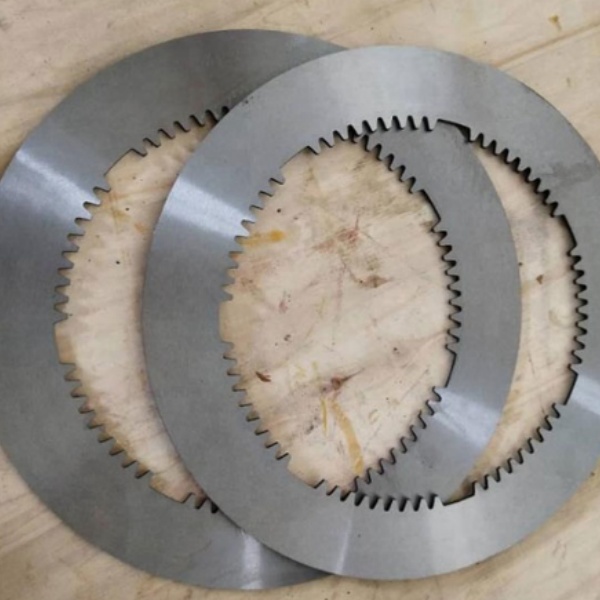

Shantui SD16 Inner drive of steering accessories friction disk original

1 、 High wear resistance: Shantui friction discs are usually made of high -quality friction materials that have excellent wear -resistant properties due to a special composition and technological processing. During frequent rotary manipulations and long -term use, they can effectively resist wear, reduce the wear of the friction plates, extend the service life of the friction disk, reduce the frequency of replacement and service costs.

2 、 Good heat resistance: during the operation of the rotary valve, the friction disk can generate heat due to friction. Shantui friction discs have good heat resistance and can maintain a stable friction coefficient and physical properties in a high-temperature environment, preventing a decrease in frictional properties, deformation or damage to materials due to overheating, ensuring reliable operation of the rotary system in various working conditions.

3 、 High production accuracy: Shantui uses advanced production technologies and accurate equipment for processing, providing high accuracy of the production of friction disks. They have a high size accuracy and a good surface plane, which allows you to tightly interact with other valve components, reduce assembly gaps and errors, increasing the overall performance and efficiency of the rotary valve.

Product representation

Detailed product information

Structural composition

A layer of friction material: made of specially designed materials, such as silicon carbide, graphite, copper alloy, etc., has good wear resistance, heat resistance and suitable friction coefficient, and can also work stably in various working conditions.

A steel support plate: as a rule, it is made of a high -strength steel plate and provides support for a layer of friction material, guaranteeing that the friction plate remains structurally stable when exposed to pressure and friction, and can also withstand the efforts that occur during braking or transmission of power.

Cooling oil groove: in the wet friction plate there are several grooves that contribute to the uniform course of lubricating oil, accelerate heat discharge and prevent overheating of the friction plate and deterioration of its characteristics.

Technical characteristics of the product: There are various technical characteristics for different models of Shantui bulldozers. For example, a model of a friction plate for D375A-5/6-424-15-12711, and a model of an external gear plate for SD22/SD16/TY220-16Y-16-02000.

Installation

The installation of friction discs in different parts is slightly different. If you take as an example a friction disk of steering, then the general steps for the installation are as follows:

Preparation: Make sure that the bulldozer is in a safe stop of stopping, tighten the manual brake and install warning signs, as well as prepare the necessary tools and new friction pads.

Disassemble the accompanying details: In accordance with the requirements of the Buldozer technical management manual, gradually disassemble the details related to the steering clutch, such as the external drum, the pressure disk, etc. to expose the friction plate.

Install a new friction plate: correctly install a new friction plate on the internal or external drum, pay attention to the correct direction and position of the friction plate and provide good interaction with other details. As a rule, the outer friction plate is installed on the outer drum, and the internal friction plate is installed in the gear groove of the inner drum.

Install other components: sequentially install a pressure plate, piston, bolts and other components and tighten the bolts with the indicated puffing moment.

Checking and adjusting: After installation, check if the clearance of the friction plate corresponds to. As a rule, it must be adjusted to the specified range. At the same time, check if each component is reliably installed and there is a play.

Trial operation: run the bulldozer and perform steering and other operational tests to check whether the steering clutch works normally and whether the friction plate of abnormal heating, slippage and other problems have.

Common errors

Slip

Reasons: wear of a passive plate leads to a too large gap of a friction plate; The operation of the spring plate spring weakens, which leads to insufficient pressure of the spring; The surface of the friction plate is contaminated with oil or the mating surface has poor contact; The neck wears out, and the oil seal is damaged, and the lubricating oil is seeped into the steering clutch and polluts the leading and driven wheels.

Method for eliminating malfunctions: clean the oiled friction discs with gasoline, and those who have poor contact should be polished or polished; Replace failed friction discs and springs; Adjust the shame of the friction discs.

Incomplete separation

Reason: the gap is too small, the passive disk is deformed or installed incorrectly.

Method for eliminating a malfunction: adjust the gap of a passive disk or turn a deformed friction plate.

Abnormal sound

Reason: the sound of a blow is caused by fasting details.

Method for eliminating faults: check the wear of the parts and perform the appropriate adjustments, repair or replacement of new parts.

Installation process

Preliminary preparation

Safe parking: Parke the Shantui bulldozer on a flat, solid and open area and make sure that there are no other people or obstacles around that may interfere with installation work. Turn on the parking brake, remove the key and disconnect the negative wire of the battery to prevent random launch of the equipment during installation.

Preparation of tools and accessories: Prepare various tools necessary for installation, such as wrappers, heads, screwdrivers, calipers, probes, hammers, copper rods, etc. At the same time, prepare new friction discs, making sure that their model and their model and The characteristics correspond to the original friction discs, as well as that they are of good quality and have no defects, such as damage and deformation. In addition, you also need to prepare some cleaners, such as clean fabric, cleaning agent, etc., as well as the corresponding amount of lubrication.

Cleaning the working area: using clean fabric and detergent, thoroughly clean the installation area of the steering coupling, including the surfaces of the inner drum, external drum, clamping plate and other components, delete pollution, such as oil, dust, iron sawdust, etc. Make sure that the installation surface is clean and even.

Removing the old friction plate

Disassemble the external drum: in accordance with the features of the bulldozer design, use the appropriate tools, such as wrenches and end heads to remove bolts, nuts and other fasteners attached to the outer drum, carefully remove the outer drum and place it in a safe place. In the process of disassembly, be sure to mark the installation site and the direction of each component, so that it can be correctly installed with subsequent installation.

Remove the old friction plate: after removing the outer drum, you can see the inner friction plate. Remove the old external friction plate from the groove on the outer drum and at the same time remove the internal friction plate from the toothed groove of the inner drum. When removing the friction disk, pay attention to the wear and injury of the friction disk to analyze the cause of the malfunction.

Check the accompanying details: after removing the old friction plate, carefully check the internal drum, the external drum, the pressure plate, the piston and other details for the presence of defects, such as wear, deformation, cracks, etc. If faulty details are detected, they should be replaced in a timely manner or replaced to ensure the normal operation of steering after installation.

Install a new friction plate

Install the internal friction plates: install new internal friction plates in the grooves of the teeth of the inner drum one after another. During the installation, make sure that the teeth of the friction plate are completely entered with the teeth of the inner drum and that the friction plate is correctly oriented. You can use a brass rod and a hammer to carefully knock on the friction plate, setting it in place, but be careful and do not put too much effort so as not to damage the friction plate or the inner drum.

Install the external friction plate: install a new external friction plate in the outer drum. Similarly, make sure that the friction plate is reliably installed and that the groove is tightly adjacent to the friction plate. When installing an external friction plate, pay attention to its relative position with an internal friction plate to make sure that the order of the location and direction of the installation of the internal and external friction plates.

Install other components: Install other components, such as a pressure plate and piston. When installing a clamping plate, make sure that the holes for the bolts on the clamping plate coincide with the holes for the bolts on the outer drum, and then, using the bolts, fix the clamping plate on the outer drum. When installing the piston, pay attention to the direction of the installation and the position of the piston to ensure its normal operation. During the installation process, tighten the bolts in the indicated order and with the specified moment to ensure the reliable installation of each component.

Adjustment and verification

Adjustment of the gap: Using the probe, check the gap between the friction plate and the pressure plate to make sure that the gap meets the technical requirements of Shantui bulldozers. As a rule, the clearance of the friction plate should be in a certain range, for example, 0.5–1.0 mm (see specific values in the equipment maintenance guide). If the gap does not meet the requirements, it can be adjusted using adjusting washers or other adjusting devices.

Check the quality of the installation: check if the friction plate is reliably installed, whether there are backlash or distortions. Check the reliability of the compounds of various components, tightening the bolts and the correctness of the installation of seals. At the same time, check for whether the steering clutch rotates easily and whether there are any problems, such as jamming or abnormal noise.

Cleaning and lubrication: after installation, clean the surface of the steering coupling again to remove the pollution and oil spots formed during the installation process. Then apply the required amount of lubrication to parts that require lubricants, such as mating surfaces of the piston and cylinder, bolts carvings, etc., to ensure normal operation and service life of the components.

Test launch

Connect the battery: After the installation and check is completed, connect the negative battery cable again.

Starting equipment: Launch the Shantui bulldozer, let the engine work for a while at idle and check the working condition of the steering coupling. Check the presence of unusual noise, vibration or other symptoms.

Follow the steering: after the equipment goes on idle and will work stably, perform steering to check the operation of the steering coupling. Check if the steering is flexible and smooth, whether there is no slip, incomplete separation, etc. If any problem is detected, you should immediately stop the machine for verification, find the cause and eliminate it.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive