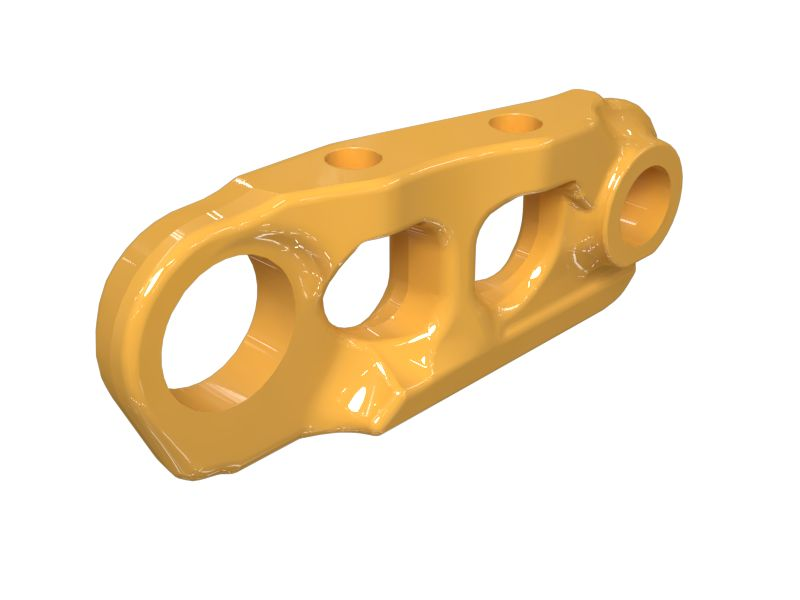

Caterpillar Track Connector 526-5459

1.High Strength: Made of alloy steel, it can withstand heavy loads and corrosion, prolonging the service life of the tracks.

2.Easy to install: Perfectly compatible with Caterpillar models, standard dimensions speed up installation, reducing equipment downtime.

3.Optimizes performance: Ensures stable movement on difficult surfaces, reducing the risk of breakdowns and repair costs.

Product representation

1. General characteristics and purpose

Caterpillar 526-5459 caterpillar connector refers to critical components of the caterpillars system of heavy construction equipment. It is intended for a reliable connection of the links of the caterpillar, ensuring the integrity and smooth operation of the entire tractor system in an intensive operational mode. This component was developed by Caterpillar specialists, taking into account the requirements for high strength, durability and adaptation to various working conditions - from construction sites with an uneven surface to extreme climatic zones (for example, the cold regions of Siberia or the Arctic, which were mentioned at the BICES 2025 international exhibition in Beijing).

The connector 526-5459 is not universal-it was created for specific models of excavators and loaders of Caterpillar, which guarantees perfect compatibility and eliminates the risks of deformation or gap rupture in the process. Thanks to thorough design, it becomes an integral part of the system that maintains high equipment performance and reducing the likelihood of downtime due to technical problems.

2. Technical parameters

Material: connector 526-5459 is made of high-quality alloy steel of the brand 4140. This steel is characterized by increased hardness (HB 280–320) and tensile strength (σ_b ≥ 1000 MPa), as well as resistance to corrosion and wear. Before mass production, the material passed a series of tests for withstanding cyclic loads and temperature fluctuations, which confirms its reliability in long -term operation.

Geometric dimensions: The connector length is 185 mm, width is 68 mm, and thickness is 32 mm. The diameter of the central pin hole is 22 mm, ensuring a strong connection with other track components. All dimensions are manufactured with high precision (H9 tolerance), eliminating gaps between connected links and preventing unwanted vibration loading.

Maximum Load: The component can withstand static loads of up to 250 kN and dynamic loads of up to 180 kN. This allows it to handle heavy equipment models weighing up to 50–80 tons—for example, the Caterpillar Cat3101 excavator (100 tons), presented at BICES 2025, which is used in coal mines and requires components with increased load capacity.

The temperature range of operation: connector 526-5459 is suitable for working in the temperature range from -40 ° C to +80 ° C. This makes it suitable for use in cold regions (where the temperature drops below -30 ° C in winter) and hot climate, without loss of strength or the occurrence of deformations.

3. Key advantages

3.1 High strength and durability

Thanks to the use of alloy steel 4140 and the use of heat treatment (vacation at 600 ° C), the connector 526-5459 has high resistance to wear and gaps. In the process of testing, the component withstood more than 10,000 load cycles, which is equivalent to 2-3 years of intensive operation at the construction site. This significantly exceeds the indicators of similar connectors from other manufacturers whose service life usually does not exceed 1–1.5 years.

3.2 perfect compatibility with Caterpillar models

The 526-5459 connector is designed to precisely fit Caterpillar excavator models, including the Cat 320D, Cat 330D, Cat 349D, and Cat 3101 (presented at BICES 2025). No additional adaptation or machining is required during installation—the component fits seamlessly onto standard track links. This reduces installation time to 30–45 minutes (compared to 1–1.5 hours for similar components) and reduces labor costs for maintenance personnel.

3.3 Protection against corrosion and aggressive environments

The surface of the connector 526-5459 is covered with a cathode-electrophoretic layer (clay color) with a thickness of 25-30 microns. This layer provides high protection against corrosion - even in contact with water, snow, salted solutions (in naval regions) or chemicals (in industrial zones), the component is not subjected to rust for 5–7 years. Additionally, an acrylic varnish layer is applied on the surface, which increases resistance to mechanical damage (scratches, shots) during operation.

4. Adaptability to working conditions

Like many innovative Caterpillar products, presented at the BICES 2025, the connector 526-5459 is adapted to difficult working conditions. During operation on uneven surfaces (crushed stone, earth, stones), it provides a stable connection of the links of the caterpillar, minimizing the risk of deformation. In conditions of low temperatures (below -20 ° C), the material does not lose flexibility -this is critical for technology working in Siberia or the Arctic, where winter temperatures often drop below -35 ° C.

In addition, the connector 526-5459 is resistant to vibrational loads that occur during the movement of heavy equipment. Vibrations can lead to relaxation of fasteners, but thanks to the special design of the pin and holes in the connector, the mount remains reliable throughout the service life.

5. Recommendations for use and maintenance

For maximum efficiency and extension of the service life of the connector 526-5459, it is recommended to adhere to the following rules:

Installation: Installation must be performed by qualified personnel using standard Caterpillar tools. Before installation, inspect the track links for corrosion, deformation, or wear. Maintain a pin torque of 450 Nm during installation to ensure a strong connection.

Regular Inspection: It is recommended to inspect the connector once a month for scratches, rust, or loose pins. If damage is detected, the component should be replaced immediately—a faulty connector can cause track breakage and serious damage to the equipment.

Lubrication: Apply Caterpillar MP Grease to the track link connector every three months. This reduces friction between components and prevents wear.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsfikation

Frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2.What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipment

3.What logistics methods can we use for delivery?

1) For most of Europe, South America and Africa etc. countries, we can go by container or Roro via ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or rail.

3) For light spare parts in urgent requirement, we can ship it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you guarantee that you have delivered the goods to customers?

A: We will provide you with full delivery information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable quality: Carefully select reliable manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by ourselves, always adopting the best materials.

2) Competitive price: Concentration of mechanized production in large quantities reduces production costs to ensure competitive price.

3) Service Team: Our sales managers are available 24/7, ready to answer your questions at any time. Our professional technical support team, with senior technicians, is ready to provide support to users and dealers. Most issues can be resolved within 24 hours.

4) Fast delivery: Generally, we can delivery within 10 working days in factory after receiving the advance payment from customers.

6. How can you provide after-sales service to customers?

A: We will reply you at the first time and help you solve the problems within 24 hours. If we really need your local, we

We will send your professional person to your locality to help you solve the problems without any hesitation, supply you with all-round