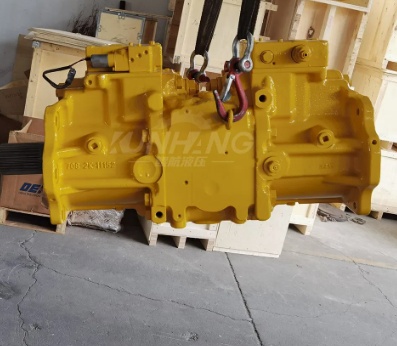

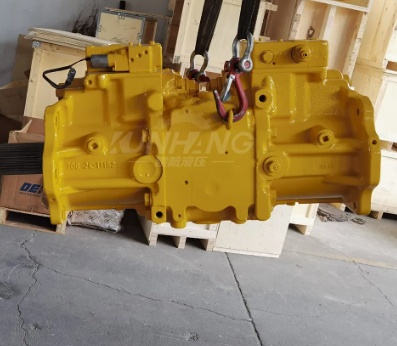

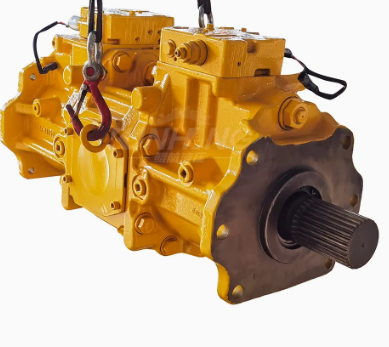

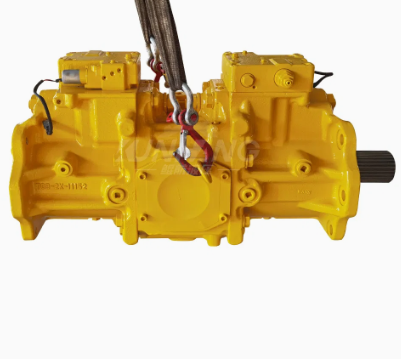

Main hydraulic pump Komatsu 708-2K-00014

1、High performance: The pump provides stable and powerful hydraulic oil flow, which can effectively complete heavy-duty working tasks.

2、High Reliability and Durability: Made of high quality materials, which ensures resistance to wear and tear and reliable performance in harsh environments.

3、Good compatibility: Well compatible with various models of excavators, ensuring easy installation and adjustment.

Product representation

1. General idea of the main hydraulic pump Komatsu 708-2k-00014

The main hydraulic pump Komatsu 708-2K-00014 is a key component of the hydraulic system of heavy special equipment Komatsu, designed to ensure high performance and reliability in difficult operating conditions. It belongs to the class of piston hydraulic pumps designed to supply hydraulic oil to the main working mechanisms of the equipment (excavator bucket, rotary mechanism, levers) with high pressure and stable consumption.

Unlike standard hydraulic pumps, this product is created according to the unique Komatsu technologies, adapted to the requirements of modern diesel engines and harsh working conditions - dust, moisture, temperature changes and long high loads. Its main task is to convert the mechanical energy of the engine into hydraulic, providing smooth and accurate control of the working bodies of equipment, which directly affects the performance and service life of the entire machine. Due to the high level of quality and durability, the pump 708-2K-00014 has become a standard component for many models of Komatsu excavators, confirming its effectiveness in construction, mining and other industries.

2. Technical characteristics of the main hydraulic pump

2.1 performance and pressure

The main hydraulic pump Komatsu 708-2K-00014 provides high performance and pressure indicators that meet the requirements of heavy equipment:

Nominal capacity: Up to 180 l/min (at a nominal shaft speed of 2000 rpm) - allows for rapid delivery of hydraulic oil to working mechanisms, accelerating work cycles (for example, lifting a bucket or turning the upper part of an excavator).

Maximum working pressure: Up to 34.3 MPa (350 kgf/cm²) - ensures sufficient power for complex tasks such as digging in dense soils, lifting heavy loads (up to 30 tons) and working under high load conditions.

Unloading pressure: 2.5–3.5 MPa – prevents system overload under no load conditions, reducing energy consumption and component wear.

2.2 Drive parameters and energy efficiency

Shaft rotation speed: 1500-2500 rpm (compatible with Komatsu engines of the SAA6D114E, SAA6D125E series installed on 20-30 ton class excavators).

Shaft inertia moment: 0.08 kg m² - ensures smooth starting and stopping of the pump, reducing shock loads on the hydraulic system.

Efficiency Ratio: Up to 92% (at nominal conditions) - High efficiency reduces energy loss as heat, reducing the load on the cooling system and saving engine fuel by 5-8% compared to similar low-class pumps.

2.3 Temperature and environmental characteristics

The pump is adapted to wide temperature ranges and aggressive environments:

Operating temperature range of hydraulic oil: -20 °C to +80 °C - ensures stable operation in cold and hot climate conditions (from northern regions to tropical zones).

Required oil quality: ISO VG 46 or VG 68 hydraulic oil (according to Komatsu KLD-1 standard) - high viscosity, oxidation-resistant oil that protects pump components from wear.

Contamination resistance: Compatible with ISO 18/15 hydraulic oil filtration systems (removal of impurities >6 µm) - prevents damage to pistons and control valves.

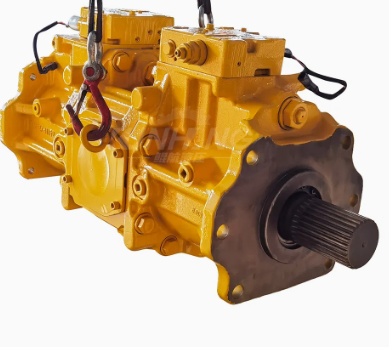

3. Design features

3.1 Main components and material

The main hydraulic pump Komatsu 708-2K-00014 has a well-thought-out design that ensures reliability and long service life:

Pump body: Made of high-strength aluminum alloy A356-T6 with thermal strengthening - has high strength (withstands pressure up to 40 MPa without deformation), corrosion resistance and low weight (约 18 kg), which facilitates installation and reduces the load on the engine bearings.

Pistons and cylinders: Pistons are made of SUJ2 alloy steel (stainless steel) with high-precision surface treatment (roughness Ra ≤ 0.2 μm) - ensures a tight fit to the cylinders, eliminating oil leakage and guaranteeing stable pressure. Cylinders are made of SCM440 steel with chromium plating of the inner surface - increases wear resistance and resistance to abrasive wear.

Distributor plate: Made of CuSn10Pb10 bronze alloy with a granulated surface - ensures smooth interaction with the pistons, reducing friction and noise during pump operation.

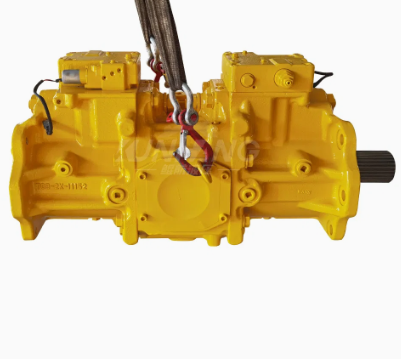

3.2 Protection and control systems

Pressure regulator: Built-in pressure relief valve with fine adjustment - operates when the maximum pressure (34.3 MPa) is exceeded, preventing damage to the pump and hydraulic cylinders.

Unloading system: Automatic unloading of the pump when there is no load (pressure 2.5–3.5 MPa) – reduces energy consumption and wear of components, extending service life.

Sealing elements: High-quality fluororubber (Viton) seals are used - resistant to hydraulic oil, high temperatures (+200 °C) and chemicals, preventing oil leaks and ensuring the tightness of the system.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsfikation

frequently asked questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2.What payment terms can we accept?

Usually we can work on T/T, 30%TT before production and 70%TT before shipment

3.What logistics methods can we work with for delivery?

1) For most of Europe, South America and Africa etc. countries, we can go by container or Roro via ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or railway.

3) For light spare parts in urgent requirement, we can ship it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you ensure that you have delivered the goods to customers?

A: We will provide you with full delivery information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable quality: Carefully select regular manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by ourselves, always adapting the best materials.

2) Competitive price: Concentration of mechanized production in large quantities reduces production costs to ensure competitive price.

3) Service Team: Firstly, our sales team work 24 hours a day, ready to answer your questions at any time. Secondly, a professional technical service team with senior technicians, ready to provide support services to users and dealers. Most problems can be resolved within 24 hours.

4) Fast delivery: Generally, we can delivery within 10 working days in factory after receiving the advance payment from customers.

6. How can you provide customers with after-sales service?

A: We will reply you at the first time and help you solve the problems within 24 hours. If we really need your local, we

We will send your professional person to your locality to help you solve the problems without any hesitation, supply you with all-round