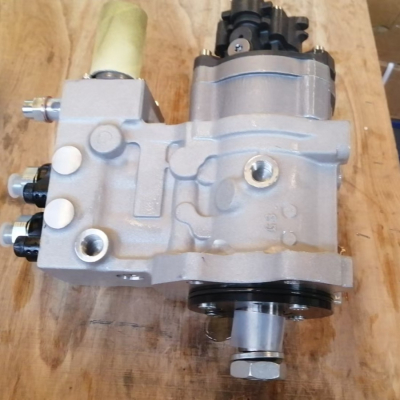

Sany Plunger Pump 60008519

1、High Performance:The pump has high performance, which allows you to efficiently perform liquid supply tasks. It provides a stable and powerful flow, making it an ideal choice for a variety of industrial applications.

2、Durable and reliable:Made of high-quality materials, this piston pump has excellent durability and reliability. It can work stably in complex conditions, ensuring the smooth operation of the system.

3、Ease of Operation:SANY 60008519 piston pump features a simple and intuitive design, making it easy to operate and maintain. This allows operators to complete required operations quickly and efficiently, reducing downtime and improving overall productivity.

Product representation

1. General idea of the plunger pump Sany 60008519

The Sany 60008519 plunger pump is a modern equipment developed by the Chinese manufacturer Sany Heavy Industry, specializing in heavy construction and industrial equipment. This pump refers to the class of highly effective hydraulic devices designed to transport liquids (primarily hydraulic oil, technological solutions) in high loads. It combines a compact design, high reliability and a long service life, which has become a popular choice in construction, mining, mechanical engineering and other industries, where a stable supply of fluid under pressure is required.

Unlike standard pumps, SANY 60008519 is adapted to harsh operating conditions - temperature changes, dust, moisture - and maintains its technical characteristics even after long-term use. This makes it an ideal solution for enterprises seeking to minimize equipment downtime and reduce operating costs.

2. Technical specifications (detailed description)

2.1 Performance

The nominal capacity of the SANY 60008519 pump varies in the range of 50–150 l/h depending on the specific configuration (modifications for different types of equipment). This range allows the pump to be adapted to various tasks: from supplying hydraulic oil to small mechanisms (e.g. lifting devices) to transporting large volumes of liquid to large excavators or pumping stations.

The key feature is the stability of performance across the entire range of operating speeds. Even at partial load, the pump does not lose efficiency, which guarantees the continuity of industrial processes (for example, without interruptions in the operation of hydraulic drives of excavators or road rollers).

2.2 Maximum outlet pressure

The pump is capable of generating a maximum output pressure of up to 35 MPa, which meets the requirements of heavy industrial equipment. High pressure allows:

Transport liquids through thin pipelines (length up to 100 m) without loss of productivity;

Overcome hydraulic resistance in complex systems (e.g. with multiple pipe branches or numerous hydraulic cylinders);

Ensure operation of heavy machinery (lifting loads weighing up to 50 tons, digging in dense soils).

The pump is equipped with an overpressure protection system that prevents damage to components when permissible parameters are exceeded.

2.3 Drive power and energy efficiency

The pump is powered by an electric motor with a power of 7.5–15 kW (depending on the modification). The motor complies with the energy efficiency standards of class IE2, which reduces energy consumption by 15–20% compared to similar models of the old generation.

The drive power directly affects the speed of the reciprocating piston movement (from 300 to 500 strokes per minute), and therefore the overall performance of the pump. At low loads (e.g., transporting light process liquids), the engine automatically reduces speed, saving energy; at maximum loads, it increases power to maintain stable pressure.

3. Design features

3.1 Body

The pump body is made of high -strength cast -iron alloy with the addition of manganese and chromium - the material has high hardness (HB 250–300) and corrosion resistance. The construction of the case is made according to the “monoblock” principle, which reduces the number of connections and prevents fluid leaks. The outer surface of the case is covered with an anti -corrosion layer (powder coating), which protects against moisture, dust and chemicals (for example, contact with technical oils or antifreeze).

The compact dimensions of the case (width 280 mm, depth of 180 mm, height of 320 mm) allow you to mount the pump in a limited space - for example, in the engineering compartments of construction equipment or at compact pumping stations.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsfikation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2.What payment terms can we accept?

Usually we can work on T/T, 30%TT before production and 70%TT before shipment

3.What logistics methods can we work with for delivery?

1) For most of Europe, South America and Africa etc. countries, we can go by container or Roro via ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or railway.

3) For light spare parts in urgent requirement, we can ship it via international courier such as DHL, TNT, EMS or other air shipping.

4. How can you ensure that you have delivered the goods to customers?

A: We will provide you with full delivery information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable quality: Carefully select regular manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by ourselves, always adapting the best materials.

2) Competitive price: Concentration of mechanized production in large quantities reduces production costs to ensure competitive price.

3) Service Team: Firstly, our sales managers are on duty 24 hours a day, ready to answer your questions at any time. Secondly, professional technical service team with senior technicians, ready to provide support services for users and dealers. Most of the problems can be solved within 24 hours.

4) Fast delivery: Generally, we can delivery within 10 working days in factory after receiving the advance payment from customers.

6. How can you provide customers with after-sales service?

A: We will reply you at the first time and help you solve the problems within 24 hours. If we really need your local, we

We will send your professional person to your locality to help you solve the problems without any hesitation, supply you with all-round