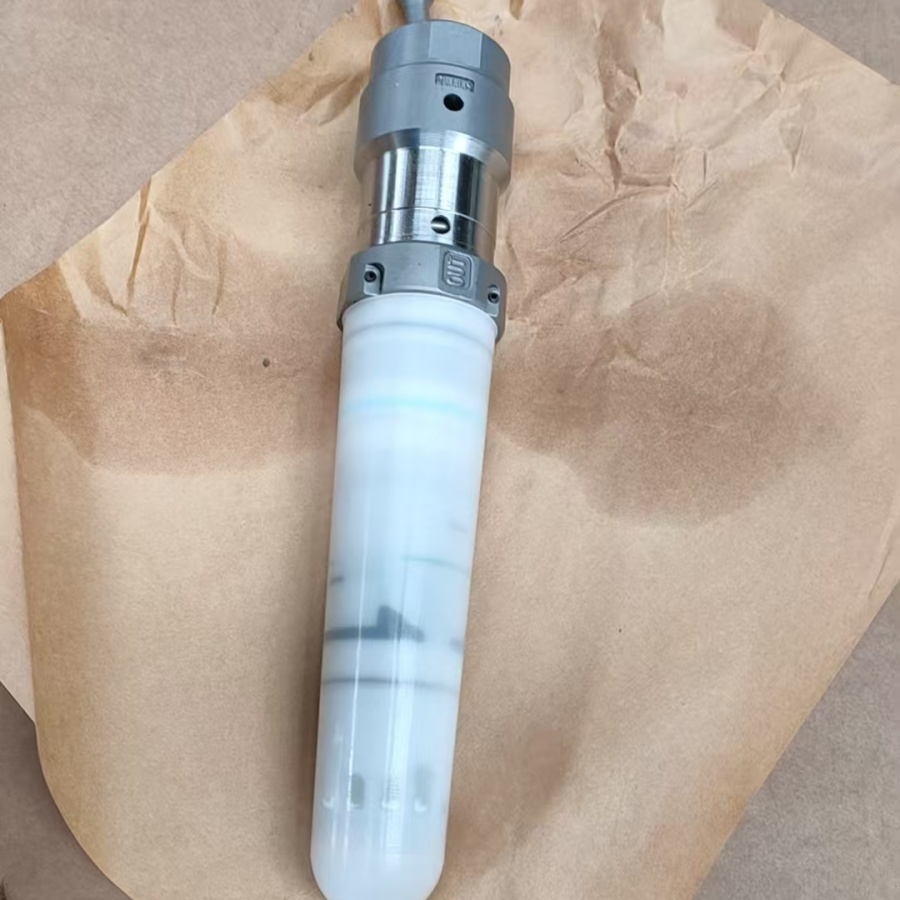

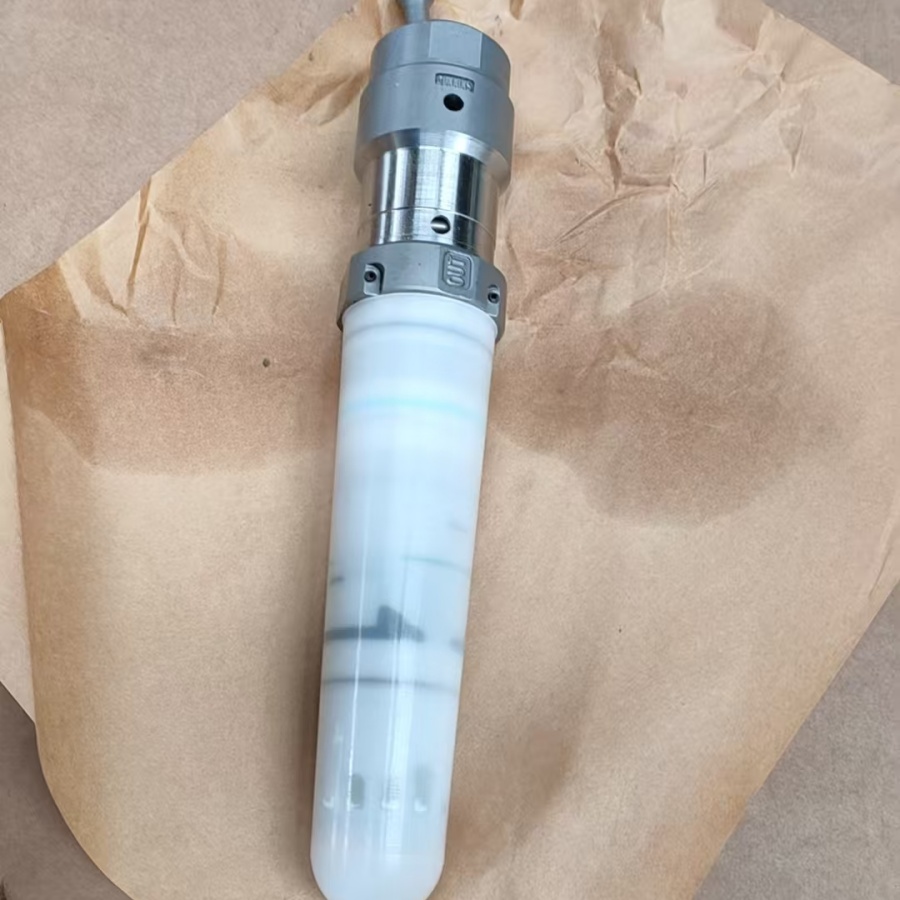

Komatsu 6560-11-1310 Fuel Injectors

1、Accurate fuel supply: Komatsu 6560-11-1310 injector provides a high degree of accuracy in fuel distribution (deviation no more than 2%), which optimizes the fuel-air mixture, improves engine efficiency and reduces harmful emissions.

2、High strength and durability: Made of alloys with high resistance to wear and corrosion, resistant to high temperatures (up to +350°C) and pressures in the system. Guarantees reliable operation in harsh operating conditions of Komatsu equipment.

3、Perfect compatibility: Designed specifically for certain Komatsu engines (including excavators and loaders), it ensures precise matching with the fuel supply system, is easy to install without additional adapters, and maintains the stable operation of the entire engine part.

Product representation

The Komatsu 6560-11-1310 fuel injector is a key component of the fuel system of the Komatsu heavy-scale engine engines, designed to ensure high performance, reliability and efficiency in harsh operating conditions. This injector has passed multi -stage tests and certification, complying with international quality standards and environmental requirements, which makes it an integral element to maintain the effective operation of excavators, loaders and other Komatsu construction machines.

1. General purpose and role in the engine system

The fuel injector performs a critical function - accurately dose, spray and supply fuel to the engine cylinders at a certain moment in the working cycle. For Komatsu engines, which often work under high loads (for example, with breed crushing, loading cargo or transporting heavy objects), the quality of injecting directly affects the efficiency, level of emissions, engine life and fuel saving. The Komatsu 6560-11-1310 injector specializes in optimizing the combustion process: due to the accurate supply of fuel, it provides an ideal ratio of fuel-air, which minimizes incomplete combustion, reduces carbon dioxide emissions, and also increases the engine power. Thanks to this, techniques with this injector demonstrate stable operation even with prolonged operation at low temperatures (up to -25 ° C) or high humidity, which is especially important for construction projects in regions with severe climate.

2. Technical characteristics and parameters

Komatsu has developed the 6560-11-1310 injector with special attention to technical parameters to ensure maximum adaptation to SAA6D107E, SAA6D114E and SAA6D125E engines, which are common models in Komatsu's heavy equipment lineup (including PC200-8, PC300-8 excavators and WA380-6 loaders). Key technical characteristics include:

Fuel supply accuracy: Fuel dosage deviation does not exceed 2%, which is one of the lowest rates on the market for this class of injectors. This ensures uniform fuel supply to each cylinder, preventing overload of individual engine components and reducing operating noise.

Injection pressure: The maximum injection pressure reaches 220 MPa, which ensures fine atomization of fuel (fuel particle size no more than 10 microns). Fine atomization improves fuel contact with air, accelerates the combustion process and increases engine efficiency by 5-8% compared to analog injectors of other brands.

Operating temperature range: The injector is resistant to temperatures from -25°C to +350°C. This is achieved by using heat-resistant materials and sealed connections that prevent overheating of components under high loads and freezing in cold conditions.

Overall dimensions: Length - 185 mm, diameter - 42 mm, weight - 0.8 kg. Compact dimensions allow easy installation of the injector in the limited space of the engine compartment, and light weight reduces the overall load on the engine company.

Service life: If operating rules are followed and regular maintenance is performed, the injector guarantees operation for up to 10,000 working hours - this is 20% longer than most similar products on the market.

3. Design and materials

The Komatsu 6560-11-1310 injector is designed for maximum durability and ease of maintenance. It consists of four main components: body, rod, nozzle and electromagnetic valve. Each element is made of high-quality materials that have undergone strict quality control:

Housing: Made of 42CrMo4 martensitic steel, which has high strength (yield strength - 900 MPa) and corrosion resistance. The housing surface is coated with a 15 micron thick cathode coating, which protects it from the effects of aggressive environments (e.g. moisture, sand, chemicals in fuel).

Rod: A tantalum-based alloy is used, which has a low coefficient of thermal expansion. This prevents deformation of the rod during temperature changes, ensuring stable operation of the injector even in extreme conditions.

Injector: equipped with seven holes with a diameter of 0.15 mm, located at an angle of 15°, which ensures uniform distribution of fuel throughout the entire volume of the combustion chamber. The injector material is superhard carbide VK8, which is resistant to wear at high pressures and temperatures.

Solenoid valve: Made of permalloy (iron-nickel alloy), which has high magnetic permeability. This ensures a fast valve response (response time - 0.002 seconds), which is critical for accurate fuel dosing in different engine operating modes.

Additionally, the design includes a pollution protection system: a filter at the fuel inlet with a cell size of 5 microns retains small particles, preventing clogging of the injector and rod. Hermetic connections based on fluororubber ensure absolute tightness of the system, preventing fuel leakage and moisture ingress.

4. Compatibility and scope of application

The Komatsu 6560-11-1310 injector is designed exclusively for Komatsu engines of certain models, which guarantees a perfect match with the fuel supply system and no need for additional adapters. The main models of equipment with which it is compatible:

Excavators: PC200-8, PC220-8, PC300-8, PC360-8.

Wheel loaders: WA380-6, WA470-6, WA500-6.

Road construction equipment: GD655-5, GD675-5 (road rollers).

Tractors: D65PX-17, D85PX-18 (tracked tractors).

This equipment is widely used in construction, mining, forestry and agriculture. For example, in coal mining, the PC360-8 excavators with an injector 6560-11-1310 demonstrate stable operation when processing up to 500 cubic meters of ore per hour, while fuel consumption is reduced by 7% compared to similar machines with injectors of other brands. In agriculture, the D65PX-17 tractors easily cope with this injector with soil processing in areas up to 10 hectares per working day, even in wet soil or low temperatures.

5. Rules for operation and maintenance

To maximize the service life of the Komatsu injector 6560-11-1310, it is important to comply with the following operating and maintenance rules:

Fuel choice: use only fuel corresponding to the EN 590 standard (for diesel) or ASTM D975 (for gasoline). Low -quality fuel with a high content of impurities can lead to clogging of the nozzle and a decrease in the accuracy of injection.

Regular filter replacement: Replace fuel filters every 500 operating hours and air filters every 1000 operating hours. This prevents dirt and sand from entering the injector.

Injection pressure check: Every 2000 working hours, carry out injection pressure diagnostics using specialized equipment (for example, Komatsu KT-3000 injector test bench). If the pressure deviates from the norm, adjust or replace components.

Storing the injector: For long-term storage (more than 6 months), the injector should be stored in a sealed package with moisture-absorbing material, at a temperature of +5°C to +25°C. Before installation, it is necessary to check the tightness and clean the contact surfaces.

Repair: Injector repairs should only be performed by Komatsu certified service centers using genuine parts. Unauthorized repairs or replacement of non-genuine components may result in engine failure and void the warranty.

6. Advantages over analogues

Compared with fuel injectors of other brands (for example, Bosch, Delphi, Denso), the Komatsu 6560-11-1310 injector has a number of significant advantages:

Perfect compatibility with Komatsu equipment: Developed directly by Komatsu, eliminating installation and engine adaptation issues. Third-party analogs often require modification of the fuel supply system, which increases installation time and the risk of breakdowns.

High injection accuracy: Fuel dosage deviation is no more than 2% (analogues have 3-5%), which ensures better fuel economy and reduced emissions.

Durability: Service life up to 10,000 working hours (analogues - 7-8,000 hours), which reduces replacement and maintenance costs.

Warranty: Komatsu warrants the 6560-11-1310 injector for 2 years or 5,000 operating hours, plus free diagnostic service at certified centers during the first year of operation.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsfikation

frequently asked questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2.What payment terms can we accept?

Usually we can work on T/T, 30%TT before production and 70%TT before shipment

3.What logistics methods can we work for delivery?

1) For most of Europe, South America and Africa etc. countries, we can go by container or Roro via ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or railway.

3) For light spare parts in urgent requirement, we can ship it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you ensure that you have delivered the goods to customers?

A: We will provide you with full delivery information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable quality: Carefully select regular manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by ourselves, always adapting the best materials.

2) Competitive price: Concentration of mechanized production in large quantities reduces production costs to ensure competitive price.

3) Service Team: Firstly, our sales managers are on duty 24 hours a day, ready to answer your questions at any time. Secondly, professional technical service team with senior technicians, ready to provide support services for users and dealers. Most of the problems can be solved within 24 hours.

4) Fast delivery: Generally, we can delivery within 10 working days in factory after receiving the advance payment from customers.

6. How can you provide customers with after-sales service?

A: We will reply you at the first time and help you solve the problems within 24 hours. If we really need your local, we

We will send your professional person to your locality to help you solve the problems without any hesitation, supply you with all-round