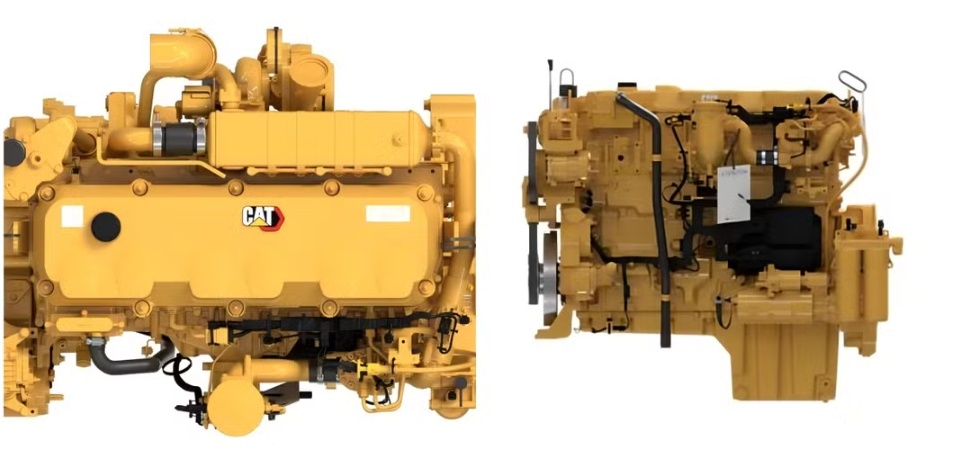

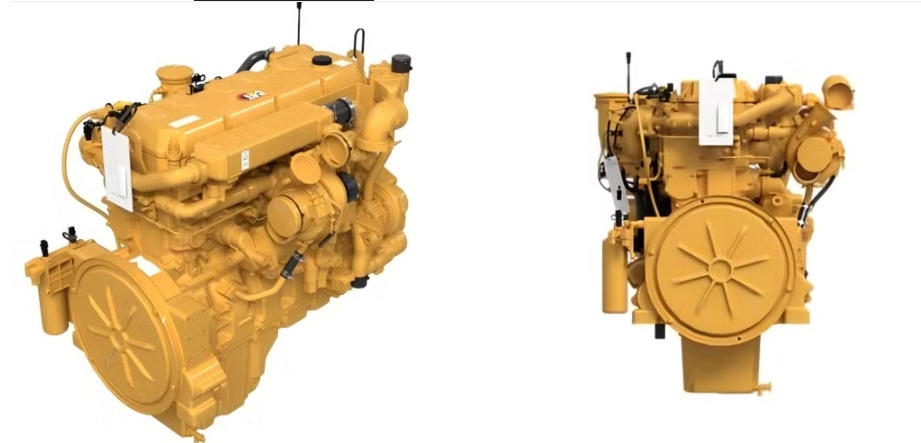

Caterpillar 20r-5121 Long cylinder assembly C13

1. Powerful power: improved adjustment technology, a large output torque, high power and ease of work in various scenarios of work with high loads.

2. Strength and reliability: made of high -quality materials, key components are processed using special technology, have wear resistance and impact resistance, and can also adapt to severe operating conditions.

3. Fuel savings: optimized combustion system and high fuel efficiency, effectively reducing fuel consumption while maintaining power.

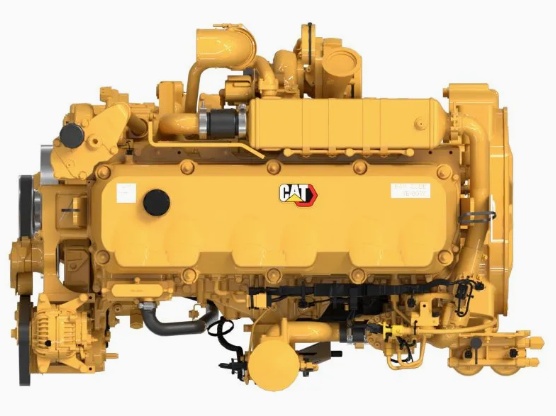

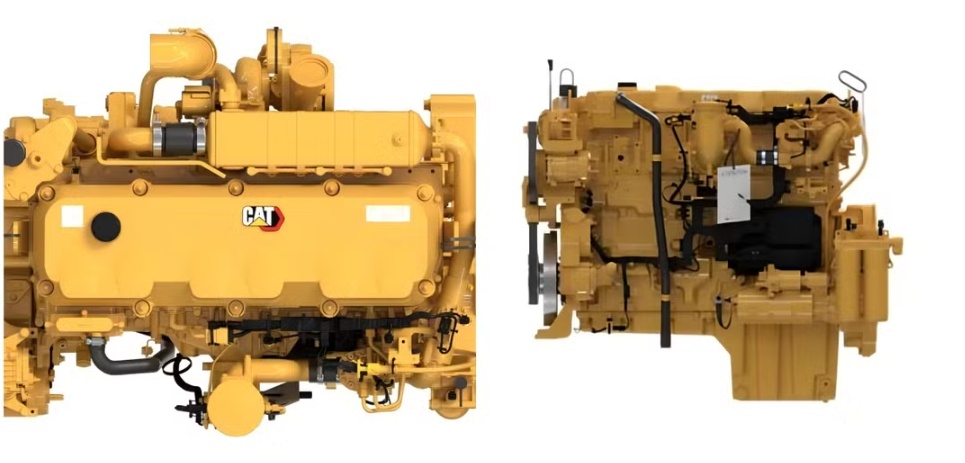

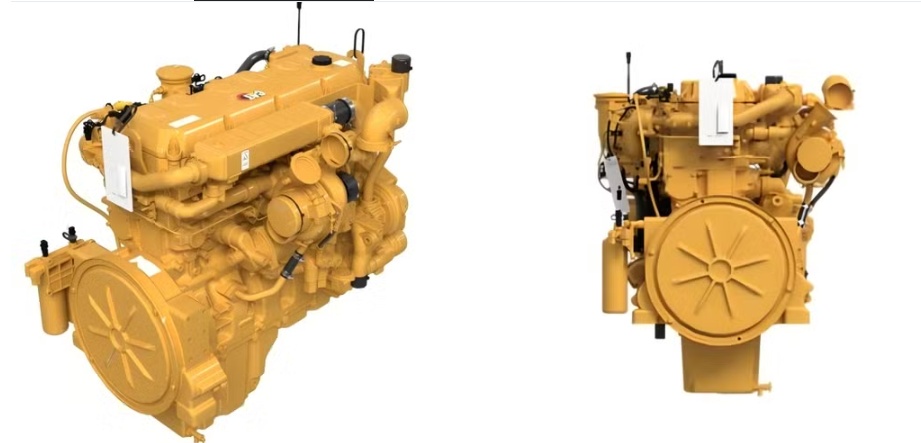

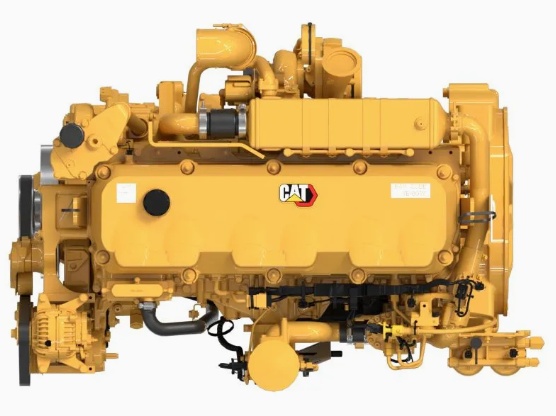

Product representation

1. Detailed product information

1. Structural composition

Engine case: Carter housing is made of high -strength cast iron or aluminum alloy, which has excellent resistance to pressure, wear and corrosion. The compact design and reasonable arrangement of components allow you to effectively maintain and protect the main components of the engine. For example, for the cylinder part, a special hining process is used, which provides a smooth internal wall of the cylinder, reduces friction between the piston and the cylinder wall, and also increases the efficiency of work and the reliability of the engine.

A crooked-shaped mechanism: consists of a crankshaft, a connecting rod, a piston and other details. The crankshaft is packed from high -quality alloy steel, subjected to accurate mechanical processing and heat treatment. It has high strength and good shock viscosity and can withstand a huge torque and shock force that occur during the operation of the engine. The connecting rod connects the piston and crankshaft, converting the reciprocating movement of the piston into the rotational movement of the crankshaft. The piston is usually made of aluminum alloy, which has characteristics of lightweight and good thermal conductivity. The surface is specially processed to improve wear resistance and sealing.

The valve mechanism: is responsible for the control of the processes of the inlet and release of the engine, mainly includes valves, valves, distribution shafts, pushers, pusher rods, rockers and other components. The camshaft controls the opening and closing time of the valves, guaranteeing that the engine will be able to achieve good intake and release in various operating conditions. The valve is made of heat -resistant and wear -resistant materials and tightly adjacent to the valve saddle, ensuring the tightness of the cylinder.

Fuel system: includes a fuel tank, a fuel filter, a fuel pump, a fuel nozzle and other components. The fuel pump takes fuel from the fuel tank, filters it through the filter, and then, under a certain pressure, supplies to the injector. The injector accurately injects fuel into the cylinder in accordance with the operating condition of the engine, providing spraying and combustion of fuel. The Carter fuel system uses the advanced Common Rail technology of high pressure, which allows you to achieve accurate control of the amount and time of fuel injection, improve the use of fuel and increase the engine power.

Lubrication system: mainly consists of an oil pump, an oil filter, an oil channel, an oil radiator, etc. The oil pump takes oil from an oil pallet, filters it through a filter, and then transports the oil channel to various parts of the engine that needs lubricant. , such as crankshaft bearings, connecting rod bearings, The camshaft bearings, etc. The oil radiator is used to cool the oil, guarantee that the oil will work at the appropriate temperature, improving the lubricant and the reliability of the engine.

Cooling system: forced circulation of water cooling is usually used, which consists of a water pump, radiator, fan, thermostat, coolant pipeline and other components. The water pump takes the coolant from the radiator, pumps it and supplies to various parts of the engine, absorbing the heat released during the engine, and then returns it into the radiator for heat removal. The thermostat automatically regulates the circulation path of the coolant in accordance with its temperature, providing the engine at the appropriate temperature.

(II) The principle of work

Most Carter engines are four -stroke, and their workflow includes four tacts: inlet, compression, working stroke and release.

Take of inlet: the piston moves from the upper dead point to the lower dead point, the intake valve opens, and the exhaust valve closes. When the piston moves down in the cylinder, negative pressure is formed, and the outer air is absorbed into the cylinder through the inlet channel and inlet valve.

Clutch: the piston moves from the lower dead point to the upper dead point, while the intake and exhaust valve are closed. The piston compresses the air absorbed into the cylinder, increasing its temperature and pressure, creating the conditions for combustion of fuel.

The working move: at the end of the compression tact, the nozzle injects the fuel into the cylinder, where it mixes with high temperature and high pressure air and quickly burns, forming high -temperature and high -enormous gas. Gaseous combustion products push the piston, forcing it to move from the upper dead point to the lower dead point, make the crankshaft rotate through the connecting rod and remove the power outward.

Take of release: the piston moves from the lower dead point to the upper dead point, the inlet valve closes, and the exhaust valve opens. The piston throws out burned exhaust gases from the cylinder through the exhaust valve, preparing for the next working cycle.

(III) Operational characteristics

High power: the Carter engine uses the advanced design of the design and production technology, providing high power density and torque. For example, some models of Carter engines can develop a larger torque at low speeds, which allows them to easily cope with various high load conditions in the construction equipment, mining equipment, etc.

Good fuel savings: due to the optimization of the fuel injection system and combustion process, Carter engines can ensure effective fuel combustion and reduce its consumption. At the same time, some engines are also equipped with an intellectual energy -saving control system, which can automatically adjust the amount of fuel injected in accordance with the conditions of the engine load, which allows to additionally increase fuel savings.

High reliability: Carter engines are highly reliable and stable due to the use of high -quality materials and strict production processes, as well as the passage of a number of strict quality checks and reliability tests. Its main components are made of high -strength materials and specially processed to ensure long -term stable work in severe conditions, which reduces the likelihood of failures and reduces the cost of maintenance.

Low level of emissions: in Carter engines, advanced emissions control technologies are still used, such as recirculation of exhaust gases (EGR) and selective catalytic neutralization (SCR), which effectively reduce emissions of the exhaust gas gases and correspond to more and more strict environmental standards.

(IV) compatible models

Caterpillar engines are widely used in various types of Caterpillar construction equipment, such as excavators, loaders, bulldozers, taps, forklifts, etc. Various types of construction equipment are equipped with various technical characteristics and performance parameters in accordance with their working needs and requirements To performance. For example, the Caterpillar C6.6 engine at the Caterpillar 320 excavator has excellent power and efficiency, and can also satisfy the operational requirements of the excavator in various working conditions; The Caterpillar C9.3b engine on the Caterpillar 950 loader is characterized by a powerful torque and reliability, which allows it to easily cope with heavy loader operations. In addition, Carter engines are used in generator installations, ship power plants, industrial equipment and other areas.

2. Stages of installation

1. Preparation before installation

Preparation of tools: Prepare various tools necessary for installations, such as wrenches (including unitary, core, end, etc.), screwdrivers (cross and flat), pliers (sparse, pliers), dynamometric keys, lifting equipment (for example , taps, tali, etc.), sealants, cleaning products, materials for sealing pipe connections (for example, sealing tape, sealing gaskets), etc.

Verification of accessories: carefully check whether the model and technical specifications of the new engine correspond to the equipment, and also whether there are defects on the appearance, such as damage, deformation, cracks, etc. At the same time, check the completeness and quality of auxiliary parts and accessories. Make sure that the accompanying engine documentation (for example, operating manual, warranty coupon, certificate of conformity, etc.) is fully equipped.

Preparation of places and equipment: select a clean, dry, well -ventilated and lit place for installation, for example, a workshop for maintenance or a special installation area. Make sure that there are no obstacles on the site that facilitate the operation of the lifting equipment. If the equipment must be disassembled to install the engine, you should prepare the appropriate support and fasteners in advance to ensure the stability and safety of equipment during the installation process.

Safety measures: Operators must wear personal protective equipment, such as protective helmets, protective gloves, protective shoes, etc., to avoid injuries during operation. If installation involves lifting work or the use of high -voltage equipment, additional safety measures should be taken, such as installing warning signs and attracting command personnel.

(Ii) engine installation

Foundation preparation: Inspect and process the foundation for installing the equipment engine in accordance with the requirements for installation of the engine. Make sure that the base for installation is even and durable, capable of withstanding the engine weight, as well as vibration and shock load that occur during operation. If the installation foundation does not meet the requirements, it should be repaired or redone.

The engine rise: using the appropriate lifting equipment, slowly lift and move the engine above the installation site. During the rise, make sure that the engine is in equilibrium, and avoid collisions with surrounding objects. At the same time, a special person is appointed who manages lifting work to ensure the safety of work.

Install the engine: slowly place the engine on the installation base and combine the mounting holes. Install the connecting bolts, but do not tighten them completely to ensure the possibility of subsequent adjustment of the engine position.

Connect pipes and lines: connect the fuel line, intake line, exhaust line, cooling water line, lubrication line, etc. In accordance with the installation drawing of the engine. When connecting the pipes, make sure that the joints of the pipes are well sealed. You can wrap the sealing tape around the joints of the pipes or install sealing gaskets and apply the corresponding amount of sealant. Use the wrench to tighten the pipe connection nut to make sure that the pipe is securely connected. Be careful not to pull it so as not to damage the pipe or connection. At the same time, connect the electric circuits of the engine, including power lines, control lines, sensors, etc., and make sure that the wiring is performed correctly and reliably.

Adjust and fix the engine: use the alcohol level to check the horizontalness of the engine and maintain its horizontal, adjusting the tightening of the connecting bolts. Check the gap between the engine and the components surrounding it to make sure that the engine will not interfere with other components during operation. Using a dynamometric key, tighten the connecting bolts one at a time in accordance with the specified moment of the tightening. Grase gradually diagonally to provide an uniform tightening force of each bolt and securely fix the engine.

Add liquids: Too small, which will affect the normal operation of the engine.

(III) check and debugging after installation

External inspection: Check if all pipes and lines are connected correctly and hermetically connected. Check if the engine is installed in the correct position and whether it is connected reliably to the installation foundation. Check the engine for damage or deformations.

Checking before launch: check whether the level of fuel, coolant and oil in the engine is normal, and whether there are no leaks in the pipelines. Check the serviceability of the engine’s electrical system, including the battery charge, reliability of the wiring, serviceability of the sensor, etc. Check the serviceability of the engine starting device, for example, the starting engine, the start button, etc.

Run the engine: making sure that all the checks are normal, start the engine in accordance with the engine starting procedure. During the launch, pay attention to the conditions of the engine start, for example, the fluidity of the launch, the absence of extraneous sounds or vibrations, etc.

Engine debugging: After starting the engine, let it work at idle to check if the idle speed is stable and if there is an abnormal shaking or flame breakdown. Gradually increase the engine rotation frequency and check whether the acceleration characteristics correspond to the norm and the output power of the engine, as well as there are no extraneous sounds or vibrations. At the same time, check if various engine devices work normally (for example, water temperature indicator, oil temperature indicator, oil pressure pointer, etc.), and whether all the sensors. In the process of debugging, the engine injection system, ignition system, valve clearance, etc. are regulated in accordance with the operating conditions of the engine in order to guarantee the achievement of the optimal state of its operation.

Test launch: after debugging the engine, a trial launch is carried out for a certain period of time. During the trial, the real conditions of the engine are modeled, such as work under load, work with a variable speed, etc. Check the operation of the engine in various working conditions, for example, whether its output power, fuel consumption, emissions, etc. .P., check for the engine cooling system, a lubricant system, an electric system, etc., and if there are no abnormal conditions. After the test start -up, the engine is carefully checked to make sure that there are no malfunctions and hidden dangers.

3. Common malfunctions

1. The engine does not start.

Reasons: a low charge of the battery, which can be caused by prolonged non -use, malfunction of the charging system or the aging of the battery; malfunction of the ignition system, for example, damage to the ignition coil, deposition or damage to the soil on the spark plugs, a high -voltage wire leak, etc.; Fuel system malfunction, including damage to the fuel pump, clogging of the fuel filter, injector malfunction, leakage in the intake pipeline, etc.; malfunction of the intake system, for example, clogging of an air filter, leakage in the intake pipeline, etc.; The mechanical malfunction of the engine, for example, wear of the piston rings, a malfunction of the valve, blocking the crankshaft, etc.

Elimination of problems and solutions: first check the battery charge and measure the battery voltage using a multimeter. If the voltage is too low, charge or replace the battery on time. Check the ignition system to see if there are signs of damage to the ignition coil. Use the spark plug tester to check the ignition of the spark plug. If there is soot or damage, clean or replace it. Check if there is a leak in high -voltage wires. You can observe if there are sparks around the high -voltage wires when starting the engine at night. For the fuel system, check whether the fuel pump is working correctly. You can evaluate this by listening to the work of the fuel pump or using a pressure gauge for measuring fuel pressure; Replace the fuel filter and check if the nozzle is not blocked or damaged. You can use professional equipment cleaning equipment to clean or replace the nozzle; Check if there is a leak in the fuel pipeline. If there is a leak, the pipeline should be repaired or replaced. Check the air intake system, clean or replace the air filter, and also check if there are leaks in the air intake line. For repair, you can use a sealant or replace the seals. If you suspect that the engine has a mechanical malfunction, you need to disassemble the engine for checking, for example, wear of piston rings, valves, crankshaft and other components, and repair or replace them depending on the degree of wear.

(II) Difficulties with the launch of the engine

Reasons: in addition to some reasons why the engine cannot start, this may also be associated with poor fuel quality containing impurities or moisture, which affects the effectiveness of fuel combustion; insufficient prevailing of the engine. In cold weather, the engine is launched without sufficient preliminary heating, which causes difficulties with the launch; Insufficient pressure in the cylinder can be caused by wear of piston rings, poor sealing valves, damage to the cylinder gasket, etc.

Elimination of problems and solutions: check the quality of the fuel, observing the color, smell and transparency of the fuel. If there are impurities or moisture, fuel should be replaced. In cold weather, use the engine pre -heating the engine, for example, an electric water shirt with heating, fuel heater, etc. Check the pressure in the cylinder and use a pressure gauge for measuring pressure in each cylinder. If the pressure is below the standard value, the engine should be disassembled to check the piston rings, valves, cylinder laying and other components, and repair or replace them as necessary.

(III) Unstable engine operation

Reasons: a fuel system malfunction, for example, uneven fuel injection, buttoning the nozzle, etc.; Failure of the inlet system, for example, air leakage in the intake pipe, a clogged air filter, etc.; Malfunction of the ignition system, for example, insufficient energy of ignition of the spark plug, inaccurate ignition ahead of the ignition, etc.; The mechanical malfunction of the engine, for example, is too large or too small a valve gap, too large the gap between the piston and the cylinder wall, the wear of the crankshaft bearing, etc.; Too many soot inside the engine affecting the effectiveness of combustion.

Elimination of malfunctions and solutions: Check the fuel system and use professional equipment to check the injector to check the injection state of the injector fuel. If uneven injection or dripping is observed, the injector should be cleaned or replaced; Check if the fuel pressure is stable. To measure it, you can use a pressure gauge. If the pressure is unstable, check the fuel pump and the fuel filter. Check the air intake system to see if there is a leak in the air intake pipe. You can use a sealant or replace seals to fix it; Clean or replace the air filter. Check the ignition system and use the spark plug tester to check the ignition energy of the spark plug. If it is insufficient, the spark plug should be replaced; Check the correctness of the ignition moment and use the ignition point indicator to adjust it. Check the mechanical parts of the engine and adjust the valve clearance to normative value; Check the wear of the piston, the walls of the cylinder and the crankshaft bearings and repair or replace them depending on the degree of wear. To clean the carbon deposits inside the engine, you can use professional cleaning agents to remove carbon deposits, such as throttle cleansers, intake channel cleaners, combustion chambers, etc.

(IV) engine temperature is too high

Reasons: clogging of the radiator, which can be caused by prolonged cleaning, accumulation of a large amount of dust, garbage and scale inside the radiator, which affects the effect of heat dispersion; insufficient amount of coolant, which can be caused by leakage, evaporation or untimely replenishment; Cooling fan malfunction, for example, damage to the fan engine, deformation of the fan blades or

Basic Info.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive