Komatsu 561-40-61531 Stift HD785-7 dump truck

1. Adaptation to difficult working conditions: developed for the main models of dump trucks in Russia, it meets the difficult road conditions and requirements for large loads, guaranteeing the stable work of a trunple shaft in harsh conditions and the effective operation of the vehicle.

2. High wear resistance and impact resistance: made of high -quality steel, has excellent wear resistance and impact resistance after special heat treatment. It can withstand high -intensity operations, reduces wear and extends the service life.

3. A simple and fast installation: has a standardized design, accurate size, simple installation, does not require complex tools and professional technologies, can be quickly replaced and reduces downtime.

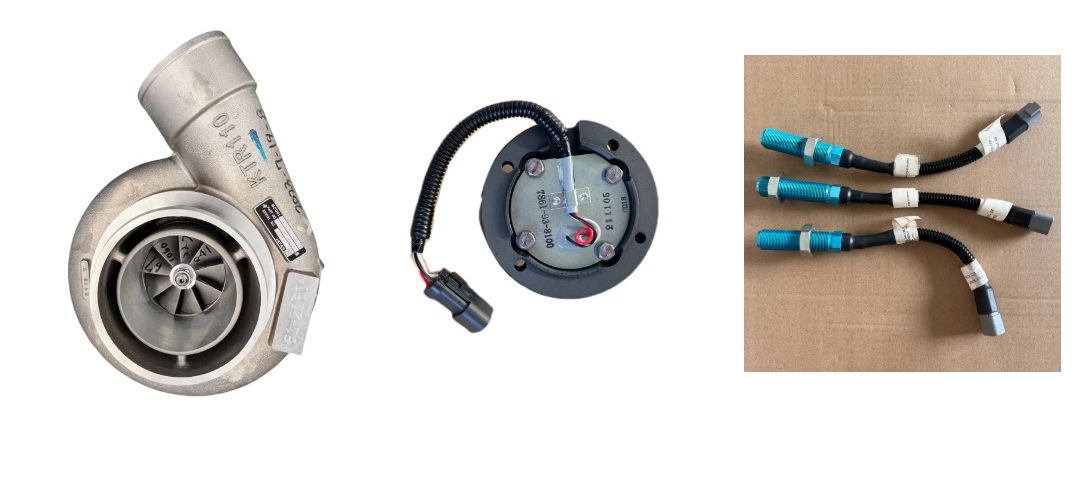

Product representation

1. Detailed product information

1. Review of the product

Being the main detail connecting the key components of the dump truck, the dump truck is responsible for the transfer of huge loads and provides smooth operation and the uninterrupted course of the vehicle. From the connection of the car body with the chassis to the key nodes of the hydraulic lifting system - our fingers are present everywhere, guaranteeing that dump trucks can work safely and efficiently in various difficult working conditions. Whether it is transportation of construction waste over short distances or long-range loading-unloading of mining materials, our fingers can provide reliable support for reliable operation of dump trucks.

2. Production process and materials

The choice of material: high -quality alloy steel, such as 40CR, 42CRMO, etc., these steel have high strength, high viscosity and good wear resistance, and are also able to withstand frequent shock loads and alternating dump trucks during operation. Take as an example 42CRMO, its fluidity limit reaches 930 MPa, and the tensile strength exceeds 1080 MPa. Providing the high strength of the pin shaft, it has excellent fatigue strength, effectively extending the service life of the pin shaft and reducing the frequency of equipment failures.

Production process: using the advanced forging technology, after heating steel to the corresponding temperature, it passes multiple precipitation and stretching in order to make the internal structure of steel more dense, eliminate forging defects and improve general mechanical properties. After forging, precision machining is performed using high -precision equipment, such as CNC turning and grinding machines, to guarantee that the accuracy of the size of the pin reaches ± 0.01 mm, the cylindrical error is controlled within 0.005 mm, and the surface roughness is less than RA0.8 μm, which provides an accurate fit pin to mating details. Then the pin is subjected to hardening and vacation to obtain good complex mechanical properties with surface hardness HRC30 - 35, which provides not only surface wear resistance, but also sufficient strength of the core. Finally, the surface of the pin is subjected to special processing, for example, using solid chrome technology, as a result of which a solid and dense layer of chromium is formed on the surface of the pin about 0.02–0.05 mm, which significantly increases the wear resistance and corrosion resistance of the pin.

(III) The advantages of the product

High -precision landing: due to the accurate control of the size and excellent processing of processing, the gap between our fingers and various parts of the dump trucks is extremely small and uniform, which ensures the stability and reliability of the connecting parts. During the operation of the vehicle, it can effectively reduce the vibration and blows caused by improper selection, reduce the wear of the components, extend the total service life of the equipment and at the same time improve the handling and efficiency of the vehicle.

Excellent bearing capacity: optimized choice of materials and advanced production technologies provide the pin with a very high bearing capacity. Faced with a huge load during the transportation of heavy -loading dump trucks and instant shock force during lifting work, a pin shaft easily copes with it without problems such as deformation and breakdown, providing a reliable guarantee of the safe operation of a dump truck. Compared to ordinary fingers, the carrying capacity of our fingers can be increased by 30% - 50%, which significantly increases the operational adaptability of dump trucks in severe operating conditions.

Long life: excellent properties of the material, the exact manufacturing process and reliable surface processing provide a long service life of the pin. Its wear resistance and corrosion resistance are significantly improved. With normal use, the pin shaft replacement cycle can be extended by 2-3 times, which reduces the downtime of equipment and service time, reduces the user's operating costs and increases economic benefits.

2. The installation method

1. Preparation before installation

Checking the model and appearance: carefully check whether the model of the finger corresponds to a particular part of the dump truck to make sure that the size and characteristics of the finger correspond to the requirements of the design. At the same time, check the appearance of the pin shaft for defects, such as cracks, sand sinks, irregularities, etc., surface smoothness and integrity of the chrome coating. If you have any problems, replace the appropriate pin in a timely manner.

Preparation of tools: Prepare professional installation tools, such as copper rods, pullers, presses, end keys, dynamometric keys, etc., and make sure that the tools are not damaged, and their accuracy meets the requirements. In addition, prepare the corresponding amount of lubrication. It is recommended to use lithium -based lubricant, which is resistant to high temperatures and high pressure and has good adhesion to provide good lubricant after installing the pin.

Cleaning: thoroughly cleaned with the cleaning product, the installation area of the pin and the surface of the corresponding holes, grooves and other parts to remove oil, pollution, rust, etc., so that the installation surface is clean and even. After cleaning, wipe the surface with a clean rag to prevent secondary contamination, and apply a thin layer of lubrication to the installation site to facilitate the installation of the pin.

(II) Stages of installation

Lubrication: evenly apply lithium lubricant to the surface of the pin to guarantee that the entire surface of the pin is covered with lubrication, especially on key parts, such as the threaded part of the pin and the cylindrical surface, in contact with mating details. Apply enough lubrication to reduce friction resistance during installation and provide good initial lubrication for subsequent use.

Positioning of the installation: Use tools such as a copper rod or press to slowly and evenly insert the pin into the mounting hole. During the insert process, make sure that the pin is in an upright position in order to avoid its inclined installation, which can cause difficulties in installing or damaging the mating parts. For some pins that need to be installed exactly, for example, key pins in hydraulic lifting systems, you can use a positioning tool that will help in the installation and ensure the accuracy of the installation pin.

Puster and adjustment: after the pin is inserted into the appropriate position, with the help of the end key, tighten the nut or bolt on the pin to make sure that the pin is reliably installed. In the process of tightening, it is necessary to observe the indicated value of the torque. Typically, the torque value is in the range from [x] n ・ m to [x] n ・ m. The specific value depends on the various models of dump trucks and the specifications of the pin. The use of a dynamometric key can guarantee that the tightening moment of each nut or bolt will be uniform, preventing the weakening of the pin due to insufficient tightening power or damage to the thread due to excessive tightening. After installation, check whether the gap between the pin and the mated details is uniform, and whether the moving parts can rotate freely. If necessary, perform the appropriate adjustment.

3. Common malfunctions and ways to eliminate them

1. Stifet wear

Cause

Long work under the heavy load leads to the fact that the sliding bearing is subjected to excessive pressure and friction, which leads to surface wear. During transportation, dump trucks are often loaded with heavy objects, and the fingers are constantly subjected to huge loads, which enhances the friction between the fingers and mating details. Especially with frequent starting, braking and raising, the force of impact and friction on the fingers increase even more, accelerating the wear of the fingers.

Poor lubrication, its absence or deterioration of lubrication characteristics cannot effectively reduce the coefficient of friction. If you do not replenish grease in time during daily maintenance or use poor -quality lubricant, it will easily flow and collapse in conditions of high temperature and high pressure, losing a lubricant, which will lead to direct friction between the pin and mating details, which will lead to wear.

Incorrect installation, the gap between the pin and the mated details is too large or too small, which leads to an uneven load on the pin during operation and severe local wear. For example, when installing the pin is not completely inserted vertically into the mounting hole or the coordinating hole is not processed quite accurately, which leads to an uneven coordinating clearance. The pin will be unbalanced during operation, which will increase the wear of one side of the pin.

Bypass

Rightly distribute the working tasks of the dump truck to avoid long -term work with a large load and overload, as well as reduce the load on the VAL DRAPFA. At the same time, during work, try to maintain smooth work, avoid sharp acceleration, sharp inhibition and excessive upsurge to reduce shock on a pin shaft.

Strengthen the lubrication control, regularly check the condition of the lubrication of the shaft and replenish or replace the lubricant in accordance with the prescribed period. Choose a lubricant of reliable quality, which meets the requirements for the use of equipment. If you work at high temperatures, you should choose a lubricant with good resistance to high temperatures; If you work in the conditions of dust, you should choose a lubricant with good dustproof characteristics.

Re -check and adjust the accuracy of the pin installation to make sure that the gap between the pin and the mated details meets the design requirements. If the gap is too large, the gap can be adjusted by replacing the appropriate sleeve or repairing the conjugated parts. If the gap is too small, the pin or conjugated parts can be properly polished, but you should pay attention to the accuracy of the size and surface quality. For strongly worn pins, new pins should be replaced in time. The quality and accuracy of the size of new pins should be carefully checked before installation.

(2) Stift deformation

Cause

A sudden huge shock load, for example, when unloading a dump truck, leads to a sudden drop in cargo in a car, which creates a powerful instant shock on a pin shaft exceeding the bearing capacity of a pin shaft, which leads to deformation of the pin shaft. In addition, if during movement the vehicle enters the pothole or obstacle and does not reduce speed in time, the tsapf can also be seriously exposed.

The problem of the material: if the steel used for the pin does not comply with the standards, its strength and viscosity will be insufficient, and during normal working loads, deformation may occur. To reduce costs, some small manufacturers can use low -quality steel for the manufacture of pins, as a result of which the quality of the pin cannot be guaranteed.

Strength damage accumulates, and under the influence of alternating loads for a long time, fatigue cracks will appear inside the pin. As the fractures gradually expand, the supporting ability of the pin decreases, which ultimately leads to deformation. With daily operation of dump trucks, the shaft of the finger is constantly subjected to alternating loads during touching the place, movement, inhibition, lifting and lowering the vehicle, which can easily lead to fatigue damage.

Bypass

Standard the work procedures and ensure a smooth unloading of materials when unloading a dump truck to avoid a sudden drop in materials and a stamp shaft. During movement, pay attention to the road conditions, reduce the speed in advance to avoid potholes and obstacles, and also reduce the effect on the tsapfu during movement.

Strictly control the quality of the purchased pins and choose maces produced by trusted manufacturers and corresponding to quality standards. When purchasing pins, suppliers are required to provide reports on the quality of product quality and conduct strict inspections of the properties of the material, the accuracy of the size, etc. Stifts to guarantee the reliable quality of the pin.

Create a regular control system and use non -destructive control technology (for example, magnetic passenger defectoscopy and ultrasonic flaw detection) to regularly check the presence of fatigue cracks inside the pin shaft. In case of detecting fatigue cracks on the pins, it is necessary to take measures to repair or replace, depending on the seriousness of the cracks. Simply deformed pins simply replace with new ones to ensure the safe operation of the car.

(III) Shtifte fracture

Cause

With severe overload or hit, when the weight of the cargo loaded into the dump truck exceeds the nominal load, or when it encounters an abnormally strong blow during operation, for example, when colliding with other vehicles or when the incident object is hit on a pin, etc., the pin can be exposed to extremely higher stress in an instant exceeding its firmness, and, and, and, and, and, the praise Thus, break.

The spread of the fatigue crack: if the pin for a long time works under alternating loads, and the previous fatigue damage was not detected and not eliminated on time, the fatigue crack will gradually spread. When the crack expands to a certain extent and the residual strength of the pin cannot withstand the working load, it will break.

Production defects: if in the process of making a pin there are foundry defects (such as pores, sand sinks), forging defects (such as folds, cracks) or processing defects (such as traces of a knife, stress concentration points), these defects will become weak parts of the pin. In the process, the voltage will concentrate on these defects, which will lead to premature breakdown of the pin.

Bypass

Strictly observe the rules for loading dump trucks, overloading is strictly prohibited. Before starting operation, carefully check the load of the cargo to make sure that the weight of the cargo is distributed evenly and does not exceed the nominal load of the vehicle. At the same time, it is necessary to strengthen the management of the workplace in order to avoid accidents, such as clashes of dump trucks with other objects.

To strengthen daily inspection and maintenance of pins, regularly non -destructive control, timely identify and eliminate fatigue cracks and other defects on the surface of the pin. In case of detection of cracks or defects on the pins, it is necessary to take measures to repair or replace, depending on the actual situation. During the repair, you can use grinding, welding and other methods, but it is necessary to make sure that the operational characteristics of the renovated pin meet the established requirements. If the pins are not subject to repair or have serious cracks, they must be replaced in a timely manner with new ones.

Choose a supplier of pin with a good reputation and advanced production technologies to guarantee the quality of the pin manufacture. When purchasing pins, we require suppliers to provide detailed reports for product quality control and strictly control the process of production of pins in order to guarantee the quality of the pin from the manufacturer and reduce the problem of a breakdown of pins due to production defects.

4. Repair and maintenance

1. Daily service

Verification of the appearance: before each operation, check the appearance of the shaft of the pin of the dump truck to check whether there are any abnormal states on the surface of the pin shaft, such as wear, deformation, cracks, etc. At the same time, check whether the connection between the pin shaft and the mating details and there are no signs of lubricating oil. If you find any problem, turn off the car in a timely manner to eliminate it and avoid further aggravation of the problem.

Lubrication maintenance: after each working day, use special lubricant equipment, for example, a lubricant syringe to add grease to the pin. When adding a lubricant, make sure that it completely fills the gap between the pin and the mated details, providing good lubricant. At the same time, check the quality of the lubricant. If the lubricant has dried, deteriorated or mixed with impurities, clean it and replace it with new grease in time.

(II) regular maintenance

Determination of wear: every [x] working hours or every [x] months use professional measuring tools (for example, calipers, micrometers) to measure the main sizes of the pin, such as diameter and length, compare them with the initial dimensions and calculate the wear of the pin. As a rule, wear of the diameter of the shaft of the stiff should not exceed 0.5 mm. If wear exceeds the indicated value, the Val Stiff should be repaired or replaced depending on the actual situation.

Tight test: regularly check the tightening of nuts or bolts on the pin shaft using a dynamometric key to make sure that the tightening moment meets the specified requirements. It is usually recommended to perform tightening each [x] hours of work or every [x] months. In the process of tightening, check and tighten each nut or bolt in turn in accordance with the prescribed tightening sequence to prevent accidents associated with safety, such as displacement and drop in the pin due to weakened bolts.

Non -destructive control: through regular intervals of time, for example, every [x] hours of work or every [x] months, use non -destructive control technology (for example, magnetic pool flavoring and ultrasonic flaw detector) to conduct a comprehensive inspection of the pin for defects, such as fatigue cracks, pores and sand sinks inside Stifta. If defects are detected, take the appropriate repair or replacement measures depending on their seriousness to ensure the safe use of the pin.

(III) precautions during maintenance

Use original accessories: During repair and maintenance, be sure to use original pins and related accessories corresponding to quality standards, such as nuts, bolts, bushings, etc. Contrafact and poor -quality products can have serious defects as a material, sizes, mechanical properties, etc., which can easily lead to frequent reasons for using and even become a cause of use and even become a reason accidents causing enormous damage to users.

Follow the working procedures: the maintenance personnel must strictly comply with the requirements of the equipment maintenance management, use the tools and standardize work procedures. For example, when installing a pin, a nut or bolt must be delayed in accordance with the indicated value of the torque; When conducting non -destructive control, it is necessary to strictly observe the procedure for the operation of testing equipment in order to guarantee the accuracy and reliability of the test results. Incorrect operation can lead to problems such as improper installation of a pin and inaccurate detection, which increases the risk of equipment failure.

Detect records: lead detailed notes about the time, content, replaced details and testing data of each maintenance. Creating a full file for repair and maintenance of equipment will help to monitor the use of a stiff shaft, timely detect potential problems, provide reference data for subsequent repair and maintenance, as well as facilitate the analysis and assessment of the service life of equipment and maintenance costs.

209-32-11350kz regular sales shaft PC700

209-32-11350ST regular sales shaft PC700

209-32-11350UC Conventional sales shaft PC700

209-32-11391 The main pin PC700

209-32-11391AK the main pin shaft PC700

209-32-11391kz The main pin shaft PC700

209-32-11391st the main pin shaft PC700

209-32-11391UC The main pin shaft PC700

20Y-30-81G20RB pin shaft

20Y-70-31250RB pin shaft

21420721SK Speep -shaft bracket Robber Ring

21420731SK Bending pin

21422701SK shaft Stifta Kronstein

21422711SK Working Val Stift Kronstein

21450731SK holder

21540711SK Working Val Stift Kronstein

21540721SK Stop ring

21541701SK shaft Stifta Kronstein

21k-70-23140RB shaft of a pin

21k-70-23220RB shaft Stifta

21m-32-11150 regular PC sales shaft

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive