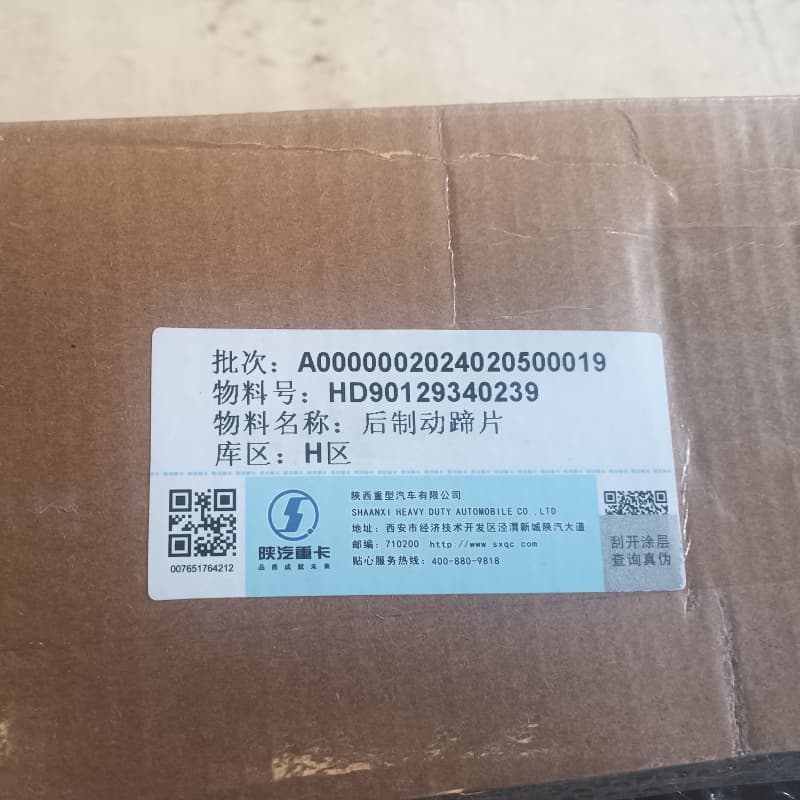

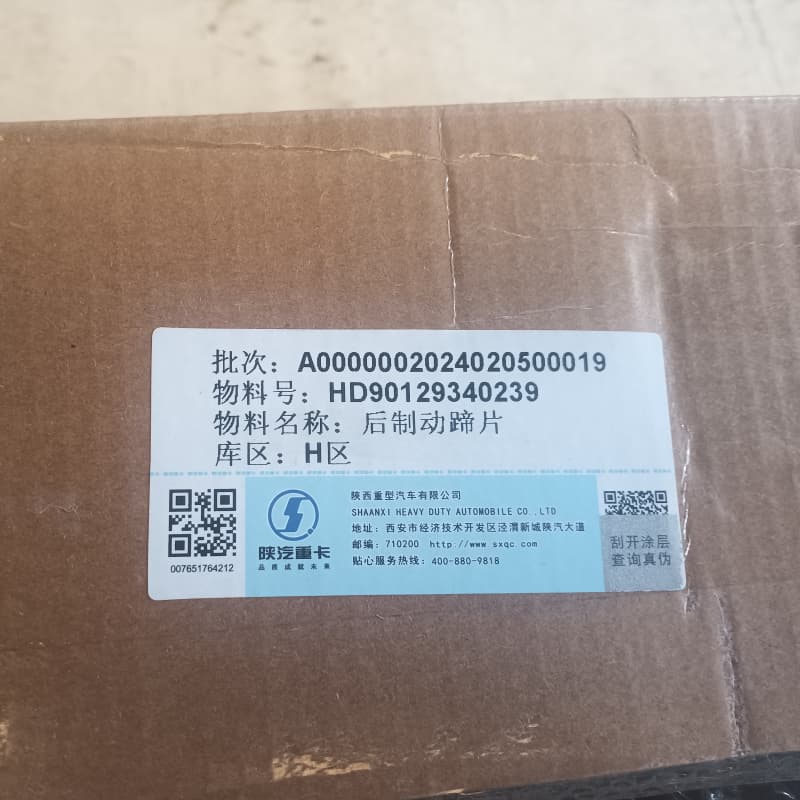

Shacman HD90129340239 Rear brake pads

1. Effective braking: highly effective friction materials with a high and stable friction coefficient are used, with rapid reacting to braking that can create a strong brake force in a short time to ensure the safety of driving.

2. Durable: after special processing, it is resistant to wear, high temperatures and thermal decay. He can withstand frequent braking operations and effectively extends the service life.

3. Accurate adaptation: fit for various models of Shaanxi cars, have an exact size, easy to install, are ideal for the brake system and a guaranteed braking effect.

Product representation

Shaanqi Delong brake pads more about the product:

Example of the model: DZ9112340060, DZ912340062, 9900340062.

The models used: Shaanxi Automobile Delong series of models can also be adapted to Hongyan Jieli, Haworth stairs, the liberation of Hum V, etc.

Type of material: half -metal, asbestos, ceramics, less metal, etc.

Product size: Take Baiyun brake pads as an example, there are 174163199*15.5/17.5mm and other sizes.

Specifications packaging: Take Baiyun brake pads as an example, 24pcs/CTN, the external size of the box 452725.

Product characteristics

Good brake characteristics: a stable friction coefficient, strong brake force, can effectively reduce the braking distance.

A long service life: a partially thickened design of the brake pads and the use of high -quality materials make the product wear -resistant and have a long service life.

High comfort: the noise created in the process of braking is small, and the vibration is insignificant, which provides good driving experience.

High safety: high compliance with the brake system of the car, sensitive reaction, reliable braking.

How to install brake pads on Shaanxi Automobile

1. Preparation before installation

1. Preparing the tool

Gay key: Prepare various specifications of the unitary, rock and end keys for removing and installing bolts and nuts on brake calipers, wheel hubs, etc. For example, a 17–19 mm key is often used to remove brake caliper bolts, and the key on 21–23 mm can be used to remove wheeled nuts.

Sprinkle: equipped with a cross -shaped screwdriver and flat screwdriver, is used to remove and install some small screws, for example, screws that fix the brake pad or dustproof cover.

Pla -rodbongers: the sharp -driving towers can be used to capture small details, such as stop rings; Plafers with a hinge connection can help remove some more tight details.

Special tools: Prepare special tools for replacing brake pads, for example, a tool for resetting a brake caliper piston. For some models of Shaanxi cars, a special tool is required to draw a brake caliper piston and free up space for installing new brake pads.

Lubrication: prepare a heat -resistant lubricant intended for the brake system, and apply it to the contact surface between the rear plate of the brake pad and the caliper to reduce the noise that occurs during braking.

Cleaner: Prepare the brake system to clean the brake discs, calipers and other parts associated with them from oil, pollution and the remains of old brake pads.

(II) Verification of accessories

Checking the brake pads: Carefully check whether the model and the characteristics of the new brake pads of the Shaanxi car are fully consistent. The size of the brake pads, the formula of friction material and the installation method can vary for different models of Shaanxi Automobile cars. Check the appearance of the brake pad to make sure that there are no cracks, refusions, bursts and other defects on the surface of the friction material, as well as that the back plate is not deformed and did not rust.

Checking other accessories: Check if the corresponding locking rings, spring sheets, bolts, nuts and other accessories are full -fledged and appropriate quality are. The locking ring and leaf spring should have good elasticity, and the bolts and nuts should not be torn or deformed to ensure the normal operation of the brake pad after installation.

(III) vehicle preparation

Parking and safety measures: Parke the car on a flat, solid and safe surface, tighten the hand brake, turn on the alarm and do not allow clashes with other vehicles. If the brake pads are replaced on the road, you need to install warning signs in the front and back of the car.

Car support: Use a suitable jack to raise the wheel on the side of the car where it is necessary to replace the brake block, so that the wheel is at a certain distance from the ground. Install protective stands under the car to support the chassis and make sure that the car will not move and will not fall during the process of replacing the brake pads. Never rely on the jack exclusively to support the car to avoid danger.

2. Remove the old brake pads.

1. Removing tires

Using the end key, weaken the mounting nut, but do not remove it completely.

Using the jack, raise the car so that the wheel breaks off the ground, then completely unscrew the wheel nuts, remove the tire and put it in a safe place.

(II) Dismantling of brake caliper

Find the brake caliper mounting bolts, which are usually located in the upper and lower part of the caliper. To weaken fasteners, use a suitable wrench.

Carefully remove the brake caliper from the brake disk. Some brake calipers can be fixed with locking rings or other means that must be released first. When removing the brake caliper, be careful not to stretch or twist the oil caliper oil tube so as not to damage it. If the brake caliper is tightly tightened, you can slightly knock on it with a rubber hammer to loosen it.

(III) Remove the old brake pads.

After removing the brake caliper, you can see the old brake pads. Typically, old brake pads are attached to the brake caliper using a stop ring or leaf spring.

Using the sprouts or another tool, carefully remove the locking ring or spring, and then remove the old brake block from the caliper. Pay attention to the degree of wear and direction of installing old brake pads to have a landmark for installing new brake pads.

3. Install new brake pads.

1. Cleaning parts

Use the brake system cleaner to thoroughly clean the surface of the brake disk from oil, pollution and the remains of old brake pads. For cleaning, you can use clean fabric or brush.

Clean the inner and outer surface of the brake caliper, especially the contact area with the brake blocks to make sure that there are no dirt residues. Check if the brake caliper piston is stuck. If so, it must be repaired or replaced.

Clean the mounting surface of the wheel hub to ensure a reliable connection of the wheel hub with the bus.

(II) Install new brake pads.

Install new brake pads on the brake caliper, making sure that they are oriented in the same direction as the old pads. On the brake blocks, there is usually a marking indicating the direction of the installation, for example, arrows or letter designations. Install them correctly in accordance with the marking to avoid installing them upside down, which will lead to a poor braking effect.

After installing a new brake pad, fix it on the brake caliper using a locking ring or leaf spring so that the block is reliably installed and does not shift during braking.

(III) installation of brake caliper

Install the brake caliper back on the brake disk, combining holes for fasteners.

Insert the fasteners and first tighten them with a wrench, but do not tighten them completely to ensure the subsequent adjustment of the brake caliper position.

Use the tool for returning the brake caliper piston to the starting position so that the caliper can fit tightly to the new brake bar. When leaving the piston, pay attention to the level of brake fluid to avoid its overflow. If the brake fluid level is too high, you can first drain part of the brake fluid.

Adjust the position of the brake caliper so that it is parallel to the brake disk, and the gap is uniform. Then, using a dynamometric key, tighten the fixing bolts one at a time in accordance with the indicated puffing moment. The torque values of the tightening of the brake caliper mounting bolts are different for different models of Shaanxi cars and should strictly comply with the requirements of the car operating manual.

(IV) tire installation

Set the tire back to the hub, combining holes for the bolts.

Install the wheel nuts, first tighten them manually, then gradually tighten them with the end key diagonally. When tightening the nuts, be careful and do not pull them so as not to damage the wheel or tire.

Lower the car so that the wheels are on the ground. Again, tighten the wheel nut with a dynamometric key to the specified torque value to ensure a reliable tire installation.

4. Checking and debugging after installation

1. External inspection

Check the correct position of the installation of the brake pad, the uniformity of the clearance between the brake block and the brake disc, as well as the absence of a backlash or displacement.

Check if the brake caliper is reliably installed and the fasteners are tightened to make sure that there is no weakening or loose fit. Check if the gap is normal between the brake caliper and the brake disc and there are no gaps.

Check the correct connection of the signaling line of the brake pads malfunction (if any) and the lack of damage or short circuit.

(Ii) Brake system check

Make sure that the brake fluid level is within normal limits. If the fluid level is too low, there is a leak in the brake system or too much brake fluid was lost during installation, so it is necessary to add brake fluid.

Check the brake highways for leaks. You can apply soapy water to each connection of the brake line and observe whether the bubbles are formed. If there are bubbles, this means that there is a leak, and it must be immediately eliminated.

Press the brake pedal and check whether its course and effort correspond to the norm. The brake pedal should have a certain resistance and moderate course. If the brake pedal seems too soft or too stiff, perhaps a problem arose in the brake system, requiring further verification.

(III) Test of braking efficiency

In a safe place, slowly eat by car and check the work of the brakes. Check the sensitivity and reliability of the brakes, as well as the absence of deviations or seals. The braking distance must comply with the requirements of the operating manual of the vehicle.

During braking, carefully listen to unusual noises. If you hear a sharp sound of friction or other abnormal sound, perhaps the brake block is installed incorrectly or has problems with quality, which requires immediate verification.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive