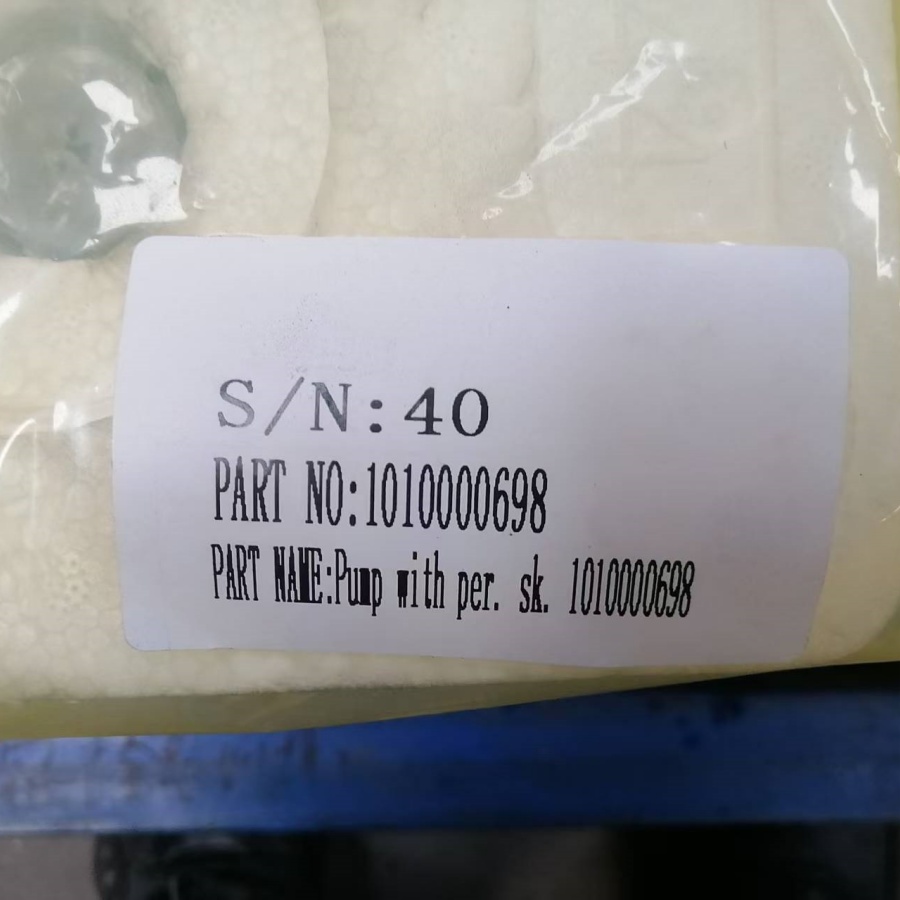

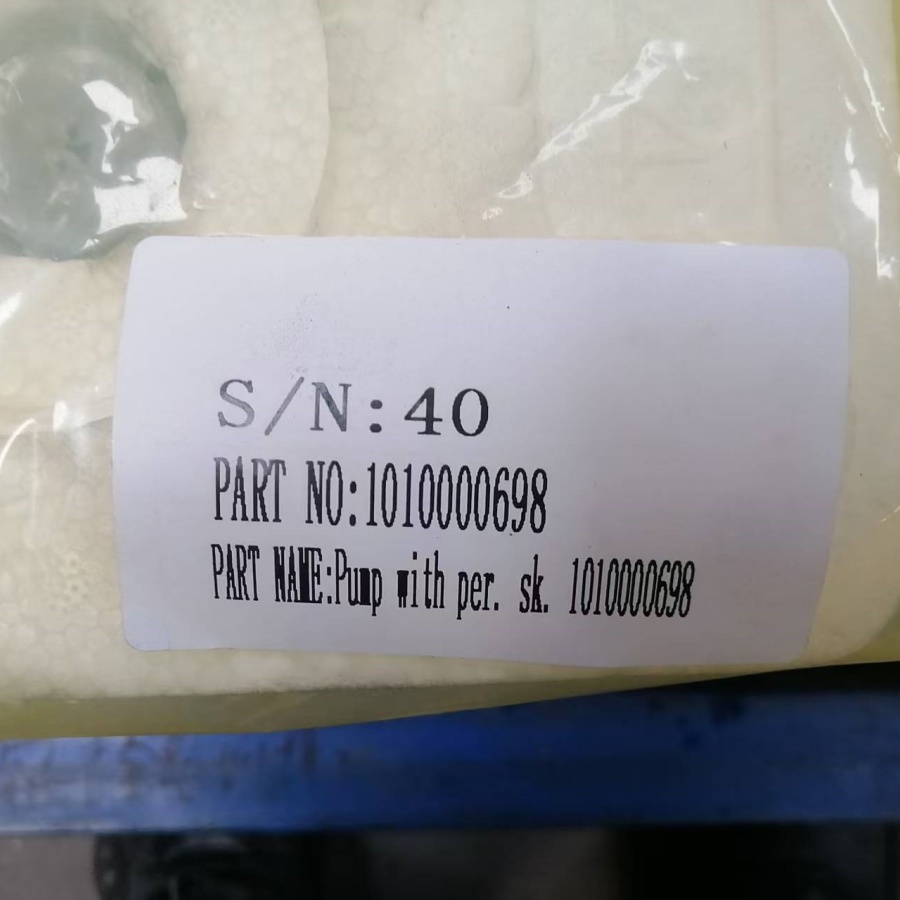

Zoomlion 1010000698 Hydraulic pump

1. High efficiency and energy conservation: it uses the advanced technology of a variable speed for accurately adjusting the flow in accordance with working conditions, reducing energy consumption and increasing the efficiency of work. For example, with large -scale earthworks, he can quickly perform the tasks of the bulldozer.

2. Strong and reliable: made of high -quality materials and processed using special technology, it is wear -resistant and resistant to corrosion, can adapt to severe working conditions, such as high temperature and high load, and can work stably for a long time.

3. Accurate management: rapid response and accurate pressure and expense management provide smooth work and accurate positioning of the bulldozer to meet the needs of accurate work.

Product representation

1. Detailed product information

1. The principle of work

The hydraulic pump of the bulldozer is a key device that converts mechanical energy into hydraulic. The gear pumps, plunger pumps and lobed pumps are common. If you take a plunger pump as an example, then it uses the reciprocating movement of the plunger in the cylinder to change the volume of the sealed working chamber to achieve absorption and oil pressure. When the engine brings the pump shaft into rotation, the plunger moves forward and back in the hole of the plunger. Когда плунжер выдвигается наружу, объем полости плунжера увеличивается, давление уменьшается, и масло всасывается через отверстие всасывания масла распределительной пластины масла; When the plunger is retracted inward, the voluman cavity decreases, the pressure increases, and the oil is produced through the oil pressure pressure hole, thereby providing a stable high pressure flow for the hipper system of the bulldozer, driveing various executive mechanisms (such as cylinders, engines and engines and engines and engines and engines. etc.) to perform operations such as bulldozer Processing and shovel.

(II) structural composition

Pump body: as the outer shell of the hydraulic pump, it is usually made of high -strength cast iron or alloy steel. It should not only withstand the pressure of the internal oil of high pressure, but should also ensure the accuracy and stability of the installation position of each component to ensure the normal operation of the pump.

The rotor node: includes a plunger, a cylinder block, an inclined washer, etc. Plunger makes reciprocating movements in the cylinder body and is the main component for absorption and compression of the oil; The cylinder body is connected to the pump shaft through the slots and rotates, driven by the pump shaft; The inclined washer controls the reciprocating movement of the plunger. By changing the angle of an inclined washer, you can adjust the output flow and the pressure of the hydraulic pump.

Oil distribution mechanism: Oil distribution plate is the key component of the oil distribution mechanism. It is located between the cylinder body and the pump body and is equipped with oil absorption windows and oil pressure windows. Thanks to a relative movement with the cylinder case, it carries out the absorption and production of oil, guaranteeing that the processes of the absorption of oil and the pressure of the hydraulic pump oil do not interfere with each other.

Bearings and seals: bearings are used to support the pump shaft and rotary unit to ensure smooth rotation; Seals are used to prevent oil leakage and maintain the pressure of the hydraulic system. Conventional seals include oil seals, sealing rings, etc. They are made of oil -resistant rubber or polytetraforoethylene and other materials and have good sealing characteristics and oil resistance.

(III) The advantages of the product

High efficiency and energy conservation: it uses the advanced technology of variable speed for accurately adjusting the flow in accordance with the working conditions, reducing energy consumption and increasing the efficiency of work. For example, with large -scale excavation work, he can quickly perform the tasks of clearing a bulldozer.

Durable and reliable: made of high -quality materials and processed using a special technology, it is wear -resistant and resistant to corrosion, can adapt to harsh working conditions, such as high temperature and high load, and can work steadily for a long time.

Accurate control: fast reaction and accurate pressure and expense management ensure the smooth operation of the bulldozer and accurate positioning to meet the needs of accurate work.

High adaptability: a universal design, suitable for various types of bulldozers, simple installation and good compatibility with hydraulic systems of bulldozers of various brands.

2. Stages of installation

Preparation before installation: check whether the model and technical characteristics of the hydraulic pump correspond to the bulldozer, and also check if the pump body is damaged or not deformed; Prepare the tools necessary for installation, such as wrenches, screwdrivers, lifting equipment, etc.; Clean the installation site to make sure that there is no debris and dust that can get into the hydraulic system. At the same time, clean and inspect the pipes, connections and other components of the hydraulic system to make sure of their purity and the absence of blockages inside.

Install the pump housing: use lifting equipment to raise the hydraulic pump steadily and slowly move it to the installation position, trying to avoid a collision with surrounding parts; Combine the installation holes of the pump case with the mounting base on the bulldozer housing, put on the bolts and pre -tighten them; Use the alcohol level to check the horizontality of the pump housing. If there are any deviations, calibrate them by adjusting the thickness of the gasket to make sure that the pump housing is installed horizontally, otherwise this can lead to uneven power on the pump shaft and influence its service life.

Connecting pipes: Connect in intake and exhaust oil pipes of the hydraulic pump in accordance with the constructive requirements of the hydraulic system. Before the connection, apply the required amount of sealant to the connection of the pipes to ensure good tightness and prevent oil leakage; Tighten the junction of the connection with a wrench with the indicated puffing moment, be careful not to pull it so as not to damage the connection or pipe. After the connection is completed, check the correct direction of the pipeline, the absence of distortions and interference, as well as the reliability of the installation of the pipeline.

Install accessories: Set the coupling, pulley and other accessories of the hydraulic pump to make sure that they are securely connected to the pump shaft, and concentricity meets the requirements. For the coupling, make sure that the connecting bolts at both ends are tightened and the gap is uniform; For pulley, adjust the belt tension. Too weak tension will lead to slipping the belt and will affect the effectiveness of the transmission, and too much tension will increase the load on the bearing and reduce its service life.

Checking and eliminating problems: after installation, check once again, whether all the bolts and nuts are tightened, as well as the reliability of pipes; Pour a hydraulic oil that meets the requirements into the hydraulic system, the oil level should reach the specified height; Run the bulldozer engine, first perform a trial launch without load and watch the work of the hydraulic pump to make sure that there are no extraneous noise, vibration or leaks. Then gradually load and check whether the pressure and consumption of the hydraulic pump correspond to the norm, and if necessary, adjust to ensure the stable operation of the hydraulic pump and its good performance.

3. Common malfunctions

Insufficient pressure: the pump can be strongly worn, for example, the wear of the plunger, the cylinder body and the oil distribution plate, which leads to a decrease in the efficiency of the seal and the leakage of the oil. It may also be that the intake oil pipeline is blocked or the oil is not smooth, for example, the filter is blocked, the intake oil pipeline is broken or the sucking opening for the oil is too shallow immersed into the oil surface, so that the pump cannot suck enough oil. In addition, the failure of the bypass valve, for example, jamming the valve core and the refusal of the spring, will also lead to the fact that the pressure in the system will not increase.

Unstable flow: the reasons are the unstable speed of the pump, for example, engine failure or transmission problems; refusal to adjust the angle of an inclined washer, the inability to accurately monitor the plunger, which leads to fluctuations in the output flow; pollution of hydraulic oil, impurities entering the pump, which affects the normal movement of the components, which leads to an unstable flow.

Abnormal noise and vibration: mechanical wear is a common cause, such as damage to the bearing, wear of a plunger and cylinder, wear of gears, etc., which leads to an abnormal noise; A hydraulic blow can also cause noise and vibration. For example, when starting, stopping or reversing, the oil flow rate suddenly changes, causing a pressure blow; In addition, the air entering the pump forms cavitation, causing an increase in noise and vibration.

Leakage: the main cause of the leak is damage to the seal, for example, aging an omentum, rupture of the sealing ring, etc.; Cracks in the pump housing or pipeline can also cause oil leakage; Incorrect installation, for example, the uneven moment of the tightening of the bolts, due to which the sealing surface is unevenly loaded, can also cause leakage.

4. After -sales service

Warranty service: A certain warranty period is provided. During the warranty period, if the product fails due to quality problems, you can use free repair or replacement services. The warranty period usually depends on the type of product and operating conditions, usually it is 1-2 years.

Technical support: Users can at any time ask questions about the use of the product, its installation, maintenance, etc. On hot lines of customer support service, online platforms and other channels, and professional technical specialists will provide the necessary recommendations. Technical experts have rich experience and professional knowledge, can quickly answer user questions and offer effective solutions.

Service network: we have created an extensive network of after -sales service throughout the country and even around the world, with many authorized service stations distributed throughout the country. Our maintenance staff has experience and can quickly respond, providing service services “from door to door” or delivery, repair. If a problem arises, it is enough for the user to call the customer support service number to receive contact information to the nearest repair station, and maintenance specialists will arrive at the place for repair in the shortest possible time.

Delivery of spare parts: a comprehensive system of deliveries of spare parts was created that provides timely supply of parts associated with hydraulic pumps of bulldozers, reducing the downtime of equipment and providing uninterrupted maintenance. There are enough spare parts, they cover the wear of the wear and key components of various models of hydraulic pumps and can be quickly involved in accordance with the user's needs, ensuring the effective performance of maintenance work.

Common malfunctions and solutions of the hydraulic pump pump

1. Insufficient pressure

Cause

Internal wear: the main components of the pump, such as the plunger, the cylinder body and the oil distribution plate, work for a long time, which leads to wear due to friction, reduces the efficiency of seal, causes oil leakage and does not allow pressure in the system to achieve a normal level.

Poor oil intake: the oil intake pipeline is blocked, for example, the filter is clogged with impurities, or the oil intake pipeline is broken, or the absorption of the oil hole is too deeply immersed in the oil surface. These problems will lead to blocking the pump during the absorption of oil and the inability to absorb a sufficient amount of oil, thereby affecting the output pressure.

The safety valve malfunction: if the safety valve core is closed and cannot open and close normally, or the spring fails and loses its proper elastic force, the pressure in the system cannot increase, and part of the oil will flow back into the oil tank through the safety valve.

Bypass

Repair or replace worn parts: disassemble the hydraulic pump and check the wear of the plunger, cylinder body and oil distribution plate. For parts with less wear, you can grind and repair; If the wear is serious, it is necessary to replace new original details in order to ensure the accuracy of planting and tightness between the details.

Clean the intake oil pipeline: check the intake oil pipeline, clean the filter from contaminants and replace the damaged filter; Repair or replace the broken intake oil wiring, make sure that the inlet oil pipeline is immersed in the oil surface to a sufficient depth to ensure smooth suction.

Obroofing valve repairs: disassemble the safety valve, clean the core and the valve saddle, remove the pollution and make sure that the valve core can move freely; Check the elasticity of the spring. If the spring is out of order, replace it with a new spring of the same specification and adjust the value of the safety valve pressure settings.

2. Unstable traffic

Cause

Unstable speed: engine malfunctions, such as insufficient fuel supply, ignition system, etc., lead to an unstable output power of the engine, which, in turn, causes fluctuations in the speed of the hydraulic pump; Problems of the transmission system, such as slipping the belt, weakening of clutch, etc., can also affect the stability of the speed of the hydraulic pump.

The malfunction of the adjustment mechanism of the angle of the sloping washer: the mechanism for adjusting the angle of the sloping puck is used to control the passage of the plunger, thereby adjusting the output flow of the hydraulic pump. If the mechanism fails, for example, the regulatory piston is stuck or the contour of the control oil, etc., it is impossible to accurately control the angle of the inclined washer, which will lead to fluctuations in the output flow.

Hydraulic oil contamination: Impurities, moisture, or air enter the hydraulic oil. Impurities will enter the pump and affect the normal movement of the components; moisture will corrode the components; The air will create cavitation, all of which will result in an unstable flow.

Avoiding line

Troubleshoot engine and transmission faults: check the engine fuel system, ignition system, etc., repair or replace faulty parts to ensure stable engine power output; Check the transmission system, adjust the belt tension, tighten the clutch, and ensure the transmission runs smoothly.

Repair the tilt washer angle adjustment mechanism: disassemble the tilt washer angle adjustment mechanism, clean the adjusting piston and control oil circuit, remove impurities, and make sure the adjusting piston can move freely; Check the tightness of the control oil circuit and repair or replace leaking parts.

Change or clean the hydraulic oil: Check for contamination of the hydraulic oil. If the contamination is severe, replace it with a new hydraulic oil that meets the standards. If the contamination is light, use filtration equipment to remove impurities, moisture and air from the hydraulic oil.

3. Abnormal noise and vibration

Reason

Mechanical wear: Bearings, plungers, gears, and other components of the hydraulic pump wear out due to friction and fatigue during long-term operation. Worn components create unbalanced forces during operation, causing abnormal noise and vibration.

Water hammer: When the bulldozer starts, stops, or changes direction, the oil flow in the hydraulic system changes dramatically, causing a pressure shock. This shock causes the hydraulic pump and pipeline to vibrate and creates noise.

Cavitation Phenomenon: When the hydraulic pump does not suck in the oil smoothly, the air will mix with the oil. Under the influence of high pressure, this air will form bubbles. When the bubbles burst, high-frequency shocks will be generated, forming a cavitation phenomenon that will cause increased noise and vibration.

Avoiding line

Replace Worn Parts: Check the wear of bearings, plungers, gears, and other parts, replace heavily worn parts in time, and ensure that the installation accuracy and clearance of each component meet the requirements during installation.

Relieve water hammers: Install buffers in the hydraulic system such as accumulators, butterfly valves, etc., to slow down changes in oil flow and reduce pressure shocks; Streamline work procedures, avoid abrupt starts, stops, or reverses, and make the hydraulic system run more smoothly.

Vent the air: Check the oil inlet line and oil suction port to ensure there are no leaks and prevent air from entering the hydraulic system; Install the exhaust valve in the hydraulic system and perform regular air release operations to release the air from the system.

4. Leakage

Reason

Seal Damage: After long-term use, the oil seals, o-rings, and other seals of the hydraulic pump will be damaged due to aging, wear, or chemical erosion by hydraulic oil, resulting in reduced sealing efficiency and oil leakage from the seals.

Cracks in the pump casing or piping: When the pump casing or piping is exposed to external stress, vibration, or prolonged high pressure, cracks may appear from which oil will leak.

Improper installation: If the bolt tightening torque is uneven when installing the hydraulic pump or connecting pipes, the sealing surface will be unevenly loaded, or the seal is not installed in place, it will leak.

Avoiding line

Replace seals: Disassemble the hydraulic pump, check for seal damage, replace them with new seals of the same specification and model. Pay attention to the installation direction and position of the seals during installation to ensure good sealing.

Crack repair: Cracks on the pump casing or pipeline can be repaired by welding, sealant, etc. After the repair, perform a pressure test to ensure that there are no leaks.

Reinstallation: Check the installation of the hydraulic pump and pipeline, and tighten the bolts evenly according to the specified torque requirements; Replace the seal to make sure it is in place and the sealing surface is level and clean.

Exhibition cabinets

Acquaintance with the plant

The factory has a team of highly qualified and experienced engineers who continuously introduce technological innovation and improve products. At present, the company owns a number of independent intellectual property rights and patented technologies. The manufactured construction equipment includes a wide range of equipment, such as excavators, loaders, cranes, bulldozers and other machines. The products are characterized by high performance, reliability, energy efficiency and environmental friendliness, as well as the ability to adapt to difficult operating conditions in various climatic and working environments around the world.

Awards and qualifiersFiction

Frequently Asked Questions

1. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, etc.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, etc.

South America: Brazil, Chile, Paraguay, Argentina, etc.

Africa: South Africa, Ethiopia, Libya, etc.

2. What payment terms can we accept?

Usually we can work on T/T, 30% TT before production and 70% TT before shipment

3. What logistics ways can we work for shipping?

1) For most countries in Europe, South America and Africa, etc., we can go by container or Roro through ocean freight.

2) For China's neighboring countries, such as Russia, Vietnam, Kazakhstan, Uzbekistan, etc., we can deliver by road or railway.

3) For light spare parts in urgent requirement, we can send it by international courier service, such as DHL, TNT, EMS or other air freight.

4. How can you ensure that you have delivered the goods to customers?

A: We will provide you with full shipping information for you confirmed.

5.What are our advantages compared with other manufacturers/factories?

1) Reliable Quality: Carefully select regular manufacturers to support spare parts such as engines, axles, transmissions, and many parts designed and produced by us, always adapting the best materials.

2) Competitive price: The concentration of mechanized production in large quantities reduces production costs to ensure a competitive price.

3) Service Team: Firstly, our sales managers are available 24 hours a day, ready to answer your questions at any time. Secondly, a professional technical service team with senior technicians, ready to provide support services to users and dealers. Most problems can be resolved within 24 hours.

4) Fast Delivery: Generally, we can deliver within 10 working days at the factory after receiving the advance payment from customers.

6. How can you provide after-sales service to customers?

A: We will reply you in the first time and help you solve the problems within 24 hours. If we really need your local, we

We will send your professional person to your locality to help you solve problems without any hesitation, supply you with all-round