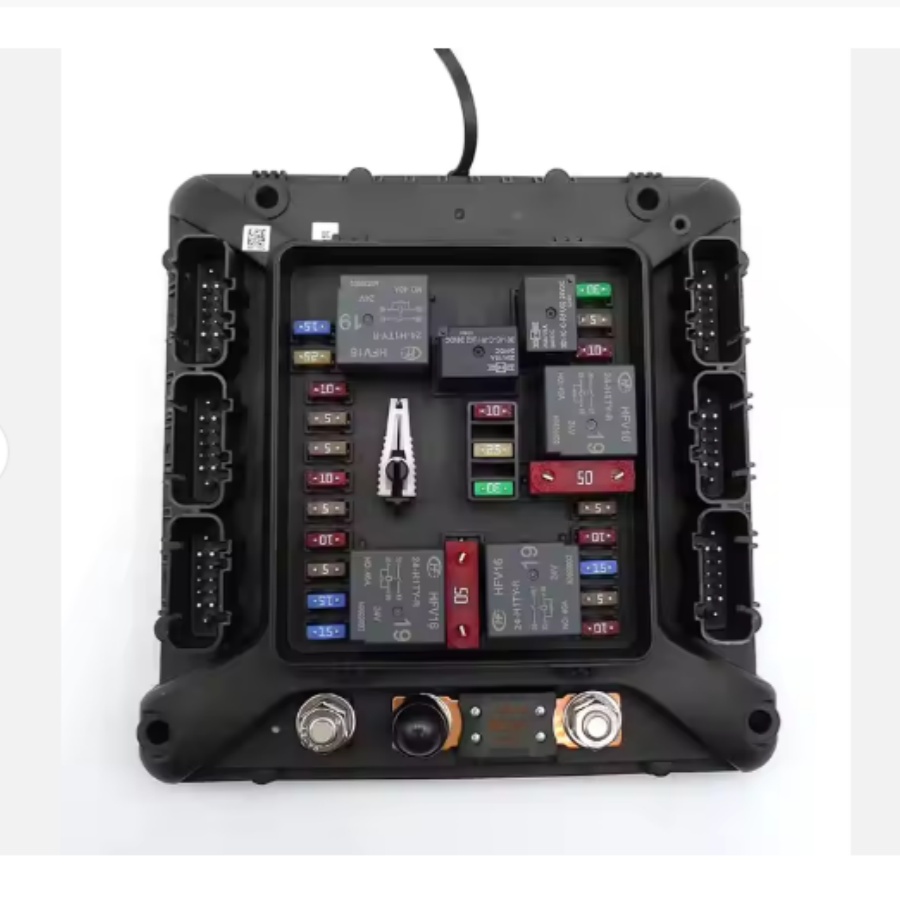

Sany 140107000091c fuses block

1. Security and reliability: accurate current protection can quickly turn off the current when malfunctions occur in the circuit, effectively preventing a short circuit and overload, as well as protecting the electrical system.

2. Durable: the outer shell is made of high -strength, fire -resistant materials, and the internal metal parts are resistant to corrosion. It can adapt to harsh working conditions and work stably.

3. Accurate adaptation: sets up for various types of Sany excavators, has an exact installation interface, convenient installation and high adaptability.

Product representation

Detailed product information

Structural composition: The Sany Excavator Frontier block mainly consists of a fuse cover, fuse base, fuse nests, as well as various fuses and safety devices. The fuse cover, as a rule, is designed so that it can be opened, which is convenient for repair and replacement of fuses; The base of the fuse is made of insulating material, used to fix and support fuses and fuse and has good insulation characteristics; The fuse holder is used to fix fuses and fuse.

The principle of operation: when an abnormal situation occurs in the chain, for example, overload or short circuit, as a result of which the current exceeds the rated current of the fuse, the fuse is automatically burned out, thereby turning off the circuit and preventing damage to the circuit and equipment due to excessive current, thereby performing a protective function. In addition to fuses, the fuse block can also be equipped with other safety devices, such as circuit breakers and fuses that can automatically turn off the circuit when the electrical malfunction occurs, providing more complex protection functions.

Functional features: the fuse unit has functions such as overload protection, super -flow protection, short circuit protection and insulation protection. It can effectively prevent damage to the excavator electrical system due to an abnormal current, for example, the engine control module, the display screen, various sensors, etc., ensure the stable operation of the electrical system of the excavator, reduce the risk of equipment failure and increase the safety of work.

Applicable models: various models of Sany excavators are equipped with various fuse blocks. For example, fuse blocks suitable for excavators of different carrying capacity, such as SY55, SY135 and SY215, are designed purposefully in terms of size, internal layout and fuse characteristics to comply with the requirements of protecting electrical systems of various models.

Stages of installation

Preparation: First, make sure that the excavator is stopped, the engine is turned off, and the negative terminal terminal is disconnected to prevent lesions with electric shock or a short circuit during the installation process. Prepare the tools necessary for installation, such as screwdrivers, pliers, island, etc., as well as the fuse block of the corresponding model.

Remove the old fuse unit (if any): Find the original fuse unit, which is usually located in an electric control unit near the cabin or side of the car. Using a screwdriver, unscrew the fasteners or open the clamps, carefully remove the old fuse unit, be sure to save the screws and other parts, and mark the joints of each line.

Install a new fuse unit: install a new fuse unit in a given position, combine it with mounting holes and fix it with screws to provide a reliable installation. In accordance with the previously marked provisions of the lines connection, carefully insert each line of the line into the corresponding interface of the new fuse unit and insert it tightly to provide a reliable electrical connection. For some connectors of wires, for fixing which you need to tighten the screws, use a screwdriver to tighten them moderately.

Checking and testing: After installation, carefully check the correctness and reliability of all linear compounds, as well as the absence of weakening or incorrect connection. After checking, connect the negative pole of the battery, run the excavator and check if the functions of the electrical system work normally, such as the instrument panel display, lighting, various controls, etc. At the same time, check if the fuse unit is heated, whether it is smoked He, etc.

Common malfunctions

A blocked fuse: this is the most common malfunction. The reasons can be an overload of the electrical system, for example, the simultaneous use of too much powerful electrical appliances; short circuit in the chain, damage to the insulating layer of the wire, leading to direct contact between positive and negative poles; or internal malfunction of electrical equipment, for example, a short circuit in the engine. When the fuse is burned, the corresponding electrical equipment stops working.

Bad contact: poor contact is possible between the fuse and the fuse holder, as well as between the cable of the power cable and the interface of the fuse of the unit. The manifestation of this is that electrical equipment is unstable, sometimes good, sometimes bad, or with the vibration of an excavator, electrical equipment suddenly loses power. Long -term poor contact can also lead to heating the contacting parts and accelerate the aging of the components.

Damage to the fuse block: external exposure or prolonged exposure to harsh operating conditions (such as high temperature, humidity and dust) can lead to cracking of the fuse of the fuse block and damage to the internal printed circuit board, which will affect its normal functioning. In addition, aging and failure of the internal components of the fuse can also lead to the fact that the fuse block will not be able to normally perform its protective function.

After -sales service

Warranty service: Sany usually provides a certain guarantee for the fuse block, as a rule, 1-2 years. During the warranty period, if the malfunction is caused by the problems of product quality, such as defects in the material of the fuse block, problems with the quality of the internal components of the fuse, etc., you can use free repair or replacement services.

Technical support: If users are faced with problems during installation or use, they can call the Sanya unified national hotline. Professional specialists will provide detailed technical recommendations by phone, answer questions and help users in eliminating problems and solving problems. You can also get technical support through the online customer support service, the technical forum and other channels of the official Sany website.

Supply of accessories: Sany has created a comprehensive system for delivering accessories to guarantee timely supply of original fuse units, as well as various fuses, safety devices and other accessories. Users can purchase suitable high -quality accessories through local dealers, service centers or the official Sany e -commerce platform to guarantee the timeliness and quality of equipment service.

Maintenance: Sany has many authorized service centers throughout the country with a professional maintenance team and rich experience in serving excavators. When the fuse is out of order, the user can send the device to the nearest service center for repair. In some emergency situations or for large equipment, the service center can also provide repair services “from the door to the door”.

Preparation for installation

Precautions: use personal protective equipment, such as protective helmets and protective gloves to avoid injuries during operation.

Preparation of tools: Prepare all the tools necessary for installation, such as a cross screwdriver of the corresponding size, flat screwdriver, witty, tools for cleaning wires, isolet, multimeter, dynamometric key (if necessary), etc.

Choosing a place: choose an even, dry, well -ventilated and lit place for the excavator parking and make sure that there are no obstacles around for ease of use. At the same time, install warning signs to prevent the erroneous actions of other persons.

Turn off the equipment: turn off the excavator engine, turn on the manual brake and make sure that the equipment is stopped. Then open the cover of the battery compartment, with the help of a wrench, unscrew the terminal nut on the negative terminal of the battery, remove the negative cable and wrap it with insulating tape to prevent random contact with electricity.

Checking details: Check the list of products to make sure that there is a full set of fuses and accessories for the new Sany excavator, including fuses, fuse holders, linear plugs, fasteners, etc. At the same time, check if there are damage fuses on the block, deformations, cracks, etc. If there are any problems, replace it on time.

Stages of installation

Removing the old fuse unit

Accommodation: depending on the model and the operating manual of the excavator, find the installation site of the old fuse unit, which is usually located under the instrument panel inside the cabin, in the electric control unit outside the cab or next to the motor compartment.

Place the lines: use a marker or sticker to mark each line connected to the old fuse block, write down the connection position and line number so that you can accurately connect it when the new fuse unit is subsequent. This step is very important, especially for excavators with a large number of complex wiring to avoid failures in the operation of electrical wiring caused by improper wiring.

Remove the mounts: use a screwdriver to unscrew the screws or open the clamps that attach the old fuse unit. Some fuse blocks may also require removal of some protective lids or decorative panels before access. During the removal process, be careful not to damage the surrounding components.

Divide the lines: disconnect the linear forks on the old fuse block one after another. For some forks, which are tightly inserted and taken out, you can use the sprouts to gently squeeze both sides of the fork and pull it out with uniform effort. Do not pull the wires with force so as not to damage the lines. If there are screw terminals on the line, unscrew the screws with a screwdriver and loosen the terminals.

Remove the old fuse block: after all the mounts and wiring are removed, carefully remove the old fuse block from the installation site and place it in a safe place.

Installation of a new fuse unit

Accommodation and installation: Place a new fuse unit in the place of installation of the old fuse unit, making sure that the mounting holes coincided. For some fuse blocks for which the installation bracket is required, first secure the bracket at the installation site, and then install the fuse block on the bracket.

Fasten the fuse block: use the screwdriver to screw the fasteners into the fasteners. Tighten the screws gradually diagonally to make sure that the fuse unit is reliably installed without shaking or displacement. When tightening the screws, be sure to apply a moderate force to avoid cracking of the fuse of the fuse block or damage to the mounting holes due to excessive effort.

Connect the lines: in accordance with the numbers of the lines and the positions of the joints marked earlier, insert the lines plugs into the corresponding interfaces of the new fuse unit at one, making sure that the plugs are inserted to the stop, and the clicks mean that the plugs are inserted reliably. For terminal blocks with a screw mount, insert the wires into the terminal holes and tighten the screws with a screwdriver to make sure that the wires are securely connected and have good contact. When connecting the lines, carefully check the connection of each line to make sure of the absence of incorrect or absent connections.

Install the fuse: In accordance with the requirements of the electrical system of the excavator, insert the fuse to the corresponding specification into the fuse holder in the fuse unit, observing caution so as not to insert it upside down. When installing the fuse, make sure that the fuse and the fuse holder are in good contact to avoid a false connection.

Checking and testing

Appearance check: After installation, carefully check the appearance of the fuse block to make sure that all lines are connected correctly and reliably, without weakening, falling off or intersection. Check if the fuse is installed and is the fuse holder damaged.

Electrical conductivity check: Use the multimeter resistance range to check the integrity of each connecting line to check its conductivity and the presence of a short circuit or a chain break. During the test, tape the multimeter of the two ends of the chain, respectively. If the multimeter shows the resistance value equal to zero or close to zero, this means that the circuit draws the current normally. If the displayed resistance value is infinite, this means that the circuit is open, and you need to check the connection of the circuit and eliminate the problems.

Power Testing Test: Having made sure that the external inspection and verification of the electrical characteristics are performed correctly, again connect the negative battery cable to the battery terminal and tighten the nut. Then run the excavator, check if the indicators on the dashboard are burning, and check if all the functions of the electric system work normally, for example, headlights, wipers, beeps, displays, various control handles, etc. During the on checking for the power of power, pay attention on abnormal heating, smoking, smell, etc. If there are any deviations, immediately stop the check and find out the cause of the malfunction.

Cleaning after installation

Clean the installation location: after the installation is completed, clean the installation site, pack the tools and the remaining parts, and also properly save or dispose of the old fuse block.

Write down the information: Write down the installation date, model, serial number and other information about the new fuse unit for ease of use at the future maintenance and repair. At the same time, write down the problems that arose in the installation process and solutions to have reference information for future service.

Models and models of long -term sales

KOM ATSU: PC55, PC60, PC130, PC200, PC220, PC300, PC360, PC400, PC450, PC650, PC1200,

Caterpillar: CAT312, 320 325 330 345 350

Hitachi: EX100, EX120, EX150, EX160, EX200, EX220, EX300, EX400, ZX200, ZX210, ZX330, ZX400

Daewoo: DH55, DH200, DH220, DH280, DH300, DH320, DH330, DH420

Hyundai: R200, R210, R220, R225, R290, R305, R335, R360, R400, R500

Volvo: EC210. EC240, EC290, EC360, EC460

Sumitomo: SH60, SH100, SH120, SH200, SH220, SH300, LS580, LS1600, LS2600, LS2650, LS2800, LS3400, LS4300

Mitsubishi: MS180, MS230, MS240, MS380

KATO: HD250, HD400, HD450, HD510, HD550, HD650, HD700, HD770, HD800, HD820, HD850, HD880, HD900, HD1200, HD1250, HD1430, HD18880

Kobelco: SK07, SK60, SK100, SK120, SK200, SK220, SK230, SK300, SK09, SK912, SK907

Shantui: SE210, SE220, SE230, SE320

Sany: SY55, SY60, SY65, SY75, SY85, SY95, SY115, SY135, SY155, SY205, SY215, SY225, SY235, SY265, S305, SY335, S365, SY465 SY700, SY850550550, SY850

Lishide: SC760, SC485, SC450, SC400, SC360, SC300, SC330, SC270, SC240, SC220, SC210

Liugong: CLG908, CLG909, CLG920, CLG922, CLG925, CLG927, CLG933, CLG936, CLG939, CLG945,

Engine: Cum Mins, Weichai, and Shangchai

Meanwhile, We Offer Parts for, Lingong, Liugong, Shangong, Hitachi, Howo and Dongfeng Parts.

20Y-32-02001

20Y-32-02011

20Y-32-00013

207-32-03900

207-32-00310

208-32-03011

208-32-03000

208-32-00300

208-32-00330

20Y-30-00030

20Y-30-00011

20Y-30-00022

207-30-00160

207-30-00150

207-30-00140

208-30-00200

208-30-00210

208-30-00340

705-11-33011 |

705-11-33011 |

704-31-24110 |

6206-61-1103 |

6206-51-1201 |

705-73-29010 |

705-11-34011 |

704-31-24110 |

6206-61-1103 |

6206-51-1201 |

705-73-29010 |

|

705-51-20170 |

705-13-28530 |

704-31-24110 |

6206-61-1103 |

6207-51-1201 |

704-21-29400 |

705-51-20180 |

705-13-23530 |

704-31-24110 |

6206-61-1103 |

6207-51-1201 |

705-73-29010 |

705-51-20070 |

705-13-26530 |

704-30-29110 |

6206-61-1103 |

6207-51-1100 |

705-73-29010 |

705-51-20180 |

704-31-24110 |

6735-61-1101 |

6735-51-1111 |

705-73-30010 |

|

705-51-20290 |

704-30-29110 |

6136-61-1601 |

6136-52-1100 |

705-51-20170 |

|

705-51-20240 |

704-30-29110 |

6136-61-1501 |

6136-52-1100 |

705-51-20170 |

|

705-51-22000 |

704-30-29110 |

6136-61-1601 |

6136-52-1100 |

705-51-20070 |

|

705-51-20140 |

704-30-29110 |

6136-61-1601 |

6136-52-1100 |

705-51-20070 |

|

705-51-20280 |

704-30-29110 |

6136-61-1601 |

6136-52-1100 |

705-51-20070 |

|

705-51-32080 |

704-30-29110 |

6136-61-1501 |

6136-52-1100 |

705-51-20070 |

|

705-55-24130 |

6735-61-1101 |

6735-51-1111 |

705-51-20430 |

||

705-52-30080 |

705-52-30080 |

704-30-32110 |

6136-52-1100 |

705-11-35010 |

|

705-56-34180 |

705-52-30220 |

704-30-32110 |

6136-52-1100 |

705-11-35010 |

|

705-55-34180 |

704-30-32110 |

6221-51-1100 |

705-51-20440 |

||

705-56-34040 |

704-30-34110 |

705-11-35010 |

|||

705-52-20240 |

705-12-37040 |

||||

705-52-20240 |

705-12-37010 |

705-12-36010 |

|||

705-22-40110 |

705-52-30260 |

705-12-38010 |

|||

705-58-46001 |

705-56-44010 |

705-58-47000 |

|||

23b-60-11100 |

6136-52-1100 |

23a-60-11200 |

|||

23A-60-11100 |

6207-51-1201 |

23a-60-11200 |

20t-60-00400 |

||

705-56-24080 |

||

6204-61-1100 |

||

704-24-24410 |

6206-61-1103 |

6240-51-1201 |

704-24-24430 |

6732-51-1111 |

6735-61-1500 |

704-24-26400 |

6206-61-1103 |

6206-51-1201 |

704-24-26401 |

6206-61-1103 |

6207-51-1201 |

704-24-24420 |

6206-61-1104 |

6207-51-1201 |

705-56-24020 |

6136-61-1102 |

6136-51-1000 |

705-51-10020 |

6136-61-1102 |

|

704-24-28200 |

6136-62-1100 |

6136-52-1100 |

704-24-28230 |

6206-61-1100 |

6209-51-1201 |

704-24-24420 |

6209-61-1100 |

6209-51-1700 |

6735-61-1502 |

6735-51-1111 |

|

705-58-34010 |

6711-62-1101 |

6710-52-1000 |

704-23-30601 |

6151-61-1121 |

6151-51-1005 |

704-23-30601 |

6221-61-1102 |

6221-51-1100 |

704-24-26430 |

6222-63-1200 |

6221-53-1101 |

6743-61-1530 |

6741-51-1110 |

|

6711-62-1101 |

6710-52-1000 |

|

704-23-30601 |

6151-61-1121 |

6151-51-1005 |

704-23-30601 |

6151-61-1101 |

6151-51-1005 |

704-24-26430 |

6151-62-1103 |

6151-51-1005 |

KP1009CHFSS |

34345-00010 |

34311-1011 |

5I6017 |

||

4181700 |

1-13610190-1 |

1-13100204-0 |

4255303 |

1-13610798-2 |

1-13100244-1 |

4276918 |

1-13650017-1 |

1-13100277-0 |

8-97125051-1 |

8-94366241-0 |

|

4181700 |

1-13610944-0 |

1-13100191-2 |

705-21-31020 |

114-60-02040 |

113-15-00470 |

6206-51-1201 |

||||

705-12-32010 |

705-12-32010 |

705-12-32010 |

6136-51-1002 |

||||

704-12-38100 |

07429-71300 |

07426-71400 |

07400-30200 |

||||

704-12-38100 |

07429-72302 |

6150-51-1004 |

6151-62-1102 |

07427-72400 |

07400-40400 |

||

704-11-38100 |

07429-71203 |

07432-72203 |

|||||

704-11-38100 |

07429-71203 |

07432-72203 |

6150-51-1004 |

6151-62-1102 |

|||

07443-67503 |

6620-51-1020 |

6685-61-1024 |

705-30-31203 |

||||

07441-67503 |

07430-72301 |

6150-51-1004 |

6150-61-1101/3 |

07433-72400 |

07400-40500 |

||

07441-67503 |

07430-72203 |

07432-71203 |

6150-51-1004 |

175-13-23500 |

6151-61-1101 |

||

705-11-38010 |

14X-49-11600 |

705-51-20370 |

6151-51-1005 |

6151-61-1101 |

|||

07441-67503 |

07430-72203 |

07432-71203 |

6151-51-1004 |

175-13-23500 |

6151-61-1121 |

||

07443-67100 |

07428-71202 |

07432-72203 |

6659-52-1010 |

6685-61-1024 |

|||

07443-67103 |

07428-71202 |

07432-72203 |

6620-51-1020 |

135-13-23500 |

6685-61-1024 |

||

07444-67504 |

07430-71400 |

07432-71300 |

6659-52-1010 |

135-13-23500 |

6685-61-1024 |

07400-30102 |

|

705-12-44010 |

07430-71400 |

07432-71300 |

6151-51-1005 |

135-13-23500 |

6151-62-1102 |

07400-30100 |

|

07444-66100 |

07432-72103 |

6620-51-1000 |

6685-61-1024 |

07431-11100 |

|||

07444-66103 |

07436-72202 |

07432-71203 |

6710-51-1001 |

175-13-23500 |

6711-62-1101 |

||

07444-66200 |

07436-72202 |

07432-71203 |

6710-51-1001 |

175-13-23500 |

6711-62-1101 |

||

705-51-30190 |

07436-72202 |

705-21-32051 |

6151-51-1004 |

175-13-23500 |

6151-61-1101 |

||

07446-66103 |

07440-72202 |

07433-71103 |

6128-52-1012 |

175-13-23500 |

6124-61-1004 |

||

07446-66200 |

07440-72202 |

07433-71103 |

6128-52-1012 |

175-13-23500 |

6124-61-1004 |

||

07400-10600 |

|||||||

705-51-30290 |

17A-49-11100 |

||||||

07448-66500 |

07442-71802 |

07438-72902 |

6128-52-1013 |

175-13-23500 |

6127-61-1008 |

||

07448-66108 |

07442-71102 |

07438-72202 |

6128-52-1012 |

195-13-13500 |

6127-61-1008 |

||

07448-66200 |

07442-71102 |

07438-72202 |

6128-52-1013 |

175-13-23500 |

6127-61-1008 |

705-11-33011 705-11-33011 704-31-24110 6206-61-1103 6206-51-1201 705-73-29010

705-11-34011 704-31-24110 6206-61-1103 6206-51-1201 705-73-29010

705-51-20170 705-13-28530 704-31-24110 6206-61-1103 6207-51-1201 704-21-29400

705-51-20180 705-13-23530 704-31-24110 6206-61-1103 6207-51-1201 705-73-29010

705-51-20070 705-13-26530 704-30-29110 6206-61-1103 6207-51-1100 705-73-29010

705-51-20180 704-31-24110 6735-61-1101 6735-51-1111 705-73-30010

705-51-20290 704-30-29110 6136-61-1601 6136-52-1100 705-51-20170

705-51-20240 704-30-29110 6136-61-1501 6136-52-1100 705-51-20170

705-51-22000 704-30-29110 6136-61-1601 6136-52-1100 705-51-20070

705-51-20140 704-30-29110 6136-61-1601 6136-52-1100 705-51-20070

705-51-20280 704-30-29110 6136-61-1601 6136-52-1100 705-51-20070

705-51-32080 704-30-29110 6136-61-1501 6136-52-1100 705-51-20070

705-55-24130 6735-61-1101 6735-51-1111 705-51-20430

705-52-30080 705-52-30080 704-30-32110 6136-52-1100 705-11-35010

705-56-34180 705-52-30220 704-30-32110 6136-52-1100 705-11-35010

705-55-34180 704-30-32110 6221-51-1100 705-51-20440

705-56-34040 704-30-34110 705-11-35010

705-52-20240 705-12-37040

705-52-20240 705-12-37010 705-12-36010

705-22-40110 705-52-30260 705-12-38010

705-58-46001 705-56-44010 705-58-47000

23B-60-11100 6136-52-1100 23A-60-11200

23A-60-11100 6207-51-1201 23A-60-11200

705-21-31020 114-60-02040 113-15-00470 6206-51-1201

705-12-32010 705-12-32010 705-12-32010 6136-51-1002

704-12-38100 07429-71300

704-12-38100 07429-72302 6150-51-1004 6151-62-1102

704-11-38100 07429-71203 07432-72203

704-11-38100 07429-71203 07432-72203 6150-51-1004 6151-62-1102

07443-67503 6620-51-1020 6685-61-1024

07441-67503 07430-72301 6150-51-1004 6150-61-1101/3

07441-67503 07430-72203 07432-71203 6150-51-1004 175-13-23500 6151-61-1101

705-11-38010 14x-49-11600 705-51-20370 6151-51-1005 6151-61-1101

07441-67503 07430-72203 07432-71203 6151-51-1004 175-13-23500 6151-61-1121

07443-67100 07428-71202 07432-72203 6659-52-1010 6685-61-1024

07443-67103 07428-71202 07432-72203 6620-51-1020 135-13-23500 6685-61-1024

07444-67504 07430-71400 07432-71300 6659-52-1010135-13-23500 6685-61-1024

705-12-44010 07430-71400 07432-71300 6151-51-1005 135-13-23500 6151-62-1102

07444-66100 07432-72103 6620-51-1000 6685-61-1024

07444-66103 07436-72202 07432-71203 6710-51-1001 175-13-23500 6711-62-1101

07444-66200 07436-72202 07432-71203 6710-51-1001 175-13-23500 6711-62-1101

705-51-30190 07436-72202 705-21-32051 6151-51-1004 175-13-23500 6151-61-1101

07446-66103 07440-72202 07433-71103 6128-52-1012 175-13-23500 6124-61-1004

07446-66200 07440-72202 07433-71103 6128-52-1012 175-13-23500 6124-61-1004

07400-10600

705-51-30290 17A-49-11100

07448-66500 07442-71802 07438-72902 6128-52-1013 175-13-23500 6127-61-1008

07448-66108 07442-71102 07438-72202 6128-52-1012 195-13-13500 6127-61-1008

07448-66200 0742-71102 07438-72202 6128-52-1013 175-13-23500 6127-61-1008

07426-71400 07400-30200

07427-72400 07400-40400

705-30-31203 20T-60-00400

07433-72400 07400-40500 705-56-24080

6204-61-1100

704-24-24410 6206-61-1103 6240-51-1201

704-24-24430 6732-51-1111 6735-61-1500

704-24-26400 6206-61-1103 6206-51-1201

704-24-26401 6206-61-1103 6207-51-1201

07400-30102 704-24-24420 6206-61-1104 6207-51-1201

07400-30100 705-56-24020 6136-61-1102 6136-51-1000

07431-11100 705-51-10020 6136-61-1102

704-24-28200 6136-62-1100 6136-52-1100

704-24-28230 6206-61-1100 6209-51-1201

704-24-24420 6209-61-1100 6209-51-1700

6735-61-1502 6735-51-1111

705-58-34010 6711-62-1101 6710-52-1000

704-23-30601 6151-61-1121 6151-51-1005

704-23-30601 6221-61-1102 6221-51-1100

704-24-26430 6222-63-1200 6221-53-1101

6743-61-1530 6741-51-1110

6711-62-1101 6710-52-1000

704-23-30601 6151-61-1121 6151-51-1005

704-23-30601 6151-61-1101 6151-51-1005

704-24-26430 6151-62-1103 6151-51-1005

KP100999999999999thfss 34345-00010311-1011

5i6017

4181700 1-13610190-1 1-13100204-0

4255303 1-13610798-2 1-13100244-1

4276918 1-13650017-1 1-13100277-0

8-97125051-1 8-94366241-0

4181700 1-13610944-0 1-13100191-2

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive