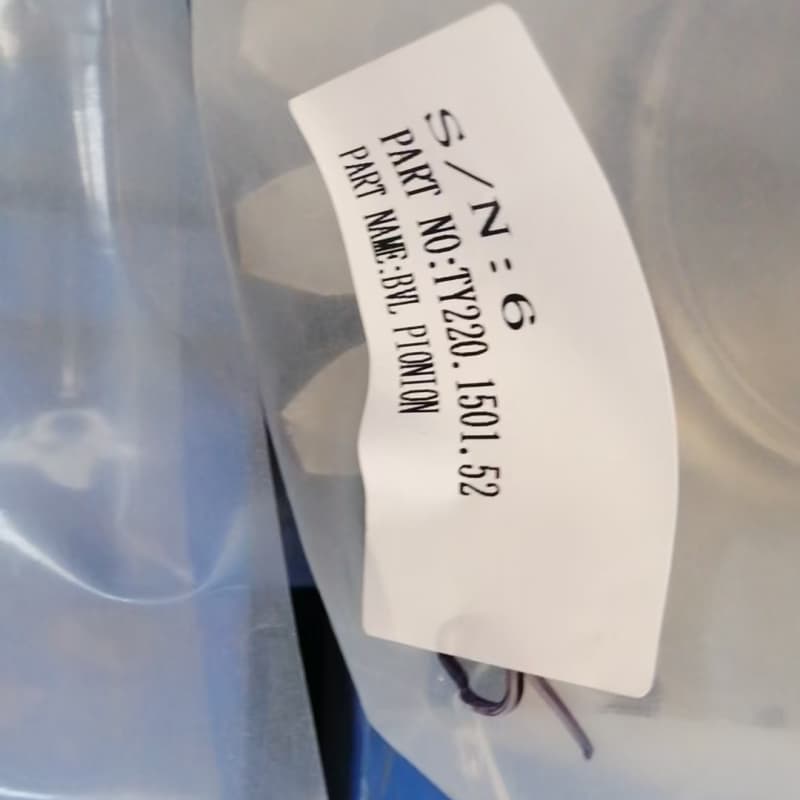

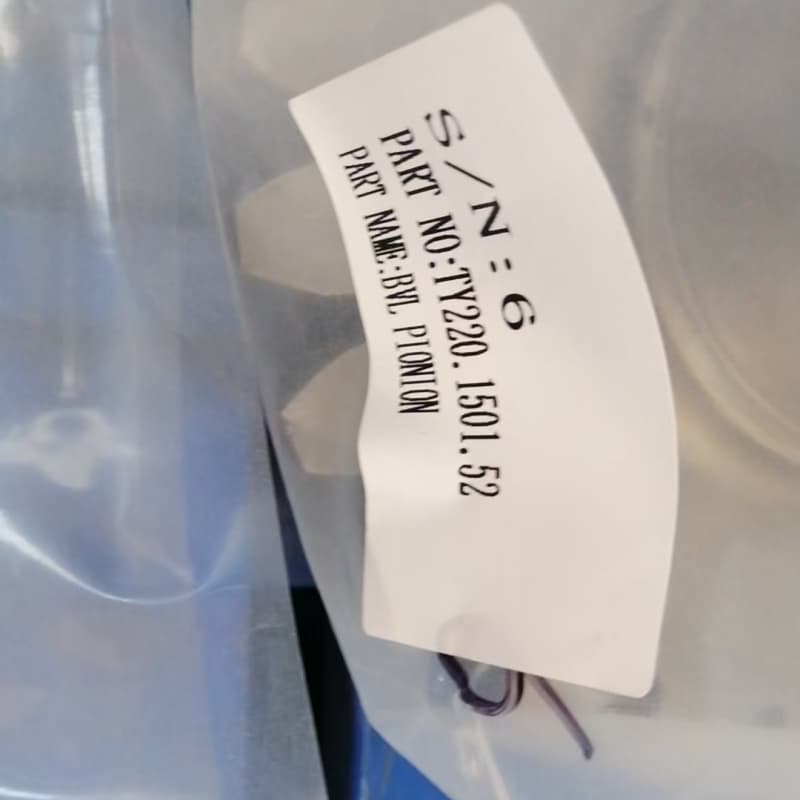

Zoomlion Ty220.1501.52 Val gearbox Val ZD220-3

1. Adaptable working conditions: The design is optimized and accurately adapted to the main bulldozers, which ensures the stability of the gearbox and increases the efficiency of construction, since it is designed for severe conditions of the terrain and difficult operating conditions in Russia.

2. Superflowing strength: made of high -quality alloy steel, passes special heat treatment, resistant to fatigue and wear, withstands high loads, reduces the number of failures and extends the service life.

3. Ease of maintenance: standardized design, simple disassembly and installation, there is no need for complex tools and professional skills, quick maintenance is possible even in remote areas, which reduces downtime and service costs.

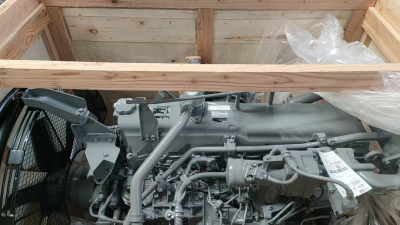

Product representation

1. Detailed product information

1. Review of the product

Our spare parts for bulldozer gearboxes are key components that ensure stable operation of the bulldozer transmission system. We offer a full range of spare parts for gearboxes for various types of bulldozers: from gears, shaft parts to various seals that regulate valves, etc. These spare parts are made strictly in accordance with original factory standards to ensure perfect compliance with the bulldozer gearbox, providing a reliable guarantee of the effective operation of your equipment.

(II) types and functions of products

Spare parts for toothed gears: including the leading gears, led gears, planetary gears, etc. The gears are forged from high -quality alloy steel, subjected to precision machining and heat treatment, which provides them with high strength, high wear resistance and good fatigue strength. The exact design of the teeth profile provides a smooth transmission of power, reduces noise and vibration, and also effectively increases the effectiveness of the transmission of the gearbox.

Spare parts of the shaft: such as the input shaft, output shaft, intermediate shaft, etc. Val parts are made of special steel and pass a strict processing technology that ensures the accuracy of their size and surface quality. The shaft body has sufficient strength and rigidity to withstand huge torque and axial efforts, ensuring the reliability of power transmission in difficult operating conditions.

Seals: oil seals, sealing rings and other seals are made of high -quality rubber materials with good oil resistance, resistance to aging and sealing properties. Effectively prevents the leakage of lubricating oil in the gearbox, provides a lubricant inside the gearbox and extends the service life of various components.

The control valve: is used to control gear shift, speed change and other operations. The control valve is precisely designed, and the valve core is sensitive. It can accurately control the direction of the flow and the pressure of hydraulic oil, to smoothly switch the bulldozer gear in various working conditions, is easy to operate and quickly responds.

(III) The advantages of the product

Strict quality control: in the production process, we introduce advanced quality control equipment and a full quality control system for strict checks of each spare part during various processes, from verification of raw materials to testing finished products to guarantee that the quality of the products corresponds or even exceeds the initial factory standards.

Wide applicability: Products cover the main brands and models of bulldozers in the market. Whether it is the repair of old equipment or serving new models, we can provide you with suitable spare parts for the gearbox without worrying about compatibility problems.

High cost efficiency: compared to original spare parts, our products have more competitive prices, while guaranteeing quality. This can reduce the costs of maintenance of equipment and increase the payback of investments without affecting the performance and service life of the equipment.

2. The installation method

1. Preparation before installation

Make sure that the required spare parts fully correspond to the bulldozer models and the characteristics of the gearbox, as well as carefully check the appearance of the spare parts for defects, such as damage and deformation.

Prepare professional installation tools such as wrenches, heads, pullers, jacks, etc., and make sure that the tools are working, and their accuracy meets the requirements.

Install warning signs at the installation site, clean the environment from garbage and provide sufficient workspace. At the same time, park the bulldozer on a flat, solid surface, turn on the manual brake and parking brake to prevent the vehicle.

(II) Stages of installation

Disassemble the old details: first drain the lubricating oil out of the gearbox, and then disassemble the details associated with the gearbox, such as the drive shaft, connecting bolts, etc., in the correct order. Use the appropriate tools to carefully remove the old spare part, trying to protect the surrounding components and avoid secondary damage. In the process of disassembly, mark the installation site and the order of each component for the subsequent installation.

Installation of new spare parts:

For spare parts to gear gears, clean a new gear gear, apply the required amount of lubricant oil, and then install it in the gearbox exactly in accordance with the marked position and direction, making sure that the gear in the gearing between the gear gears meets the specified requirements. Use special installation tools and avoid strong strokes so as not to damage the gear.

When installing the spare parts of the shaft, first clean the shaft housing and check the integrity of the key groove. Smoothly insert a new shaft into the corresponding hole, paying attention to the axial and radial position of the shaft to ensure a reliable installation. During the installation, be careful to prevent the collision of the shaft with other components.

Before installing the seal, apply a thin layer of lubricating oil to the seal, and then carefully install it in the corresponding sealing groove to make sure that the seal is installed evenly, without distortions and deformations. After installation, check the tightness of the sealing edge to prevent a leak.

When installing the control valve, fix it in accordance with the correct direction of the conjugation and the installation position, and then connect the hydraulic pipeline. Make sure that the compounds of the pipeline are durable and not weakened, and after installing, perform a simple test to check the flexibility and accuracy of the control valve.

Assembly and commissioning: After the installation of all spare parts is completed, collect the gearbox and related components step by step in the order in reverse disassembly. During the assembly, carefully check the reliability of each connection and tightening of the bolts with the specified moment. After installation, add the required amount of lubricant that meets the specification requirements, run the bulldozer and perform the launching work at idle and under load. In the process of debugging, pay attention to the working condition of the gearbox, for example, whether there are no extraneous noise, vibration, smooth transfers, etc. If you have any problems, stop the car in a timely manner to check and eliminate the malfunction.

3. Common malfunctions and ways to eliminate them

1. Difficulties with gear shift

Cause

A malfunction of the control valve, for example, the sequel or wear of the valve core, leads to the fact that hydraulic oil cannot normally control the gearbox.

The clutch disc is very worn out or burned out, which affects power transmission and gear shift.

The level of transmission oil is too low or the quality of the oil has worsened, which leads to a deterioration in the lubrication and an increase in friction between the gear components.

Bypass

Disassemble the control valve for cleaning and inspection. If the valve core is strongly worn, replace it with new in time. At the same time, check if the hydraulic pipeline of the control valve is closed or whether the hydraulic pipeline flows. If there are any problems, repair or replace the appropriate pipeline.

Check the clutch disc for wear. If wear exceeds the specified range, replace it with new ones. When installing the clutch disc, pay attention to the installation sequence and adjustment of the clearance.

Check the level of transmission oil and share the oil to the specified level, if it is not enough. If the quality of the oil has worsened, replace it in a timely manner with a transmission oil that meets the requirements. At the same time, clean the inner part of the gearbox to remove pollution and oil spots.

(2) Transmission oil leakage

Cause

The seals are aging, damaged and lose their sealing properties.

The gearbox body has cracks or sandy holes, which leads to a leakage of lubricating oil.

The connecting bolts are weakened, which leads to poor sealing the surface of the joint.

Bypass

Check the seals, such as oil seals, sealing rings, etc. If any seals are old or damaged, replace them with new ones with the same characteristics. When replacing seals, pay attention to the installation method and cleanliness of the sealing surface.

If the gearbox body has cracked or has sand sinks, it can be repaired by welding or replaced with a new one. After the repair, conduct a test under pressure to make sure that there are no leaks.

Check the tightening of the connecting bolts and tighten them with the indicated puffing to ensure the tightness of the joints. At the same time, check if the joint surface is deformed or damaged. If there are any problems, repair or eliminate them.

(III) abnormal noise from the gearbox

Cause

The wear of the gears and the collision of the teeth lead to poor hooking gears and noise.

The bearing is damaged and makes an abnormal noise during operation.

An extraneous body fell into the gearbox, which led to a clash and friction between the components.

Bypass

Disassemble the gearbox and check the wear of the gears. Replace timely with new strongly worn out or having chips of gears. At the same time, check the gap in the engagement of the gears and contact of the surfaces of the teeth, as well as perform the necessary adjustments and repair.

Check the work of the bearings and replace them with new ones if they are damaged. When installing bearings, pay attention to the method of installing and adjusting the preliminary tight strength.

Clean the inner part of the gearbox and delete all extraneous objects. At the same time, check if other details are damaged due to a collision with foreign objects. If damaged, repair or replace them.

4. Repair and maintenance

1. Daily service

Examination: daily before starting work, check the appearance of the gearbox for the presence of any malfunctions, such as oil leak, weakened bolts and damaged parts. If you find the problem, take measures on time to prevent its aggravation.

Checking the oil level: regularly check the level of transmission oil to make sure that it is in the indicated range. Too low oil level will lead to a deterioration in lubrication and increased wear of components; Too high oil level can lead to an increase in oil temperature and affect the transmission. Checking the oil level should be done when the tractor is in a horizontal position, and the engine is turned off for a while.

Cleaning and maintenance: maintain the surface of the gearbox clean, regularly clean it of dust, oil and garbage to prevent these contaminants from entering the gearbox and violation of its normal operation. At the same time, clean the ventilation openings of the gearbox to ensure good ventilation and prevent the occurrence of excess pressure in the box.

(II) regular maintenance

Replacement of transmission oil: depending on the use of the bulldozer and operating conditions, the transmission oil should be replaced at the established time or in accordance with the working clock. As a rule, transmission oil must be changed every 100 working hours or 1 month. When replacing the transmission oil, use the oil that meets the requirements of the equipment, thoroughly drain the old oil and clean the transmission oil filter.

Checking and adjusting the components: regularly disassemble the gearbox and check the wear of internal gears, shafts, bearings, seals and other components. Parts close to the limiting wear should be replaced in a timely manner; Parts with minor wear can be repaired or adjusted. At the same time, check and adjust the gap of the clutch disc, the stroke of the control valve and other parameters to make sure of all the components of the gearbox.

Maintenance of the lubricant system: Check oil pipelines, oil pumps, filters and other components of the gear lubrication system to make sure that there are no clogs in the lubricant. Regularly clean or replace the lubricant filter to prevent the filter clogging with impurities and deterioration in the efficiency of lubrication. At the same time, check the working pressure of the oil pump to make sure that it corresponds to the needs of the gear lubrication.

(III) precautions during maintenance

Before performing maintenance work, be sure to make sure that the bulldozer is stopped, and take reliable security measures, such as the inclusion of a manual brake and installing warning signs to prevent accidents.

The maintenance personnel must have professional knowledge and skills, as well as be familiar with the design and principle of operation of the bulldozer gearbox. During operation, strictly observe the requirements of the maintenance management to avoid damage to equipment due to improper operation.

When replacing spare parts, choose reliable quality products and make sure that it corresponds to the original equipment. Avoid the use of low -quality spare parts, which can affect the performance and service life of the gearbox.

Strived oil, waste parts and other waste generated during maintenance should be disposed of properly in accordance with the requirements for environmental protection in order to avoid environmental pollution.

5. After -sales service

1. After -sales service team

We have a professional after -sales service team, whose members have undergone serious technical training and have rich experience in servicing and technical support for bulldozer gearboxes. Regardless of whether the malfunction occurs during the installation and commissioning of the product or during the operation of equipment, our after -sales service team can quickly respond and provide you with effective and professional services.

(II) Warranty service

We offer [x] years of guarantees for the spare parts of the transmission of the bulldozer. During the warranty period, if the goods have any quality problems, we will provide you with free repair or replacement services. You just need to call our hotline of after -sales service, and our employees will contact you as soon as possible to organize maintenance.

(III) Technical support

Online consultation: We provide customers with online technical consultation services. You can consult with our technical personnel at any time on any problems that arose during the use of the product through our official website, the WeChat public account and other channels. Our experts will quickly respond to your requests during working hours and provide you with detailed decisions.

Learning on the spot: at the request of the client, we can organize the departure of professional technical specialists to the place for training operators and maintenance personnel for the use and maintenance of products. The content of the training includes the principle of operation of the gearbox, methods of operation, diagnosis and elimination of malfunctions, daily maintenance, etc., to guarantee that your staff will be able to master the appropriate skills.

4. Quick response

We have created a comprehensive response mechanism for after -sales service. After you report the problem with the product, we will contact you within [x] hours to find out more about the problem. In situations requiring repairs on the spot, we will organize a speedy departure to the place of the closest specialist in after -sales service to guarantee a solution to the problem as soon as possible and minimize the impact on your production operations.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive