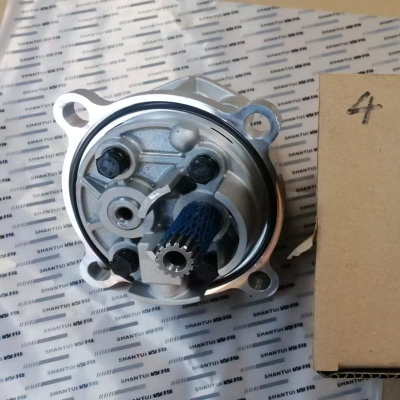

Shacman dz9114160023 Clutch shift bearing original spare parts

1 、 ease of installation: the ball bearing of the clutch disconnect DZ9114160023 has a simple and intuitive design, which allows mechanics to quickly and without much effort to install or replace it. This significantly reduces the downtime of the car and increases the efficiency of car services.

2 、 High reliability and durability: using advanced production technologies and high -quality materials, this bearing provides stable operation in the most difficult conditions. It is resistant to high temperatures, mechanical loads and other adverse factors, which guarantees its long service life.

3 、 High -quality materials: the ball bearing is made of high -quality bearing steel, which has excellent characteristics of strength and wear resistance. This allows him to successfully withstand intensive wear and ensures his reliability in his work.

Product representation

The main functions

In the car adhesion system, the function of smooth disconnection and connection between the engine and the transmission performs. When the clutch pedal is pressed, the disconnection bearing moves along the shaft, disconnecting the clutch disc from the double wheel of the engine, which allows you to change the transmission and stop the machine without vibrations and jerks.

It guarantees a smooth transmission of power, preventing wear and damage to other clutch details, such as clutch discs, pressing discs, etc., thus ensuring the durability and reliability of the entire clutch mechanism.

Technical characteristics

Type of bearing : For example, a roller bearing with a flat holder or a bearing with balls, depending on the model.

Materials

The outer ring : is made of high -quality steel with good corrosion resistance and high hardness, which can withstand high loads and for a long time of use.

The inner ring : is also made of special steel for bearings, providing accurate rotation and resistance to wear.

Rollers or balls : are made of high -strength steel to ensure smooth rotation and durability of the bearing.

The holder : is usually made of aluminum alloy or plastic composition, which allows you to reduce the weight of the product, as well as ensure good rigidity and reliability.

Advantages

High reliability : Due to the strict quality control and the use of high -quality materials, the disconnection bearing can work stably for a long time, even in conditions of heavy loading and difficult operating conditions.

Low noise : accurate processing and high -quality manufacture provides low noise and viscosity during rotation, which significantly improves driving comfort and reduces the noise level in the car.

Good tightness : Using special sealing rings and sealing technologies are used, preventing dust, dirt and lubrication, which helps to maintain the cleanliness and performance of the bearing for a long time.

Lightness and compactness : Modern design and the choice of materials allow you to create a compact and light bearing, which not only simplifies installation, but also helps to increase the efficiency of the entire adhesion mechanism.

Abnormal sound

Signs of a malfunction: when pressing or releasing the clutch pedal, obvious abnormal sounds are heard, such as “rustle” or “click”.

Analysis of the causes

The bearing is poorly lubricated, the internal lubricant dries or deteriorates, which leads to an increase in friction between balls or rollers and internal and outer rings.

The bearings are very worn out. After prolonged use, balls, rollers, internal and outer rings wear out, the gap increases.

The improper installation and improper installation of the bearing will lead to uneven strength during operation.

Bypass

If the problem is in grease, try adding or replacing the lubricant. If this is an open bearing, you can directly inject the required amount by heat -resistant, high -skinned lubrication.

In the case of severe wear of the bearings, replace the squeezing of the clutch in a timely manner, as well as check the appropriate installation parts for damage.

Set the bearing correctly, provide the exact position of the installation, use professional tools when installing and observe the specified moment and tightening method.

Stuck

Signs of a malfunction: the clutch pedal does not return to the starting position after pressing or a squeezed bearing cannot flexibly move during operation, which leads to incomplete disconnecting of the clutch or insoluble inclusion of the clutch.

Analysis of the causes

Inside the bearing is garbage, such as dust, iron sawdust, etc., which interferes with the normal rolling of balls or rollers.

The guide sleeve or fork for the bearing is deformed or damaged, which blocks the trajectory of the squeezer bearing.

The malfunctions in the hydraulic adhesion system, such as leakage of hydraulic oil, insufficient oil pressure, etc., affect the normal operation of the squeezing bearing.

Bypass

Disassemble the bearing for cleaning and remove all the garbage inside. If the bearing is damaged, it must be replaced.

Check the guide sleeve and fork, correct or replace any deformed parts and make sure that the squeezer bearing can move normally.

Check the hydraulic clutch system, find and eliminate leaks, share a sufficient amount of hydraulic oil and, if necessary, replace hydraulic pumps, oil tubes and other components.

Stuck

Signs of a malfunction: the clutch pedal does not return to the starting position after pressing, or a squeezing bearing cannot flexibly move during operation, which leads to incomplete separation of clutch or non -payment inclusion.

Analysis of the causes

Inside the bearing is garbage, such as dust, iron sawdust, etc., which interferes with the normal rolling of balls or rollers.

The guide sleeve or fork for the bearing is deformed or damaged, which blocks the trajectory of the squeezer bearing.

The malfunctions in the hydraulic adhesion system, such as leakage of hydraulic oil, insufficient oil pressure, etc., affect the normal operation of the squeezing bearing.

Bypass

Disassemble the bearing for cleaning and remove all the garbage inside. If the bearing is damaged, it must be replaced.

Check the guide sleeve and fork, correct or replace any deformed parts and make sure that the squeezer bearing can move normally.

Check the hydraulic clutch system, find and eliminate leaks, share a sufficient amount of hydraulic oil and, if necessary, replace hydraulic pumps, oil tubes and other components.

overheat

Signs of a malfunction: after the vehicle has worked for a while, a squeezed bearing can become too hot to the touch and can even begin to smoke or burn.

Analysis of the causes

The free course of the clutch pedal is too small, due to which the squeezing bearing is in a half-disabled state for a long time, which increases friction.

The pressure between the squeezing bearing and the pressure plate is too large, which can be caused by an uneven or too strong force of the pressing plate.

The vehicle is operated in harsh conditions, for example, with prolonged driving at high temperatures and high loads.

Bypass

Adjust the free clutch pedal in accordance with the technical requirements of the car, which is usually achieved by adjusting the adjusting bolt under the pedal.

Check the spring disc spring and replace the spring with uneven effort or too strong to ensure normal pressure between the squeezing bearing and the pressure disk.

Try to avoid prolonged operation of the car in difficult working conditions. If this is impossible to avoid, it is possible to strengthen the measures to remove heat from the car, for example, regularly clean the motor compartment and chassis from dust, as well as check the serviceability of the cooling system.

Basic Info.

Model no.

DZ9114160023

Type

Sinotruk Howo Truck Spare Parts

Certification

TUV, GS

Transport Package

Wooden Box Transportation

Trademark

Yd

Origin

Shandong

Hs Code

8716400000

Production Capacy

500000vehicle/year

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive