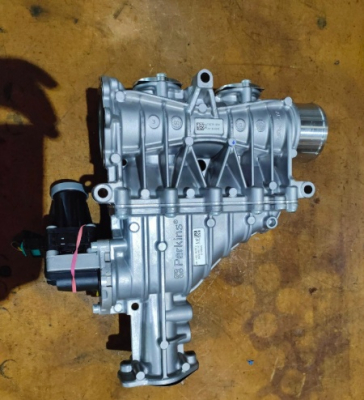

Shantui SD16 cardan coupling assembly original

1 、 High strength and durability : is made of durable and resistant to wear of the material, which withstands strong mechanical loads and vibrations that occur during operation. This provides a long service life and reliability in the work, reducing the frequency of repair and replacement of parts.

2 、 exact compatibility : specially designed for Shantui SD16/SD22/SD32, is ideally combined with other transmission components. This facilitates the installation and replacement, and also increases the effectiveness of the interaction of all elements of the system.

3 、 Stable power transmission : provides stable power transmission from engine to wheels or tracks, even with large rotation angles and changes in the direction of movement. This allows you to work with high efficiency and smoothness.

Product representation

Detailed product information

Structural composition: usually consists of a transverse shaft, a fork of a cardan hinge, a needle bearing, etc. The transverse shaft is the main component connecting two cardan forks, allowing them to transmit power at different angles. In the connection between the transverse shaft and a fork of the cardan hinge, needle bearings are installed to reduce friction and wear, as well as ensuring the flexibility of rotation.

The principle of operation: A special design of the transverse shaft and fork of the cardan hinge allows the transmission shaft to change direction in a certain range of angles, thereby ensuring power transmission. When the bulldozer transmission system works in various working conditions, such as turns, upward or down the slope, a universal hinge can adapt to changes in the angle between drive shafts, providing smooth power transmission.

Characteristics of the material: The transverse shaft is usually forged from high -quality carbon steel or alloy steel and is subjected to hardening and grinding to give it high strength, hardness and wear resistance. Cardata hinged forks are usually made of cast steel or multiple cast iron, which have good strength and impact resistance. The needle rollers of needle roller bearings are made of high -precision bearing steel, and the surface of the hardened. The internal and outer rings of needle roller bearings are also made of wear -resistant bearing steel, which ensures the service life of a cardan hinge.

Installation

Preparation: Clean the universal hinge and related mounting parts from oil, dust and rust. Prepare the necessary tools, such as wrenches, hammers, copper rods, calipers, dynamometric keys, etc. Check whether the details of the cardan hinges are integral and there are no defects, such as damage and deformation. Make sure that the needle bearing can rotate flexibly, and the transverse shaft has no cracks, wear and other problems.

Stages of installation

Install the transverse shaft and fork of a universal hinge: insert the neck of the transverse shaft into the hole of the bearing saddle for the fork of the universal hinge so that the lubricated stump on the transverse shaft is facing the side of the shaft pipe and was in the same position as the lubricant on the sleeve.

Install the needle bearing: apply lubricant on a needle bearing, install it with an oil seal and place it in the hole of the bearing saddle, combine the groove on the bearing with the opening under the bolt on the lid, then put it on the neck of the transverse shaft, using the copper rod and the hammer slowly pour Bearing liner in The bearing hole and set the lid.

Install the clamp on the other side: use the same method to install another pair of transverse shafts and clamps, making sure that the installation angles of the two clamps are correct. As a rule, the clamps at both ends of the drive shaft should be in the same plane.

Installation on a bulldozer: install the installed cardan drive shaft of the bulldozer in the correct position and direction, fix it with bolts and nuts and gradually tighten the bolts and nuts with a dynamometric key in accordance with the indicated torque value.

Common errors

Abnormal sound

Reasons: the needle bearing is worn out or damaged, which increases the gap between the transverse shaft and the fork of the cardan hinge, causing a knock during operation; The neck of the transverse shaft is worn out, potholes and scratches appear on the surface, which makes the cardan hinge unstable during rotation and creates an abnormal noise; The connecting bolts of the cardan hinge are weakened, which causes vibration and collisions during operation, causing noise.

Exposure: this affects the working environment of the bulldozer and increases the fatigue of the operator. It can also be a signal that the malfunction continues to deteriorate. If you do not eliminate it on time, this can lead to further damage to the universal hinge.

Stuck

Reasons: in the needle roller bearing there is not enough oil or it is poorly lubricated, which increases the friction between the needle roller and the transverse shaft and fork of the cardan hinge, which leads to seizure; The transverse shaft or fork of the cardan hinge is deformed, which leads to a displacement of the position of the installation of the needle roller bearing and uneven rotation; Narround objects, such as dust, iron sawdust, etc., fall into the cardan joint, which prevents the normal rotation of the cardan hinge.

Exposure: this will lead to the fact that the transmission system of the bulldozer will become uneven and reduce the efficiency of power transmission. In severe cases, it may not transmit power normally, which will affect the working characteristics of the bulldozer.

Excessive wear

Reasons: prolonged operation under high loads and severe operating conditions leads to the fact that the transverse shaft, needle bearing and other components of the cardan hinge are subjected to greater pressure and friction, which accelerates wear; low quality of lubricating oil or untimely replacement of lubricating oil does not allow effectively lubricating and drain heat, which leads to increased wear; Incorrect installation, such as an excessive deviation of the corner of the cardan hinge, the uneven moment of the tightening of the connecting bolts, etc., leads to an uneven effort to the cardan joint during operation, which leads to severe local wear.

Consequences: the service life of a universal hinge is reduced, the costs of maintenance and downtime are increasing, and the effectiveness of the bulldozer is reduced.

Elimination of malfunctions associated with anomalous noise

Check the needle roller bearings:

First, park the bulldozer on a safe and even place, put it on a manual brake and install warning signs to ensure safe operation.

Disassemble the cardan shaft and check the appearance of the needle bearing. If it is found that the needle roller bearing is clearly worn out, cracked, deformed, or the needle roller fell off, it must be replaced by a new one. When replacing, make sure that the characteristics and model of the new bearing correspond to the characteristics and model of the original bearing, and before installation, apply the required amount of lubrication.

Check the gap between the needle bearing, a transverse shaft and a fork of a cardan hinge. To measure the gap, you can use a probe. If the gap exceeds the specified range (usually 0.02-0.05 mm), worn parts must be replaced to restore the normal planting gap.

Check the transverse axis:

Carefully check the surface of the neck of the transverse shaft for defects, such as potholes, scratches and wear. If the surface of the neck is slightly worn out, it can be repaired, for example, using chromium, brush coating and other processes to increase the diameter of the neck, and then polish it to achieve a given accuracy of sizes.

If the neck of the transverse shaft is strongly worn out or has cracks, it is necessary to replace the transverse shaft with a new one. When replacing the transverse shaft, pay attention to the direction and position of the installation, and also make sure that the lubricant nozzle on the transverse shaft is directed correctly to facilitate the subsequent lubricant and maintenance.

Check the connecting bolts:

Use a suitable wrench to check the moment of tightening the universal joint bolts to make sure that the moment of tightening the bolts meets the technical requirements of Shantui bulldozers (usually 100–150 N · m, see specific values in the equipment operation manual). If the bolts are weakened, they should be tightened with the indicated puffing moment.

Check the bolts for damage, deformation or torn thread. In the presence of any damage, the bolts should be replaced in a timely manner to ensure the strength of the connection.

Elimination of problems with the jam

Check the lubricant:

Check the hole for filling the lubricant on a universal hinge to make sure that there is enough lubricant. If the lubricants are not enough, it should be replaced with a suitable lubricant (for example, on a lithium basis). When adding a lubricant, make sure that it completely fills the needle bearings and other rotating parts.

Check the quality of the lubricant. If the lubricant has deteriorated, dried or impurities, the old grease should be completely removed and filled with new high -quality lubricant. At the same time, check if the hole is clogged for filling the lubricant. If clogged, it should be cleaned.

Check the presence of component deformation:

Check the transverse shaft and fork of the cardan hinge for deformation. To measure and verify the compliance of the rectilicity of the transverse shaft and the flatness of the fork of the cardan hinge with the requirements, you can use the dial indicator or other measuring tools. If it is found that the component is deformed, appropriate repair measures should be taken, such as correction or replacement, depending on the degree and place of deformation.

For the repair of slightly deformed parts, you can use methods of mechanical correction. However, if the deformation is serious and affects the normal use and performance of the component, it must be replaced with a new one.

Remove extraneous objects:

Disassemble the cardan hinge and carefully check if there are foreign objects inside. If you find extraneous objects, such as dust, iron sawdust, dirt, etc., you should remove them with a clean cloth or brush.

Check the integrity of the sealing device of the cardan hinge. If the sealing device is damaged, it should be replaced in a timely manner with a new one in order to prevent the re -hit of foreign objects into the cardan hinges.

Elimination of problems associated with excessive wear

Optimization of working conditions:

Try not to allow prolonged continuous operation of the bulldozer under high load and in severe operating conditions. Reasonably distribute working tasks and working hours, as well as to equip enough time for rest to reduce the wear of components such as universal hinges.

Before starting work, clean and align the working site as necessary, remove sharp stones, obstacles, etc., reduce the tremors and blows during the movement of the bulldozer, and also reduce the load on the cardan joint.

Replace lubricating oil:

According to the operating instructions of the Shantui bulldozer, regularly replace the lubricating oil of the cardan hinge. Choose a reliable quality lubricant that meets the requirements of the equipment to provide a good lubrication effect.

When replacing the lubricating oil, drain the old lubric oil and clean the lubricant system to ensure the full performance of the new lubricating oil.

Check and adjust the installation:

Check the correct installation of a universal hinge, make sure that the plugs of a universal hinge at both ends of the drive shaft are in the same plane, and the angle of installation of a universal hinge meets the requirements of the equipment. If the deviation of the installation angle is too large, it should be adjusted to ensure the normal operation of the cardan hinge.

Check if the tightening of the connecting bolts is uniform. When installing a universal hinge, the bolts should be tightened in the prescribed manner and with the specified moment to ensure the same moment of tightening of each bolt and avoid increased local wear due to uneven effort.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive