Zoomlion 004906278b000101 Stop ring

1. High strength and wear resistance: made of high -quality steel, processed using special technology, has high hardness and strong wear resistance. It can withstand high loads and friction of the final transmission system and effectively extends its service life.

2. Adaptation: developed in strict accordance with the specifications of the components of the final transmission, with accurate dimensions and a dense landing with each component to ensure stable transmission and reduce the potential danger of malfunctions.

3. Simplicity of installation: reasonable design, simple installation and disassembly, reducing the complexity of service, reducing downtime and increasing the efficiency of work.

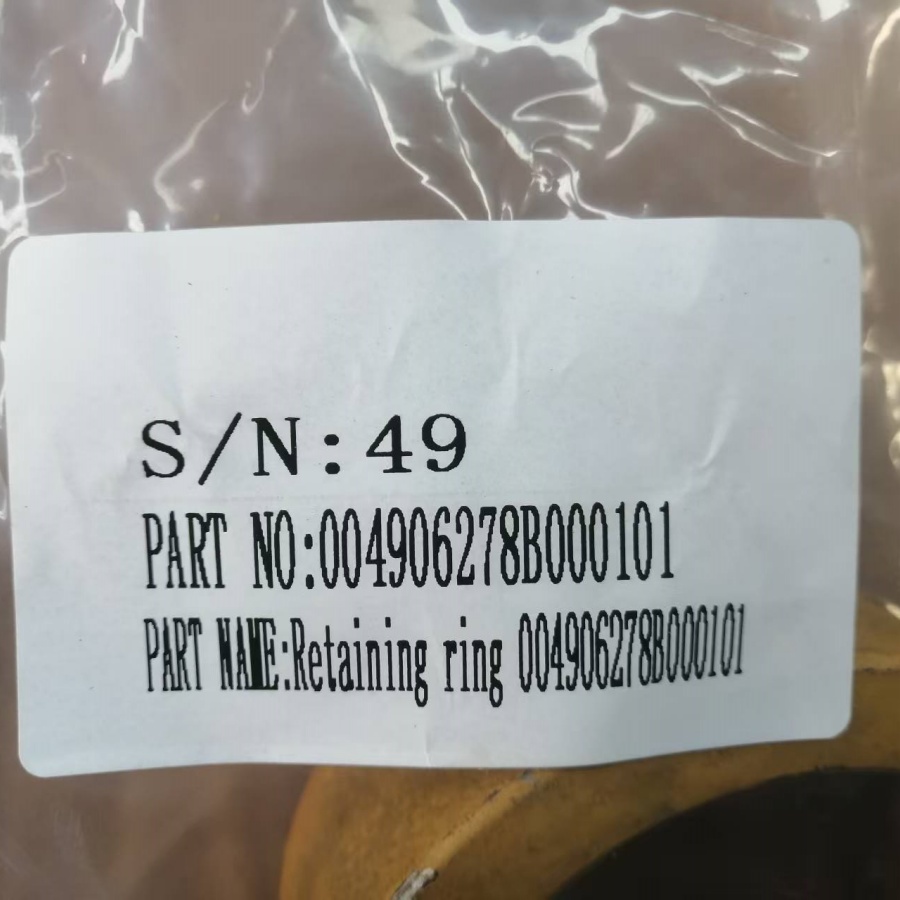

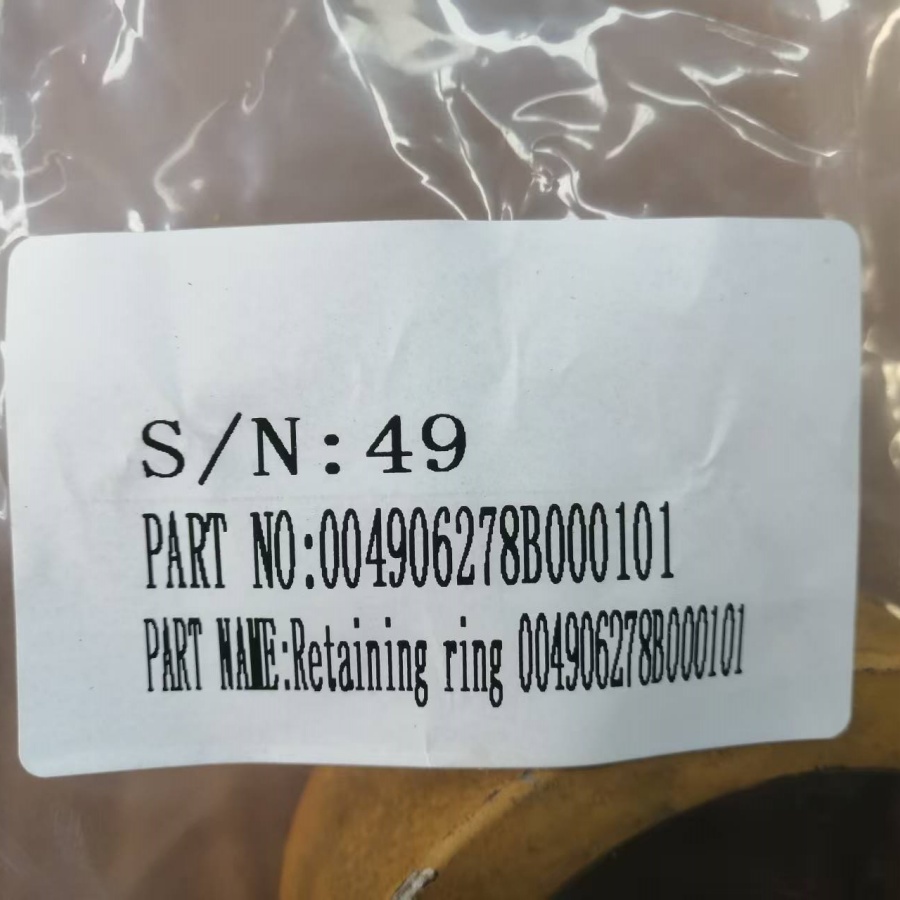

Product representation

Detailed product information

Elastic stop ring: it relies on its own elastic deformation to achieve installation and fixation. It can be divided into elastic locking rings for ramparts and elastic locking rings for holes. It is often used to fix gears, bearings and other components in the main gear of bulldozers to prevent their axial movement.

Stop ring of type C and a locking ring of type E: these are the most common types of elastic stop rings. The transverse section of the locking ring of type C has the shape of the letter C, and the shape of the locking ring of type E is similar to the letter E. They have good elasticity and strength and can adapt to certain working pressure and vibrations.

A spiral locking ring: made from a spring steel strip and can be divided into left -sided and right -handed. It must be screwed into the groove of the shaft or groove of the hole in parts during installation. It is often used in places with limited space and should withstand large axial loads.

Material: usually made of spring steel, stainless steel and other materials. Stop rings made of spring steel have high elasticity and strength and can maintain stable operational characteristics during prolonged work; Stoping stainless steel rings have good corrosion resistance and are suitable for use in harsh working conditions, as well as where they are easily exposed to moisture and caustic substances.

Function: It is mainly used to limit the axial displacement of the components of the final transmission of the bulldozer, ensuring the gears, bearings and other components to maintain the correct position during operation, prevent damage to the components, reducing the effectiveness of the transmission, abnormal noise and other problems caused by axial movement, and also plays a role in sealing and preventing dust, Preventing dust and pollution in the final transmission system and affecting its normal operation.

Stages of installation

Preparation: Make sure that the bulldozer is stopped and is in a safe condition, turn off the power or remove the ignition key to prevent random launch. Prepare the necessary tools, such as pliers for stopping rings, a screwdriver, cleaning fabric, lubricating oil, etc., as well as the corresponding locking ring of the main gear.

Remove the old stop ring: determine the location and type of old stop ring. If it is an elastic locking ring, use the pliers for the stop rings to carefully clarify one side of the locking ring to get out of the groove, and then slowly remove it. If this is a spiral stop ring, you will have to carefully twist it from the groove.

Cleaning and inspection: thoroughly clean the groove of the locking ring on the shaft or hole with cleaning fabric and detergent to remove contaminants such as oil, dust, iron sawdust, etc., and make sure that the groove is clean and smooth. Check the groove of the locking ring for damage, such as wear, deformation, cracks, etc. If there are any problems, replace it in a timely manner or replace the appropriate details. At the same time, check whether the size and shape of the new locking ring correspond to the original locking ring, and also whether there are no defects or burrs on the surface.

Install a new locking ring: for elastic locking rings, such as locking rings of type C and locking rings of type E, use pliers for locking rings to open the stop ring so that its diameter is slightly larger than the diameter of the shaft or hole, then combine the locking ring from with a seizure and slowly place it in the groove, making sure that the locking ring has completely entered the groove and is in the correct position. For spiral stop -rings, insert one end of the locking ring into the groove, and then, using the tool, screw it into the section by the section, paying attention to the correct direction of screwing until the lock ring is completely installed. During the installation process, apply the required amount of lubricating oil to the surface of the lock ring and groove to reduce friction and facilitate the installation.

Checking and debugging: After installation, carefully check whether the stop ring is reliably installed, whether it is weakened, not deformed and not displaced. Turn the related details such as gears, shafts, etc., to check the presence of anomalous phenomena, such as jamming and abnormal noise. If there are any problems, in a timely manner adjust or reinstall it.

Common errors

Rupture of the locking ring: this can be caused by defects in the glass ring, such as internal cracks, inclusion, etc.; or excessive external effort during installation leads to the appearance of cracks in the locking ring, which gradually expands until it breaks down during the subsequent work; Or a stop ring can work in high load and high vibration for a long time, which leads to insufficient fatigue strength and destruction.

Stop ring deformation: if the locking ring is installed incorrectly during installation, the range in the groove will be uneven and it will be easily deformed; Or during operation, the locking ring will be squeezed, encounter neighboring details and other external forces, which will also lead to deformation. In addition, the effects of high temperatures can change the properties of the glass ring, reduce its elasticity and strength, which will lead to deformation.

The weakened locking ring: the locking ring is not completely inserted into the groove during the installation, or the gap between the lock ring and the groove is too large. During the operation of the equipment, the stop ring can gradually weaken due to vibration, impact, etc. In addition, after prolonged use, the elasticity of the locking ring weakens, which also leads to a deterioration in its fixing effect and loosening.

Stop ring wear: prolonged contact and friction with neighboring moving parts will lead to wear of the surface of the lock ring. Dust, pollution, etc. From the working environment fall between the locking ring and details, which leads to an increase in wear. A worn locking ring can lose its initial sealing and fixing functions, which will affect the normal operation of the final transmission system.

After -sales service

Quality guarantee: usually manufacturers provide a certain period of quality guarantee, as a rule, from 6 months to 1 year, depending on the product and the rules of the manufacturer. During the warranty period, if the locking ring has broken, deformed, etc. Due to quality problems, the manufacturer must replace or repair it for the user for free.

Technical support: The manufacturer must have professional technical specialists in his staff who can provide users with technical consulting services and answer questions on the installation, use and maintenance of stop -rings. Support can be provided to users in various ways, such as phone, email and online customer service.

Supplies of accessories: ensure a sufficient supply of locking rings of the main transmission and related accessories so that users can timely purchase suitable products if you need to replace, reducing the time of downtime of the equipment. For some special specifications or stop -rings models, individual services can be provided.

Processing of customer reviews: creating a full -fledged feedback mechanism with customers, timely collection of opinions and users about products, analysis and elimination of existing problems, as well as a constant improvement of product quality and level of after -sales service.

To determine whether the replacement of the locking ring of the main transmission of the bulldozer is required, you can start with the following aspects:

Appearance verification: regularly inspect the on -board transmission of the bulldozer and pay attention to the appearance of the stop ring. If obvious cracks or zabrines are found on the surface of the lock ring, then even if the cracks or the chizes are small, they will gradually expand under the influence of external forces in the process of subsequent work, which will affect the performance of the lock ring, and it must be replaced. In addition, if the locking ring is very deformed, for example, the initially round locking ring has become oval, or the size of the lock ring of type C or E has changed significantly, and it can no longer be installed normally in the groove or cannot perform the fixing function, it should also be on time replace.

Determination of the gap: Use a probe or other tool to determine the gap between the lock ring and the mounting groove. If the gap is too large and exceeds the normal range of the planting of this model of the locking ring, this means that the stop ring is worn out or installed incorrectly. It can weaken or shift during the operation of the equipment, which will affect the stability of the components of the final transmission. In this case, you need to consider the possibility of replacing the locking ring. At the same time, check the gap between the locking ring and motionless parts (such as gears, bearings). If the gap increases abnormally, this can lead to an axial movement of parts, and the locking ring must be replaced.

Operating Condition Assessment: If you hear unusual noises from the final drive, such as sharp friction sounds, bumps, etc., while the bulldozer is running, it may be caused by looseness, wear or breakage of the retaining ring, interference, or collision with other parts. At this time, the machine should be stopped and checked immediately. If the problem is determined to be in the retaining ring, it will need to be replaced. In addition, if the bulldozer final drive components are found to work abnormally, such as unstable gear rotation, bearing heating, etc., it may be caused by the failure of the retaining ring, resulting in a change in the position of the components. The retaining ring must be further inspected and replaced if necessary.

Elasticity Test: For elastic retaining rings, a simple elasticity test can be performed to determine if they need to be replaced. Using pliers, carefully open the retaining ring and check its elasticity. If you feel that the elasticity of the retaining ring has weakened significantly, or if there are obvious deformations or cracks during the expansion process, it means that the effectiveness of the retaining ring has decreased and it can no longer effectively fix the part, so it should be replaced. In addition, if the retaining ring cannot fit tightly into the groove after installation and is easy to loosen, it also indicates that its elasticity is insufficient and it is necessary to replace the retaining ring with a new one.

Assessment of the degree of wear: If there are obvious signs of wear on the surface of the retaining ring, such as a large depth of wear, rough surface, etc., especially if the worn parts affect the normal functioning and installation stability of the retaining ring, it needs to be replaced. In addition, if the edge of the retaining ring in contact with the component is badly worn, resulting in a significant reduction in the thickness of the retaining ring, its locking effect will also be impaired, and the retaining ring should be replaced with a new one in a timely manner.

Exhibition cabinets

Acquaintance with the plant

The factory has a team of highly qualified and experienced engineers who continuously introduce technological innovation and improve products. At present, the company owns a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment, such as excavators, loaders, cranes, bulldozers and other machines. The products are characterized by high performance, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working environments around the world.

Awards and qualifiersFiction

Frequently Asked Questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipment

3. What logistics ways can we work for shipping?

1) For most countries in Europe, South America and Africa, etc., we can go by container or Roro through ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or railway.

3) For light spare parts in urgent requirement, we can send it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you ensure that you have delivered the goods to customers?

A: We will provide you with full shipping information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable Quality: Carefully select regular manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by us, always adapting the best materials.

2) Competitive price: The concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive