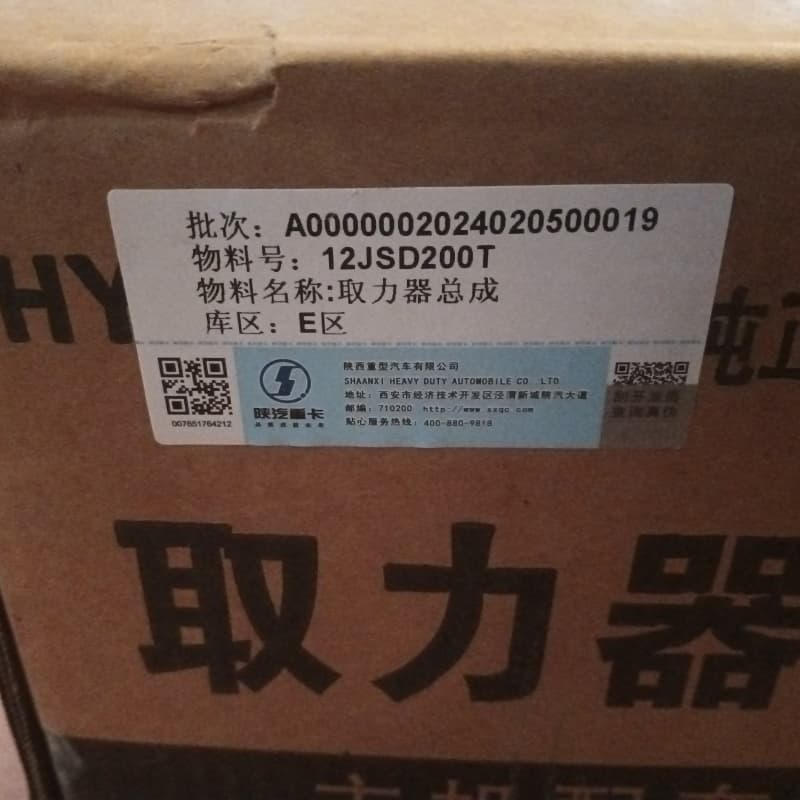

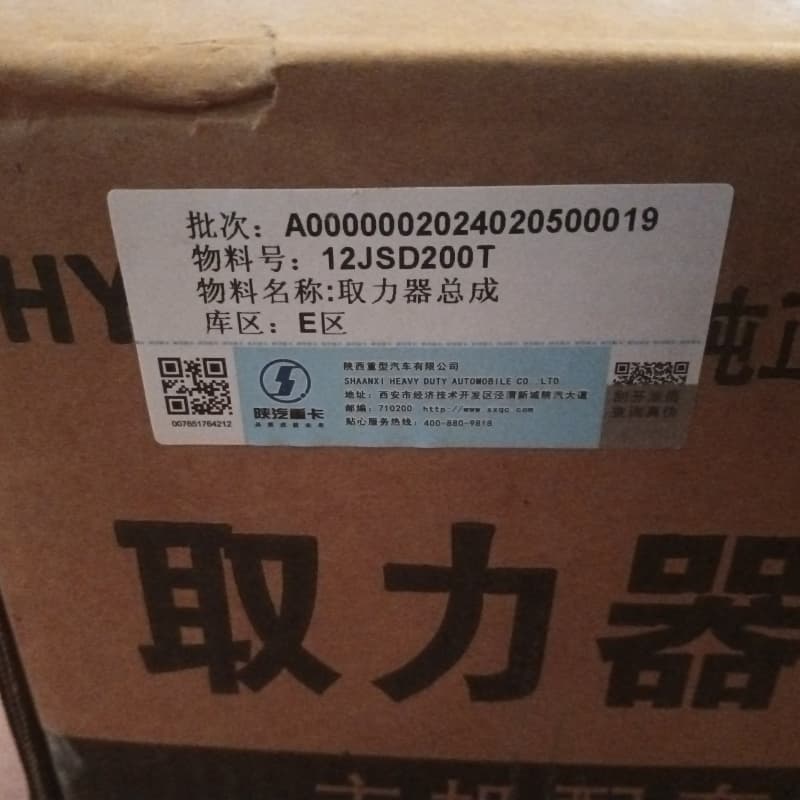

Shacman 12JSD200T selection of power assembly for

1. High power: the improved gear structure and high transmission efficiency allow you to effectively transmit engine power and satisfy the needs for the power of various working equipment.

2. Strength and durability: made of high -strength alloys, key components undergo special heat treatment, have wear resistance and impact resistance, and can also adapt to complex operating conditions.

3. Accurate adaptation: individual setting for various models of Shaanxi Automobile, accurate installation dimensions, perfect adaptation to the power system and ease of installation.

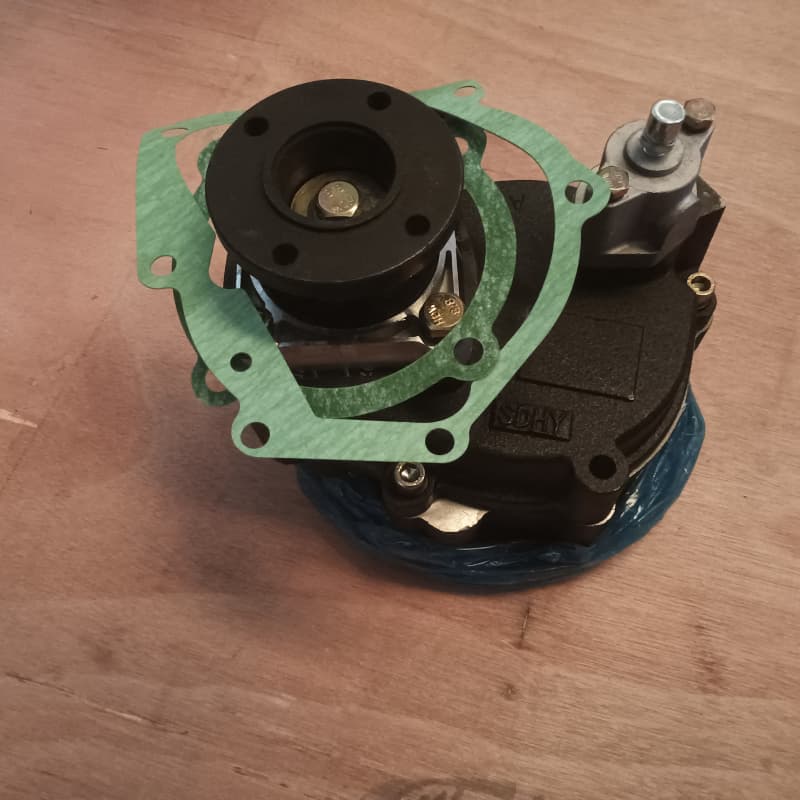

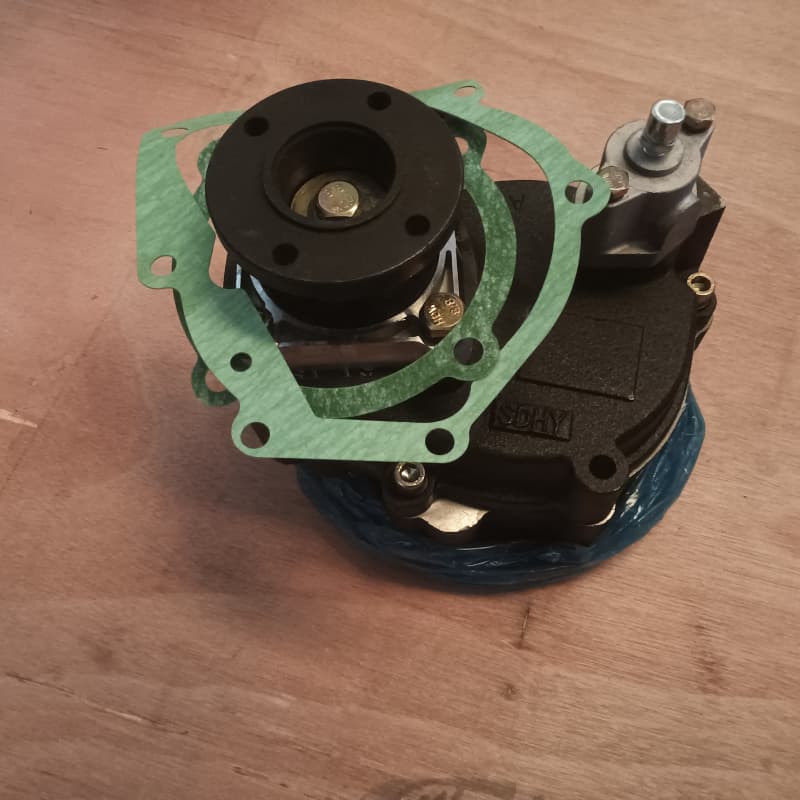

Product representation

Basic information

Brand: As a rule, there is an original Shaanqi brand, and there are also brands such as Dingheng.

Place of origin: partly from Jinan, Shandun.

Part number: for example, 12JSD200T

Structural design

Reducer: consists of high -strength gears and shaft parts, withstands heavy loads and ensures stability and reliability of power transmission.

Clutch: mainly pneumatic, electrical or hydraulic clutch control, to achieve the inclusion and separation of power, rapid response, convenient control.

Controller: connected to the electrical system of the car, it can implement the control of the selection of power in the driver's cabin, and some of them have an intellectual control function, which can automatically regulate the mode of operation of power selection in accordance with the state and working needs of the car.

Technical parameters

The torque is at the output: varies depending on the model and configuration, and in general meets the working requirements of various equipment with the upper load, and can issue a larger torque to ensure the normal operation of equipment with the upper load, such as dump trucks and concrete mixing tanks.

Adapted transmission: adapted to Faster and other transmission brands, good adaptability, can be connected to a lower gearbox or output shaft subcortunics to achieve an effective transmission of power.

The ratio of speeds: various speed ratios provide to satisfy power requirements in various working conditions, users can choose the corresponding ratio of speeds in accordance with the actual operating conditions, so that extractor and equipment with the upper load to achieve the best working condition.

Functional characteristics

Power output mode: basically there are forms of power output in the rear of the transmission, which can be divided into power output at the back end of the intermediate shaft and output at the rear end of the second shaft.

Maneuration mode: mainly unilateral pneumatic manipulation, input gear and hooking sleeve of combined teeth often have inverted conical teeth to play the role of anti-shutdown.

SHAANXI car power selection control method

1. Preparation before installation

1. Preparation of tools and materials

Gadie keys: Prepare unitary, lacture, end keys, etc. To remove and install various bolts and nuts. For connectors of different sizes, the keys of different specifications should be used. For example, 17-19 mm keys are used for ordinary fasteners, and keys of 22-24 mm can be used for connecting bolts of the drive shaft.

Sprinkle: equipped with cross and flat screwdrivers, used to unscrew and twist some small screws, for example, fasteners of electrical components or sensors.

Pla -rosmers: sharp -rubles are used to capture small parts, such as stop rings; Plafers for carp joints can help remove tight details.

Lifting equipment: depending on the weight of the power box, select the appropriate lifting equipment, for example, a small valve, a winch, etc., to ensure a safe rise in the power selection box to the installation site.

Lubrication: prepare a lubricant resistant to high temperatures and pressure, and apply it to gears, bearings and other parts of the power selection mechanism to reduce friction and provide smooth operation.

Sealing materials: such as sealants and gaskets used to prevent oil leakage in places of connection of the power gearbox with a gearbox and other interfaces.

Cleaning: prepare a cleaning product to clean the installation site from oil and pollution to ensure the cleanliness of the installation surface and improve installation quality.

(II) Verification of power selection and accessories

Checking the power gearbox: Carefully check the model and technical specifications of the power selection box to make sure that it fully corresponds to the Shaanxi car and the corresponding gearbox. Check the appearance of the power gearbox for damage, deformations, cracks, etc., the integrity of all connecting parts, wear of the gears, the absence of teeth, etc.

Verification of accessories: check the completeness and quality of the corresponding bolts, nuts, gaskets, sealing rings, transmission shafts and other accessories. The bolts and nuts should not be broken or deformed, the gaskets should be flat, the sealing rings should not be worn out, deformed or damaged, the drive shaft should not be curved or deformed, and universal hinges should rotate flexibly.

(III) vehicle preparation

Parking and safety measures: Parke the car on a flat, solid and safe surface, tighten the hand brake, turn on the alarm and do not allow clashes with other vehicles. If a power selection mechanism is installed on the road, the warning signs must be installed in front and behind the vehicle.

Support for the vehicle: Use a suitable jack to raise the vehicle chassis in such a way that there is enough working space from the side where the power selection mechanism is installed. Install safety stands under the car to support the car chassis and ensure the stability of the car during installation. Never rely on the jack to support the car.

Transmission operation: if the transmission is installed at the transmission, then for subsequent operation, it is first necessary to drain the transmission oil from the transmission. In addition, make sure that the transmission is in a neutral position to prevent accidental rotation during installation.

2. Stages of installation

1. Determining the installation site and cleaning

Determine the installation location of the power gearbox on the gearbox in accordance with the vehicle model and the requirements for the installation of a power selection box. Usually, on the side or back of the gearbox, there is a special interface for fastening the power gearbox.

Carefully clean the surface of the installation location with a cleaning agent to remove oil, rust, pollution, etc., and also make sure that the installation surface is even and clean to ensure a reliable connection of the power gearbox with the gearbox and prevent oil leakage.

(II) Power selection installation

Use lifting equipment to raise a power selection box to the installation site and leve it with mounting holes. During the rise, make sure that the power gearbox is balanced to avoid a collision with other parts of the car.

Slowly move the power selection box closer to the installation site, insert the connecting bolts and tighten them first manually to ensure the initial fixation of the power selection box. Be careful, do not allow the collisions of the gears of the power selection box with the gears of the transmission so as not to damage the gears.

Using a wrench, gradually tighten the connecting bolts diagonally to ensure a tight fit of the power selection box to the gearbox. During the tightening process, constantly check the correctness of the power shaft position to avoid deviations. Finally, using a dynamometric key, tighten the connecting bolts one at a time in accordance with the indicated puffing point to ensure a reliable installation of a power selection box.

(III) Connection of the transmission shaft

Select the drive shaft of the corresponding length depending on the position of the power gearbox and the operating device (for example, the oil pump, winch, etc.).

Connect one end of the transmission shaft to the output shaft of the power gearbox, install connecting bolts, nuts and washers and tighten them first manually.

Connect the other end of the transmission shaft to the entrance shaft of the operating device and similarly install the connecting bolts, nuts and washers, tightening them manually.

Adjust the angle of the drive shaft so that it is coaxial with the power axis and the working device to avoid vibration and abnormal wear caused by excessive deviation of the angle of the drive shaft. After adjustment, tightening the connecting bolts at both ends of the drive shaft using a wrench in accordance with the specified moment of the tightening.

(IV) lubrication and sealing

Apply the required amount of lubrication on the gears, bearings and other parts of the power selection mechanism to ensure the proper lubrication of all moving parts during operation.

Apply a sealant or set the gaskets for the connection between the power gearbox and the gearbox, as well as the connection between the drive shaft to prevent oil leakage. When applying sealant, apply it evenly and moderate thickness to provide a good sealing effect.

(V) Electric connection (if applicable)

If the PTO has an electromagnetic control device or sensor, an electrical connection is required. Connect the power line, control line, and sensor line according to the circuit diagram.

Check that the electrical circuit connections are secure and that there are no loose connections, short circuits, or open circuits. Make sure the wiring is routed correctly to avoid friction or interference with other parts of the vehicle.

3. Inspection and testing after installation

1. External inspection

Check whether the power take-off is properly installed, whether it is securely connected to the gearbox and working device, whether the connecting bolts are tightened for missing or loose fastening.

Check whether the drive shaft is securely installed, the angle is correct, and whether the gimbal joint can rotate freely.

Check that the electrical circuits are connected correctly, that they are securely fastened, and that there are no damages or short circuits.

(ii) Leak test

Add the required amount of transmission oil to the gearbox to reach the specified oil level.

Start the car and bring the power take-off into working order. Check for oil leakage in the power take-off connection, drive shaft connection, and other possible oil leaks. If an oil leak is detected, the machine should be stopped immediately, the cause of the leak should be found out and repaired.

(iii) Functional testing

Work with the power take-off controls such as joysticks, buttons, etc., to check that the power take-off is smooth on and off and that there is no jamming.

Start the operating device and check whether it is operating normally from the PTO actuator and whether the performance is as required. For example, when the oil pump is running, check whether the oil pressure at the outlet of the oil pump is normal; When the winch is working, check whether the retraction and extension speeds, as well as the pulling force of the winch, meet the standards.

When the power take-off is operating, listen for any unusual noises, vibrations, etc. If any abnormalities are detected, the machine should be stopped immediately to check and troubleshoot.

Exhibition cabinets

Acquaintance with the plant

The factory has a team of highly qualified and experienced engineers who continuously introduce technological innovation and improve products. At present, the company owns a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment, such as excavators, loaders, cranes, bulldozers and other machines. The products are characterized by high performance, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working environments around the world.

Awards and qualifiersFiction

Frequently Asked Questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipment

3. What logistics ways can we work for shipping?

1) For most countries in Europe, South America and Africa, etc., we can go by container or Roro through ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or railway.

3) For light spare parts in urgent requirement, we can send it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you ensure that you have delivered the goods to customers?

A: We will provide you with full shipping information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable Quality: Carefully select regular manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by us, always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive