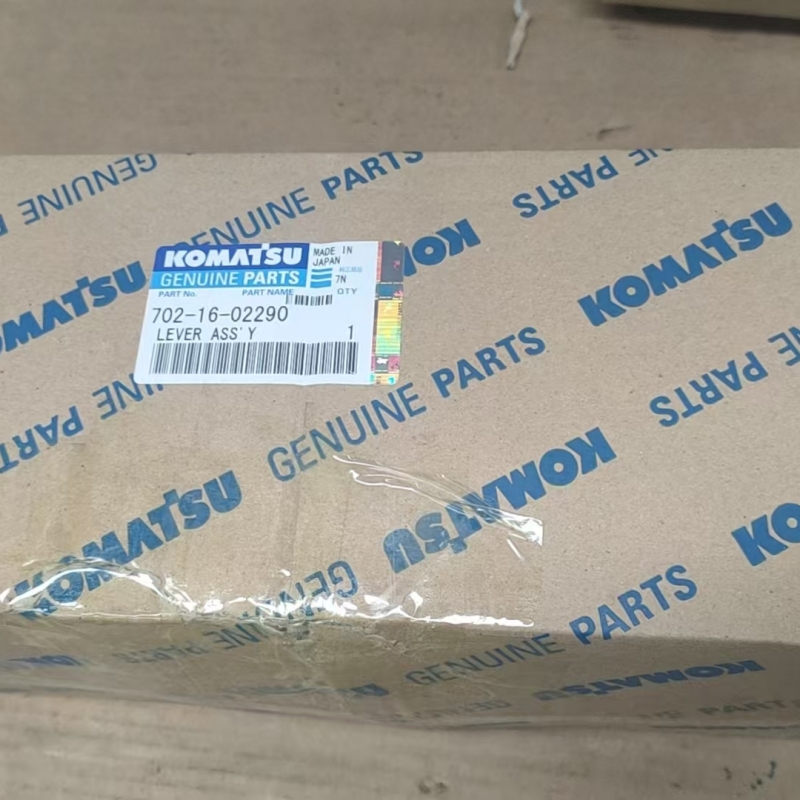

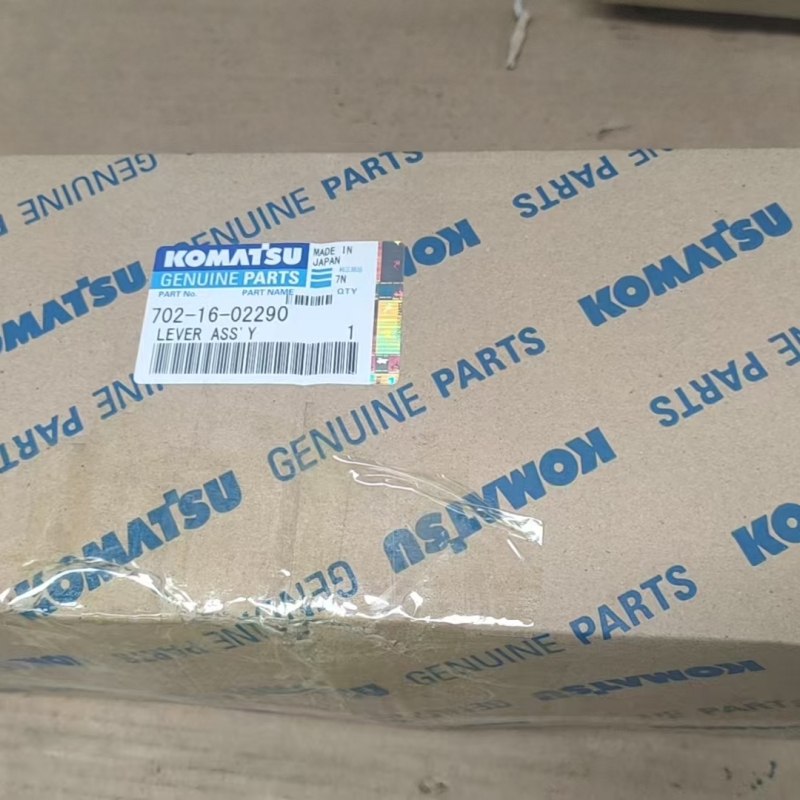

Product Introduction

1. Design feature of control lever component 702-16-02290

The 702-16-02290 control lever component for the Komatsu D65EX features a sophisticated design that combines strength, compactness, and ease of use. Key components include the lever body, internal signal transmission mechanisms, control handle, and fasteners—all of which are crafted using high-quality materials and meet Komatsu manufacturer standards.

Lever body: Made of high-strength S45C carbon steel (Japanese JIS standard), which has high tensile strength (tensile strength up to 600MPa) and corrosion resistance. Before assembly, the housing is subjected to heat treatment (tempering) to reduce internal stresses and increase wear resistance, and is also coated with cathode sputtering (Coating thickness 8–12 microns) - this is additional protection against dust, moisture and chemicals that are often present in the working environments of the Komatsu D65EX. The dimensions of the case exactly repeat the original component: length 185 mm, width 92 mm, height 110 mm - thanks to this, it ideally fits into the installation location in the equipment cabin, without requiring additional adaptations.

Internal transmission mechanisms: Includes a system of levers and elastic elements that ensure smooth transmission of operator movements to the Komatsu D65EX hydraulic or electronic systems. All moving parts are made of alloy steel (grade 40Cr) with high hardness (HRc 50–55) after carburizing and tempering - this prevents wear during frequent movements of the lever (up to 10,000 cycles per month under normal operating conditions). Each hinge is equipped with a sealed nitrile (NBR material) packaging that prevents dust and dust particles from entering the mechanism, thereby extending the life of the component by 30-40% compared to similar products from other brands.

Control handle: Made of impact-resistant ABS (polyacrylonitrile butadiene styrene) plastic with anti-slip coating. The surface of the handle has a textured texture that provides a secure grip on the operator's hand even on wet or dirty surfaces. The length of the handle is 120 mm, the diameter at the grip points is 32 mm - these parameters are selected taking into account the anatomical features of the human hand, which reduces operator fatigue during long-term work (for example, when compacting soil or loading materials for 8-10 hours in a row).

Fasteners: Four hex head screws (size M8x16) made of A2 stainless steel (DIN 933) are provided to securely secure the component to the control panel. The screws have a protective zinc and chrome plated coating to prevent oxidation and jamming when replacing components in high humidity conditions.

2. Specifications and compliance

The 702-16-02290 control lever component fully complies with Komatsu's specifications for the D65EX model and undergoes strict quality control at all stages of production, from component manufacture to final assembly. Key specifications include:

Part number: 702-16-02290 (matches the original Komatsu number, which guarantees compatibility with the equipment).

Equipment model: Designed for Komatsu D65EX loader tractors (all modifications: D65EX-15, D65EX-16, D65EX-17).

Control type: Hydromechanical (compatible with Komatsu hydraulic systems with an operating pressure of 25–30 MPa).

Operating temperature range: -40°C to +80°C — the component is resistant to extreme temperatures, which allows it to be used in regions with cold climates (e.g., Siberia, northern regions of Europe) and hot climates (Middle Eastern countries, Africa).

The maximum lever tilt angle is ±35° horizontally and ±25° vertically – a sufficient range for precise control of equipment movement and working bodies (for example, a bulldozer or crane).

Component weight: 1.8 kg - compact weight does not increase the load on the control panel and facilitates installation.

Service life (guaranteed): 2 years or 3000 operating hours - above average for similar components from other manufacturers (typically 1 year or 2000 operating hours).

In addition, the product is certified in accordance with international standards:

ISO 9001:2015 (quality management system) – guarantees consistent quality at all stages of production.

ISO 14001:2015 (environmental management system) – materials and production technologies are safe for the environment (absence of toxic substances in coatings and plastics).

DIN EN 13306:2019 (heavy-duty spare parts standard) – confirms component compatibility and reliability when used in harsh conditions.

3. Advantages of the component compared to analogues

The 702-16-02290 control arm component for Komatsu D65EX has a number of key benefits that make it the preferred choice for operators and equipment owners. These advantages are based on high quality materials, thoughtful design and compliance with Komatsu standards:

High strength and durability: The use of high-strength steel for the body and alloy steel for internal mechanisms ensures resistance to mechanical damage (for example, from accidental impact of a tool in the cabin) and wear from frequent use. According to test results, the service life of the component exceeds similar non-original spare parts by 50–60% - this reduces the frequency of replacement parts and reduces equipment downtime. For example, when working in a quarry (where dust and vibrations are high), the component remains operational for up to 3,500 working hours, while analogues from other brands require replacement after 2,000–2,200 hours.

Precise control and smooth operation: Internal mechanisms with precise signal transmission steps provide high responsiveness of the lever - the operator can precisely adjust the speed of the Komatsu D65EX, the angle of the dozer or the loading force. This is especially important when performing work that requires high precision: for example, when leveling surfaces for road construction or when loading delicate materials (wood, concrete blocks). The smooth operation of the mechanism also reduces the load on the hydraulic system of the equipment, which extends the service life of the main pump and hydraulic motors by 15–20%.

Ease of installation and maintenance: The component has standard dimensions and mounting points that replicate the original Komatsu component - this means that installation can be completed by an operator or service technician in 30-40 minutes without the use of special equipment. For maintenance (cleaning, replacing seals) there is no need to disassemble the entire control panel - just unscrew four screws and remove the housing. Additionally, the delivery package includes an installation diagram and a list of recommended maintenance materials (for example, seal cream), which simplifies the operation process.

Compatibility with original equipment: Article 702-16-02290 fully complies with Komatsu requirements, so the component can be used in D65EX tractor-loaders of any model year (from 2010 to the present). This eliminates the risk of incompatibility with the electronics or hydraulics of the equipment - after installation, the component immediately begins to work without additional configuration or programming.

4. Scope of application and operating recommendations

The 702-16-02290 control lever component is designed for use on Komatsu D65EX loader tractors, which are widely used in the following industries:

Construction: Work on leveling the territory, digging trenches, loading building materials (gravel, sand, concrete), compacting the soil using a bulldozer or vibrating platform.

Mineral resources: Quarrying (coal, ore, granite), loading minerals into trucks, compacting rock to prevent collapses, and clearing waste from mining sites.

Agricultural industry: Clearing fields of stones and weeds, forming furrows for planting crops, loading grain or hay, compacting the soil before sowing.

Logging: Loading timber into vehicles, forming roads for timber trucks, clearing areas after fires or logging.

Public utilities: Snow removal in cities and towns (using snow removal equipment), garbage and waste removal, road and utility repairs.

To ensure maximum component life, it is recommended to follow these operating guidelines:

Regular Cleaning: Every week (if using the appliance daily), clean the lever housing of dust and dirt using a dry or damp cloth. Do not use high-pressure water for cleaning, as this may introduce moisture into the internal mechanisms and cause corrosion.

Periodic inspection of seals: Check the condition of the sealing rings in the joints every 3 months - if cracks or wear appear, replace them with original Komatsu seals (article 702-16-02291).

Temperature control: Avoid using equipment in conditions exceeding the operating temperature range (-40°C to +80°C). When working in cold climates, warm up the equipment cabin to +10°C before starting work to prevent damage to plastics and seals.

Correct use: Do not use the lever to hang objects (tools, bags) or subject it to strong impacts - this may damage the internal mechanisms and lead to loss of control precision.

Conclusion

The 702-16-02290 Control Arm Component for Komatsu D65EX Tractor Loader is a high quality replacement part that combines durability, precision and ease of use. Using premium materials, thoughtful design and compliance with Komatsu standards, this component ensures reliable operation of equipment in the most severe conditions - from extreme temperatures to high mechanical stress. Benefits such as durability, precision control and ease of installation make it the preferred choice for Komatsu D65EX operators and owners looking to minimize machine downtime and increase productivity.

![D65EX Komatsu 702-16-02290 LEVER ASSEMBLY D65EX Komatsu 702-16-02290 LEVER ASSEMBLY]()

![D65EX Komatsu 702-16-02290 LEVER ASSEMBLY D65EX Komatsu 702-16-02290 LEVER ASSEMBLY]()

![D65EX Komatsu 702-16-02290 LEVER ASSEMBLY D65EX Komatsu 702-16-02290 LEVER ASSEMBLY]()

![D65EX Komatsu 702-16-02290 LEVER ASSEMBLY D65EX Komatsu 702-16-02290 LEVER ASSEMBLY]()

![D65EX Komatsu 702-16-02290 LEVER ASSEMBLY D65EX Komatsu 702-16-02290 LEVER ASSEMBLY]()

![D65EX Komatsu 702-16-02290 LEVER ASSEMBLY D65EX Komatsu 702-16-02290 LEVER ASSEMBLY]()

Exhibition cabinets

![Exhibition cabinets Exhibition cabinets]()

Getting to know the plant

The plant employs a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. The company currently owns a number of independent intellectual property rights and patented technologies. The construction equipment produced includes a wide range of equipment such as excavators, loaders, cranes, bulldozers and other machines. Products are characterized by high performance, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to challenging operating conditions in a variety of climates and operating environments around the world.

![Getting to know the plant Getting to know the plant]()

Awards and qualificationsfication

![Awards and qualifications Awards and qualifications]()

frequently asked questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2.What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipment

3.What logistics methods can we use for delivery?

1) For most of Europe, South America and Africa etc. countries, we can go by container or Roro via ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or rail.

3) For light spare parts in urgent requirement, we can ship it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you guarantee that you have delivered the goods to customers?

A: We will provide you with full delivery information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable quality: Carefully select regular manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by ourselves, always adapting the best materials.

2) Competitive price: Concentration of mechanized production in large quantities reduces production costs to ensure competitive price.

3) Service Team: Firstly, our sales managers are available 24/7, ready to answer your questions at any time. Secondly, our professional technical support team, with senior technicians, is ready to provide support to users and dealers. Most issues can be resolved within 24 hours.

4) Fast delivery: Generally, we can delivery within 10 working days in factory after receiving the advance payment from customers.

6. How can you provide after-sales service to customers?

A: We will reply you at the first time and help you solve the problems within 24 hours. If we really need your local, we

We will send your professional person to your locality to help you solve the problems without any hesitation, supply you with all-round