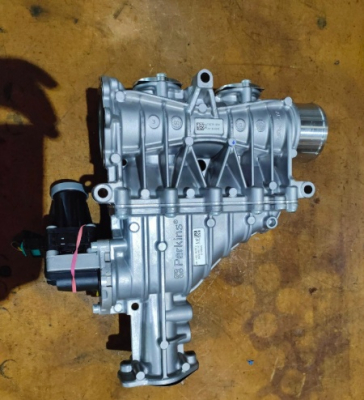

Weichai J135A/W58T Urbo -compressor

1 、 High energy efficiency

Increases engine power by 30–40%, reduces fuel consumption by 3-5%and Co₂ emissions by 20%.

2 、 technological superiority

Efficiency is over 66%, resistant to temperatures from -40 ° C to +120 ° C and pressure up to 8 bar.

3 、 Flexibility of use

Compatible with the engines WP10/WP12 and M26.33/M26.35, works in high -grade conditions.

Product representation

1. Introduction to turbocharged technology

The turbocharged J135A/W58T is an innovative device that uses the energy of the exhaust gases of the engine to compress the incoming air. This allows you to increase the air density in the combustion chamber, increase the engine power by 30–40% and reduce fuel consumption by 3-5%. The technology is based on the principle of converting the kinetic energy of gases into mechanical work, which is achieved by combining the turbine and compressor on a common shaft.

2. The design of the turbocharged j135a/w58t

Turbocharged consists of three main components:

Turbine

Function: converts the energy of the exhaust gases into a rotational movement.

Design:

Blades: titanium alloy products (TI-6L-4V) with an aerodynamic form that provides maximum efficiency.

Corps: power steel with anti -corrosion coating (zincing + epoxy paint).

Balancing: carried out to G2.5 (ISO 1940) to minimize vibrations.

Compressor

Function: squeezes air and directs it into the engine.

Design:

Lapes: magnet -packed with laser -leveled ribs.

Rotation camera: optimized geometry for reducing energy water.

Burning group

Function: Holds the shaft in the working position and provides smooth rotation.

Design:

Air-oo-resistant bearings: use a combination of pneumatic and liquid suspension.

Lubrication system: automatic lubricant through motor oil (guarantees work up to 180,000 rpm).

3. Detailed working cycle

Stage 1: The entry of exhaust gases into the turbine

Gase temperature: up to +850 ° C.

Pressure: 1.2–1.5 bar.

Process:

Gases are entered through a special pipe in the turbine.

The turbine blades rotate under the influence of gases, transmitting rotation to the shaft.

Stage 2: Compressor stage

Rotation of the shaft: 180,000 rpm.

Compressor:

Highs air through an air filter.

Squeezes the air to a pressure of 0.3-0.5 bar.

Compressed air temperature: +150 ° C.

Stage 3: Air cooling in the heat exchanger

Heat exchanger:

Uses a coolant (water or solo solution).

The air temperature is reduced to +50 ° C.

Air density increases by 20–25%.

Stage 4: Clusted air intake to the engine

Combustion chamber:

Compressed air is mixed with fuel.

The increased air density allows you to burn more fuel, increasing power.

Stage 5: operating modes and regulation

(Bypass value):

It opens with excess pressure (for example, 0.8 bar).

Part of the gases is sent to the exhaust, preventing the wear of the turbine.

T UrboCharger Control Unit (TCU):

Automatically regulates the pressure of the infusion depending on the load of the engine.

4. Technical solutions to increase efficiency

4.1. Aerodynamic modeling

CFD analysis:

Computer modeling of air and gases.

Optimization of the shape of the blades for minimizing funnels and turbulence.

Results:

The effectiveness of turbocharged: 66–72%.

Maximum performance: 25 kg/min.

4.2. Materials and production technologies

Titanium blades:

Reducing weight by 30% compared to steel.

Corrosion resistance and high temperatures.

Ceramic coating:

On turbine blades (thickness 0.2 mm).

Hardness: HRC 60–62.

4.3. Lubrication and cooling system

Lubrication:

Synthetic lubricant (Castrol GTX 20W-50).

Replacing every 1000 hours of work.

Cooling:

Two -stage heat exchanger (water + air).

Temperature regime: -40 ° C → +120 ° C.

5. Environmental friendliness and energy efficiency

5.1. Reducing emissions

NOX: -15% (through the EGR system).

Co₂: -20% (due to complete combustion).

SCR technology:

Additional gas purification using ammonia.

5.2. Fuel saving

Example:

Weichai WP12 engine (336 hp):

Without turbocharged: consumption 38 l/100 km.

With turbocharged: consumption 36.5 l/100 km.

6. Testing and certification

6.1. Laboratory tests

Wear test:

10,000 loading cycles (90% of the maximum power).

Vibration test:

100,000 cycles with an amplitude of 2 mm (frequency 50 Hz).

Climate tests:

100 cycles of temperature differences (-40 ° C → +80 ° C).

6.2. Certification

ISO 4548-12: International standard for turbocharges.

IMO Tier II: the world standard of environmental friendliness.

CCS: Chinese court registration (for marine applications).

7. Application in various industries

7.1. Cargo transport

Advantages:

Increasing traction when driving on steep lifting.

Fuel saving on intercity routes.

7.2. Shipbuilding

Requirements:

Resistance to moisture and saline.

Compactness for installation on low -power ships.

7.3. Construction equipment

Peculiarities:

Work in dusty conditions.

Resistance to overheating at construction sites.

8. Instruction and maintenance instructions

8.1. Installation

Requirements:

Used pillows (noise reduction).

Accurate lubrication level control.

8.2. Periodic service

500 hours of work:

Checking shafts and bearings.

Replacement of lubrication.

1000 hours of work:

Checking the tightness of the compounds.

Service

9. Comparison with competitors

Parameter J135A/W58T competitive product

Efficiency 66–72% 58–65%

Maximum temperature +850 ° C +750 ° C

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional maintenance team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive