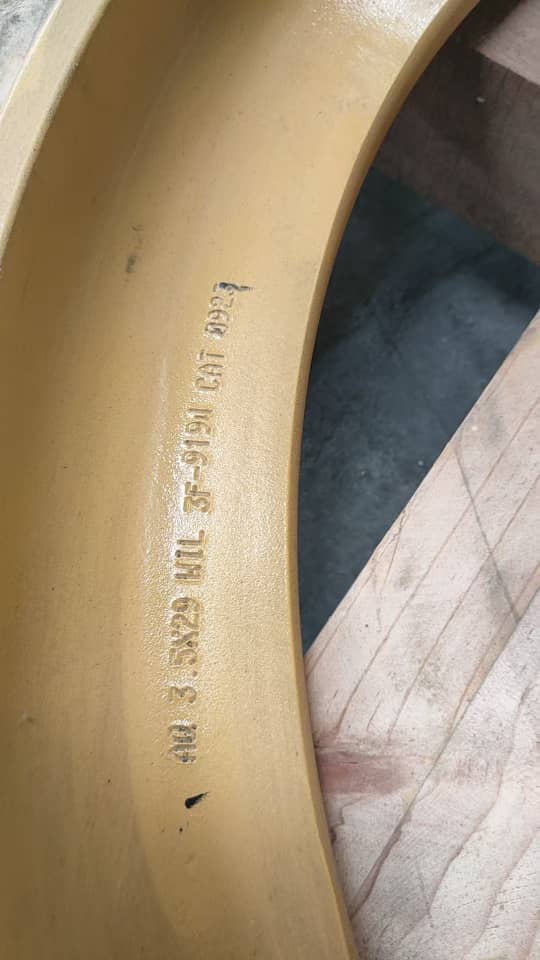

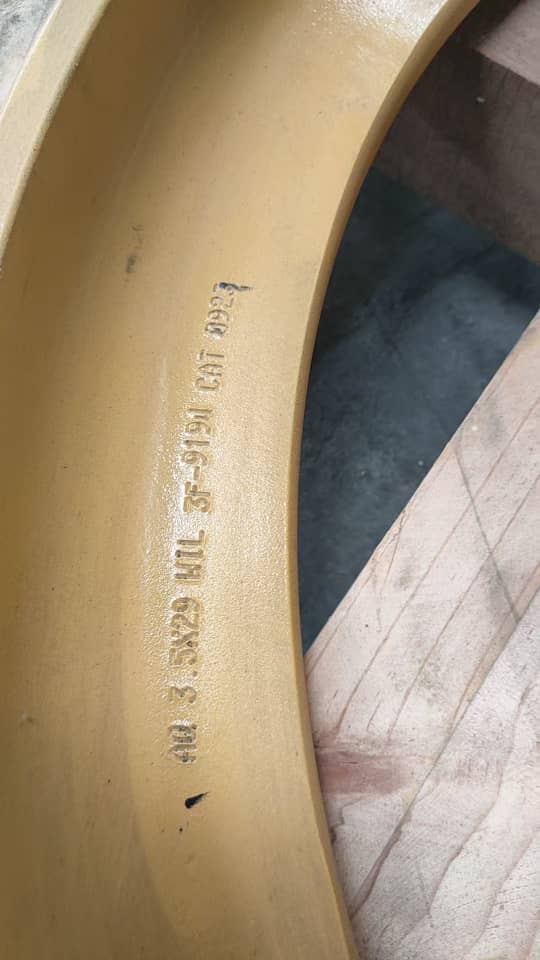

The high quality of the 3F9194 flange is due to carefully selected material - high -strength alloy steel, passing comprehensive quality tests and mechanical properties. The manufacturing process begins with precision cutting of the workpiece on a special CNC machine to ensure that its sizes compliance with strict design requirements. Then the workpiece is undergone hot forging at a temperature of more than 1000 ° C, which grows the structure of the grain of metal and significantly increases its strength and shock viscosity.

Thermal treatment, which is a critical stage of production, includes normalization and vacation to eliminate internal stresses and regulate the hardness of the material. The final mechanical processing, performed on high -precision machines, provides a surface of a surface of less than 1.6 microns and the accuracy of size up to 0.01 mm. The final surface treatment includes grinding and the application of the anti -corrosion coating, which increases moisture resistance, chemical effects and mechanical damage.

Technical advantages and operational characteristics

The main advantage of the 3F9194 flange is its exceptional strength and durability. Manganese and chromium alloy steel provides superior wear resistance and static load ratings of up to 500 MPa, allowing the component to be used in applications with overall gear ratios up to 26.8:1 (typical of Caterpillar mining trucks). Even under extreme loads and over long periods of time, it effectively resists deformation and breakage.

Secondly, the flange is completely compatible with the original Caterpillar equipment. Fully consistent with the standards of ASME B16.5 and GOST 12820, it provides the perfect docking with leading stars, shafts and transmission components. This simplifies the installation and replacement, reducing service time by at least 30% compared to non -original details.

The third advantage is reliability in extreme conditions. The 3F9194 flange withstands temperatures from -40°C to +120°C, making it suitable for use in Canadian oil sands, high-altitude regions of South America, and other harsh environments. An anti-corrosion coating provides protection in humid and contaminated environments, extending component life to 10,000 hours.

Application and Compatibility

The 3F9194 flange is designed for Caterpillar heavy-duty trucks and mining equipment, including models 725, 730 EJ, 735, 740 GC, and 745. It is widely used in mining, road construction, quarries, and other industries where transmission reliability is paramount.

This component is fully compatible with the Cat MineStar Health condition monitoring system, allowing operators to monitor operating parameters in real time. Temperature, load, and flange wear data are automatically transmitted to the cloud platform, providing early warning of potential problems and optimizing maintenance schedules.

Caterpillar Warranty and Support

Each 3F9194 flange comes with documentation of origin, including the batch number, test results, and certificate of conformity. Caterpillar provides a 2-year/2,000-hour warranty on this component. A global dealer network, stretching from Asia to North America, ensures fast parts delivery and professional service.

Customers also receive additional services: expert advice on component selection, installation and maintenance training, and refurbishment and upgrade programs. This makes the 3F9194 flange not only a reliable component but also an investment in the efficient operation of your entire fleet.

In short, the Caterpillar 3F9194 sprocket flange combines high-precision manufacturing technology, superior performance, and global brand support. It's the ideal choice for professionals who value reliability, durability, and efficiency in harsh operating conditions.

Exhibition cabinets

Getting to know the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly performance, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and qualificationsfikation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2.What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipment

3.What logistics methods can we use for delivery?

1) For most of Europe, South America and Africa etc. countries, we can go by container or Roro via ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or rail.

3) For light spare parts in urgent requirement, we can ship it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you guarantee that you have delivered the goods to customers?

A: We will provide you with full delivery information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable quality: Carefully select reliable manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by ourselves, always adopting the best materials.

2) Competitive price: Concentration of mechanized production in large quantities reduces production costs to ensure competitive price.

3) Service Team: Firstly, our sales managers are available 24/7, ready to answer your questions at any time. Secondly, our professional technical support team, with senior technicians, is ready to provide support to users and dealers. Most issues can be resolved within 24 hours.

4) Fast delivery: Generally, we can delivery within 10 working days in factory after receiving the advance payment from customers.

6. How can you provide after-sales service to customers?

A: We will reply you at the first time and help you solve the problems within 24 hours. If we really need your local, we

We will send your professional person to your locality to help you solve the problems without any hesitation, supply you with all-round