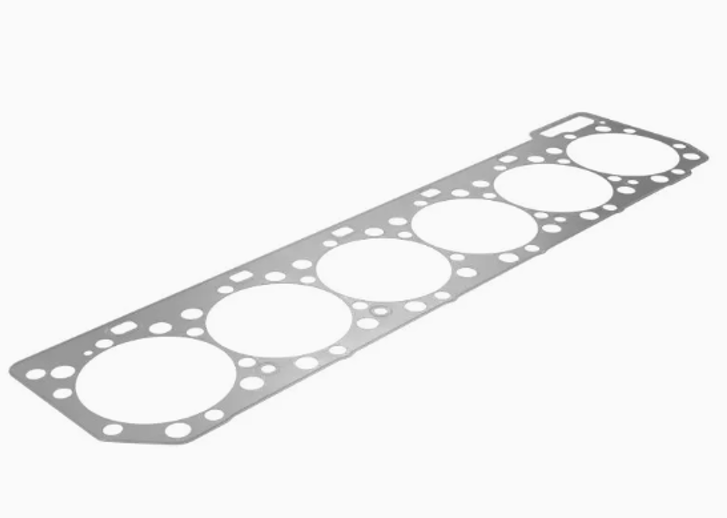

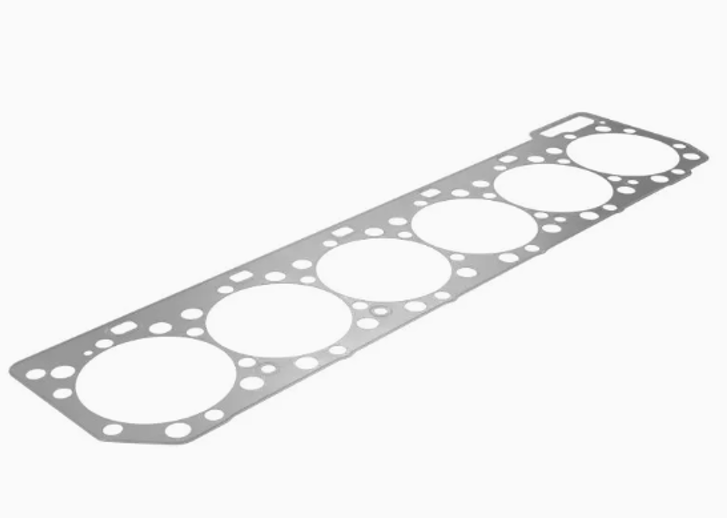

Caterpillar 592-7333 Set of the block head Original spare parts

1 、 High reliability: set 592-7333 made of high-quality materials, which ensures its durability and stable operation in various operating conditions of the C18 engine.

Accurate compatibility: especially developed for the CAT C18 engine, guarantees perfect compatibility with other engine details, which avoids installation problems and reduces the risk of failures.

2 、 The possibility of improving performance: helps to improve the tightness of the combustion system, which contributes to a more efficient burning of fuel and, as a result, increases the power and efficiency of the engine.

3 、 completeness of configuration: includes all the necessary parts for the installation of the cylinder head, which simplifies the replacement and repair process, reducing the time and efforts necessary for work.

Product representation

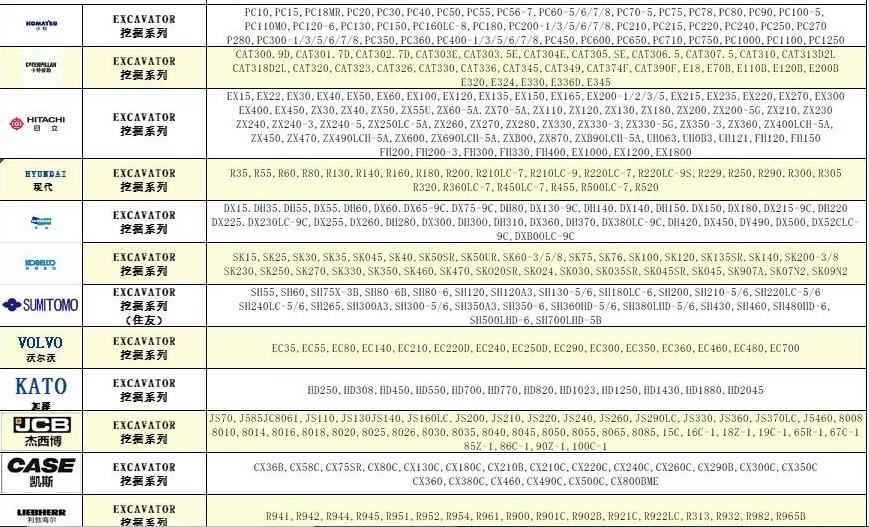

I. Applied models

Caterpillar seals are widely used in many types of Caterpillar construction equipment, including excavators, loaders, bulldozers, graders, taps and so on. In excavators such as common models 306, 315D, 320D, etc., seals are used in the engine, hydraulic system, cabin and other key parts to prevent oil and gas leakage, as well as dust and impurities to ensure the stable operation of the equipment . In loaders, such as 950M, 966M and other models, seals ensure the normal operation of the transmission system, working bodies and reduce the likelihood of failures. In bulldozers, such as D6K and D8T, seals maintain the tightness of the equipment in difficult working conditions and increase operation efficiency.

Secondly, classification of products

Oil seals: mainly used to compact a rotating shaft to prevent lubrication leakage. Skeletal cuffs consisting of a cuff body, an enhanced skeleton and a self -izing spiral spring are usually used. In the free state, its inner diameter is less than the diameter of the shaft, and after installing the edge of the seal and the self -izing spiral spring create radial tightness on the shaft, forming the seal. For example, oil seals used in the crankshaft engines can effectively prevent oil leakage and ensure the normal operation of the engine lubrication system.

Sealing ring: in the cross section, a round rubber sealing ring, which has good tightness and elasticity. It is widely used in the hydraulic system of pipes, valve blocks and other parts, can withstand a certain pressure to prevent hydraulic oil leakage. Sealing rings of various specifications are suitable for various density clearance and pressure conditions.

Cuff seals: used for rotating or reciprocating parts of the seal, can prevent oil leaks inside the machine, simultaneously protecting the machine from external pollution. For example, cuff seals on the piston rod of a hydraulic cylinder can effectively seal hydraulic oil and ensure the normal operation of the cylinder.

Sealing: usually used for sealing between two motionless parts, such as the cylinder head of the engine and the cylinder block between the cylinder laying, using multi -layer metal or rubber and metal composite material, can withstand high temperature, high pressure to prevent gas leakage, cooal fluid and cooler oils.

Thirdly, the advantages of performance

High tightness: Carter seals use advanced design and production process, can maintain good tightness in various difficult working conditions. For example, in a hydraulic system with high temperature and high pressure, seals can effectively prevent oil leakage, provide stable pressure in the system, and increase equipment efficiency.

Wear resistance: the choice of high -quality rubber, metal and other materials, with excellent wear -resistant characteristics. In the process of prolonged use, even with mechanical friction, erosion of the medium, etc., you can maintain the performance of the seal, extend the service life, reduce the frequency of the replacement, reduce the costs of equipment maintenance.

Anti-start: the material of the seal was specially treated, has good anti-start properties, can be in various ambient temperatures, humidity and ultraviolet radiation to maintain stable physical and chemical properties to guarantee that the effect is durable and reliable.

Adaptation to various environments: can adapt to the oil, hydraulic oil, coolant, gas and other working environments to satisfy the needs for compaction of various equipment and systems, with a wide range of applicability.

Fourth, technology of materials

Rubber materials: nitrile rubber (NBR), fluoride (FKM), silicone rubber (VMQ) and so on. NBR has good oil resistance, wear resistance and waterproofness, suitable for general oil, hydraulic environmental oil oil; Freedlastomer with high heat resistance, excellent chemical corrosion resistance, is usually used in high temperature, strong corrosion seals of the medium; Silicone rubber has good resistance to high and low temperatures and electrical insulation, suitable for some cases of the requirements of the harsh requirements.

Metal material: reinforcing frame and part of the sealing laying of skeletal oil seals are made of metal, such as carbon steel, stainless steel and so on. Metal material is processed with stamping, forging and other methods that has high strength and good size stability and provides reliable support for seals.

Production process: to ensure high accuracy of the size and stability of the form of seals, the advanced processes of molding and casting under pressure are used. In the production process, strict quality control and testing of each process guarantee that the quality of the products complies with the standard.

Possessing excellent characteristics of tightness and reliability, Caterpillar seals are widely used for all types of engineering equipment and capillar equipment, namely:

Excavators: small excavators, such as 305.5, 306, 307 of the series, are usually used in small maintenance of urban infrastructure, landscape construction and other scenarios, working conditions are relatively flexible, but the requirements for the tightness of the equipment are high, Carter seals play a role in the engine and hydraulic system to prevent oil leakage to ensure stable work equipment; Medium excavators, such as 315, 320, 323, 324. 325, 329 episodes, are the main models in the construction of buildings, road construction, Carter compaction are widely adapted to various engineering equipment of Caterpillar as follows, 325, 329 series, is the main model in construction buildings, road construction, Carter seals in conditions of high temperature, high pressure, high load of the working environment, to maintain the tightness of the equipment systems, to ensure the efficient operation of the excavator; Large excavators, such as 330, 336, 340 series, are mainly used in the mining industry, large projects of reservoirs, Carter compaction in harsh working conditions, effectively blocking the Carter, can effectively prevent the penetration of dust and pollution inside the equipment, preventing the wear of key components and Providing the service life and efficiency of equipment.

Loaders: common models, such as 950M, 962M, 966M, etc., are responsible for loading, unloading and transportation of materials in ports, mines, construction sites and in other places. Carter seals are used in the transmission system and the working bodies of loaders to prevent lubricant leakage, ensure the normal operation of the mechanical parts, reduce the likelihood of equipment failure and increase the efficiency of work.

Bulldozers: such as D6K, D8T, D10T and other models, are mainly used to align the sites, movement of soil and other operations, the working environment is harsh, the reliability of the equipment is extremely high. Caterpillar seals are used in the engine, hydraulic system and running device of bulldozers to withstand the effects of dust, soil and poor weather, maintain tightness and normal operation of the equipment, as well as ensure efficient operation even in difficult working conditions.

Autograms: 12M, 14M, 16M and other models of motor graders are used to align the soil in the construction of roads, airports and other projects. Carter seals are used in all the key nodes of the auto grader to prevent leakage of hydraulic oil, ensure accurate control of lifting and turning the scraper, as well as guarantees of the stable operation of the auto grader.

Cranes: Carter crane products, such as caterpillar and tire cranes, plays an important role in the construction and installation of large equipment. Carter seals are used in the hydraulic system, rotation mechanism, lifting mechanism and other parts of the cranes to ensure good tightness of the equipment with frequent launches, stops and work with a large load, as well as to prevent potential threats to safety and equipment failure caused by leaks.

Basic Info.

Model no.

592-7333

Application

Excavator

Certification

CE, ISO9001: 2000

Condition

New

Engine

C18

Applicable Industries

Machinery Repair Shops, Manoufacturing Plant, Const

Quality

High Quality, 100% Professional Test

Brand

Original Factory Cat

Transport Package

Carton

Specification

20*10*15

Trademark

cat

Origin

China

Hs Code

8409999100

Production Capacy

5000/year

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive