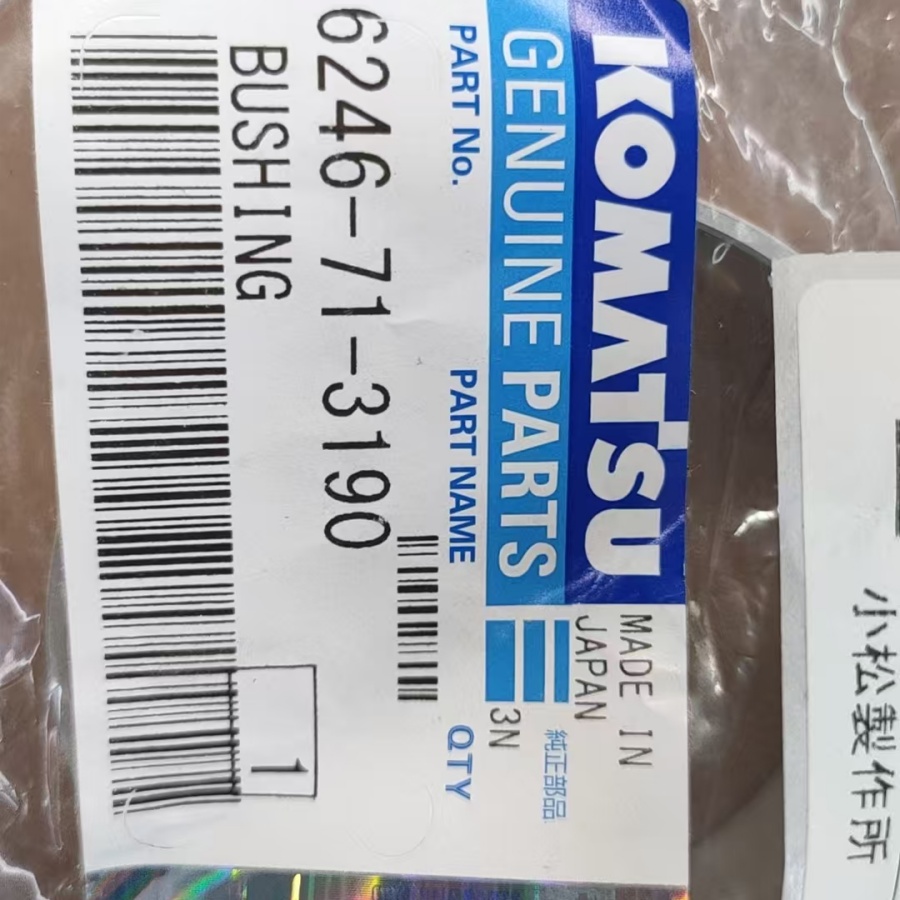

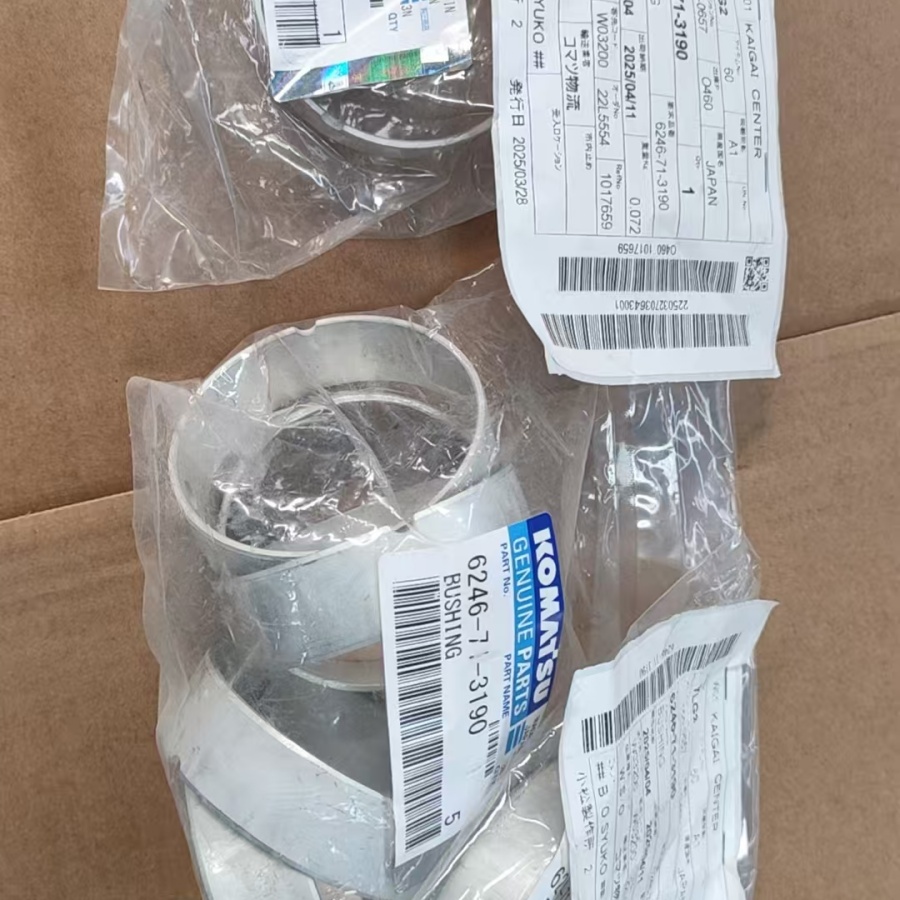

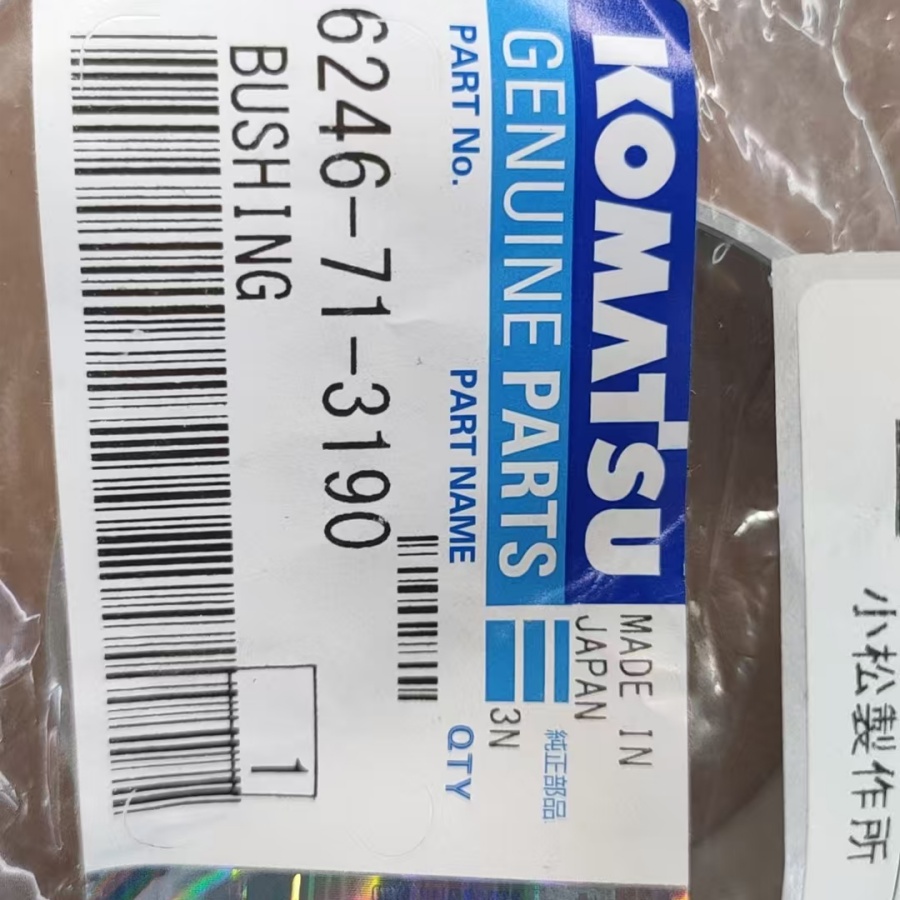

Komatsu 6246-71-3190 BUSHING

1. Premium Materials: The bushing is made of high-quality materials, ensuring strength and durability. This allows it to withstand heavy loads and extended use, minimizing the risk of breakage and wear.

2. Excellent surface finish: The bushing's surface treatment technology improves its finish, allowing it to maintain its performance even under harsh operating conditions. This reduces the frequency of component replacement and improves equipment efficiency.

3. Compatibility: The Komatsu 6246-71-3190 bushing is perfectly compatible with the Komatsu 6246-71-3190 bushing, ensuring easy installation and reliable operation within the system. It meets manufacturer standards, ensuring trouble-free equipment operation.

Product Introduction

Revised description of Komatsu bushing 6246-71-3190

1. General description

The Komatsu 6246-71-3190 bushing is a genuine factory part designed and manufactured by Komatsu Corporation to company quality and manufacturing standards. As a key element of the chassis and articulated part of Komatsu special equipment, it is responsible for the stability and durability of moving joints, is adapted for intensive use in harsh industrial conditions and is indispensable for maintaining the performance of construction, quarry and other heavy equipment.

2. Specifications

2.1 Material and strength properties

The part is made from a specialized high-strength alloy that combines increased resistance to abrasive wear and impact loads. The material maintains geometric stability under long-term static and dynamic loads, eliminates plastic deformation, and guarantees the maintenance of performance characteristics under intensive use.

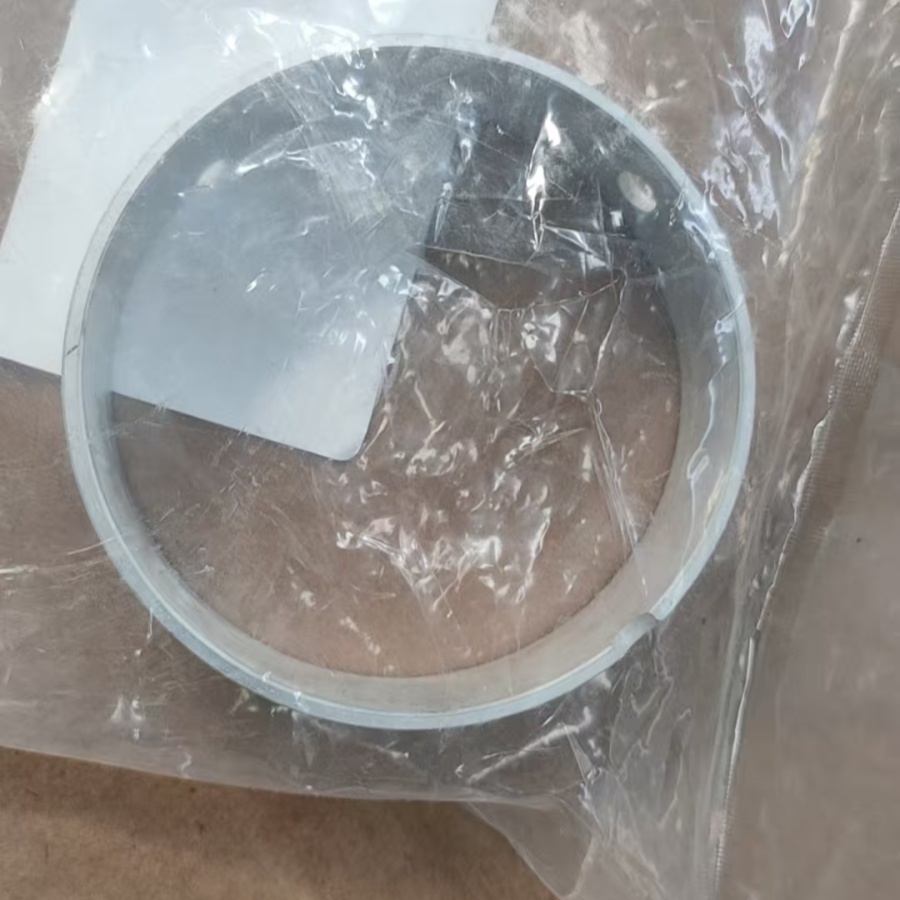

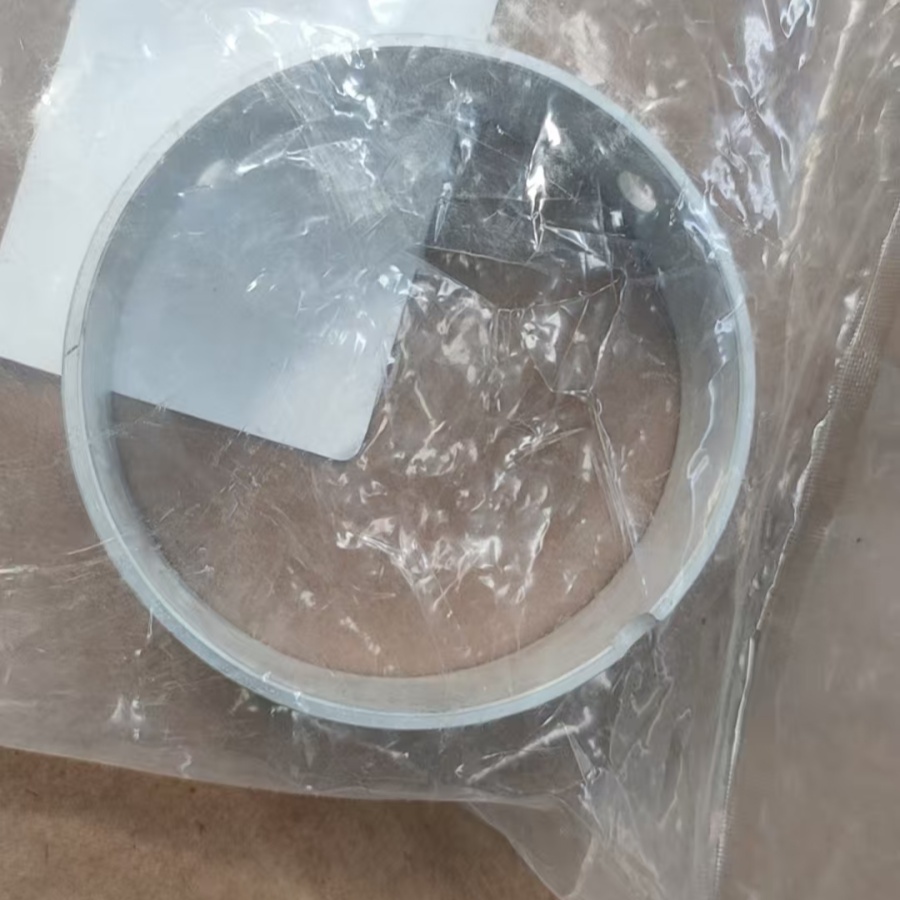

2.2 Geometric accuracy

The 6246-71-3190 bushing is manufactured on precision equipment with all dimensional parameters (diameter, length, wall thickness) controlled according to Komatsu specifications. Its perfect geometry ensures a gap-free fit in mating assemblies, a tight seal with adjacent components, and eliminates runout or play in the connection.

2.3 Resistance to operational factors

The bushing is resistant to adverse environmental conditions, including dust, moisture, temperature fluctuations, and contact with operating fluids (oils, lubricants, and coolants). This allows the part to maintain its properties without losing efficiency on construction sites, quarries, agricultural fields, and other challenging conditions.

3. Application in Komatsu equipment

Bushing with part number 6246-71-3190 is designed for installation in the hinge assemblies of a wide range of Komatsu special equipment models, including excavators, bulldozers, and road construction equipment. Main applications:

Hinges of the rotating mechanism of the working element (excavator bucket);

Extension and lifting units of lever mechanisms;

Other moving joints requiring smooth rotation and uniform load distribution.

The part performs two main functions: it ensures smooth interaction of moving elements and protects the axles, hinges, and adjacent components from premature wear, thereby extending the overall service life of the equipment.

4. Key benefits

4.1 Increased reliability

Strict quality control at all stages of production, from raw material selection to final inspection, guarantees reliable operation of the bushing under intensive use. The absence of unexpected failures and breakdowns minimizes equipment downtime and improves overall fleet productivity.

4.2 Long service life and cost effectiveness

The material's high wear resistance significantly increases the interval between repairs and reduces the frequency of component replacement. This reduces operating costs, spare parts, and maintenance expenses.

Exhibition cabinets

Getting to know the plant

The plant employs a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. The company currently owns a number of independent intellectual property rights and patented technologies. The construction equipment produced includes a wide range of equipment such as excavators, loaders, cranes, bulldozers and other machines. Products are characterized by high performance, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to challenging operating conditions in a variety of climates and operating environments around the world.

Awards and qualificationsfication

frequently asked questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2.What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipment

3.What logistics methods can we use for delivery?

1) For most of Europe, South America and Africa etc. countries, we can go by container or Roro via ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or rail.

3) For light spare parts in urgent requirement, we can ship it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you guarantee that you have delivered the goods to the customers?

A: We will provide you with full delivery information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable quality: Carefully select reliable manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by ourselves, always adopting the best materials.

2) Competitive price: Concentration of mechanized production in large quantities reduces production costs to ensure competitive price.

3) Service Team: Firstly, our sales managers are available 24/7, ready to answer your questions at any time. Secondly, our professional technical support team, with senior technicians, is ready to provide support to users and dealers. Most issues can be resolved within 24 hours.

4) Fast delivery: Generally, we can delivery within 10 working days in factory after receiving the advance payment from customers.

6. How can you provide after-sales service to customers?

A: We will reply you at the first time and help you solve the problems within 24 hours. If we really need your local, we

We will send your professional person to your locality to help you solve the problems without any hesitation, supply you with all-round