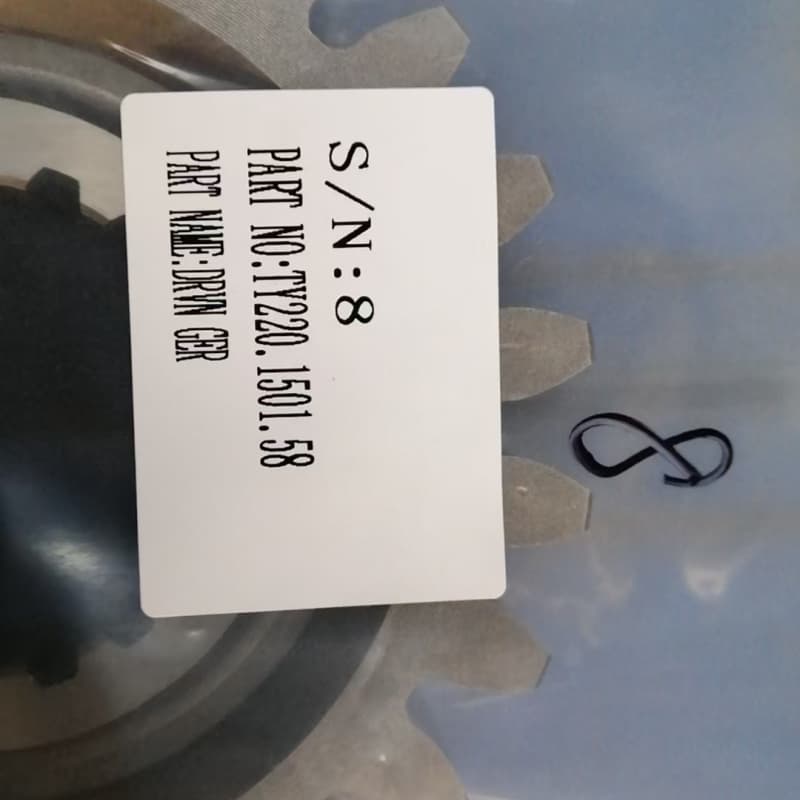

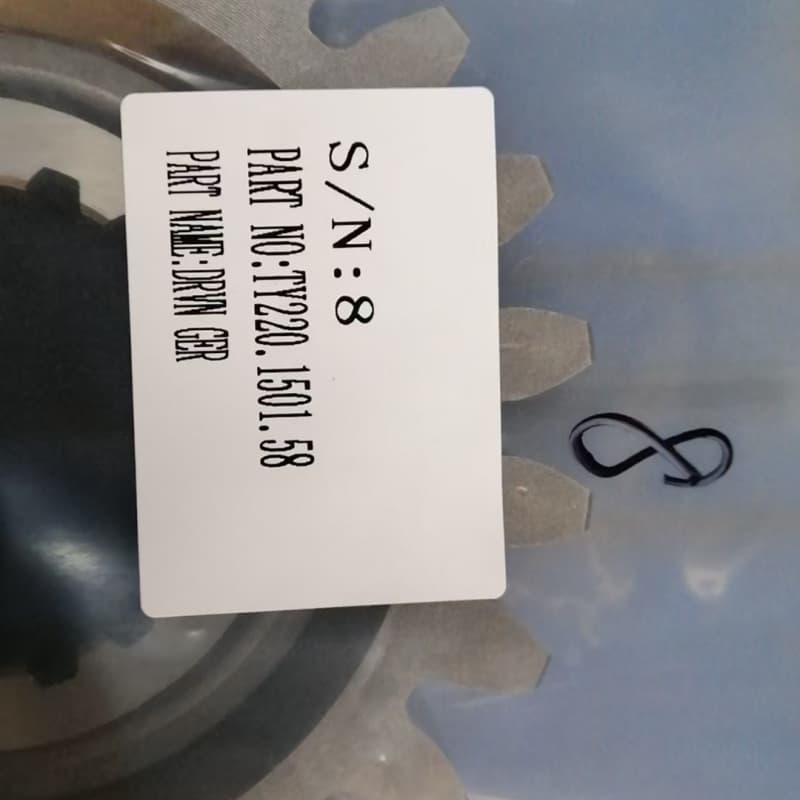

Zoomlion Ty220.1501.58 gear ZD220-3

1. Adaptable working conditions: The design is optimized and accurately adapted to the main bulldozers, which ensures the stability of the gearbox and increases the efficiency of construction, since it is designed for severe conditions of the terrain and difficult operating conditions in Russia.

2. Superflowing strength: made of high -quality alloy steel, passes special heat treatment, resistant to fatigue and wear, withstands high loads, reduces the number of failures and extends the service life.

3. Ease of maintenance: standardized design, simple disassembly and installation, there is no need for complex tools and professional skills, quick maintenance is possible even in remote areas, which reduces downtime and service costs.

Product representation

1. Detailed product information

1. Review of the product

The gears of the bulldozer gearbox are the main components of the power transmission, and their performance directly affects the efficiency of work and the stability of the bulldozer. Our transmission transmissions are specially designed for various types of bulldozers and cover various types, such as the leading gears, the driven gears, planetary programs, etc., fully consistent with the needs of power transmission in various working conditions.

2. Production process and materials

The choice of material: high -quality alloy steel, such as 20CRMNTI, 42CRMO, etc., these steels have high strength, high viscosity and good wear resistance, are able to withstand huge loads and frequent shots that are undergoing gears of the bulldozer gearbox in difficult operating conditions. For example, when operating in high-mountain cold areas, low-temperature viscosity steel guarantees that the gears will not break due to coldness; In conditions of high temperatures and high loads, its high -temperature strength and wear resistance can effectively extend the life of gears.

Production process: the use of advanced forging technology to increase the density of the internal structure of steel and improve the complex mechanical properties of gear wheels. Then, precision mechanical processing is performed using high -precision equipment, such as celestial turning machines and tooth grinding machines, to ensure the accuracy of the profile of gears and accuracy of the size. Finally, the processes of heat treatment, such as cementation and hardening, are used to form a solid and wear -resistant cemented layer on the surface of the gear, while the core retains good strength, which significantly increases the fatigue strength and wear resistance of the gear.

(III) The advantages of the product

The high -precision design of the teeth profile: after the accurate calculation of optimization of the teeth profile, the gear engagement becomes more smooth, which effectively reduces noise and vibration during transmission and increases the efficiency of power transmission. Compared to traditional transmissions, the efficiency of power transmission can be increased by 5-10%, which reduces energy consumption and extends the life of the transmissions and other components of the transmission.

Strict quality control: a comprehensive quality control system has been created, starting from checked raw materials, processing control to the factory control of finished products, each process is strictly monitored. Thanks to the advanced testing equipment, such as three -coordinate measuring machines, dentrated wheels measurement centers, etc., we guarantee that all dentate wheel parameters correspond or exceed industry standards, and the product qualification level reaches more than 99%.

2. The installation method

1. Preparation before installation

Checking the correspondence of the model: Carefully check whether the gear model and the bulldozer gearbox are fully coincided, and also check the appearance of the gear to make sure that there are no defects, such as cracks, sand shells, bumps, etc.

Preparation of tools: Prepare professional installation tools, such as pullers, presses, end keys, dynamometric keys, etc., and make sure that the accuracy of the tools meets the requirements for installation.

Cleaning: thoroughly clean the gearbox installation area and the surface of the gears to remove oil spots, pollution, etc., to prevent pollution entering the gearbox during installation and violation of the normal operation of the gears.

(II) Stages of installation

Histerens cleaning and lubrication: clean the new gears with a special cleaning agent, then apply the required amount of high -quality transmission oil to reduce friction during installation and provide initial lubrication for subsequent operation.

Installation and positioning: Use tools such as a puller or press to smoothly install the gear on the gear shaft in the correct direction and installation position. In the process of installation, it is necessary to strictly control the axial and radial beating of gears to ensure the accuracy of installation. For example, for planetary transfers, it is necessary to ensure that the gear in the engagement between each planetary gear, solar gear and crown gear is uniform and constant, and the error was controlled within ± 0.05 mm.

Puffing and adjustment: use a dynamometric key to tighten the gear bolts in accordance with the specified puffing moment to ensure reliable installation of the gear. After installation, check the gear engagement and adjust the gaskets so that the gear clutch gear shall comply with the technical requirements of the equipment. Typically, the gap is controlled in the range from 0.15 to 0.3 mm.

3. Common malfunctions and ways to eliminate them

1. District of gears

Cause

Long work in large loads leads to the fact that the gears withstand excessive loads, which leads to increased wear of the surface of the teeth.

The quality of the oil in the gearbox worsened, it has lost sufficient lubricant and anti -symbolic properties, which led to direct friction between the gears.

The insufficient accuracy of the installation of gears and poor engagement lead to local wear.

Bypass

Misefully organize the work of the bulldozer to avoid prolonged work with a large load or overload.

Regularly check the quality of transmission oil and replace it with high -quality transmission oil in accordance with the prescribed period.

Re -check and adjust the accuracy of the installation of gears, and also, if necessary, repair slightly worn gears, for example, by grinding gear to restore the accuracy of the teeth profile. Replace the strongly worn gears with new ones in a timely manner.

(ii) gear breakdown

Cause

A sudden huge shock load, for example, when a bulldozer encounters a solid obstacle during operation.

There are defects inside the material of the gear or the wrong process of heat treatment, which leads to insufficient strength of the gear.

Strength cracks accumulate. After prolonged operation in gear gears, under the influence of alternating loads, fatigue cracks are formed, which will ultimately lead to a breakdown of the teeth.

Bypass

When working on a bulldozer, pay attention to the working environment and avoid strong blows to solid items.

Strictly control the quality of raw materials and the process of manufacturing gears to guarantee sufficient strength and rigidity of the gears.

Install a regular check system for the operational detection of fatigue cracks on the surface and inside the gears using non -destructive control methods (such as magnetic passage control and ultrasound control). Replace the cracked gears in advance to prevent accidents associated with teeth breakdown.

(III) abnormal noise of gears

Cause

The gears wear out unevenly, protrusions or hollows appear on the surface of the teeth, causing blows and noise during the gearing.

The gear clutch is too large or too small and does not meet the design requirements.

Damage to the bearing leads to a radial or axial beating of the gear during operation, which leads to noise.

Bypass

Check the wear of the gears and repair or replace the gears with uneven wear.

Reprint and adjust the gear to the gear engagement in accordance with standard requirements.

Check the condition of the bearing. If there is any damage, replace it with new in time, and also make sure that the bearing is installed correctly and has the appropriate gap.

4. Repair and maintenance

1. Daily service

Appearance examination: Before each operation, check the appearance of the gears for the presence of oil spots, pollution, as well as obvious wear, cracks or other abnormal conditions. If there are oil spots, clean them in a timely manner; If any deviations from the norm are detected, immediately stop the car for verification.

Monitoring of the sound of work: During the work of the bulldozer, pay attention to the sound of the work of gears of the gearbox. Under normal conditions, the sound of the gearbox is even and uniform; If there is an abnormal noise, such as a sharp whistle, blow, etc., you should immediately stop the car and check the fault.

Checking the oil temperature: regularly check the temperature of the transmission oil. High oil temperature can indicate poor lubrication of gears or abnormal friction. As a rule, the temperature of the transmission oil should be maintained within 60–80 ° C. If the oil temperature exceeds 90 ° C, you should timely find out the cause and take appropriate measures.

(II) regular maintenance

Checking the quality of the oil and its replacement: transmission oil should be checked every 200-300 working hours to determine whether the quality of the oil corresponds to such indicators as the content of metal particles, viscosity and acid number in oil. If the quality of the oil has worsened, replace it with a new one and at the same time clean the oil filter of the transmission.

Determining of dough gears: every 500-800 working hours use professional measuring tools (for example, calipers, dough gears for measuring, etc.) to determine the wear of gear gears, measure parameters such as the thickness of the teeth, the error of the teeth profile, the gap in the gearing, etc., and compare them with the initial data. If the wear of the gears exceeds the indicated value (usually the wear of the thickness of the teeth does not exceed 0.5 mm), it is necessary to take measures for repair or replacement depending on the degree of wear.

Checking the accuracy of the installation: regularly check the accuracy of installation of gears to make sure that the parameters of the gears, such as axial and radial beating, the backlash in the engagement, etc., meet the requirements. If deviations are found in the accuracy of the installation, make adjustments in a timely manner to ensure normal engagement and operation of gears.

(III) precautions during maintenance

Use the original accessories: in the process of repair and maintenance, be sure to use original gears and related accessories that meet the standards of quality, and avoid the use of low -quality products so as not to affect the life of the gear and equipment productivity.

Follow the working procedures: the maintenance personnel must strictly comply with the requirements of the equipment maintenance management, use the tools, standardize work procedures and ensure the quality of maintenance work.

Detect records: take detailed records of the time, content, replaced details and various parameters checked for each maintenance, as well as compile a full file for equipment maintenance to facilitate the subsequent analysis of the operating conditions of the equipment and developing maintenance plans.

5. After -sales service

1. After -sales service team

We have an experienced and qualified after -sales service team. All team members have many years of experience in servicing bulldozer gearboxes and are familiar with the structure and operational characteristics of the gearboxes of bulldozers of various brands and models. The after -sales service team is able to quickly respond to customer needs and provide professional technical support and maintenance services.

(II) Warranty service

We provide [x] years of guaranteeing quality of products. During the warranty period, if the equipment fails due to problems with product quality, we will provide customers with free repair or replacement services and take on the appropriate transportation costs. It is enough for customers to call the hotline of after -sales service, and we will organize a speedy connection with professionals in order to understand the situation with a malfunction and develop a solution.

(III) Technical support

Online consultations: a special online platform of technical consultations has been created, on which customers can at any time ask questions about the use of equipment, its maintenance, etc. through the official website, a public WeChat account and other channels. Technical personnel will quickly respond to customer requests during working hours and provide detailed technical recommendations and solutions.

Place training: depending on the needs of the customer, professional technical specialists can go to the object for free training of operators and the customer service personnel. The content of the training includes the principles of gear gears, installation and dismantling methods, daily maintenance points, diagnostics and elimination of common faults, etc., to help customers improve equipment operation and maintenance skills, as well as reduce the number of equipment failures.

4. Quick response

We have created a complete mechanism for response after sales service. After customers report the problem, we will contact them within 12 hours to find out the details. For problems that require repairs on the spot, we will organize a quick exit of the nearest after -sales personnel to the place in the shortest possible time, depending on the location of the client. Usually we arrive at the place for repairs within 24-48 hours to guarantee that the equipment will resume normal operation as soon as possible, and minimize economic losses for customers caused by equipment failures.

6. Advantages of export to Russia

1. Adaptation to difficult working conditions in Russia

Frost -resistant structure: in Russia long and cold winters, while in some areas the lowest temperature drops below -50 ℃. Our gearboxes were specially optimized from the point of view of choosing the material and the heat treatment process to guarantee that they will retain good strength and shock viscosity at extremely low temperatures and will not break due to coldness, adapting to operating conditions in the cold regions of Russia.

Wear resistance: Operation conditions in Russia are complex and diverse, including a large amount of sand, gravel, frozen soil and other harsh working conditions. Our gears are made of highly hard, wear -resistant materials, and due to the advanced technology of surface processing on the gear surface, a solid wear -resistant layer is formed, which significantly increases the wear resistance of the gear in difficult operating conditions, extends the life of the gear and reduces the costs of customers for the maintenance of the equipment.

(II) comply with Russian certification standards

We attach great importance to the quality of the product and its correspondence. Our products passed strict tests of the relevant Russian certification bodies and received a number of certificates of certification necessary for access to the Russian market, such as GOST certification. This means that our products are fully consistent with Russian security standards, quality and ecology. Russian customers can buy and use it with confidence, not worrying about various risks caused by the inconsistency of products to local standards, such as products reviews, fines and other problems.

3. Localized service support

After -sales service team: A professional after -sales service team has been created in Russia. The team members are familiar with the local language and culture and can effectively communicate with customers. The local after -sales service team can quickly respond to customer needs and arrive in time to the place to repair equipment and provide technical support, reducing the time of equipment downtime and increasing the efficiency of customer production.

The warehouse of spare parts: A warehouse of spare parts was created in Russia, on which there are a sufficient number of standard transmissions and the corresponding spare parts. When the client’s equipment fails and the replacement of spare parts is required, we can quickly send spare parts from local warehouses to guarantee timely maintenance work, reduce the problem of long downtime of equipment due to lack of spare parts and provide customers with reliable logistics support.

Exhibition cabinets

Acquaintance with the plant

The plant operates a team of highly qualified and experienced engineers who continuously introduce technological innovations and improve products. Currently, the company has a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment such as excavators, loaders, taps, bulldozers and other machines. Products are highly productivity, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working media around the world.

Awards and fightsFixation

frequently asked questions

1. In which countries are we exporting?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What kind of payment conditions can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipping

3. What ways can we work for delivery?

1) for most countries in Europe, South America and Africa, etc. We can go along the container or Roro through the ocean freight.

2) for neighboring countries of China, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc. We can deliver by road or railway.

3) for light spare parts in the urgent requirement, we can send it using the international courier service, such as DHL, TNT, EMS or other air transportation.

4. How can you guarantee that you delivered goods to customers?

A: We will provide you with complete information about delivery for you.

5. What are our advantages compared to other manufacturers/factories?

1) Reliable quality: we carefully choose permanent manufacturers to support spare parts, such as engines, bridges, transmission, and many parts developed and produced by us always adapting the best materials.

2) a competitive price: the concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) The service team: firstly, our sales managers work 24 hours a day, are ready to answer your questions at any time. Secondly, a professional training team with senior equipment, ready to provide support services to users and dealers. Most problems can be solved within 24 hours.

4) Fast delivery: As a rule, we can deliver within 10 working days at the plant after receiving prepayment from customers.

6. How can you provide customers after sales service?

A: We will answer you at first and help you solve problems within 24 hours. If we really need your local, we

We will send your professional person to your settlement to help you solve problems without any fluctuations, supply you with comprehensive