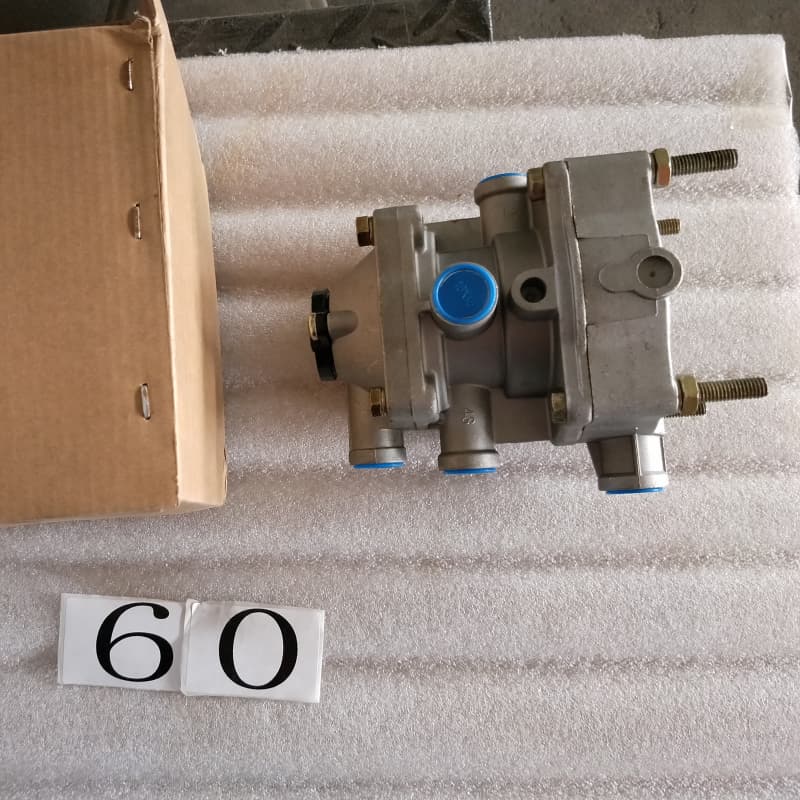

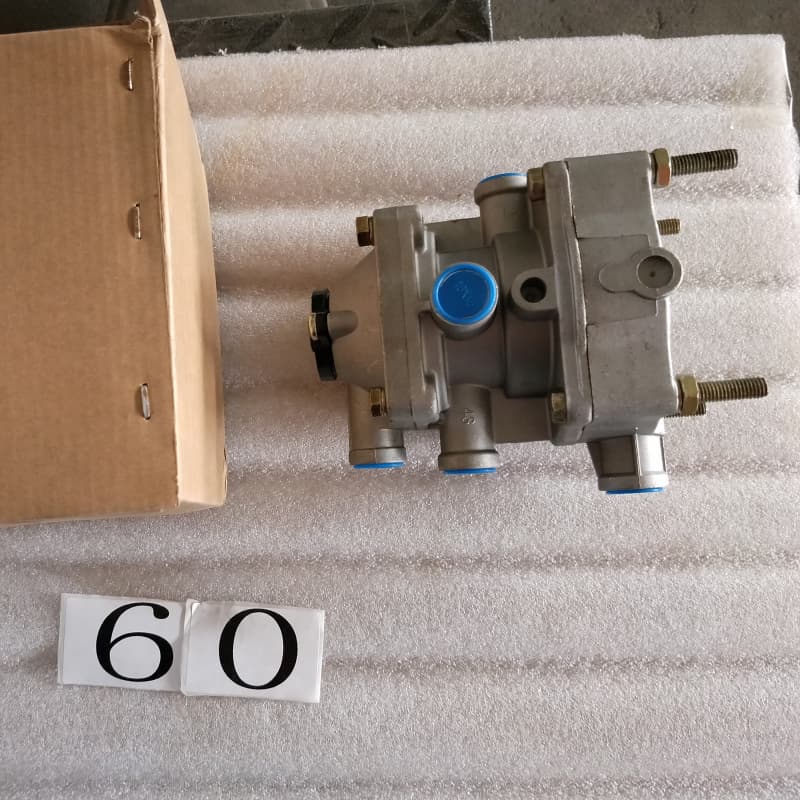

Sinotruk WG9000360180 Regulatory valve

1. Accurate control: the system reacts quickly and can accurately regulate the braking and supply of the air trailer, ensuring synchronization of the brakes of the main vehicle and trailer to ensure the safety of driving.

2. Strong and durable: made of high -quality alloy, with anti -corrosion surface treatment, resistant to pressure, vibration and wear. It can work stably in harsh conditions and has a long service life.

3. High adaptability: designed for various models of Sinotruk trailers, has standard interfaces, easy to install, universal and can quickly perform installation and debugging.

Product representation

1, structural design

Double design of pipelines: there are inflatable pipelines and brake control pipelines, inflatable pipelines are often inflatable and usually red; Brake control pipelines remove the air of the brake signal air when pressed the main brake and often yellow.

Multicapled control: the front, medium and rear main brakes and the parking brake valve are controlled, some models are also equipped with a separate valve of the manual brake of the trailer, through the two -way check valve and the output of the main brake valve to control air pressure parallel control.

2, the principle of work

Normal work: with normal movement, the inflatable line is inflated through the inflatable connector and the outlet valve of the trailer brake to inflate the trailer brake tank. When the main car slows down, the air pressure signal in the brake control line makes the trailer brake valve work, opening the road between the air trailer and the brake compartment to achieve synchronous braking. When the brake of the main car is released, the air pressure control valve in the brake control line is empty, the air from the trailer brakes exits through the trailer brake valve, and the brake is released.

Elimination of malfunctions: if the gas line is damaged or flows to a certain extent, the brake valve of the trailer automatically switches to the brake position. When the brake control line is damaged or flows, the normal movement of the main vehicle will not have any effect. When the main car slows down, the brake valve of the main car automatically overlaps the inflatable pipeline, and the braking synchronized with the main car will be created automatically through the brake valve of the trailer.

3 、 Functional configuration

The load adjustment function: some Haworth trailers are equipped with a manual load control valve with three “without load”, “half load” and “full load” provisions, which can regulate the trailer braking force and improve the anti -lock effect of the trailer. The effect of braking.

The brake unlock function: there is an unlock valve, when the trailer is disconnected from the main vehicle and it must be moved, the brake can be unlocked manually.

Connection to the system

It works with a double -circuit main brake system, a spring energy drive and a parking brake, an emergency braking system and an auxiliary brake system of exhaust gases to ensure the reliability and safety of inhibition of the entire vehicle.

4 、 Technical parameters

Air pressure range: working air pressure is usually about 7.5bar ~ 8bar.

Strong material: some products are made of iron and other materials to ensure durability in various difficult working conditions.

In order to use after -sales maintenance of the sinotruk trailer control valve, the following conditions are usually required:

Active commodity check: the user must provide a valid invoice or other check confirming the purchase of the Sinotruk trailer control valve, which clearly indicates the purchase time, place, product model and other information that allows you to determine the source of purchase of the product and the start of the warranty.

During the warranty period: the specified warranty should be valid for the goods. As a rule, the warranty period of Sinotruk products varies depending on the model and product. For example, a guarantee for a period of 24 months or 200,000 kilometers is provided for key nodes of road tractors, depending on what will come earlier.

Normal use and maintenance: users must use and serve the vehicle control valve and trailer in accordance with the requirements of the operating manual and warranty coupon for the product, including regular inspection and maintenance of the vehicle, the use of appropriate oils and accessories, etc. To guarantee the work of the product in normal working conditions and the environment.

Unauthorized modification or disassembly is prohibited: the valves of driving a vehicle and trailer were not modified, disassembled or repair by the user or third party, not authorized by Sinotruk. If the product was modified or disassembled without permission, the initial structure and productivity of the product can be damaged, which will make it impossible to determine the cause of the malfunction. Sinotruk does not bear guarantee liability.

Providing reliable information: Users must provide sinotruk or its authorized service stations with reliable and accurate information about the use of the vehicle, malfunctions, etc., as well as cooperate with SinoTRUK or service stations for checking, analyzing and identifying product malfunctions. If the user provides false information or refuses to cooperate with the relevant inspections, this may affect the after -sales service.

Use original or approved accessories: when using vehicle control valves and trailers, use the original Sinotruk accessories or accessories approved by Sinotruk. The use of unresolved accessories can lead to damage to the product. In this case, Sinotruk cannot take appropriate obligations for after -sales service.

Using in the specified area: the product should be used in the specified area of application and working conditions specified by Sinotruk, such as loading the vehicle, the condition of the road surface, the ambient temperature, etc., which must comply with the requirements for the design of the product. If the product is out of order due to use outside the specified range, a free warranty may not be extended to it.

If, after after -sales maintenance of the control valve, the Sinotruk trailer arose, it can be solved by the following steps and methods:

Contact the dealership dealers: first try to contact the authorized Sinotruk dealer, which provides you after sales service, and clearly and accurately explain the after -sale of the post -sales the problems of the problem, including the phenomenon of malfunction and dissatisfaction that arose in the process of after -sales maintenance (for example, untimely maintenance, unresolved, unresolved Problems, poor service, etc. d.). From the after -sales services points, it is required to provide reasonable solutions and clear time frames to guarantee a timely solution to the problems.

Set a complaint to the Sinotruk customer support service: if communication with after -sales service representatives did not help solve the problem, you can call the official Sinotruk customer support number to file a complaint. When submitting a complaint, provide detailed information, for example, the vehicle model, the number of the chassis, the time of purchase, the status of the trailer control valve, the name of the after -sales service point, the processing status, etc. Employees of the customer support service will register the complaint and transmit information about the problem to the appropriate Department for processing.

Feedback on the official Sinotruk channels: In addition to the number of the customer support service, you can also take advantage of the complaints and offers on the official Sinotruk website, official accounts on social networks and other channels in order to describe the problem in text form and attach the appropriate evidence (for example. maintenance records, photos, videos, etc.) to the corresponding departments of Sinotruk Could more clearly understand the situation and accelerate the solution of the problem.

Contact the help of the industry regulatory authorities: if the mechanism for considering complaints in Sinotruk does not allow you to effectively solve the problem, you can file a complaint and apply for help to the local transport management departments, consumer associations and other control bodies or consumer protection organizations. These departments will investigate and resolve the issues of after -sales service Sinotruk in accordance with applicable laws, rules and industry standards to protect the legal rights and interests of consumers.

Consider the possibility of using legal funds: in extreme cases, if your legal rights and interests are seriously violated and cannot be properly settled with the help of the above funds, you can apply for legal assistance, consult a professional lawyer, file a lawsuit taking into account specific circumstances and demand From Sinotruk, take on appropriate obligations and compensate for your losses in legal ways.

Throughout the process of solving the problem, be sure to maintain appropriate evidence and records, such as technical documents, correspondence records, complaints, etc., so that if necessary you can convincingly confirm your claims.

Below is a more common method for installing the sinotruk trailer control valves. Products of different models and specifications may vary slightly. Please read the operating manual and appropriate technical information for actual operation:

Preparation

Confirmation of products and tools: check if a new model of the Sinotruk trailer control valve is compatible with the vehicle, and also make sure that its appearance is not damaged, and the details are whole. Prepare the tools necessary for installation, such as wrenches, screwdrivers, sealants (as necessary), tools for connecting gas pipes, etc.

Safety measures when driving a car: Parke the car on a flat, solid and safe surface, turn on the parking brake and set the warning signs to prevent accidental movement of the car. Turn off the engine and disconnect the main circuit breaker of the car to eliminate the accidental turning on the electric system due to improper operation during installation.

Clean the installation location: thoroughly clean the installation site of the control valve, remove dust, oil, rust and other contaminants from the surface, and also make sure that the installation surface is even and clean to ensure tightness and stability after installation.

Set the control valve body.

Fasten the control valve: install the control valve of the trailer to the expected installation location and securely fix it on the vehicle using suitable bolts, nuts or other fasteners. Make sure that the fasteners are tightened with the specified moment to prevent the weakening or displacement of the control valve during the movement of the car.

Connect the air ducts: correctly connect the air ducts in accordance with the air system circuit and the interface label on the control valve. As a rule, interfaces with various functions have the corresponding marking (for example, an input for air, output for air, control port, etc.). When connecting the air tube, make sure that it is inserted into place, and securely fix it with a clip for an air tube or other connecting device to prevent air leakage. For some interfaces that need to be sealed, you can apply the corresponding amount of sealant before the connection to improve sealing.

Connection and check of the gas line

Connection of the gas circuit: In accordance with the design of the gas circuit system, correctly connect the control valve to the trailer to the fuel tank of the vehicle, the brake valve, the interface of the gas circuit of the trailer and other related components. Make sure that the gas line is reliably connected, without twisting, excesses or blockages to provide a smooth flow of gas.

Verification check: After the connection of the gas line is completed, turn on the gas source switch to pump up the gas system to normal working pressure. Then apply soap water or other suitable fluid to detect leaks on all ducts of the ducts, sealing parts of the regulatory valves and other places where there may be leaks, and check if there are bubbles. If the leak is detected, immediately redraw the gas source, re -check the connection and repair it until the leak in all parts of the gas connection is eliminated.

Functional testing

Preliminary test: Having made sure that the gas line is connected correctly and there are no leaks, start the car engine and let the gas line system achieve normal working pressure. Then use the pedal of the brakes of the vehicle, the hand brake valve and other relevant controls, check the working condition of the trailer control valve and the presence of extraneous sounds, vibrations or air leaks.

Brake test: conduct the brake test in a safe place, and first conduct the brake test only on the vehicle to make sure that the vehicle itself is in the normal efficiency. Then connect the trailer for the combined brake test to check whether the trailer control valve can accurately control the trailer brakes and whether the brake effect meets the requirements. During the test, pay attention to parameters such as a change in air pressure during braking and the brake operation time to make sure that the trailer control valve is normal.

Completion of installation and finishing

Fix the air ducts and components: place and fix the connected air ducts, as well as use cable screeds or other fasteners to fix the ducts in the appropriate position to prevent their friction, tension or squeezing during the movement of the vehicle.

Clean the installation site: after the installation is completed, clean the installation site, remove the tools and the remaining parts and maintain cleanliness at the workplace.

If you have difficulties or uncertainty during installation, it is recommended that you contact the vehicle operating manual or consult professional technical specialists or in the Sinotruk company after -sales service.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive