SANY Single -button starting switch SY215

1. High safety

A special system of protection against unauthorized access and the FOB wireless authentication technology guarantee that the SY215 engine can only be launched using the original key.

2. Maximum ease of use

One pressing button for starting/stopping the engine, which saves the operator’s time and eliminates errors with starting systems.

3. Resistance to operation

Made of high -strength materials with hermetic coating, which allows you to work in conditions of dust, moisture and temperature fluctuations from -40 ° C to +85 ° C.

Product representation

Interaction with FOB key

Keys Authentication: a single -flowing SY215 switch operates on the basis of wireless technology. When you bring the FOB key to the switch, the key and the switch exchange unique codes. This is the authentication process, and only in the case of the codes between the FOB key and the switch, the system allows further actions.

Signal transmission: After successful authentication, the FOB key sends the signal to the start -up switch, indicating that the device is ready to launch or stop.

Engine launch

When you press the button: when the operator presses and holds the start button on the starting switch for a certain time (usually 2 seconds), the switch sends an electric signal to the engine electronic controller (ECU).

ECU signal: the signal reports ECU about the need to start the engine. Then the ECU begins the sequence of operations for starting the engine, including fuel supply, the ignition turning on and other processes necessary for the engine to start working.

The power system: simultaneously with sending the signal to the ECU, the switch also provides power for other systems that are necessary for the engine operation, such as fuel injection systems, ignition systems, etc.

Engine stop

Pressing the stop button: When you press the stop button on the start switch, a signal is sent, which informs ECU about the need to stop the engine.

Interruption of processes: ECU stops the fuel supply, turns off the ignition and performs other actions necessary to stop the engine. At the same time, the circuit breaker power for some systems that operate only when the engine is turned on.

Security and control system

Checking the status of the battery: The switch constantly monitors the battery charge level. If the charge level becomes too low, the switch can prevent the engine to launch to prevent the battery. In addition, he can issue a sound or light warning for the operator.

Environmental control: in some cases, the switch can be equipped with sensors that control the temperature, humidity and other environmental parameters. If the parameters fall out of permissible values, the switch can limit the engine operation or even stop it to protect the equipment from a possible Damage.

Automatic shutdown: if the FOB key is outside the switch area (usually with a radius of 3 meters), the switch automatically turns off the engine for safety. This prevents the accidental use of equipment without the availability of the owner with the key.

Wireless technology

Fob wireless key:

The frequency of 433 MHz is used to transmit a signal with minimal energy flow.

The key contains an integrated chip with a unique identifier (UID), which generates a random encryption code for each connection session.

Encryption algorithm:

Key data are encrypted using the AES-128 algorithm, which prevents fake signals.

The connection session is automatically discarded after 30 seconds of inaction.

Network interactions

Can-nine:

The start-up circuit breaker is connected to the SY215 central controller via a CAN track with a Canopen protocol.

Exchange data with other systems:

Onboard computer (error display, fuel level).

Battery monitor (charge/discharge control).

Safety system (automatic shutdown in case of violation).

Emergency mode of operation

Key without key mode:

In case of breakdown of the FOB key or the low charge of the battery, you can use the backup code entered through the panel buttons.

The code is generated on the basis of the HMAC-SHA256 algorithm and is stored in the protected memory of the controller.

Emergency stop:

Press the button twice for 1 second - the switch will immediately turn off the power from the engine and systems.

Energy saving

Automatic sleep:

If the FOB key is not detected in the area of action within 5 minutes, the switch goes into energy conservation mode, reducing consumption to 0.1MA.

Working consumption:

When working in standby mode - 1.5ma; With active management - 5ma.

Technological features

Anti -vibration structure:

The use of silicone pillows and mounts with vibration sensors to prevent damage when working in extreme conditions.

Function "Pure Start":

Before starting, it checks the state of the cooling system, oil pressure and fuel level. If the parameters are critical, it blocks the start with the issuance of an error.

An example of a sequence of work:

The nearest FOB key (distance <1 m) sends a signal with a unique code.

SY215 The starter checks the compliance of the code in protected memory.

When pressing the button:

Sends the command to ECU via a cane.

ECU activates the injection system, ventilation and ignition.

After a successful launch:

The monitoring system monitors the engine temperature and

If the parameters go beyond the norm, the starter gives the signal to the stop.

These technologies are made by the SY215 starter one of the most protected and reliable in the construction industry.

Why choose us?

1. We are the manufacturer and official distributor of many famous brands.

2. More than 25 years of experience in the industry to provide you with professional support.

3. Exclusive channel, high quality and competitive price.

4. Fast delivery, support of OEM/ODM orders.

5. A large stock, we have a warehouse of spare parts with an area of 7000+ square meters.

6. 100% quality guarantee, we offer details for excavators of various quality requirements, new and former use original parts, OEM-west parties, spare parts, etc.

Recommended details for hot sale |

|

| Engine Parts | Cylinder Head, Cylinder Block, TurboCharger, Piston, Piston Ring, Metal, Crankshaft, Oil Pump, Fuel Injection Pump, Water Pump,Alternator, Starting Motor, etc. |

| HydraulicParts | Main Valve, Main Pump, Main Valve, Travel Motor, Swing Motor, Final Drive, Reducer, Solenoid Valve, Boom/ARM/BUCKET CYLINDER, ETC. |

| Electrical Parts | Electronic Priming Pump, Pilot Lock Assy, Sensor, Lamp, Radio, Wiper Motor, AC Compressor, Harness, Wire, Start Switch, Throttle Motor, etc. |

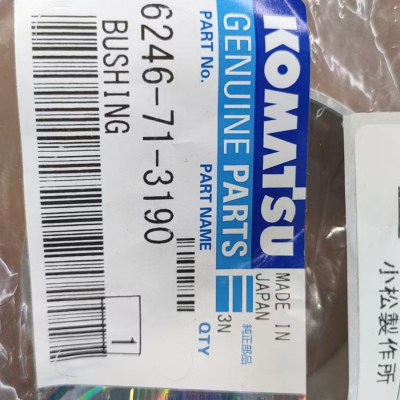

| Structural Parts | AC Condenser, Engine Oil Case, TurboCharger, Genuine Bushing, Pin Shaft Bushing, Muffler, Exhaust Pipe, Seat, etc. |

| Undercariage Parts | Track Shoe, Track Link, Bolt, Track Roller, Carrier Roller, Sprocket, Front Idler, Idler Cushion, etc. |

| Rubber Parts & Seals | Fuel Tank Cap, Wiper Motor Cap, Handle, Fuel Tank Filter Screen, Sucation Hose, Engine Gasket, Boom Cylinder Kits, Center Joint Seals, Swing Motor Repair Kits, Seal Kits (Swing Motor), Control Valve O-Ring Kits, Pilot Pump Seals, etc. |

| Maintenance Parts | Engine Oil, Universal Lubricating Grease, Antifreeze, Universal Hydraulic Oil, Pipe Filter, Pilot Filter, Hydraulic Return Oil Filter, Return Oil Filter, etc. |

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive