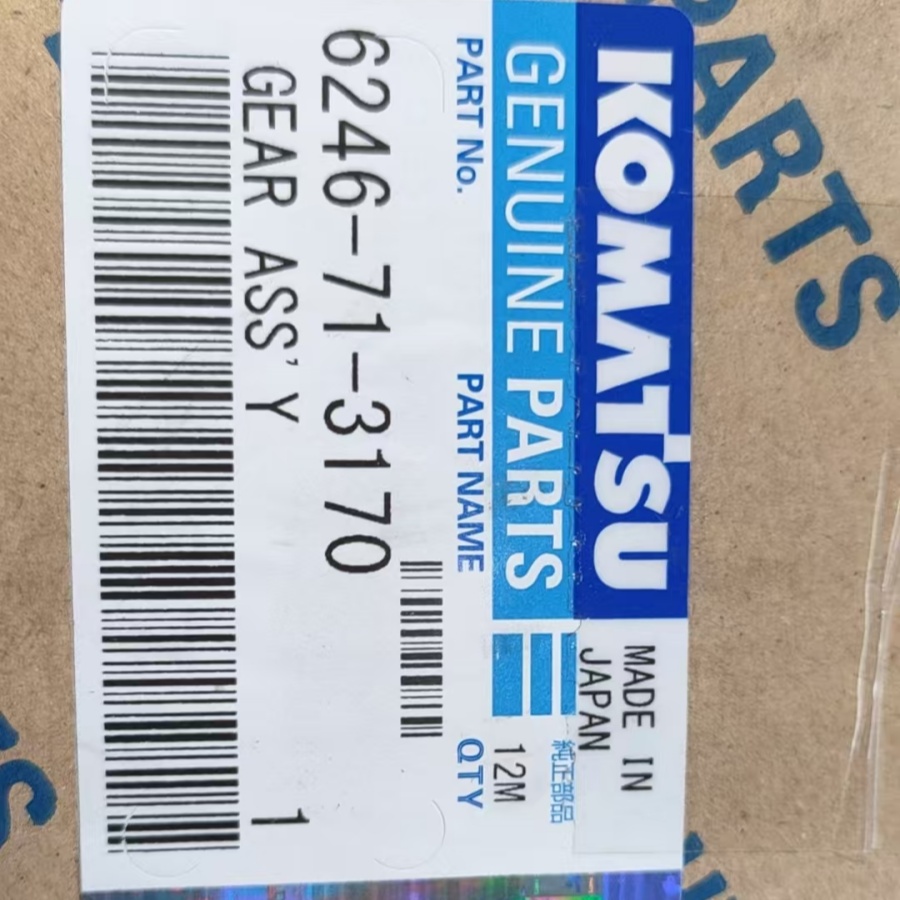

Komatsu 6246-71-3170 Gear Set

1、High transmission capacity:The gear reducer is equipped with precision gears, ensuring minimal power loss and high working efficiency. It enables the equipment to generate powerful torque for demanding tasks.

2、High wear resistance:Made of durable 합 material with special heat treatment, the reducer can withstand heavy loads and harsh working conditions without losing its functional properties for a long time.

3、Compatibility and easy installation:Komatsu 6246-71-3170 gearbox is ideally compatible with a wide range of Komatsu special equipment. Standard design and precise dimensions ensure its easy and quick installation and replacement.

Product Introduction

1. General overview of the Komatsu 6246-71-3170 gear unit

The Komatsu 6246-71-3170 gear unit is a critical component of transmission and drive systems of Komatsu heavy special equipment, designed to transmit torque and adjust the speed of working mechanisms. It belongs to the class of pre-cylindrical gears with direct engagement, which ensures high accuracy of power transmission and stability under long-term high loads.

Unlike standard gear nodes, this product was created according to unique Komatsu technologies: high -strength materials, high -precision teeth processing and additional anti -icing coatings were used, allowing it to work in harsh conditions - dust, moisture, temperature differences and vibrations characteristic of construction sites, quarries and mining facilities. The main task of the sixth node is to ensure a smooth and reliable transfer of energy from the engine to the working bodies (for example, the drive of the excavator caterpillars, a bucket rotation mechanism), which directly affects the performance, maneuverability and service life of all equipment. Due to the high quality level, the 6246-71-3170 unit has become a standard component for many models of Komatsu excavators and tractors, confirming its reliability in conditions of intensive operation.

2. Technical characteristics of the gear unit

2.1 Tails and structures parameters

The Komatsu 6246-71-3170 gear unit has well-thought-out tooth parameters that ensure high transmission efficiency and durability:

Gear type: Straight-tooth (DIN 3960 standard), ensuring ease of manufacture, high precision and low noise level during operation.

Number of teeth: 28 (drive gear) and 42 (driven gear) - gear ratio 1:1.5, optimized for torque and speed balance in mid-range transmissions (for equipment with engines of 150–250 hp).

Tooth module: 5 mm (according to ISO 54 standard) - guarantees sufficient tooth strength when transmitting torque up to 800 Nm.

Keyway module: 8 mm (keyway width 12 mm) - provides a reliable connection to the transmission shaft, preventing play and wear due to vibrations.

2.2 Strength and material characteristics

Gear Material: 20CrMnTi alloy steel (according to GB/T 3077 standard) - has high hardness (HRC 58-62 after heat treatment), wear resistance and fatigue strength, withstanding repeated loads without tooth deformation.

Heat treatment: Carbonization cycle (temperature 920–950 °C) + hardening + tempering — increases the hardness of the tooth surface (up to 62 HRC) and the plasticity of the core (30–35 HRC), preventing peeling and cracks under impact loads.

Surface treatment: Hybrid treatment - tooth grinding (roughness Ra ≤ 0.8 µm) + chemical-thermal TiN coating (titanium nitride, thickness 3–5 µm) - reduces friction between meshed teeth by 20% and increases wear resistance by 35% compared to unpainted gears.

2.3 Working parameters

Maximum transmitted torque: 850 Nm – sufficient for operation in transmissions of 20–30 ton class excavators (e.g. models PC200-8, PC220-8).

Maximum rotation speed: 3000 rpm (for the drive gear) - corresponds to the speeds of the transmission shafts of Komatsu SAA6D114E series engines.

Operating temperature range: -30 °C to +120 °C — adapted for operation in cold regions (northern regions of Russia) and hot climate conditions (south of Kazakhstan, Central Asia), without loss of material strength.

3. Design features

3.1 Main components and their purpose

The Komatsu 6246-71-3170 gear assembly consists of three key components integrated into a single assembly unit:

Leading gear (28 teeth): equipped with a key hole with a diameter of 40 mm for connection to the input shaft of the transmission - the surface of the hole has a high processing accuracy (accuracy class H7), ensuring a tight fit to the shaft and preventing backlash.

Driven gear (42 teeth): has a central hole with a diameter of 55 mm with an internal thread M60×2 - designed for connection to the output shaft or gearbox, ensuring reliable transmission of torque without spontaneous unscrewing.

Unit housing (optional): made of aluminum alloy A356-T6 for models with open transmissions - provides protection of gears from dust and moisture, and also serves to mount bearings (type 6208-ZZ, outer diameter 80 mm).

3.2 Protection and noise reduction systems

Anti-friction bearings: Built-in closed-slot bearings (precision class P6) - reduce friction between the shaft and housing, extending the service life of the unit by 40% and reducing operating noise (≤65 dB at rated speed).

Greasing channels: Special channels for supplying lubricant (lift oil class ISO VG 150) - provide continuous lubrication of the meshing teeth, preventing dry friction and overheating under high loads.

Backlash limiters: Viton fluororubber seals between housing and shafts - prevent dust and moisture from entering the tooth engagement and preventing loss of lubrication, reducing the risk of corrosion and wear.

3.3 Ease of installation and maintenance

Marking: The body and gears are marked with article number 6246-71-3170, serial number and mark of the initial position of the teeth (check mark "△") - facilitates identification, correct engagement during installation and tracking of service life.

Standard dimensions: Unit weight 7.2 kg, overall dimensions 180×120×95 mm — compact design allows installation in limited space under the hood of equipment (for example, in the transmission compartment of an excavator).

Ease of dismantling: No special tools required - just unscrew the mounting bolts (M10×30) and remove the unit from the transmission, which reduces repair time to 1–2 hours.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsfikation

Frequently Asked Questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2.What payment terms can we accept?

Usually we can work on T/T, 30%TT before production and 70%TT before shipment

3.What logistics methods can we work with for delivery?

1) For most countries in Europe, South America and Africa etc. we can go by container or Roro via ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or railway.

3) For light spare parts in urgent requirement, we can ship it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you ensure that you have delivered the goods to customers?

A: We will provide you with full delivery information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable quality: Carefully select regular manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by ourselves, always adapting the best materials.

2) Competitive price: Concentration of mechanized production in large quantities reduces production costs to ensure competitive price.

3) Service Team: Firstly, our sales managers are on duty 24 hours a day, ready to answer your questions at any time. Secondly, professional technical service team with senior technicians, ready to provide support services for users and dealers. Most of the problems can be solved within 24 hours.

4) Fast delivery: Generally, we can delivery within 10 working days in factory after receiving the advance payment from customers.

6. How can you provide customers with after-sales service?

A: We will reply to you at the first time and help you solve the problems within 24 hours. If you really need us local, we

We will send your professional person to your locality to help you solve the problems without any hesitation, supply you with all-round