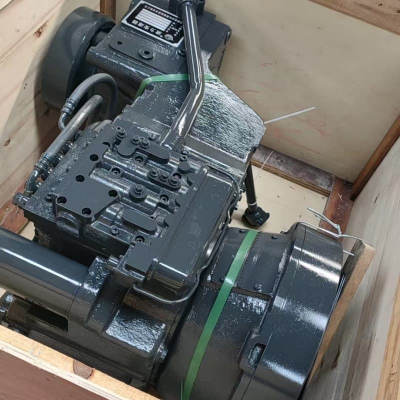

Shacman HD425 differential in collection original spare parts

1 、 Convenient installation : HD425 has a simple installation circuit, which significantly reduces the time and costs of installation. This is beneficial for workshops and services in Russia that need operational maintenance.

2 、 Modern technologies : Using advanced production technologies, HD425 provides high transmitting efficiency (up to 96%) and reliability. Technologies with low -friction elements also improve the characteristics and work resource.

3 、 High -quality materials : The unit is made of high -quality materials that provide resistance to abrasion and deformations. This allows you to use it in various climatic conditions of Russia.

Product representation

1. Method of installation

Installation of the SHAANXI Automobile Delong differential unit (for example, DZ90149320000 models) should be performed by professional specialists to ensure accurate compliance with compatible models such as Hande Bridge. Below are the main steps and precautions:

Model adaptation: Make sure that the differential node model corresponds to the configuration of the rear axle of the car (for example, the Hande central bridge center differential) to avoid functional failures due to the discrepancy between specifications.

Dismantling and cleaning:

Use special tools to remove the original differential node and pay attention to the protection of precision details, such as gears and bearings.

Clean the installation site and the interface of the connection to make sure that there is no oil or pollution that may affect the tightness.

Assembly of components:

Install the planetary row, the gear of the semi -axles and the differential body in the sequence corresponding to the factory technology, making sure that the gear surfaces are completely in contact without distortions or excessive clearance.

Use the pressing tool to accurately install a new bearing and avoid deformation of the components due to sharp operation.

Debugging and testing:

After installation, check the smoothness of the gearbox by trial rotation to make sure that there are no extraneous noise or seals.

Connect the tourniquet of the differential lock control wires and check if the differential blocking function works normally.

Note: Unauthorized maintenance personnel do not have the right to disassemble or install the product yourself. It is recommended to contact the specified SHAANXI Automobile maintenance station to make sure the quality of the installation.

2. Common malfunctions and ways to eliminate them

Differential abnormal noise or jamming

Reason: wear of planetary transmission, bearing damage or an abnormal gap in the engagement of gears.

Solution: Replace worn parts and adjust the gear gear to the initial standard value.

Differential blocking malfunction

Reason: The line is weakened, the sensor connector is faulty or clogged with an electromagnetic valve.

Solution: Check the connection of the wire harness, clean or replace the electromagnetic valve and calibrate the differential blocking sensor.

The problem of oil leakage

Reason: aging of the oil seal, cracks in the case or weakened bolts.

Solution: Replace the oil seal, tighten the bolts and, if necessary, replace the entire differential node.

The car fluctuates or the tires are abnormally worn out

Reason: deformation of the differential case and wear of the gears of the bridge lead to an uneven distribution of power.

Solution: straighten or replace the differential body and check if the working surface of the gear of the half -shafts is flat.

3. After -sales warranty

Shaanxi Auto Delong provides comprehensive service support for differential nodes, guaranteeing user rights:

National Warranty Network:

More than 1200 authorized service stations throughout the country provide round-the-clock support (hot line: 400-880-9818).

Supports online reporting (for example, the “E Suixing” application), and the system automatically selects the nearest service station to reduce the maintenance cycle.

Delivery of original spare parts

All accessories were certified by the quality of Shaanxi Automobile and support scanning the QR code for checking for fake, which guarantees 100% compatibility with car models.

Conventional wear parts (such as seals and bearings) are available in sufficient quantities in warehouse, and round -the -clock delivery is possible in some regions.

Warranty policy

In the absence of damage caused by the human factor, the main components of the differential node (gears, housing) are provided with a warranty for a period of 1 year.

During the warranty period, faulty parts will be replaced for free, and a labor discount will also be provided.

Technical support and training

The Shaanxi Automobile expert team uses a remote diagnostic platform to comprehensively eliminate malfunctions and reduce the level of erroneous diagnostics.

Regularly conduct technical training of users and maintenance stations to increase the possibilities of differential maintenance and forecasting faults.

Preparation for installation

Confirm the correspondence of the model: carefully check whether the model of the differential unit is fully consistent with the Shaanxi Automobile Delong model and the axis specifications. For example, make sure that it corresponds to Hande 425, 485, 469 and other axes to avoid problems with the installation due to the non-compliance of the model.

Check the integrity of the components: check if the differential node and related details are integral, are there any damage, deformations or absence. For example, gears, half axes, bolts and other details should not have cracks, excessive wear and other problems.

Clean the details: use a clean fabric or a special cleaning agent to carefully remove oil, dust and garbage from the differential unit and installation parts, make sure that the installation surface is clean and smooth, and do not allow foreign substances that may affect the differential operation.

Prepare tools: Prepare the tools necessary for installation, such as end keys, dynamometric keys, calipers, dial indicators, etc., and make sure that the tools are in good condition, and their accuracy meets the requirements.

Establishing points of the installation

Set the differential box correctly: evenly install the differential box to the axis installation, pay attention to the correct direction of the installation, combine the mark on the differential box with a mark on the axis, and then evenly tighten the fasteners. Tighten them step by step several times in accordance with the indicated value of the torque. The total value of the torque is about 100-150 N · m. Please contact the management of the vehicle model to obtain a specific value.

Installation of the semi -axle: When installing the half -axle, make sure that the slots of the half -shafts, the gears of the differential and the wheel hubs coincide well, without jamming or backlash. Insert the semi -axis into the slotted opening of the gear of the differential and the wheel hub and the wheel hub, then install the fixing nut of the semi -axle and tighten it in accordance with the indicated puff moment, which is usually about 200-300 N · m.

Adjusting the gap in the hook: it is very important to adjust the gap in the engagement and the contact of the gear surfaces of the leading and led the gears of the differential. The gap in the engagement should usually be 0.15-0.3 mm and can be adjusted by increasing or decreasing the thickness of the adjustment laying. Use the dial indicator to measure the clearance, simultaneously rotate the gear and observe the contact mark on the surface of the tooth. It should be in the middle of the surface of the tooth, and the contact area should not be less than 60% of the tooth surface. If it does not meet the requirements, it must be adjusted.

Installation of the bearing and preliminary load: When installing the differential bearing, make sure that the bearing is installed in place and has no damage. After installation, the bearings must be correctly loaded. The preliminary tightness will lead to overheating of the bearings and more severe wear, while too small a preliminary stretch will lead to a weakening of differential, the appearance of abnormal noise and other problems. Usually, the corresponding preliminary load is achieved by adjusting the bearing or gasket adjustment nut. Specific values can be found in the operating manual for the vehicle model. The torque of the preliminary load is usually about 1-3 N ・ m.

Basic Info.

Model no.

HD425

Type

Sinotruk Howo Truck Spare Parts

Certification

TUV, GS

Transport Package

Wooden Box Transportation

Trademark

Yd

Origin

Shandong

Hs Code

8716400000

Production Capacy

500000vehicle/year

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive