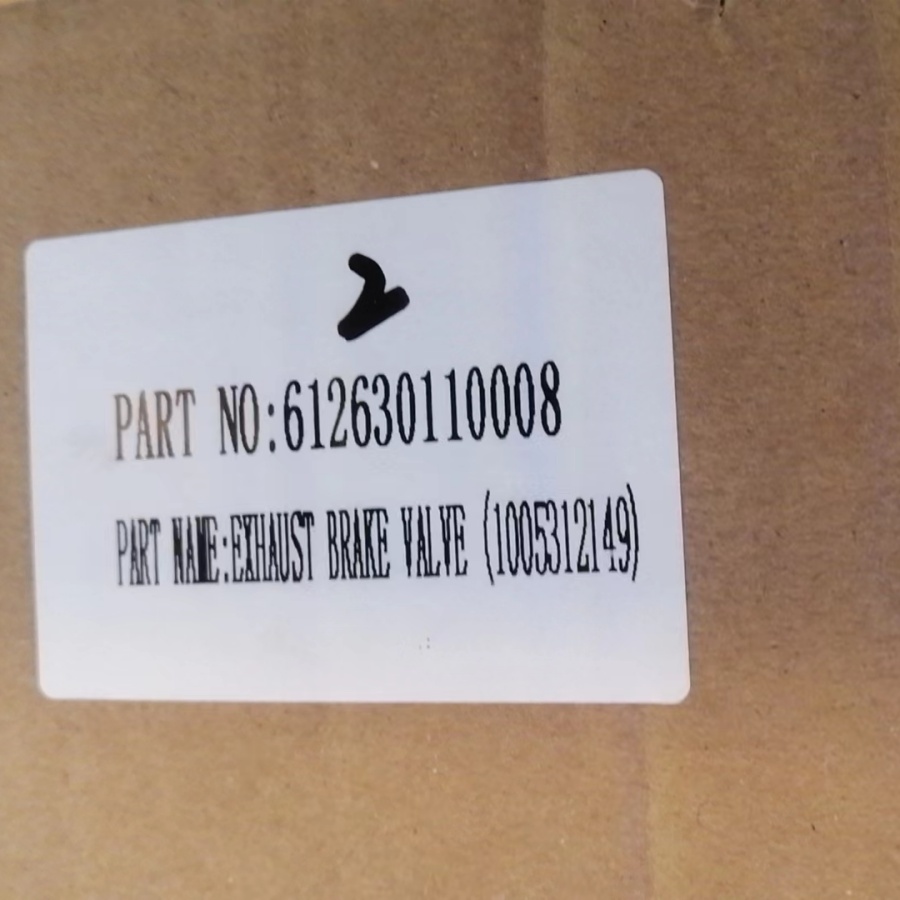

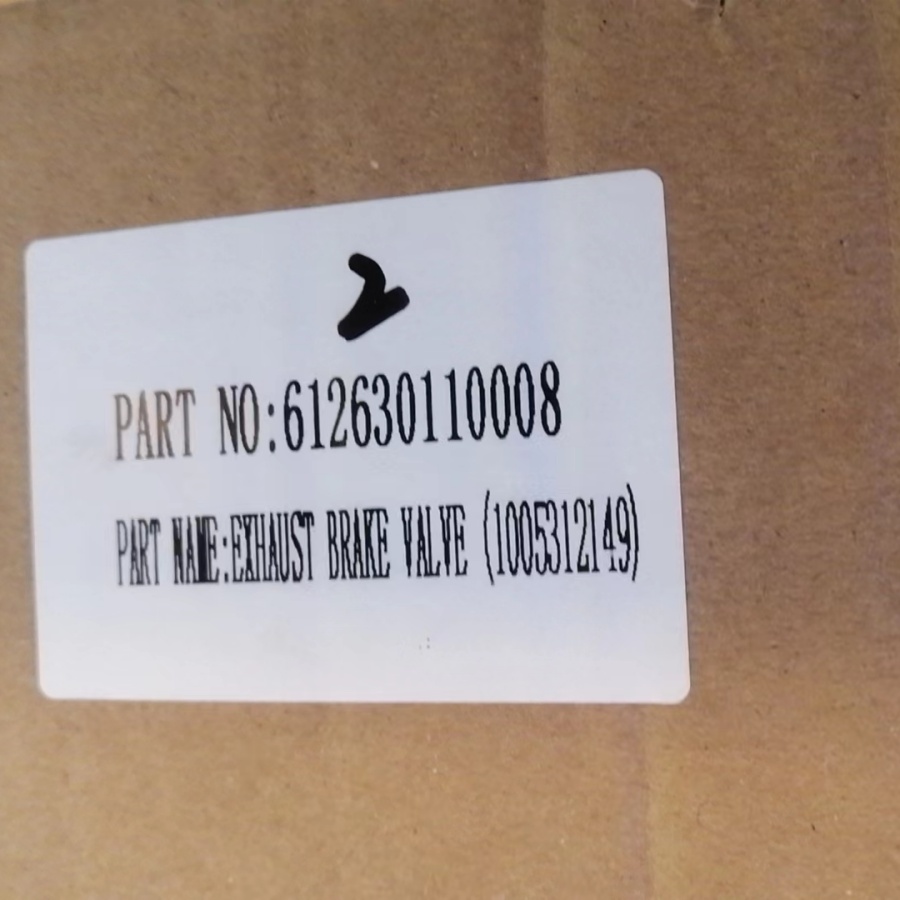

Sinotruk 612630110008 brake valve of the exhaust pipe Original

1. Effective braking: fast reaction, an effective increase in the resistance of exhaust gases, a significant improvement in the brake effect and reducing the brake path.

2. Stability and reliability: reasonable design, durable material, can adapt to difficult working conditions and harsh conditions, as well as work stably.

3. Simplicity of operation: it goes well with the vehicle control system, is easy to operate, and the driver can easily master it.

4. Energy saving and decreasing fuel consumption: auxiliary braking, reducing wear of the brake system, reducing the cost of maintenance and fuel saving.

Product representation

1. The principle of work

Weichai exhaust pipe brake valve provides auxiliary braking by increasing the resistance with exhaust gases. When the vehicle must slow down, the driver activates the corresponding control device, and the brake crane is activated. At this time, the throttle dashing in the brake valve overlaps the exhaust pipe channel, and the engine piston is exposed to gas during the release tact, which prevents the engine, thereby creating the braking effect. This process turns the engine into an air compressor, which uses the brake moment created by it to constant the car or stabilize its speed. Unlike traditional braking using exhaust gases, some advanced weichai brake valves technologies, such as Wevb (Weichai Power Exhaust Valve Braking Technology), use a phenomenon in which the exhaust valve automatically opens a wave of pressure during the braking process. During the compression tact and subsequent expansion tact, the exhaust valve always remains open to the gap, which additionally increases the efficiency of engine braking. Compared to traditional methods, the braking effect can be improved by 40%-50%.

2. Structural composition

The control cylinder knot: compressed air from the air tank enters here, forcing the piston to move, and is a source of energy for the operation of the brake valve. When the compressed air is supplied to the working cylinder, the piston is pushed, and then, through the connecting rod mechanism, the opening and closing of the throttle is controlled.

The connecting part: connects the working cylinder and the throttle knot to ensure the effective transmission of the effort and stability of the entire brake valve design, as well as coordinating its movements.

The throttle knot: the main component controls the exhaust pipe channel by opening and closing the throttle plate. When braking, the throttle is completely closed, blocking the exhaust channel for the implementation of the braking function; With normal driving, the throttle is open to ensure smooth output.

3. The advantages of the product

Effective braking: the braking reaction is fast, which can quickly increase the resistance of exhaust gases, significantly improve the brake effect, significantly reduce the brake distance and effectively ensure the safety of the vehicle during movement, especially on the descents in the mountains, which can ensure a stable slowdown in the vehicle.

Stable and reliable: the general design is scientific and reasonable, made of durable and durable materials. It can adapt to complex and variable working conditions and harsh working environment, maintain stable performance with prolonged use and reduce the likelihood of refusal.

Simplicity of operation: it goes well with the vehicle drive system. The driver can manage it simply and conveniently, and it is easy to master. The driver can easily open and close the brake valve, simply by pressing the corresponding control buttons or pedals in the car.

Energy saving and reducing consumption: as an auxiliary braking device, it can reduce the frequency of use of the main brake system of the vehicle, reduce the wear of the brake system, extend its service life and, thus, reduce maintenance costs. At the same time, under certain conditions of operation, combined with the mechanism for turning off the oil supply, fuel saving can be achieved.

4. Applicable models

It is widely used in medium and heavy trucks, buses and various types of construction equipment equipped with WeICHAI engines. For example, for heavy trucks, such as Shaanxi Automobile, the Delong and Foton Auman series, this brake valve can effectively help in braking during long distances and in difficult road conditions; Some city and tourist buses are also equipped with this brake valve to ensure the safety of driving during frequent touching and stops, as well as on rises and descents; It can also be used in vehicles of construction equipment, such as loaders and excavators, to adapt to special working conditions in the performance of engineering work.

5. Precaution measures for installation

Choosing a place of installation: It is preferable to install it next to the exhaust collector to guarantee that the flow of exhaust air can directly affect the brake valve, reduce the loss of exhaust resistance and improve the brake effect. At the same time, make sure that the installation site is convenient for subsequent maintenance and inspection, and avoid installing in hard -to -reach angles. In addition, it is necessary to stay away from heat sources and other high-temperature components to prevent damage to the brake valve due to overheating. There should be enough space around it to guarantee that the brake valve will not interfere with other components during operation.

Technical characteristics of pipeline joints: thoroughly check the connecting pipelines for damage, deformations or blockages to make sure that there are no obstacles to their cross -country ability. Use pipe connecting fittings corresponding to the specifications of the brake valve interface, for example, sealing rubber rings, clamps, etc., to ensure the tightness of the joints and prevent air leakage. When connecting, observe the correct order and direction of the installation to avoid twisting or bending the pipeline, which can affect normal circulation of compressed air. After installation, conduct a comprehensive check of the pipeline to make sure that there are no weakening and leaks.

Connection of an electric circuit: For brake valves with electronic control components, be sure to turn off the power supply of the vehicle before connecting the electric circuit to prevent damage to an electric current or short circuit. Correctly connect each fork and outlet in accordance with the electrical wiring circuit to ensure a reliable connection of the circuit and avoid weakened connections. Check if the line is the intake. If it is damaged, repair or replace it on time to prevent malfunctions caused by a leak. After the connection is completed, turn on the power and check the operability of the electrical control of the brake valve.

Debugging and calibration: after installing the brake valve, it must be carefully debugged and calibrated. First, check whether the brake tap is easy and smoothly opened and closed, if there are no seals. Then, with the help of professional testing equipment, in accordance with the specific parameters of the vehicle and the requirements for braking, key parameters such as the opening pressure and the pressure pressure of the brake valve are adjusted to guarantee that the brake valve is launched and closed at the right time to achieve the best effect braking. In the process of debugging, pay close attention to the efficiency of braking and the working condition of the vehicle. If there are any deviations, check and eliminate them in a timely manner.

Correspondence to other systems: During the installation, make sure that the brake valve corresponds well to the entire brake system of the car, the engine control system and other related systems. Check the coordination between the brake valve and the main brake system to avoid the brake conflict or problems with inconsistency. At the same time, communication is carried out with the engine control system to make sure that the operation of the brake valve will not have a negative effect on the normal operation of the engine. If the vehicle is equipped with other auxiliary brake devices, such as a slowdown, the order of operation and the distribution of the effort between the brake devices should be reasonably adjusted to achieve the best effect of braking and the stability of the vehicle.

6. Cycle of service

Daily inspection: before each trip, the driver must conduct a simple inspection. Visually check the brake valve for damage or deformation, and connecting tubes for weakening, rupture or leakage. After starting the engine, press the brake valve control button, listen to any unusual sounds and check if the brake valve works normally.

Regular maintenance: It is recommended to carry out more comprehensive maintenance every 10,000-15,000 km or every three months. During maintenance, first clean the surface and surrounding space of the brake valve of dust, oil, and other contaminants to ensure good heat dissipation. Check whether the piston seal of the control cylinder is worn or aged. If there is any problem, replace it in time to prevent compressed air leakage and affect the normal operation of the brake valve. At the same time, check the tightness of the throttle valve to see if there is any carbon, corrosion, or damage. If the soot is insignificant, use a special cleaner to clean it; If the seal is severely damaged, the throttle valve must be replaced. In addition, the connecting bolts and brake valve nuts must be tightened to prevent them from loosening.

Deep Maintenance: Perform deep maintenance every 50,000 to 60,000 km or once a year. In addition to performing regular maintenance points, professional testing equipment is also needed to check and calibrate key operating parameters such as opening pressure and brake valve closing pressure to ensure that the brake valve braking performance is always maintained in the best condition. At the same time, conduct a comprehensive inspection of the electrical part of the control, including sensors, controllers, etc., to check the reliability of the line connections and the absence of damage to the electronic components. Make appropriate repairs or replacements if necessary.

Exhibition cabinets

Acquaintance with the plant

The factory has a team of highly qualified and experienced engineers who continuously introduce technological innovation and improve products. At present, the company owns a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment, such as excavators, loaders, cranes, bulldozers and other machines. The products are characterized by high performance, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working environments around the world.

Awards and qualifiersFiction

Frequently Asked Questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipment

3. What logistics ways can we work for shipping?

1) For most countries in Europe, South America and Africa, etc., we can go by container or Roro through ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or railway.

3) For light spare parts in urgent requirement, we can send it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you ensure that you have delivered the goods to customers?

A: We will provide you with full shipping information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable Quality: Carefully select regular manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by us, always adapting the best materials.

2) Competitive price: The concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) Service Team: Firstly, our sales managers are available 24 hours a day, ready to answer your questions at any time. Secondly, a professional technical service team with senior technicians, ready to provide support services to users and dealers. Most problems can be resolved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive