Caterpillar 348-7824 Cross of the fan shaft assembly

1 、 accurate compatibility : is designed specifically for the corresponding models of the Cat equipment , compatible with other components of the ventilation system and fan shaft. This ensures the ease of installation and uninterrupted operation as part of the whole system.

2 、 High strength and durability : is made of strong and resistant to wear of the material, which withstands high loads, rotation speeds and strong vibrations that occur during the operation of the fan. This guarantees a long service life and rare breakdowns.

3 、 manufacturing accuracy : has high accuracy of manufacture, which ensures proper and smooth rotation, as well as uniform load distribution. This increases the efficiency of the fan and its reliability.

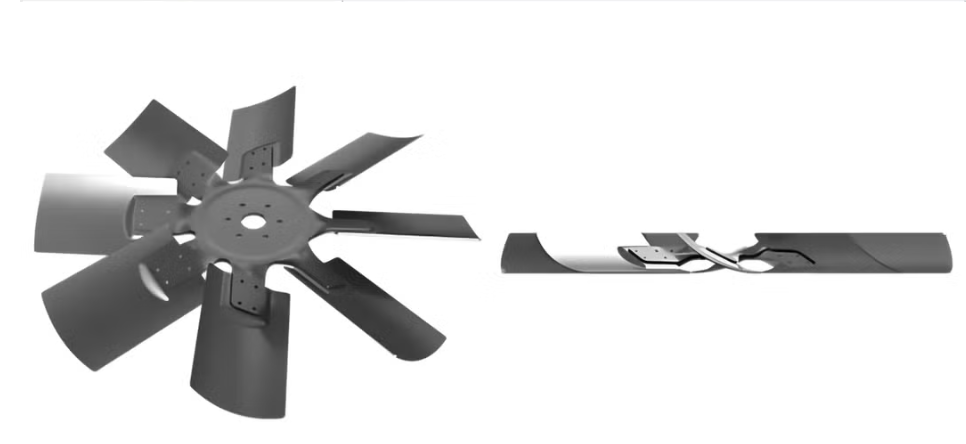

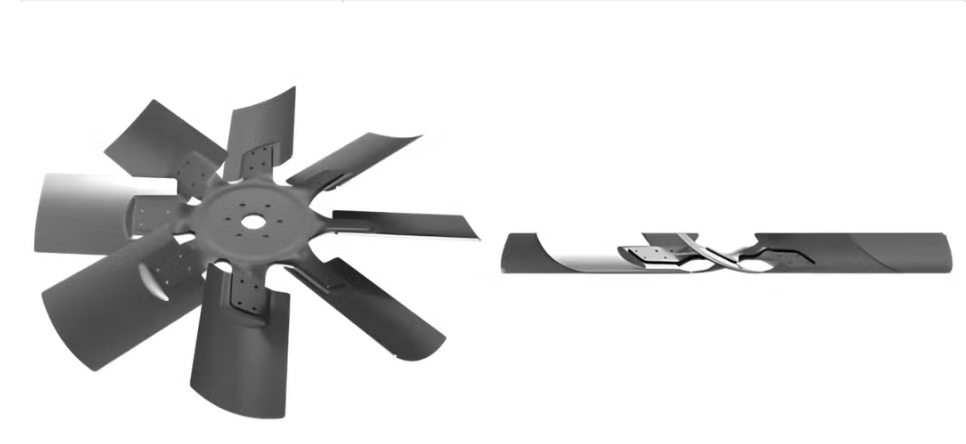

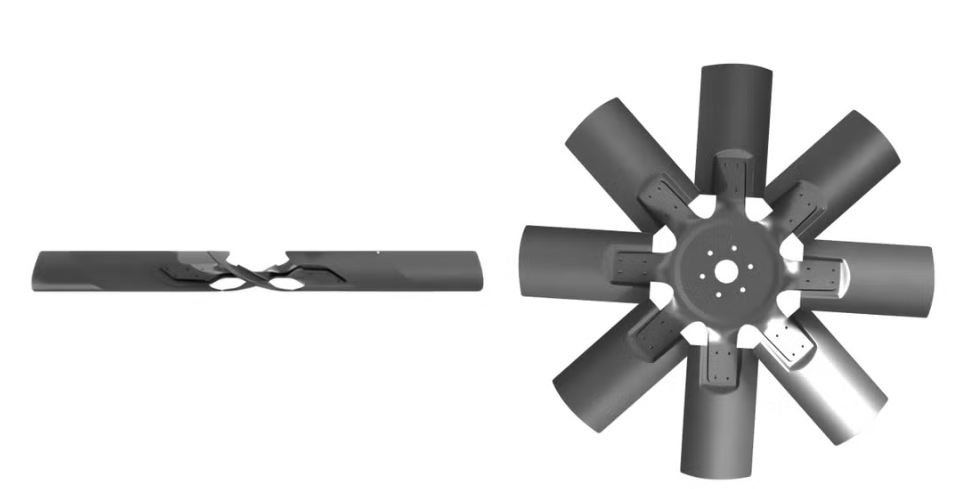

Product representation

I. Applied models

Caterpillar engine blades are suitable for a wide range of construction equipment Caterpillar, including, but not limited, common models of excavators 306, 307b/d/v1v2, 315C, 315D, 316C, 316D, 318D, 320D2, 322C, 322D, 325D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D, 329D 320d, 323D, 336D, 330D, 330C, 345D, 349D, etc.; 345D, 349D, etc. They are also widely used in rotary drilling rigs, loaders and other equipment. The fan blades of various models will be made to order in accordance with specific models in terms of size, shape and installation to ensure accurate fitting, satisfying the need to disperse heat for various types of equipment engines and ensure stable equipment.

Secondly, the main structure

Lope: usually consists of 8 - 12 blades. The shape of the blades is carefully thought out from an aerodynamic point of view, basically they have a unique curved or twisted shape. This design allows the fan to effectively pump the air flow and increase it during rotation, which significantly increases the effectiveness of cooling. The length and width of the blades varies depending on the model and requirements for engine power, but usually is 20-50 cm in length and 5-15 cm in width for the optimal cooling efficiency.

The hub: as the main supporting component connecting the blades to the engine shaft, the hub usually has a round or polygonal shape. It is made of high -strength metals such as cast steel, or highly effective engineering plastics. The hub is equipped with accurate mounting holes, and the connection with the output shaft of the engine usually has a key or bolt fastener, which ensures the stability and reliability of the fan blades during rotation at high speeds, and also prevents their weakening or dumping.

Thirdly, operational characteristics

Effective heat discharge: Carter engine blades can generate a strong air flow, quickly remove the heat released by the engine, so that the engine is always maintained in the suitable operating temperature range. If you take as an example of the fan blades adapted for 320d excavators, then when operating an engine with full load, the air flow around the engine can be increased to 500 - 800 cubic meters per minute, effectively reducing the engine temperature by 20-30 degrees Celsius, providing stable operation engine, significantly reducing the likelihood of breakdowns due to overheating and extending the service life of the engine.

Low -noise work: optimizing the shape, angle and angle of inclination of the blades allows you to effectively control the noise created by the fan of the crankcase during operation. Under normal operating conditions, the noise created by the fan blades is usually controlled at the level of 70-80 decibels, which is 5-10 decibels lower than that of conventional fan blades. This not only provides a more quiet working environment for operators, but also helps to reduce the noise environmental pollution.

High reliability: after a thorough check of quality and testing for the strength of the Carter fan blad, they are able to withstand long -range rotation and harsh working conditions. Whether it is sandy deserts or hot and wet tropical areas, they can maintain good performance and stability. A long service life reduces the frequency of replacement, reduces the cost of equipment maintenance and brings greater economic benefits for users.

Material and technology

Material: The blade is mainly made of aluminum alloy or high -strength engineering plastic. The aluminum alloy material has advantages of lightweight, high strength, good heat transfer, can effectively reduce the total weight of the fan blad, reduce the load on the engine, while improving thermal efficiency; Engineering plastics have good corrosion resistance, wear resistance and depreciation characteristics, relatively low cost, and can satisfy most of the requirements for using working conditions. The sleeve is usually made of cast steel or high -strength aluminum alloy to ensure sufficient strength and rigidity to support high -speed rotation of the blade.

Process: for the manufacture of the blade, the process of accurate casting or casting under pressure is used to ensure the accuracy of the size and constancy of the shape of the blade, as well as improve aerodynamic characteristics. The surface is subjected to special processing, for example, anneal oxidation for aluminum alloy blades in order to increase their corrosion and wear resistance; Anti -Urtophyolet rays and antioxidants are added to the engineer blades from engineering plastic to extend the service life. The connection between the hub and the blade is carried out by welding, riveting or casting under pressure, which provides a strong and reliable connection.

V. Technical principle

The aerodynamic principle: the special shape and angle of inclination of the blades are designed in such a way that when the fan rotates between the surface of the blades and air, the pressure difference is formed. According to the principle of Bernoulli, the air will flow from the side with high pressure to the side with low pressure, thus creating a strong air flow. This air flow is able to quickly carry the heat secreted by the engine, providing an effective heat removal.

The technology of noise reduction: optimizing the shape and angle of inclination of the blades allows you to reduce turbulence and friction of the air flow between the blades, which reduces the noise level. At the same time, the use of advanced soundproofing materials and the structural structure additionally reduce the noise level created by the fan during operation.

VI. Maintenance points

Regular inspection: regularly check the fan blades for deformation, cracks or damage. Check the strength of the jacket with the hub and tighten it in a timely manner if it is weakened. At the same time, check the balance of the fan blades, if there is an imbalance, it must be adjusted in time so as not to disrupt the normal operation of the fan and the cooling effect of the engine.

Cleaning and maintenance: regularly clean the fan blades of dust, oil and garbage on the surface. When working in a sandy and dusty environment, the cleaning frequency should be increased. For cleaning, you can use compressed air or vacuum cleaners, but be careful and do not use too sharp tools so as not to scratch the surface of the blades.

The replacement cycle: depending on the use of equipment and working conditions, it is advisable to determine the fan blades replacement cycle. As a rule, with normal use, the life of the fan blades is 2 - 3 years. However, if the equipment often works in harsh conditions, or if the fan blad has obvious damage or performance deterioration, it should be replaced in a timely manner.

Caterpillar engine fan blad applies to a wide range of models, covering many Caterpillar construction machines as follows:

Excavators of the series: 306, 307b/d/v1v2 Small excavators, usually used in urban small infrastructure, garden operations and other scenes, the size of the fan blades relatively small to satisfy the need for cooling the compact engine of the body; 315C, 315D, 316C, 316D, 318D, 320D2, 322C, 322D, 325D, 329D and other medium -sized excavators, which are often used in overall construction, road construction. On excavators of the type 336D, 330D, 330C, 345D, 349D, which are mainly used in the mining industry, large water protection projects, etc., the fan blades are more durable from the point of view of the material and structure, and can withstand more severe working conditions and more High intensity of cooling. The suitable fan blades is more durable and durable from the point of view of the material and structure, and can withstand more severe working conditions and higher requirements for the intensity of heat transfer.

Rotor drilling installation: Carter fan blades are also used on rotary drilling rigs to help the rotary drilling rigs to cope with the heat released during prolonged operation of the engine with high load during the construction of the pile foundation, to ensure stable operation of the equipment and increase the efficiency of construction.

Jilled unloading cars: 725, 730, 735, 740, D350E, D35HP, D400, D400D, D400E, D40D and other models, in large open quarries, large -scale construction projects, transportation of materials, and an efficient heat removal, and BOOD of the CARTER engine fan are needed They can ensure The engine in conditions of frequent launch and stop and difficult transportation conditions maintained normal operating temperature.

Industrial equipment: adapts to engines such as 3408C, 3408B, 3408, 3406C, G3306B, G3406, 3406, 3406B, 3408E, 3412, 3412C, 3412E, etc., industrial engines, is used on various industrial equipment, such as generator settings, Large air compressors, etc., to ensure stable and reliable support for cooling to ensure uninterrupted operation of the equipment. Engines are used in various industrial equipment, such as generator installations and large air compressors, to ensure stable and reliable support for heat transfer to ensure uninterrupted operation of the equipment. For example, when generator installations equipped with 3412 engines are used to supply electricity to remote areas or in emergency situations, Carter engines blades may guarantee that the engines will not overheat for a long period of electricity production and provide continuous and stable energy supply.

On wheeled excavators, such as W330B, during the construction of city roads, laying pipelines and other operations requiring high mobility, the fan blades work with the engine, ensuring good heat removal from the equipment, guaranteeing that engine performance will not suffer when the equipment is frequent and change works.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive