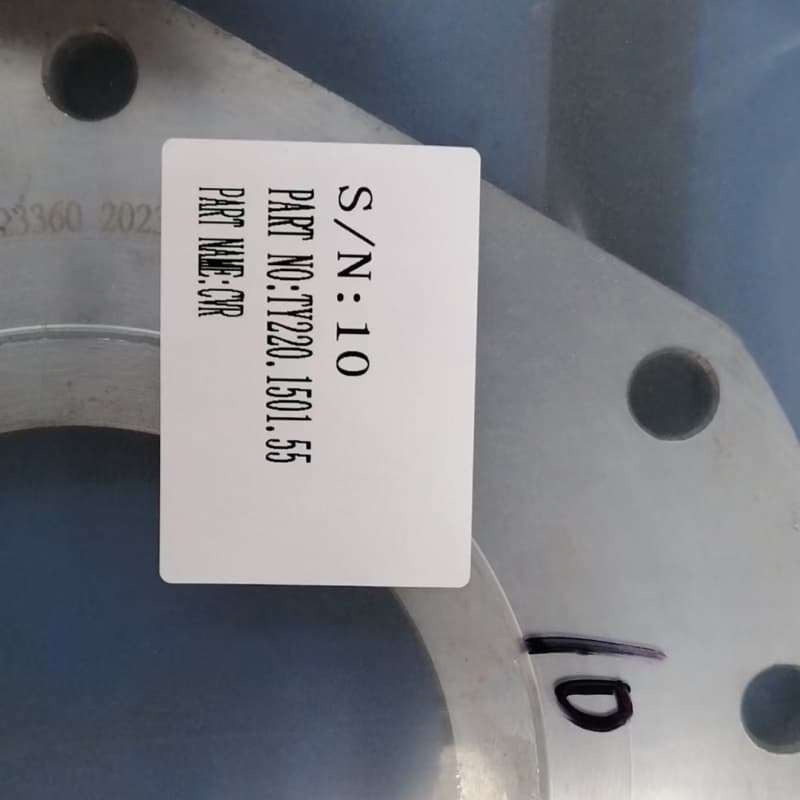

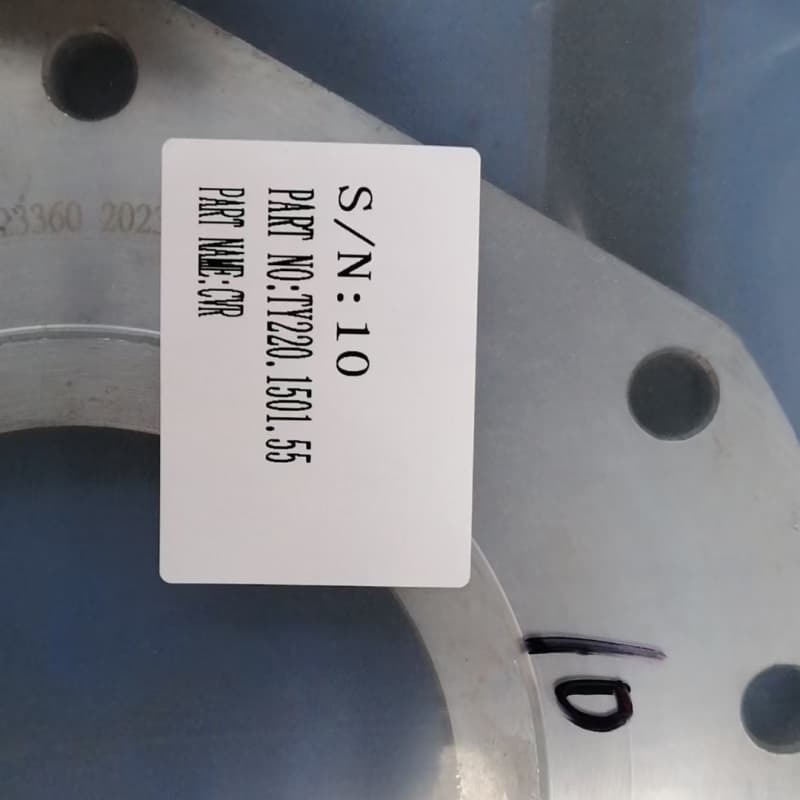

Zoomlion Ty220.1501.55 ZD220-3 cover

1. Adaptable working conditions: The design is optimized and accurately adapted to the main bulldozers, which ensures the stability of the gearbox and increases the efficiency of construction, since it is designed for severe conditions of the terrain and difficult operating conditions in Russia.

2. Superflowing strength: made of high -quality alloy steel, passes special heat treatment, resistant to fatigue and wear, withstands high loads, reduces the number of failures and extends the service life.

3. Ease of maintenance: standardized design, simple disassembly and installation, there is no need for complex tools and professional skills, quick maintenance is possible even in remote areas, which reduces downtime and service costs.

Product representation

1. Detailed product information

1. Review of the product

Being a key protective and sealing component of the gearbox, the bulldozer gearbox lid is responsible for protecting internal gears, shafts and other precision details from the penetration of external pollution, while supporting good sealing inside the gearbox and preventing lubricating oil leakage. Spare parts of the gearbox cover that we provide are made strictly in accordance with the original technical conditions for the design of bulldozers of various brands and models to ensure perfect compatibility with existing gearboxes. Whether it is a bulldozer of common brands, such as Shantui, Caterpillar or Komatsu, it can be accurately selected to provide reliable protection for the stable operation of the equipment.

2. Production process and materials

The choice of material: the main material is a high -strength aluminum alloy or high -quality cast iron. The lid of the gearbox made of aluminum alloy has advantages of lightweight and good heat transfer. It can effectively reduce the weight of the entire machine and improve fuel savings. At the same time, good heat transfer helps maintain the internal temperature of the oil gearbox stable and extends the life of gears and other components. It is especially suitable for long -term continuous operating conditions. High -quality cast -iron material, which has excellent compression and wear resistance, works great in difficult and harsh working conditions. He can withstand large external blows and vibrations, as well as ensure the tightness and structural integrity of the gearbox.

Production process: advanced casting processes are used, such as casting in sand forms and casting under pressure, to ensure the accuracy of the design and quality of the surface of the gear cover. In the process of casting, the process parameters are strictly controlled to ensure that the internal structure of the casting will be dense and will not contain defects, such as pores and sand sinks. Then, precision machining is performed, as well as high -precision milling, drilling, bore and other operations of processing key parts, such as mating surfaces, holes for bolts and sealing grooves, at the processing centers with CNC, due to which the accuracy of each part is controlled in the range of ± 0.05 mm, and the fence of flatness does not exceed 0.03 mm, which makes it possible to comply with strict requirements for assembly and sealing. Finally, the surface of the gearbox cover is treated with a protective way, for example, anodizing for aluminum alloy and painting or electrophoretic coating for cast iron, to increase its corrosion resistance and extend the product life.

(III) The advantages of the product

The exact correspondence of sizes: due to deep research and accurate measurements of various types of bulldozer gearboxes, the sizes of our spare parts for gearbox covers are fully consistent with original products. Whether it is the position of the mounting hole, the characteristics of the connecting bolts or the sizes of the gearbox body, all of them have been repeatedly checked to ensure the uninterrupted installation process without the need for additional adjustments or modifications, which significantly saves installation and labor costs, and also increases the efficiency of service.

Excellent characteristics of the seal: a specially designed seal design and high -quality sealing materials. When designing the sealing groove, the characteristics of the compression deformation and the principle of sealing the sealing strip are fully taken into account, due to which the sealing strip can be evenly loaded after assembly, forming a reliable sealing barrier. In this case, oil -resistant, heat -resistant and resistant to aging rubber sealing stripes are selected. Their sealing properties are stable, and they can maintain good elasticity and tightness in the temperature range from -40 ° C to 120 ° C, effectively preventing the leakage of lubricating oil from the gearbox, avoiding the wear of gears and reducing the effectiveness of the transmission due to the leakage of the oil, as well as ensuring reliable seal protection for the normal operation of the gearbox.

Strict quality control: we have created a full quality control system, starting from the control of raw materials, monitoring the processing process, processing control and ending with finished products, each link is strictly controlled. We use advanced testing equipment, such as three -coordinate measuring machines for accurate measurement of products, ultrasonic flaw detectors to detect internal defects in castings and testing equipment to test the tightness to simulate the tightness of the products to guarantee that the each spare the transmission covered from the plant corresponds or exceeds the industry Standards. The percentage of products that have passed the first technique reaches more than 98%, which provides customers with high -quality and reliable products.

2. The installation method

1. Preparation before installation

Checking the model and appearance: thoroughly check whether the model of the spare part of the gearbox lid is fully consistent with a particular bulldozer model. At the same time, check the appearance of the product to make sure that there are no defects in casting, irregularities and deformations, damage to processing and other problems. Check if the sealing groove is smooth and flat, whether there are no outsiders in it that block it, as well as the integrity of the sealing strip and its correct installation.

Preparation of tools and materials: Prepare the necessary installation tools, such as a end key, a dynamometric key, a rubber hammer, a scraper, a cleaning tool, etc. At the same time, prepare the required amount of sealant, make sure that the type of sealant is compatible with the gearbox and the working environment, and also has good oil resistance, adhesion and sealing properties.

Cleaning: thoroughly clean the editing surface of the gearbox with the cleaning agent and the mating surface of the gearbox cover to remove oil, pollution, the remains of the old sealant, etc., so that the mating surface is clean and even, which is the basis for a good sealing effect. After cleaning, wipe the surface dry with a clean cloth to prevent secondary contamination.

(II) Stages of installation

Installing the sealing tape: evenly insert a new sealing tape into the sealing groove of the transmission cover, making sure that the tape is installed firmly, without distortions and clearance. In places of joints of the rubber strips, special sealants for gluing are used, ensuring tightness of the joints. After gluing, the joints should be thoroughly trimmed to ensure a smooth transition to the rubber strip.

Installing the transmission cover: smoothly align the transmission cover, applying the corresponding amount of sealant to the mounting surface of the transmission, and slowly lower it to make sure that the mounting holes are precisely combined. Use the end key for the initial tightening of the connecting bolts, but do not tighten them completely. Keep a certain degree of weakening for subsequent adjustments.

Regulation and tightening: using a rubber hammer, carefully tap on the gearbox cover so that it completely adjacent to the editing surface of the gearbox, and check whether the installation gap of each part is uniform. Then use the dynamometric key for the gradual tightening of the connecting bolts in accordance with the indicated value of the torque and the tightening sequence, guaranteeing that the tightening moment of each bolt will be uniform. As a rule, the tightening moment is from [x] n ・ m to [x] n ・ m. The specific value depends on the technical characteristics of various models of the bulldozer and the transmission cover. During tightening, be careful not to pull the bolts, as this can lead to damage to the thread or deformation of the transmission cover.

3. Common malfunctions and ways to eliminate them

1. Oil leak

Cause

The sealing tape is aging, wear out or damaged and loses its sealing properties, which leads to a leakage of lubricant oil from the seal. In the process of prolonged use, the sealing stripes gradually age and harden under the influence of factors such as high temperature, oil erosion and mechanical vibration, and cracks and wear appear on the surface, which makes it impossible to effectively prevent lubricating leakage.

The surface of the lid of the gearbox and the gearbox of the gearbox is uneven, there are errors of processing, deformation or hitting foreign objects, which makes uniform tension of the sealing tape impossible, which leads to the formation of the leak channel. For example, during the transportation, installation or operation of equipment, the gearbox cover can be impressed or squeezed, which can lead to deformation of the mating surface; Or during maintenance, the mating surface will not be thoroughly cleaned, and pollution will remain on it that affect the effectiveness of the seal.

The connecting bolts are weakened or the tightening moment is uneven, which leads to insufficient pressure pressure between the transmission cover and the transmission case, which leads to oil leakage. Factors such as vibration and blows during the operation of the equipment can lead to a gradual weakening of the connecting bolts; If the bolts are not tightened in accordance with the specified moment and sequence during installation, this can also lead to a deterioration in sealing.

Bypass

Replace the sealing tape: select the sealing tape of the same model or with the best characteristics than the original and replace it in accordance with the correct installation method. Before installing, make sure that the sealing groove is clean and free from garbage. After replacing, check whether the rubber gasket is reliably and evenly installed, as well as how good the effect of the compaction is.

Repair of the glued surface: if the glued surface is uneven, it can be repaired with grinding, scratching and other methods so that the plate of the glued surface meets the requirements. If the surface of the joint is greatly deformed and cannot be repaired, it is necessary to replace the transmission cover with a new one or repair the transmission housing. After repair or replacement, when re -setting the transmission cover, be sure to clean the mating surfaces and apply the required amount of sealant to ensure tightness.

Tighten the bolts: Use the dynamometric key for the re -tightening of the connecting bolts in accordance with the indicated puffing moment and the tightening sequence. In the process of tightening, it is necessary to check and tighten each bolt one at a time in order to ensure a uniform moment of tightening the bolts. At the same time, regularly check the tightening of the bolts to prevent their weakening due to the vibration of the equipment and for other reasons.

(II) deformation

Cause

The impact of external power: during operation, the bulldozer may encounter unexpected clashes, flying stones, etc., which can lead to the fact that the gearbox cover will be subjected to greater external exposure and deformed. For example, a bulldozer can hurt other equipment on the construction site, or a heavy item can fall and hit the transmission cover during the clearing of the site.

The impact of excessively high temperatures for a long time: the gearbox produces a large amount of heat during operation. If the cooling system fails, the oil temperature in the gearbox will be too high. If it is in an environment with a high temperature for a long time, the mechanical properties of the material of the gearbox lid will deteriorate, which will lead to deformation. In addition, work at high temperatures, for example, hot summer or near the heat source, also increases the risk of thermal deformation of the gearbox cover.

Incorrect installation: if when installing the transmission cover is too large or uneven, the transmission cover will be subjected to excessive local voltage, which will lead to deformation. In addition, if the transmission cover is incorrectly installed and adjusted during the installation and forcibly assembled with the transmission housing, deformation may also occur.

Bypass

For the repair of slightly deformed gearbox covers, you can use the methods of mechanical correction. Use special corrective tools, such as presses, jacks, etc., to make an appropriate external effort to deformed details and gradually return them to their original state. In the process of correction, pay attention to the control of the magnitude and direction of external power to avoid excessive correction, which can lead to material damage.

If the deformation is serious and cannot be eliminated mechanically, it is necessary to replace the transmission cover. When replacing, choose reliable quality products that meet the technical requirements, as well as strictly observe the installation process to guarantee its quality.

At the same time, it is necessary to investigate and eliminate the root cause of the deformation of the transmission cover. For example, check the serviceability of the cooling system and timely clean the surface of the radiator of garbage to ensure a good cooling effect; During the installation process, tighten the bolts strictly in accordance with the indicated tightening moment and the tightening sequence to ensure the accuracy of the installation.

(III) Weakened bolts

Cause

Equipment vibration: During operation, bulldozers create strong vibration due to movement on uneven roads, digging, bulldozer processing and other operations. Constant vibration can gradually weaken the bolts attaching the transmission cover.

Failure to prevent weakening measures: if you do not take effective measures to prevent weakening, for example, spring washers, nuts that impede the weakening are not taken when installing the bolts, or the thread fixers are not used, there is a likelihood of weakening bolts due to vibration and external forces.

Bolt fatigue: prolonged vibration and alternate loads cause fatigue damage to the bolts, which leads to a gradual decrease in tightening the bolts and, ultimately, to their weakening.

Bypass

Spend the tug of the bolts regularly: create a regular check system. During daily equipment, use a wrench to check the tightening of the connecting bolts of the transmission cover and tighten them in time if they are weakened. At the same time, a marking paint can be applied to the bolt head or nut to visually determine whether the bolt is weakened.

Take measures to prevent weakening: When re -tightening the bolts, add spring washers, use nuts that prevent weakening, or apply thread fixators to increase the efficiency of preventing the weakening of the bolts. Spring washers use the reaction force created by their elastic deformation to maintain a certain friction between the bolt and nut to prevent weakening; anti -winding nuts increase friction between thread and self -locking characteristics due to a special design; Threaded clamps can form a solid adhesive layer on the surface of the thread, firmly connecting the bolt and nut together in order to effectively prevent weakening.

Bolts that cannot comply with tightening requirements due to fatigue damage should be replaced in a timely manner with new ones. Choose reliable quality bolts corresponding to the requirements of the strength class, and tighten them in accordance with the specified torque value to provide a strong and reliable connection.

4. Repair and maintenance

1. Daily service

External inspection: before each operation, conduct an external inspection of the gearbox cover to check it for obvious deformations, cracks, damage, etc., as well as signs of lubricating leakage. Pay attention to whether the connecting bolts are weakened, whether the sealing tapes are worn out, whether they are falling off or whether other abnormal phenomena are observed. If you find any problems, immediately eliminate them.

Cleaning: regularly clean the surface of the lid of the gearbox from oil, dust, dirt and other pollution to maintain its cleanliness. When cleaning, use a detergent and a clean rag for wiping, do not scratch the surface with sharp tools so as not to damage the surface coating or sealing stripes. The clean surface helps to detect potential problems in time, and also reduces the effect of pollution on the effectiveness of the seal.

(II) regular maintenance

Checking the effectiveness of the seal: check the sealing of the transmission cover every [x] hours of work or every [x] months. You can check if there are new signs of oil leakage around the gearbox, or use professional equipment to detect seals, for example, a pressure testing device to attach a certain pressure to the inside of the gearbox and check if there are leaks through the seal. If a deterioration in tightness is detected, timely find out the cause and repair or replace the sealing tape.

Puffing bolts: regularly tighten the connecting bolts with a dynamometric key so that the moment of tightening the bolts meets the specified requirements. It is usually recommended to carry out the tightening operations every [x] hours of work or every [x] months. In the process of tightening, check and tighten each bolt in turn in accordance with the prescribed tightening sequence to prevent oil leak or other malfunctions caused by weakened bolts.

Checking the mating surface: through regular intervals of time, for example, every [x] hours of work or every [x] months, check the mating surface between the transmission lid and the transmission case. Check if the joint surface and whether there are foreign objects or corrosion on it. If you find any problems on the surface of the junction, clean it, repair or timely take the appropriate protective measures to ensure a good sealing effect.

(III) precautions during maintenance

Use original accessories: During the repair and maintenance, be sure to use original spare parts for the transmission cover and related accessories that correspond to quality standards, such as sealing tapes, bolts, etc. Contrafact and low -quality products may have defects in the quality of the material, accuracy of size, tightness, etc., which can easily lead to frequent failures after use, violating normal operation equipment and even causing more serious damage.

Follow the working procedures: the maintenance personnel must strictly comply with the requirements of the equipment maintenance management, use the tools and standardize work procedures. For example, when installing the transmission cover, tighten the bolts in accordance with the indicated puffing moment and the tightening sequence; When replacing the sealing tape, make sure that the tape is installed correctly and reliably. Incorrect operation can lead to problems such as improper installation and poor sealing, which increases the risk of equipment failure.

Detect records: lead detailed notes about the time, content, replaced details, discovered problems, etc. Each maintenance. Creating a full file for repair and maintenance of equipment will help to monitor the working condition of the equipment, timely identify potential problems, provide reference information for subsequent repair and maintenance work, as well as facilitate the analysis and assessment of the service life of equipment and maintenance costs.

5. After -sales service

1. After -sales service team

We have a professional and effective after -sales team. All team members have rich experience in servicing bulldozers and are familiar with the design and principle of operation of gearboxes of various brands and models of bulldozers. After careful technical preparation and evaluation, after -sales maintenance engineers can quickly and accurately diagnose the malfunctions in the transmission cover and related components and offer practical solutions. Whether it is a product installation manual, elimination of malfunctions and maintenance or technical advice, we can provide customers with professional and attentive services.

(II) Warranty service

We provide [x] years of guaranteeing quality of products. During the warranty period, if the gearbox lid fails due to problems with product quality, we will provide customers with free repair or replacement services and take on appropriate transportation costs. Clients only need to call the hotline of after -sales service, and we will organize the speedy arrival of specialists to the client to find out the cause of the malfunction, check the product information, determine the solution and speedy work on repair or replacement to guarantee the speedy resumption of the normal operation of the client’s equipment.

(III) Technical support

Online consultations: a special platform has been created for online consultations on technical issues where customers can at any time ask questions about the use, maintenance, elimination of malfunctions, etc. The gearbox covers through the official website, the WeChat public account and other channels. Our experts will quickly respond to customer requests during working hours and provide them with detailed and accurate technical recommendations and solutions based on professional knowledge and rich experience. For some common problems, we also provide an online knowledge base where customers can independently look for the necessary information and quickly get solutions.

Place training: depending on the needs of the customer, professional technical specialists can go to the object for free training of operators and the customer service personnel. The content of the learning includes the principles of the design of the gearbox covers, installation and dismantling methods, daily maintenance points, general methods for diagnosing and eliminating malfunctions, etc. Using local demonstrations, practical design recommendations and other methods, we help customers improve the skills of operation and maintenance of equipment, increase their ability to independently solve problems, reduce the number of equipment failures and increase the efficiency And the reliability of its use.

4. Quick response

We have created a comprehensive mechanism for response after sales service. As soon as the client reports on the problem, we contact the client within [x] hours to learn more about the situation. In the event of problems requiring repairs on the spot, we will organize the leave of the nearest specialist in after -sales service to the place in the shortest possible time, depending on the location of the client. In general, we arrive at the place for 24 hours in China. For customers exporting to foreign regions, such as Russia, we will closely cooperate with local partners in order to guarantee arrival at the place for service within 48-72 hours, minimize the economic losses caused to customers by the refusal of equipment, and guarantee that the customer construction will not be affected.

6. Advantages of export to Russia

1. Adaptation to difficult working conditions in Russia

Optimized frost resistance indicators: in Russia long and cold winters, while in some areas the lowest temperature drops below -50 ° C. Given such extremely cold climatic conditions, we conducted a special optimization when choosing the material and the process of making the gearbox cover. As materials, an aluminum alloy or cast iron with excellent refined hardness is used, which at the same time retain good strength and shock viscosity at low temperatures and are not subject to fragile deformation at low temperatures. At the same time, the frost-resistant formula of sealing stripes was improved, so they still have good elasticity and sealing properties at extremely low temperatures, effectively preventing sealing and oil leakage caused by low temperatures, and guaranteeing the normal operation of the bulldozer in cold regions.

The anti -pale and wear -resistant design: the working environment in Russia is complex and diverse. In many areas, strong winds blow and there is sand, and a large number of solid particles, such as sand and gravel, are present at the construction site. Our gearbox cover is designed taking into account these factors, and the surface is treated with special wear -resistant processing, such as show -off processing and surface coating, to increase the hardness of the surface and improve its resistance to sand and dust. At the same time, the structure of the seal was optimized and the protection of clearance, holes and other details was strengthened, which effectively prevents the gearbox from entering the gearboxes such as sand and dust, reduces the wear of precision parts, such as gears and shafts, extends the service life of the gearbox and reduces the cost of customer maintenance maintenance.

(II) comply with Russian certification standards

Attaching great importance to the quality of the products and compliance with the standards, our spare parts for the covers of bulldozer gearboxes passed strict tests in the relevant Russian certification bodies and received a number of certificates of certification necessary for access to the Russian market, including certification according to GOST. This means that our products are fully consistent with Russian security standards, quality and ecology, and all aspects - from the choice of materials, the production process to the operational characteristics of products - are strictly controlled. By purchasing and using our products, Russian buyers may not worry that the products will not meet local standards.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive